Tornado Karcher BR 530 BAT User manual

5.959-398 A2005839 06/03

BR 530 BAT BD 530 BAT

BR 53/40 W BD 53/40 W

www.karcher.com

!

Operating Instructions Page 3

Spare Parts List Page 35

Notice d’instructions Page 12

Liste des pièces de rechange Page 35

Instrucciones de servicio Página 23

Liste des pièces de rechange Página 35

Français

English

Español

- 3 -

English 5.959-398

Importantinformation

For your safety

Before using this appliance for the first time, please read

andpay attentionto theseOperating Instructions,and the

enclosedleaflet“SafetyInformation”.

Guarantee

The terms of the guarantee that is applicable in each

country have been published by our authorized sales

companies.Anyfaultthatoccurswithyourapplianceduring

theguaranteeperiodwillberepairedfreeofcharge,provided

that it has been caused by a material or manufacturing

defect. Guarantee claims should be addressed to your

dealer or the nearest authorized customer service depot,

andsupportedbydocumentaryevidence ofpurchase.

Protection of the environment

Pleasedisposeofpackaging

in an environmentally friendly manner

Thepackagingmaterialscanberecycled.Please

do not dispose of the packaging with domestic

refuse but have it recycled.

Please dispose of old units

in an environmentally friendly manner

Old units contain valuable recyclable materials

which should be reclaimed. Batteries, oil and

similar substances must not pollute the

environment. Please therefore dispose of old units via

suitable collection systems.

General Information

TheFloorCleanersareintendedforusewith24Vd.c.They

arepoweredby2x12Vbatteriesconnectedinseries.Only

included in supply kit for BAT Package units. (For other

models – see section “Battery Types and Chargers”.)

Thefloorcleanershavebeendesignedsothattheusercan

easily recognize and operate all functions. The operating

console contains all the switches and indicators, the

functions of which are represented by symbols.

Contents

IMPORTANTINFORMATION .................................. 3

For your safety..............................................................3

Guarantee ....................................................................3

Be environmentally aware! ..........................................3

General Information .....................................................3

UNITDIAGRAM ...................................................... 4

OPERATION ........................................................... 5

Preparation for commissioning...................................5

Commissioning and notes on use .............................5

Shut-down procedure ..................................................6

BATTERIES ............................................................ 7

Hazard warnings..........................................................7

Charge battery

Battery types ................................................................. 7

