Contents

Safety...........................................................................3

SafeOperatingPractices...........................................3

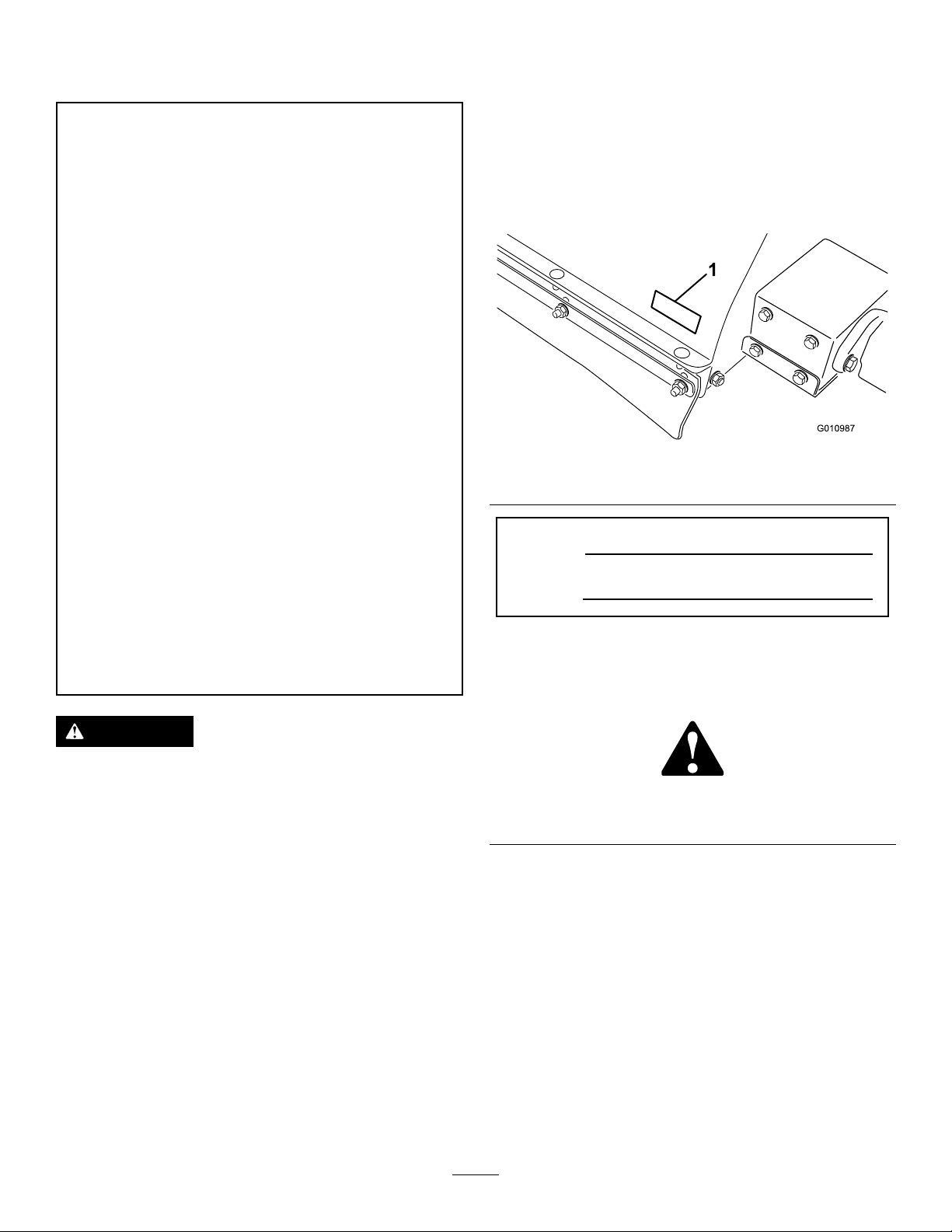

