Haklift Oy

Asessorinkatu 3-7

20780 Kaarina, Finland

Tel. +358 2 511 5511

www.haklift.com

Lifting Solutions Group

Axel Johnson International

Read these instructions carefully! Keep the document within easy access of operators. It is important

that operators understand these warnings and instructions before using the product.

SAFETY & WARNINGS

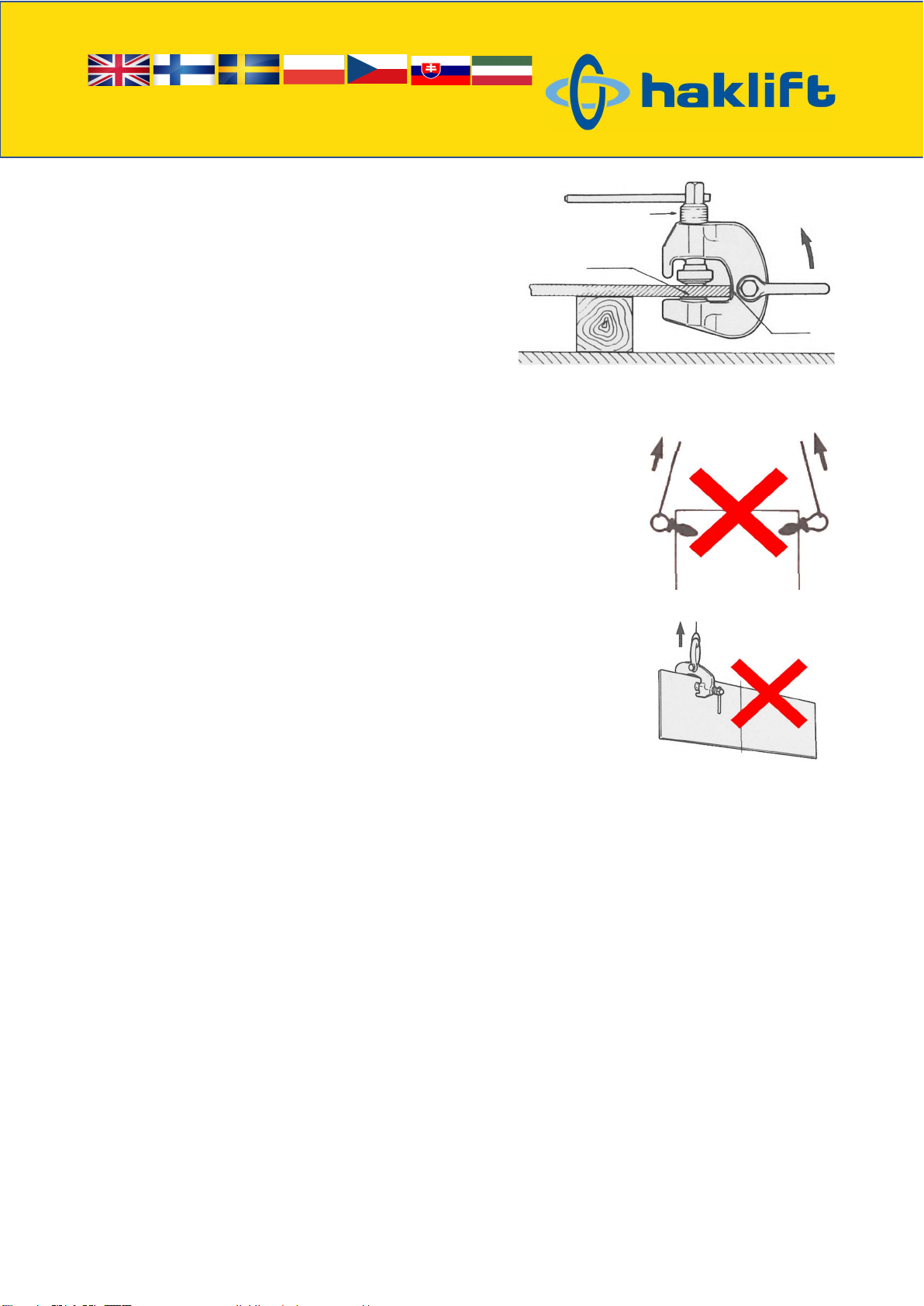

Select a proper size clamp for the job/lifting application. Determine the weight of the plate or steel

structure to be lifted.