CAREANDMAINTENANCE ................................... 8

Maintenance schedule ................................................8

Sub-zero temperature protection.................................8

Maintenance agreement..............................................8

Transporting the Unit ...................................................8

Replace the squeegee blades....................................8

Replacing the disc brush ............................................8

Replacing the brush rollers .........................................8

Recommended cleaning agents ................................8

Accessories .................................................................9

TECHNICALSPECIFICATIONS............................ 10

TROUBLESHOOTING........................................... 11

BD530BAT BD 53/40W BR530BAT BR 53/40W

- 4 -

English

5.959-398

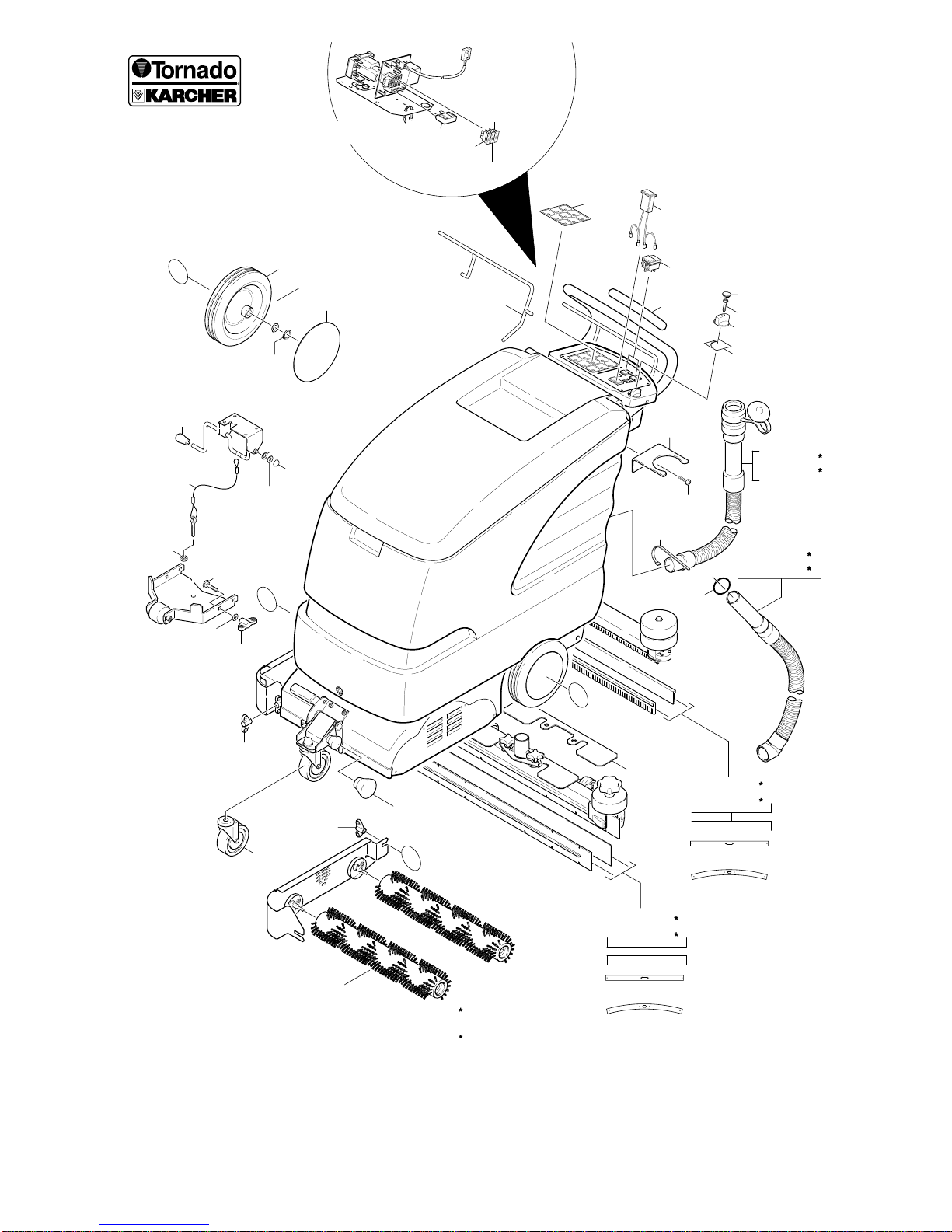

1 Pushhandlewith hand leverforbrush

operation

2 Controlpanel

3 Adjustinglever“Suctionbar”

4 Drainhosedirtywater

5 Suctionturbine

6 Ratingplate

7 Suctionhose

8 Connectionfor suctionhose

9 Suctionbar

10 Star knobs “Fixing of suction bar”

12 Brush rollers (BR 530 BAT/BR 53/40 W)

Disc brushes * (BD 530 BAT/BD 53/40 W)

13 Cleaninghead

14 Runninggear

15 Handle

16 Lockingdevice

17 Fuses and electronics *

18 Batterycharger**

19 Batteries **

20 Reservoircatch

21 Dirty-waterreservoir

22 Fresh-waterreservoir

23 Cover

* notshown

** only included in supply kit for BAT Package units

Controlpanel

24 Meteringdetergentsolution

25 Batterychargingcontrolindicator

26 Switch suction turbine

27 Switchbrushoperation

Unit diagram

- 5 -

English 5.959-398

Commissioning and notes on use

Selectionofthecorrectbrushesforthecleaningtask:

In the Chapter “Accessories” you will find a selection of

variousscrubbingbrushes,paddrivingdiscsandpadswith

application notes, which enable you to make the correct

selection for adapting to the particular cleaning task.

Fill with detergent solution

– Openreservoircover.