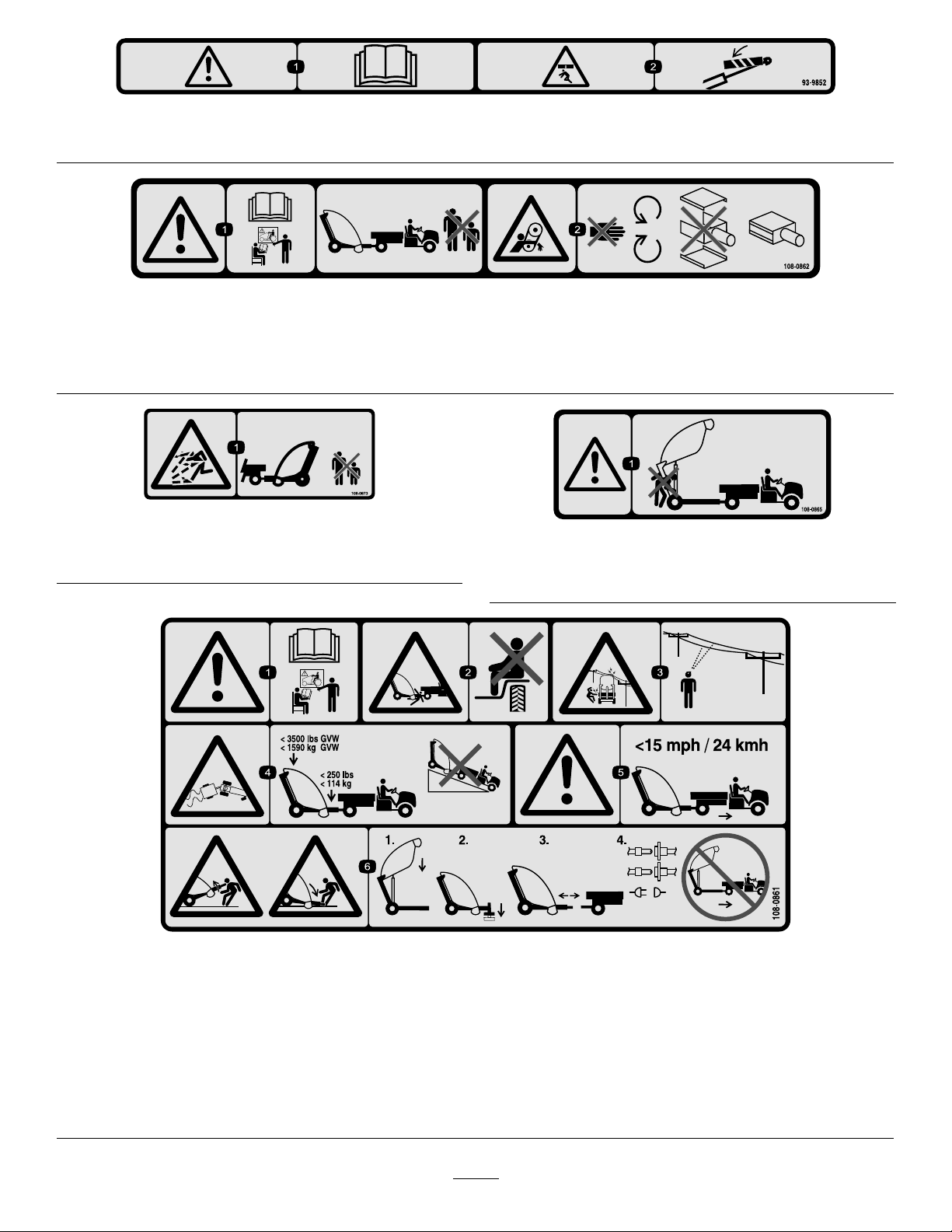

SafetyandInstructionalDecals.................................5

Setup............................................................................8