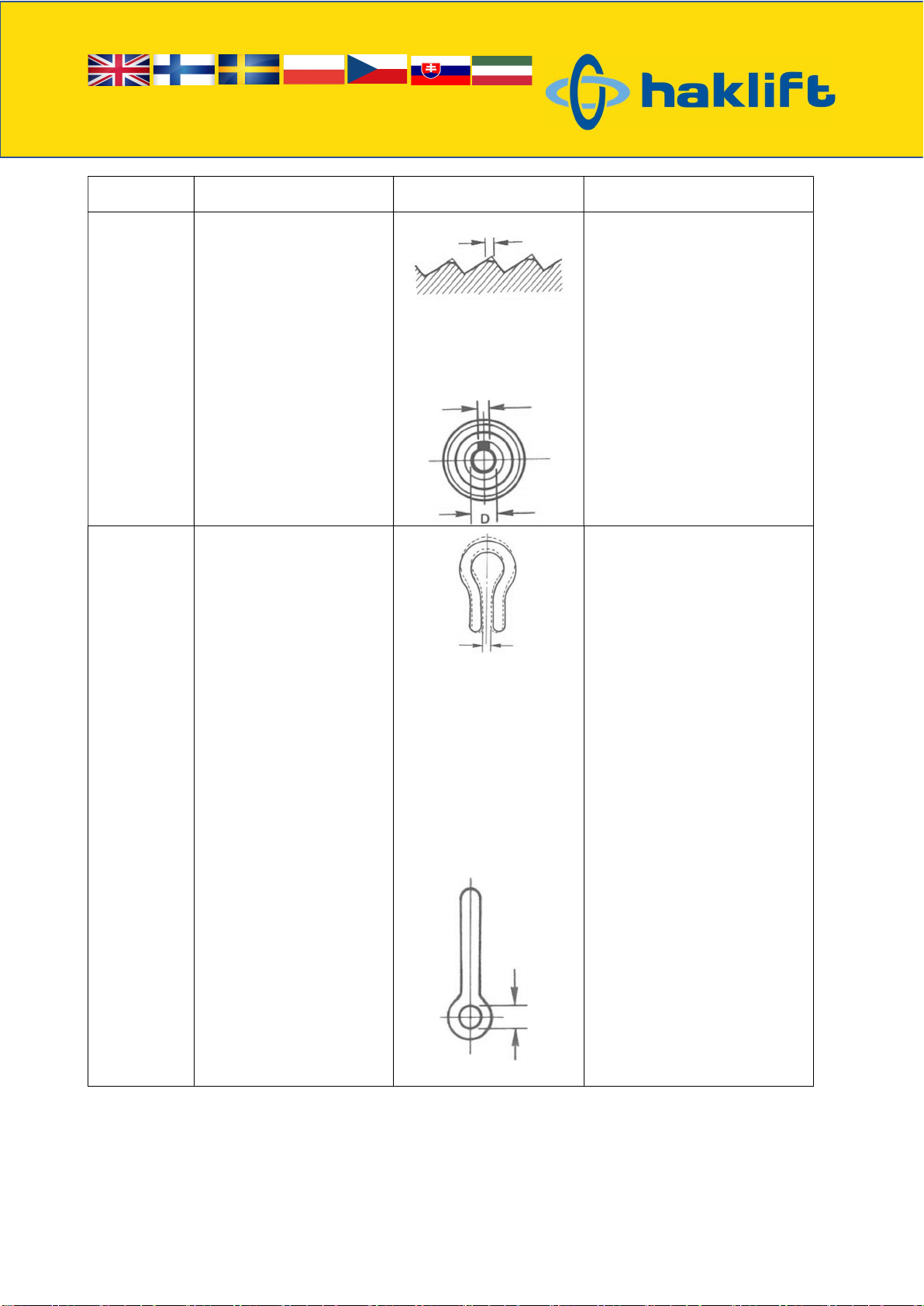

Do not exceed the limited working load shown in the WLL diagram. Plate thickness must be within the

grip range of the clamp. In some cases, with hardened plates, light plates (less than 1/5 of capacity

marked on the clamp) and thin plates (less than 1/4 of the maximum clamping range), the clamping

force of the clamp will be reduced. In these cases, confirm that the clamp has a positive grip before

lifting.

Inspect the clamp before each use; if cam or pad teeth are worn, or if the clamp is damaged, DO NOT

USE it.

All the markings on the clamp must be legible.

All personnel must stand clear of the load while it is being lifted or moved.

Lift the load slowly and steadily. Do not bounce or jerk the load.

Use the clamp with correct manners and read the following instructions for lifting and clamping

manners.

Never use the clamp on material other than steel.

When operating with clamps, always maintain a firm footing and only operate from a location that will

be always safe.

Before lifting the load, confirm that the clamps are in good condition and functioning properly.

Always protect the surface of the cam and pad from weld spatters or other damaging contaminants.

The surface of the load must always be clean and free of scale, grease, paint, dirt and coating or other

foreign matters that can reduce friction.

Note that the service life of clamps is reduced considerably when stainless steel sheets or high-tensile

steel are clamped. Do not use clamps for hard steel (30 HRC or higher).

Never vertically lift material that tapers towards the edge.

Never lift more than one steel plate at a time.

Always use slings correctly. Pay special attention to the correlation between the lifting angle and the

rated load.

Never operate clamps unless the load is properly centered.

After the load has been lifted a few centimeters, confirm that the load is well balanced.

Never allow the operator’s attention to be diverted when operating with clamps and never leave the

suspended load unattended.

Do not use the clamp as a suspension element.

Do not modify the product.

The clamp is only suitable for use in normal atmospheric conditions, not in acid environment or at

high/extreme temperatures.

Only use genuine parts when repairing clamps.

Make sure that the lifting accessories that are to be attached to the clamp are legitimate and of the

adequate capacity.