3

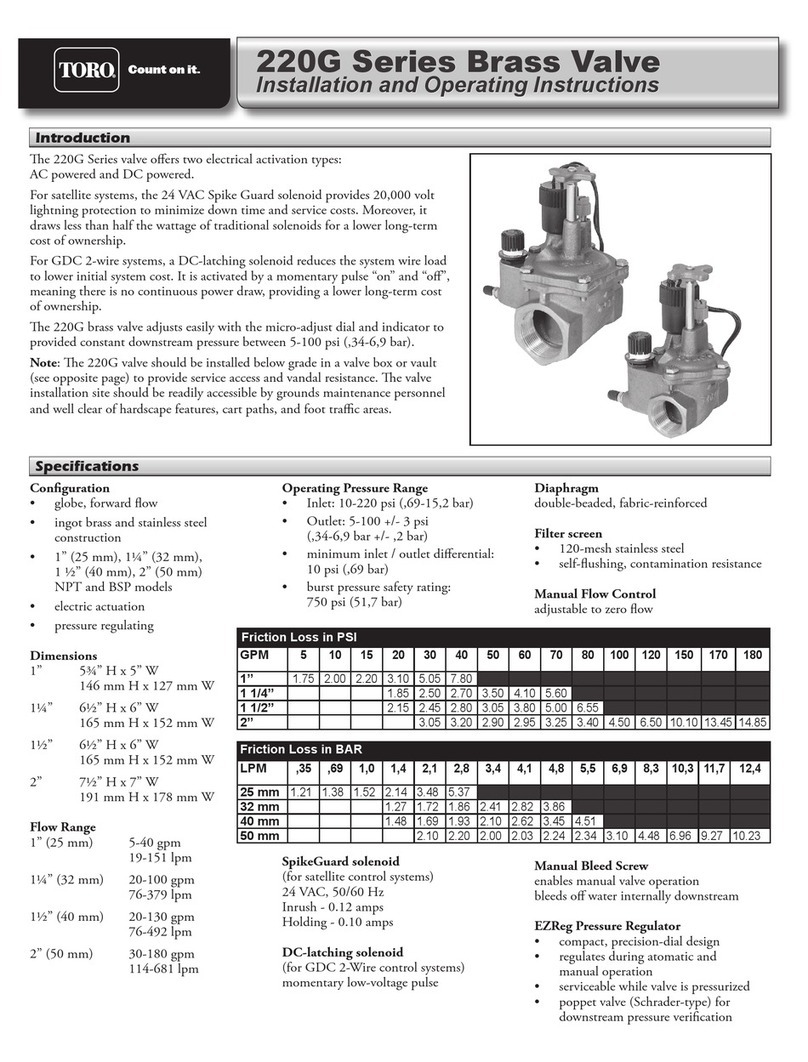

Valve Adjustment

Flow Control

e ow control is used to reduce the ow and pressure to

valve outlet. By turning the

ow control handle clockwise,

the ow will be gradually

reduced to zero.

Note: e ow control

should remain in the fully

open position. Use only for

emergency shut o or for valve

zone ne-tuning.

Internal Bleed Knob -

Downstream pressure

regulation maintained

e internal manual bleed

system is used to manually

operate the valve. Turning

the internal bleed knob

(located beneath the solenoid)

counterclockwise allows water

to bleed downstream from the diaphragm chamber. Internal

pressure is relieved from the top of the diaphragm, allowing

the valve to open. Turning the bleed knob clockwise until

tight shuts o the discharge enabling pressure to build within

the diaphragm chamber, causing the valve to close.

External Manual Bleed Knob (ush mode)

e external manual bleed knob, located on top of the ow

control handle, is used for system ushing. Turning this knob

counterclockwise allows water in the diaphragm chamber to

vent to atmosphere, creating maximum opening power and

debris ushing action. is operation bypasses the regulator

and opens the valve fully, regardless of regulator setting. In

addition, the metering rod (attached to the external bleed

knob) can be easily removed for cleaning as necessary.

EZReg Adjustment

An accurate, adjustable dial, coupled with a forward-ow

valve design, allows the P220

series valve with EZReg to

regulate downstream water

pressure with precision.

It’s easy and simple to use

and requires only 10 PSI

dierential pressure to operate.

e EZReg will operate

during powered and manual

valve operation using internal

manual bleed.

To adjust the downstream

pressure, remove the cover

from the regulator dial, then

turn the dial until the pointer

is on the desired pressure of

5-100 PSI (EZR-100).

Note: Due to the micro-

adjustment feature of the EZReg, the dial requires 10

revolutions for complete regulation range.

Operate the valve (electrically or manually). Check the

ow control to conrm that it is in the fully open position.

Adjust the regulator dial if necessary for optimum sprinkler

operation.

To conrm the downstream pressure using a pressure gauge,

remove the cap from the Schrader-type valve located directly

below the EZReg. Attach a Toro pressure gauge (Model 995-

51) to the Schrader-type valve for a direct reading. Adjust the

EZReg dial as necessary for the desired pressure.

Note: e valve will remain watertight in the closed position

if removal of the EZReg assembly is required.