1RequirementsBeforeUsingtheVehicle....................9

2RemovingtheHitchTongueandHydraulic

CylinderfromtheShippingPosition.......................9

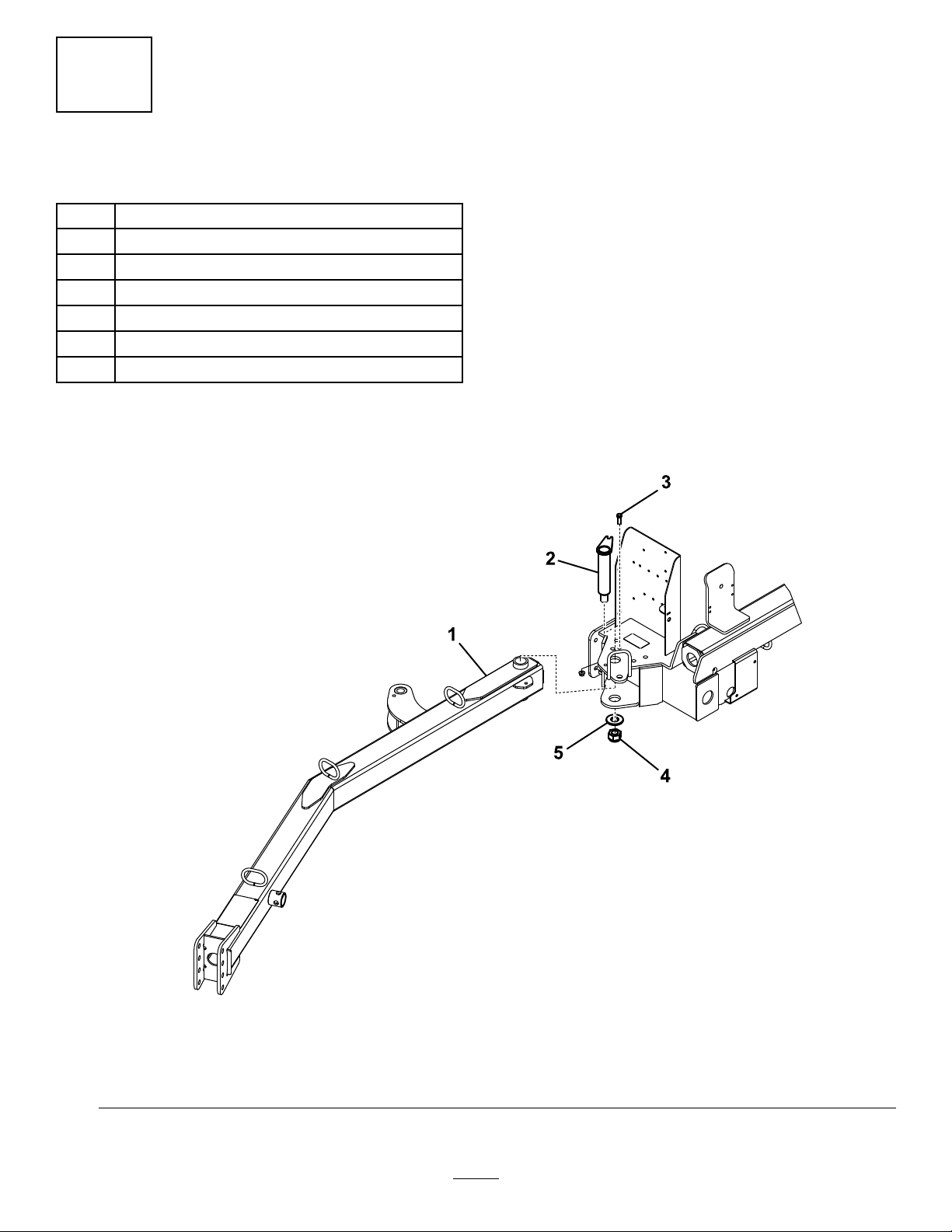

3InstallingtheHitchTongue....................................9

4InstallingtheHydraulicCylinder............................11

5InstallingthePowerWiringHarness.......................12

6MountingtheSweepertotheTowVehicle................12

7RoutingandSecuringtheHydraulicHosesand

WiringHarness..................................................13

8ConnectingtheHydraulicHoses............................13

9ConnectingtheHarness........................................14

10MountingtheWindrowBlades.............................14

11AssemblingtheHandheldRemote........................16

ProductOverview.........................................................17

Controls...............................................................17

Specications........................................................18

DimensionsandWeights.........................................18

Attachments/Accessories........................................18

Operation....................................................................19

OperatingtheSweeper............................................19

AdjustingtheBrushHeight.....................................20

AdjustingtheRollerScraper.....................................21

AdjustingtheFrontFlapHeight..............................22

CheckingtheTirePressure......................................22

CheckingtheWheelLugNutTorque.........................22

ActivatingtheController.........................................22

UsingtheControllerTimeOut.................................23

UsingtheHopperSafetySupport.............................23

CheckingtheInterlockSystem.................................23

OperatingTips.......................................................23

DumpingtheHopper.............................................24

LoweringtheHopper..............................................24

InspectingandCleaningtheMachine........................25

TransportingtheSweeper........................................25

OperatingtheMachineinColdWeather.....................25

SwitchingtheSweeper-UpMode..............................25

Maintenance.................................................................26

RecommendedMaintenanceSchedule(s)......................26

DailyMaintenanceChecklist....................................27

Lubrication............................................................28

AssociatetheRemoteControlandtheBaseUnit

........................................................................29