– It is best to fill the fresh-water reservoir with a water

hose,

max. 60 °C.

– Add detergent appropriate to the cleaning task (see

Chapter“Recommendeddetergents”).

– Do not fill the fresh-water reservoir higher than one

hand’swidthbelow the rim ofthereservoir opening.

– Before taking into use close the reservoir cover.

– Foam-limitingdetergentsaretobeaddedwithappropriate

metering.

Operation

Preparation for commissioning

a) After removing the packing wrapping the unit is still

standingatfirstonitswoodenpallet.Thesideplanksof

the packing are used to construct a ramp.

b) Openthe reservoircatch–turnthe socket-headscrew

with the supplied key and tip up the reservoir.

c) Obtain batteries (only included in supply kit for BAT

Packageunits)–seeChapter“Batterytypesandcharging

devices”

d) The batteries must be installed and connected by

a specialist.

Asshowninthesketchthebatteries

are placed in the trough and the

connecting cable is connected

(greasethepoles).

Theconnectingcableisclampedon

tothefreebatterypoles,(+)and(–).

Caution:makesurethepolarityis

correct! Connect red cable to (+)

pole, black cable to (–) pole. Close reservoir again.

Charge the batteries before taking the unit into

operation!

e) Fastenthepushhandlewiththe4screwssuppliedand

fit the protective caps.

f) Attach drain hose to plugs on the push handle.

g) Move the unit off the pallet:

Preparation(seesketch):

Whentheunitisreceivedthesupplieddiscbrushisnot

yet installed in the cleaning head.

Installitbeforecommissioning–seeChapter“Careand

Maintenance”.

Forvariousdiscbrushes–seeChapter“Accessories”.

BR 530 BAT / BR 53/40 W

On delivery the brush rollers are already fitted.

Forexchangeofbrushrollers–seeChapter“Careand

Maintenance”.

Fordifferingbrushrollers–seeChapter“Accessories”.

k) Park the unit; for this purpose press the push handle

downwards.Inthecleaningheadthelockingleverfolds

downwards and holds the unit in its idle position. To

release again simply push the unit forwards.

Makea rampfromthelong,side boardsof thepacking

by laying them on the pallet. Secure the boards with

nails.Laytheshorterboardsundertherampforsupport.

Removewoodenskirting.

Raise the cleaning head and draw out the cardboard

coverandboard.

Theunitcan now be moveddownwardson the ramp.

h) Install suction bar

Installsuppliedsuctionbarinthesuction-barcarrierand

tighten the star knobs.Pushthesuctionhoseontothe

connection to the suction bar.

i) Install disc brush and brush rollers

BD 530 BAT / BD 53/40 W

Pallet Wooden skirting

Cardboard cover / Board

Ramp arranged from the

side boards

- 6 -

English

5.959-398

Startingthework

– Closereservoircover.

– Turn on the switches for brush operation and suction

operation.

Note:Thechargingcontrollampsshowthechargingstate

of the battery.

Ifthebrushmotordoesnotrunafterswitchingiton,relieve

the strain on the brush head by drawing back the unit.

Runninggear

Down:Transportation

Up:Cleaning

– Raise the unit slightly with the handle.

– Pull out the locking device.

– Swiveltherunninggear into the desired position.

– Engage the locking device.

Driving to the place of work

– Swiveldownthe running gearandlock.

– Push the unit to the place of work.

Cleaning

– Swivel up the running gear and lock.

– Cleantheunit.

Adjustforwardspeed

(only BD 530 BAT / BD 53/40 W)

Slowerspeed(–)

– rotate towards left

Greaterspeed(+)

–rotate towardsright

Important: Before brush removal,

turnspeeddown

Settingthewaterflowrate

– Openupthe meteringforthe detergent solution.

Note:Theselectionofthepositiondependsonthetypeand

degree of the accumulation of dirt on the floor covering.

Loweringthe suction bar

– Raise the suction bar with the foot, locking releases

itself and the suction bar is lowered.

Note: The suction bar adapts autonomously to the floor

circumstances and does not require special adjustment.

