Introduction

Built on proven technologies and components, the ToroP 220 Series plastic

valves are tough, have excellent performance and are extremely reliable.

Aself-cleaning metering system and 220 PSI rating assures years of

trouble-free performance.

In commercial installations, it is advantageous to install the valves in a

valve box. This enables the valve to be located, accessed and maintained

easily. The use of clean aggregate in the the bottom of the box, and

keeping valve box locations away from structures, potential hardscaping

features (such as sidewalks) and large planting locations is recommended.

Additionally, valve box locations generally should be in shrub beds and at

right angles to structure locations. If the valves are installed below grade

without a valve box, access to the top of the valve should be provided using

a section of 4" PVC pipe and a Toro Valve Cover (Part No. 850-00) installed

directly over each valve.

P220 Series Plastic Valves

Installation Instructions

Specifications

■Models:

❚220 Series electric, 1", 11⁄4", 11⁄2", 2", 21⁄2", 3”

❚220 Series electric pressure regulating, 1", 11⁄4", 11⁄2", 2”,

21⁄2", 3"

■Flow range:

❚1" —5-40 GPM

❚11⁄4" —20-100 GPM

❚11⁄2" —20-130 GPM

❚2" —30-180 GPM

❚21⁄2" —60-250 GPM

❚3" —80-350 GPM

■Operating pressure:

❚Electric models: 10-220 PSI maximum

❚Pressure-regulating models:

–Outlet: 5-30 PSI, ±3 PSI

(EZR-30)

5-100 PSI, ±3 PSI

(EZR-100)

–Inlet: 15-220 PSI

■Minimum pressure differential (between inlet and outlet):

10 PSI

■Burst pressure safety rating: 750 PSI

■Body styles:

❚Globe valve —1", 11⁄4", 11⁄2", 2" female threads

❚Angle valve —21⁄2", 3" female threads

❚BSP threads available

■Solenoid: 24 V a.c.

❚Inrush: 0.40 amps, 11.50 VA

❚Holding: 0.20 amps, 5.75 VA

■Dimensions:

❚1" —53⁄4" H x 5" W

❚11⁄4" —61⁄2" H x 6" W

❚11⁄2" —61⁄2" H x 6" W

❚2" —71⁄2" H x 5" W

❚21⁄2" —83⁄4" H x 81⁄2" W

❚3" —83⁄4" H x 81⁄2" W

■220 PSI maximum pressure rating

■Ingot brass and stainless-steel construction

■Removable, self-flushing, contamination-proof, 120-

mesh, stainless-steel filter screen (electric models)

Voltage Requirement (standard solenoid)

Voltage Inlet Pressure

22.5 V a.c. 220 PSI

21.1 V a.c. 200 PSI

20.2 V a.c. 175 PSI

19.1 V a.c. 150 PSI

18.2 V a.c. 125 PSI

17.1 V a.c. 100 PSI

16.1 V a.c. 75 PSI

16.0 V a.c. 50 PSI

Specifications (continued)

■Precise pressure control with compact EZReg dial design

■Pressure regulates in electric and manual modes, serviceable

under pressure

■Schrader-type valve for pressure gauge attachment

■Manual flow control: adjustable to zero flow

■Manual bleed screw: bleeds internally downstream

Note: For optimum performance, calculate total friction loss to

ensure sufficient downstream pressure.

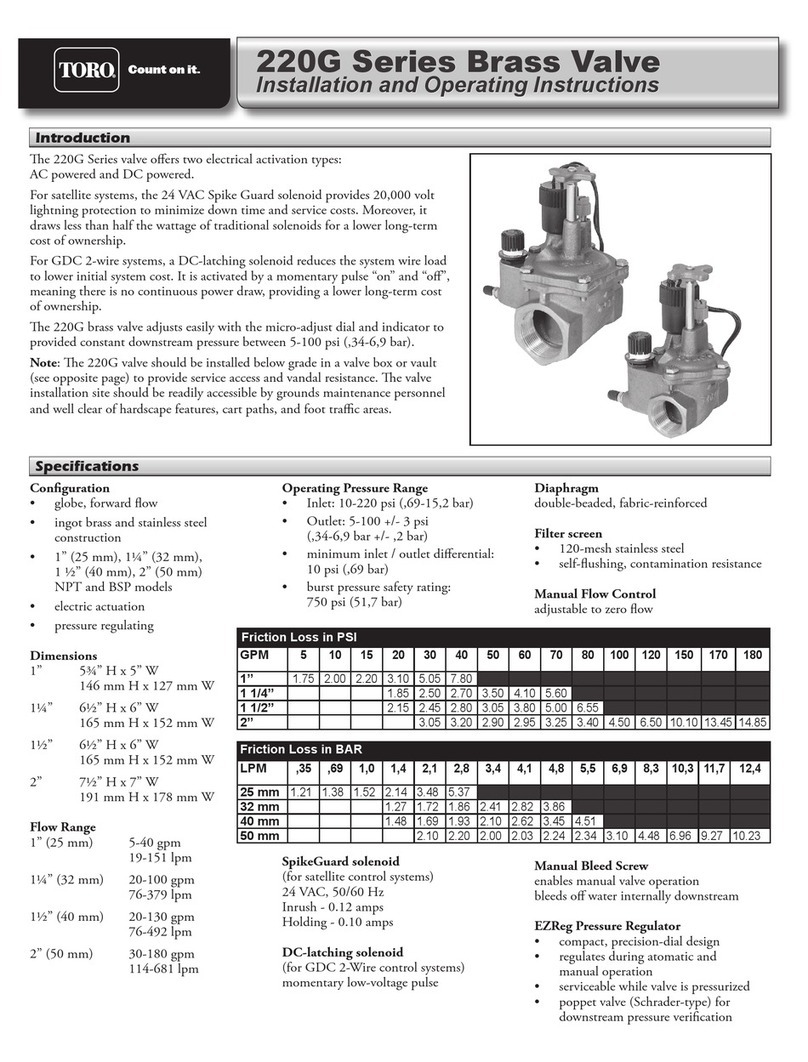

Friction Loss

Flow (GPM)

Model 5 10 15 20 30 40 50 60 70 80 100 120 150 170 180 200 250 300 350

1" 2.0 2.5 1.5 2.5 5.5 7.0

11⁄4" 5.5 6.5 7.5 8.0 8.5 9.0 13.0 16.0

11⁄2" 4.0 5.2 5.4 6.0 6.5 7.0 8.0 10.0 15.0

2" 1.0 2.0 2.0 2.5 3.0 3.5 6.0 7.5 10.0 12.0 14.0

2-1⁄2" 2.0 2.2 2.3 2.4 2.5 3.0 4.0 4.5 5.5 7.0

3" 2.2 2.4 2.5 3.0 4.0 4.5 5.5 6.5 7.0 7.5