ReplacingtheRemoteBatteries................................29

Storage........................................................................30

Troubleshooting...........................................................31

CheckingFaultCodes.............................................31

EnteringDiagnosticModeandCheckingthe

Codes................................................................32

ResettingtheFaultCodes........................................33

ExitingDiagnosticMode.........................................33

Safety

Hazardcontrolandaccidentpreventionaredependent

upontheawareness,concern,andpropertraining

ofthepersonnelinvolvedintheoperation,transport,

maintenance,andstorageofthemachine.Improper

useormaintenanceofthemachinecanresultininjury

ordeath.Toreducethepotentialforinjuryordeath,

complywiththefollowingsafetyinstructions.

ThefollowinginstructionsarefromANSIstandard

B71.4-2012.

SafeOperatingPractices

Supervisor'sResponsibilities

•Ensuretheoperatorsarethoroughlytrainedandfamiliar

withtheOperator'sManualandalldecalsonthemachine.

•Establishyourownspecialproceduresandworkrulesfor

unusualoperatingconditions(e.g.,slopestoosteepfor

machineoperation,adverseweatherconditions,etc.).

BeforeOperating

•Read,understandandfollowtheinstructionsinthe

Operator'sManualandonthemachinebeforestarting.

Becomefamiliarwithallcontrolsandknowhowto

stopquickly.Afreereplacementmanualisavailableby

contactingTorodirectlyatwww .Toro.com.

•Neverallowchildrentooperatethemachine.Neverallow

adultstooperatethemachinewithoutproperinstruction.

Onlytrainedoperatorswhohavereadthismanualshould

operatethismachine.

•Neveroperatethemachinewhileundertheinuenceof

drugsoralcohol.

•Becomefamiliarwiththecontrolsandknowhowtostop

thetowvehicleenginequickly.

•Keepallshields,safetydevices,anddecalsinplace.

Ifashield,safetydevice,ordecalbecomesdamaged,

malfunctioning,orillegible,repairorreplaceitbefore

operationiscommenced.Alsotightenloosenutsand

boltstoensuremachineisinsafeoperatingcondition.

•Alwayswearsubstantialshoes.Donotoperatemachine

whilewearingsandals,tennisshoes,orsneakersorwhen

barefoot.Donotwearloose-ttingclothingthatcould

getcaughtinmovingpartsandpossiblycauseinjury.

Wearingsafetyglasses,safetyshoes,longpants,anda

helmetisadvisableandrequiredbysomelocalordinances

andinsuranceregulations.

•Donotalterthisequipmentinanymannerwhichmay

causehazardousconditions.

•Safetyinterlockswitchesarefortheoperatorsprotection.

Disconnectedormalfunctioningsafetyinterlockswitches

couldallowthemachinetooperateinanunsafemanner

andmaycausepersonalinjury

–Donotdisconnectthesafetyinterlockswitches.

3