The inclination of the suction bar is adjusted at the

works for normal, common floor coverings. Any setting

changes can be made on the suction bar suspension.

Switching on the brush head

– Pushtheunitforwardswiththepushhandleandactivate

thehandlever–thebrushesswitchthemselveson,and

the work can be started.

Importantnote:Donotlettheunitrunwhilststandingstill,

inorder toavoiddamaging thefloor.

Shut-down procedure

– Close off the metering of the detergent solution.

– Movetheunit1–2mforwardsinordertosuckupresidual

water.

– Turn off the switches for brush operation and suction

operation.

– Raise suction bar.

– Swiveldownthe running gearandlock.

Important: After terminating work it is essential that the

disc brushes and the brush rollers are relieved of strain

(dangerofdeformingthebrushes).

– Drainawaydirtywater(observelocalregulations!).

– Before long periods of no use, empty and clean the

fresh-waterreservoir.Forthispurpose,undothelocking

knob with an appropriate tool (e.g. a coin).

– Unloadbatteries.

- 7 -

English 5.959-398

BATTERIES

The unit contains circuitry that provides protection

against over-discharging the batteries; i.e., when the

minimum permissible battery capacity has been

reached,thebrushmotorsandtheturbineareswitched

off. In this case the battery charge indicator on the

operating console flashes red.

Pushthescrubbertothechargingstationandrechargethe

battery.

Never use battery chargers in the rain, in areas with

high humidity or in damp rooms!

Hazard warnings

Naked flames, activities that might generate sparks,

and smoking is strictly forbidden in the vicinity of

batteries or in a charging room (DANGER OF

EXPLOSION!).

Any cuts or abrasions should not be allowed to come

into contact with lead; always wash hands thoroughly

after working on batteries.

Neverdeposittoolsorsimilarobjectsontopofbatteries;

i.e., on terminals and cell connections (DANGER OF

SHORT CIRCUIT AND EXPLOSION!).

The following information applies to batteries

that are NOT maintenance-free:

Always add distilled water about one hour before the

charging process is due to end. Check that the acid

content is correct. The batteries are marked

correspondingly. Adding water to a discharged battery

can cause acid to escape.

Observe whether bubbles form in all the cells when

charginghasbeencompleted.Measuretheaciddensity

of each cell every 4 weeks.

Batteries should only be charged with the unit cover

opened (DANGER OF EXPLOSION!).

Always use chemically pure battery acid (as per VDE

0510) with a density of 1.28 kg/L.

Use only distilled or desalinated water (VDE 0510) to

dilute the sulphuric acid.

Never use any additives (so-called enhancing agents)

otherwise the guarantee will be void. Take special

care when handling battery acid (danger of injury and/

or damage to clothing!), use protective goggles, and

observe relevant regulations! If any acid touches skin

or clothing, rinse immediately with plenty of water.

Please dispose of battery or rechargeable

battery in an environmentally friendly manner

Batteries and rechargeable batteries contain

substances which must not pollute the

environment. Please therefore dispose of

batteries via suitable collection systems.

Charge battery

BR/BD530BAT/BR/BD53/40W

Openthereservoircatch–turnthesocket-headscrewwith

the supplied key and tip up the reservoir.

Important:Beforetippingupthereservoirpleasepullaway

the suction hose on the suction bar (Danger of snapped

hose!).

Clamp the charging device to the batteries and switch on,

ensurecorrectpolarity!Onaverage,chargingtakes10–

15 hours. The charging devices recommended by us

(suited to the batteries being used!) are electronically

regulatedandterminatethechargingprocessautomatically.

Battery types

Thefollowingtypesofbattery aresuitableforusewith this

cleaner:

Batteries:

Manufacturer Designation Capacity Voltage Kärcher

Order No.

SONNENSCHEIN 12 V / 70 Ah

maintenance-free 70 Ah 12 V -

DETA * 12 V GIS 80

low-maintenance 80 Ah 12 V 6.654-097

12 V GIV 75 DT

maintenance-free 75 Ah 12 V 6.654-093

* Recommended by manufacturer

- 8 -

English

5.959-398

CARE AND MAINTENANCE

Thebatteryplugmustbedisconnectedbeforecleaning

and servicing the unit, or replacing any components.

