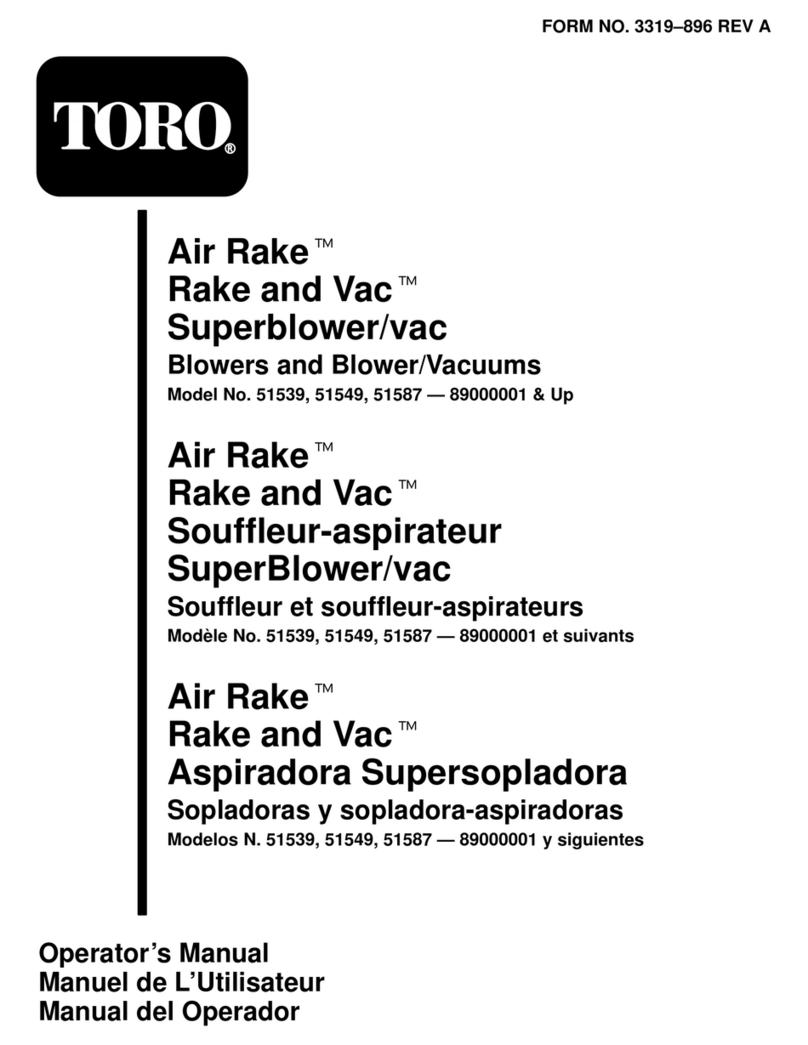

Safety

Hazardcontrolandaccidentpreventionare

dependentupontheawareness,concern,and

propertrainingofthepersonnelinvolvedinthe

operation,transport,maintenance,andstorageof

themachine.Improperuseormaintenanceofthe

machinecanresultininjuryordeath.Toreduce

thepotentialforinjuryordeath,complywiththe

followingsafetyinstructions.

BeforeOperating

•ReadandunderstandthecontentsofthisOperator’s

Manualbeforeoperatingthemachine.Become

familiarwithallofthecontrolsandknowhowto

stopquickly.Afreereplacementmanualisavailable

bysendingthecompleteModelandSerialNumber

toTheToro®Company,8111LyndaleAvenue

South,Bloomington,Minnesota55420-1196.

•Neverallowchildrentooperatethemachine.Do

notallowadultstooperatemachinewithoutproper

instruction.Onlytrainedoperatorswhohaveread

thismanualshouldoperatethismachine.

•Neveroperatethemachinewhenundertheinuence

ofdrugsoralcohol.

•Keepallbystandersawayfromtheoperatingarea.

•Keepallshieldsandsafetydevicesinplace.Ifa

shield,safetydevice,ordecalisillegibleordamaged,

repairorreplaceitbeforeoperationiscommenced.

Alsotightenanyloosenuts,bolts,andscrews

toensurethatthemachineisinsafeoperating

condition.

•Donotoperatethemachinewhilewearingsandals,

tennisshoes,sneakers,orshorts.Also,donot

wearloosettingclothingwhichcouldgetcaught

inmovingparts.Alwayswearlongpantsand

substantialshoes.Wearingsafetyglasses,safety

shoes,andahelmetisadvisableandrequiredby

somelocalordinancesandinsuranceregulations.

WhileOperating

•Donotruntheengineinaconnedareawithout

adequateventilation.Exhaustfumesarehazardous

andcouldpossiblybedeadly.

•Themaximumseatingcapacityisoneperson.Never

carrypassengers.

•Sitontheseatwhenstartingtheengineandoperating

themachine.

•Thisproductmayexceednoiselevelsof90dB(A)

attheoperatorposition.Hearingprotectionis

recommendedforprolongedexposuretoreducethe

potentialofpermanenthearingdamage.

•Usingthemachinedemandsattention.Toprevent

lossofcontrol:

–Operateonlyindaylightorwhenthereisgood

articiallight.

–Driveslowlyandwatchforholesorotherhidden

hazards.

–Donotdriveclosetoasandtrap,ditch,creek,or

otherhazard.

–Reduceyourspeedwhenmakingsharpturnsand

whenturningonhillsides.