– The unit should be tested at least once per year by

KÄRCHER or a qualified person; e.g., for damage, leaks,

and for correct functioning of the control devices.

Maintenance schedule

Daily,andafter eachuse:

– Drain off dirty water.

– Rinseoutdirty-water tank.

– Checkthefluffstraineronthesuctionconnectionofthe

suctionturbine.

– Run finger along the squeegee blades to ascertain

condition,andreplace/turnroundifrequired.

– Checkbrushes forwear, andreplaceifrequired.

– Cleantheexterioroftheunit;donotuseahigh-pressure

cleaner.

Monthly:

– Checkbrushes forwear, andreplaceifrequired.

– Checksqueegee blades;disassemble andturn round/

replaceifrequired.

– Check battery terminals for oxidation; brush over

terminals, and smear with grease. Check that the

connecting cable is firmly attached.

– Check tank cover seals for leakage, and replace if

required.

– Overall cleaning of the inside and outside is

recommended,and prolongs thelife oftheappliance.

Annually:

– Arrangefortheprescribedinspectiontobecarriedoutby

aserviceengineer.

Sub-zero temperature protection

If there is a danger of freezing temperatures, activate the

pumpuntilnomorewaterisdischarged.Thesafestprocedure

isto store theappliance inaroom protectedfromfreezing

temperatures.

Maintenance agreement

A maintenance agreement can be concluded with the

responsibleKÄRCHER SalesOffice.

Transporting the Unit

When loaded onto a transport vehicle, the unit must be

secured by straps or ropes to prevent movement during

transit.

Brushheadmustalwaysbeintheraisedposition,otherwise

thebrushescouldbecomedeformed. This would result in

the brushes running out-of-true, and to subsequent

destructionofthe bearings.

For transportation of the unit it is recommended that you

take the disc brushes and the brush rollers out of the

cleaninghead.

Replace the squeegee blades

Inthecourseoftimethesqueegeebladesofthesuctionbar

becomeworn andmustthen bereplaced:

– Undostarknobsinorderthatthedeflectorrollersandthe

squeegeebladescanberemoved.

– Fit the new squeegee blades and tighten up the star

knobsagain.

Replacing the disc brush

BD 530 BAT, BD 53/40 W

– Turn the positive drive to slow speed (–).

– Raise the disc brush slightly, turn it anti-clockwise by

approx. 45° and detach it by pulling it downwards.

– To attach the replacement brush, reverse the above

procedure.

– Turn the positive drive to the required speed (+).

Replacing the brush rollers

BR 530 BAT, BR 53/40 W

– Undo the star knob screws. Remove the side bearing

cover.

– Withdrawthebrushrollers from the side.

– Wheninsertingthenewbrushrollers,turnthemslightly

so that it is easier for them to join with the driver.

– Finallyreplacethebearingcoversandclosethemagain

with the star knob screws.

Recommended cleaning agents

Cleaningagentscanbeobtainedfromyourdealer,quoting

theappropriateordernumber.

– Use only cleaning agents that contain no solvents,

hydrochloricacid norhydrofluoric acid.

– Donotusecleaningagentsthatgeneratelargeamountsof

foam,astheycouldcausedamagetothesuctionturbine

orothercomponents.

Recommended for: Part No.

Routine cleaning

(including alkali-sensitive surfaces) RM 746 6.291-462

Removal of greasy dirt deposits RM 69 ASF 6.291-523

PVC surface stripping RM 752 6.291-466

Linoleum surface stripping RM 754 6.291-425

Sanitary cleaner RM 25 ASF 6.291-252

Disinfectant cleaner RM 732 6.291-382

- 9 -

English 5.959-398

Accessories

The following table gives details of the various accessories that are available for use with this unit. Accessories can be

obtainedfromyourlocaldealer,quotingtheappropriatepartnumber.

BD 530 BAT / BD 53/40 W Part No.

BD 530

BAT

Part No.

BD 53/40 W Quant Quantity required by unit

Disc brush, white for slightly dirty or delicate

surfaces 6.906-054 6.905-864 1 1

Disc brush, grit

(hard, grey) for very dirty floors 6.906-055 6.905-865 1 1

Disc brush, black (soft) for polishing 6.906-056 6.905-866 1 1

Cleaning pad base for fitting cleaning pads 6.906-078 6.906-075 1 1

Cleaning pad, black for very dirty floors 6.369-022 6.369-015 5 1

Cleaning pad, green for medium dirty floors 6.369-023 6.369-016 5 1

Cleaning pad, red for slightly dirty floors 6.369-024 6.369-017 5 1

BR 530 BAT / BR 53/40 W Part No.

BR 530

BAT

Part No.

BR 53/40 W Quant Quantity required by unit

Brush drum, white

(standard) for routine cleaning, also for

medium to very dirty floors 5.762-169 5.762-208 1 2

Brush drum, black (soft) for polishing, and for routine

cleaning of delicate surfaces 5.762-172 5.762-211 1 2

Brush drum, red

(high/low) for scrubbing uneven

patterned surfaces

(safety/non-slip tiles, etc.)

5.762-170 5.762-209 1 2

Brush drum, grey (hard) for thorough cleaning of very

dirty floors, and for surface

stripping

(e.g., waxes, acrylates)

5.762-171 5.762-210 1 2

Pad roller shaft for mounting roller pads 4.762-184 4.762-214 1 2

Roller pad (red) for slightly contaminated

floors 6.369-453 20 60

(80-BR 53/40 W)

Roller pad (green) for normally contaminated

floors 6.369-452 20 60

(80-BR 53/40 W)

Roller pad (yellow) for polishing 6.369-451 20 60

(80-BR 53/40 W)

Roller pad (white) for fine polishing 6.369-388 20 60

(80-BR 53/40 W)

BD 530 BAT / BR 530 BAT

BD 53/40 W / BR 53/40 W

One-sided rubber strips

Part No.

BD 530 BAT/

BR 530 BAT

BD 53/40 W/

BR 53/40 W

Quant Quantity required by unit

Rubber lip, blue standard 6.273-185 pair 1 pair

Rubber lip, brown oil-resistant 6.273-168 pair 1 pair

Suction bar straight standard 4.777-027 1 1

Suction bar curved standard 4.777-028 1 1

Reversible rubber strips (only for suction bars 4.777-047 and 4.777-054)

Suction bar straight standard 4.777-047 1 1

Suction bar curved standard 4.777-054 1 1

Rubber lip, blue standard 6.273-229 1 1

Rubber lip, brown oil-resistant 6.273-207 1 1

- 10 -

English

5.959-398

TECHNICAL SPECIFICATIONS

BR530BAT(BR53/40W*)

Power

Nominalvoltage .................................................... 24 V

Battery capacity........................................... 75AH(5h)

Powerconsumption.............................. 1200(1560*)W

Suctionmotor .................................................... 500W

Brushmotor ....................................................... 600W

Suction

Air flow.................................................................30 l/s

Negativepressure ..........................................140mbar

Brushrollers

Length................................................... 460(530*)mm

Diameter ........................................................... 96 mm

Brushspeed................................................ 15001/min

DimensionsandWeight

Effective cleaning width ........................ 460(530*)mm

Theoreticalarearating.......................1840(2120*)m²/h

Containervolumes,freshwater ...............................40 l

Containervolumes,dirtywater ................................40 l

Totalweight ............................................ 150 (155*)kg

Soundpressurelevel(EN60704-1) ............... 70 dB(A)

BD530BAT(BD53/40W*)

Power

Nominalvoltage .................................................... 24 V

Battery capacity........................................... 75Ah(5h)