–Avoidsuddenstartsandstops.

–Beforebackingup,looktotherearandensure

thatnooneisbehindthemachine.

–Watchoutfortrafcwhennearorcrossing

roads.Alwaysyieldtheright-of-way.

•Stayawayfromthedischargeopeningwhenthe

machineisoperating.Keepallbystandersawayfrom

thedischargeopeninganddon’tdirectdischarge

towardbystanders.

•Iftheenginestallsorthemachinelosesheadwayand

cannotmakeittothetopofaslope,donotturnthe

machinearound.Alwaysbackslowlystraightdown

theslope.

•Donottakeaninjuryrisk!Whenapersonorpet

appearsunexpectedlyinorneartheoperatingarea,

stopoperation.Carelessoperation,combinedwith

terrainangles,ricochets,orimproperlypositioned

guardscanleadtothrownobjectinjuries.Donot

resumeoperationuntiltheareaiscleared.

•Donottouchtheengineormuferwhiletheengine

isrunningorsoonafteritisstopped.Theseareas

couldbehotenoughtocauseaburn.

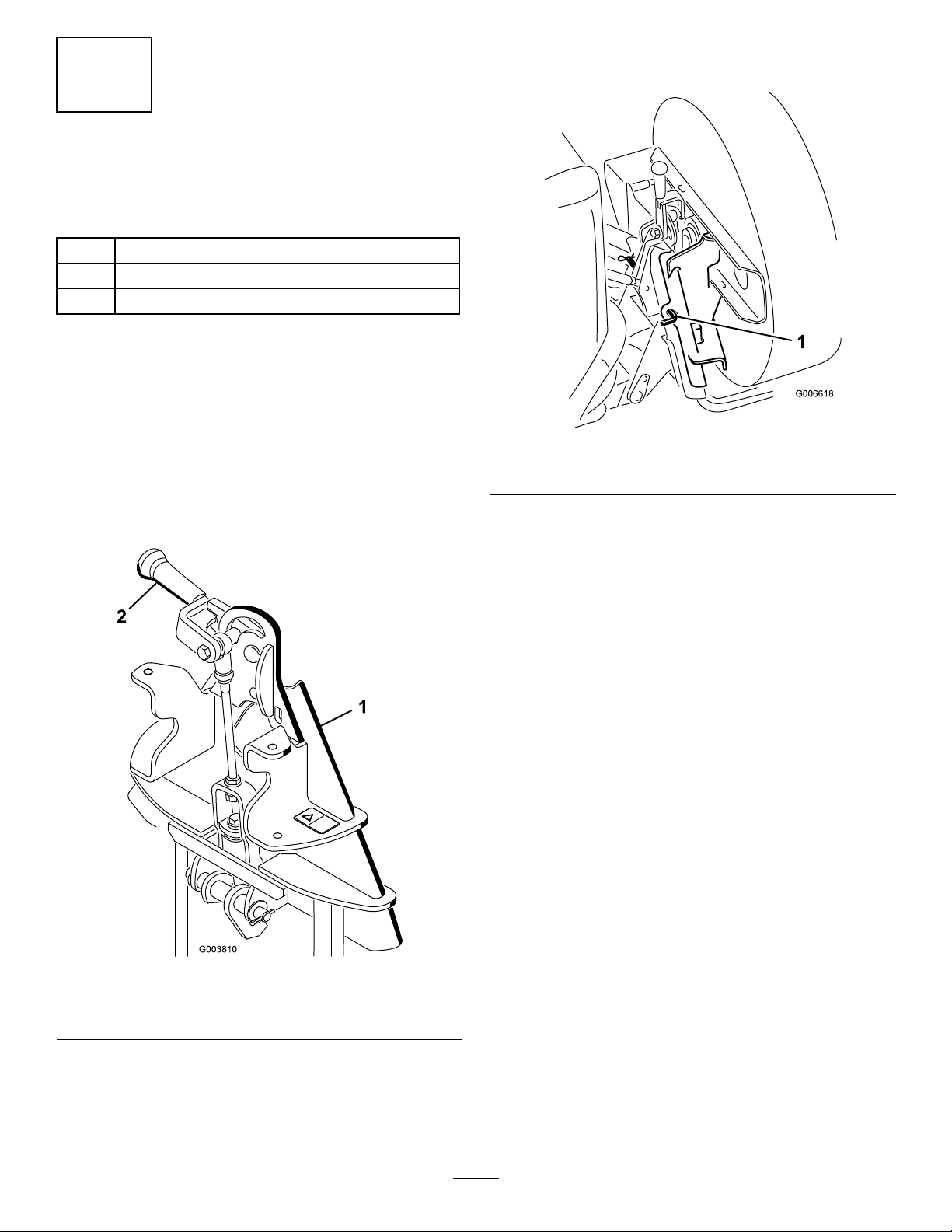

Maintenance

•Removethekeyfromtheignitionswitchtoprevent

accidentalstartingoftheenginewhenservicing,

adjusting,orstoringthemachine.

•Performonlythosemaintenanceinstructions

describedinthismanual.Ifmajorrepairsare

everneededorassistanceisdesired,contactan

AuthorizedToroDistributor.

•Toreduceapotentialrehazard,keeptheenginefree

ofexcessivegrease,grass,leaves,andaccumulations

ofdirt.Neverwashawarmengineoranyelectrical

partswithwater.

3