Powerconsumption.............................. 1200(1560*)W

Suctionmotor .................................................... 500W

Brushmotor ....................................................... 600W

Suction

Air flow.................................................................30 l/s

Negativepressure ..........................................140mbar

Discbrush

Diameter ............................................... 460(530*)mm

Brushspeed.................................................. 1401/min

DimensionsandWeight

Effective cleaning width ........................ 460(530*)mm

Theoreticalarearating.......................1840(2120*)m²/h

Containervolumes,freshwater ...............................40 l

Containervolumes,dirtywater ................................40 l

Totalweight ............................................ 150 (155*)kg

Soundpressurelevel(EN60704-1) ............... 70 dB(A)

- 11 -

English 5.959-398

TROUBLESHOOTING

All tests and other work to be carried out on electrical components should be performed by a suitably qualified expert.

Please contact Kärcher Customer Service in the case of more complex problems.

Problem Possible causes Clearance

Cleaner cannot be started Fuse defective Clear cause of damage, replace fuse

Battery run down Charge battery

Plug or connector on battery

loose Check and connect

No or not enough detergent

solution on the floor Fresh-water reservoir empty Fill up

Water feed blocked Check hoses and coupling for

blockage

Not enough suction or

unsatisfactory vacuuming

results from floor

Fuse defective Clear cause of damage, replace fuse

Seal on cover contaminated or

damaged Clean or replace

Fluff strainer blocked Clean

Rubber lips on suction bar

contaminated or worn Clean or replace

Suction hose blocked Clean

Suction turbine defective Call Customer Service

Inadequate cleaning results Brushes worn down Replace

Brushes not suited to application Install other brushes – see Chapter

“Accessories”

Brushes have jammed,

Indicator light illuminated Foreign object has penetrated Undo connection to the battery. Clear

away foreign object and connect

battery again.

Brushes do not rotate Fuse defective Clear cause of damage, replace fuse

Toothed belt torn

(BR 530 BAT, BR 53/40 W) Call Customer Service

Brush motor defective Call Customer Service

Worm drive defective

(BD 530 BAT, BD 53/40 W) Call Customer Service

Switch defective Call Customer Service

6.388-549.0

5.059-011.0

7.306-119.0

5.382-594.0

5.380-209.0

6.368-076.0

7.303-065.0

5.321-509.0

5.442-930.0

6.630-005.0

6.682-395.0

6.310-128.0

6.310-128.0

4.172-016.0

6.321-154.0

7.343-300.0

6.343-132.0

7.311-224.0

7.343-300.0

7.303-139.0

6.310-129.0

7.312-003.0

B

(standard/ standard/

standard/)

2

(ölfest/ oil resistent/

resistant à l'huile/)

3

B

7.644-040.0

6.644-277.0

7.644-006.0

7.644-018.0

6.362-089.0

4.034-107.0

12.2002

6.390-733.0 3

6.390-610.0 2

BR 53/40 W B TO*USA

1.127-881.0

4.777-027.0

4.777-028.0

6.273-185.0 2

6.273-168.0 3

A

6.390-166.0 2

6.390-730.0 3

BR 53 / 40

5.762-208.0 (weiss/ white/ blanc/)

5.762-209.0 (rot/ red/ rouge/)

5.762-210.0 (grau 0,6/ grey 0,6/ gris 0,6)

5.762-263.0 (grau 1,0/ grey 1,0/ gris 1,0)

5.762-211.0 (schwarz/ black/ noir/)

A

6.435-356.0

6.435-301.0

5.115-608.0

7.343-004.0

4.777-047.0

4.777-054.0

6.273-207.0 3

6.273-229.0 2

5.128-339.0

6.321-001.0

6.435-061.0

This manual suits for next models

2

Table of contents

Other Tornado Karcher Floor Machine manuals

Popular Floor Machine manuals by other brands

Minuteman

Minuteman Mirage 27" Parts and instruction manual

Crescent

Crescent SC430 53 B GO FULL PKG Operator's manual

Nobles

Nobles Concorde 608349 Operation and parts manual

diversey

diversey Taski swingo XP CO75XP.2 manual

Alto

Alto TW 1400 HD operating instructions

RCm

RCm Brava 800 Use and maintenance manual