Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

ToroMowerSafety...............................................5

SoundPressure.....................................................6

SoundPower........................................................6

Vibration..............................................................6

SafetyandInstructionalDecals.............................7

Setup..........................................................................10

1ActivatingandChargingtheBattery..................11

2PositioningtheSeat..........................................12

3InstallingtheBattery........................................13

4InstallingtheCuttingUnits(ForCutting

UnitModels04610and04611Only)...............14

5AddingRearBallast..........................................15

6InstallCEDecals.............................................15

7ReadingtheManualsandViewingthe

Video.............................................................16

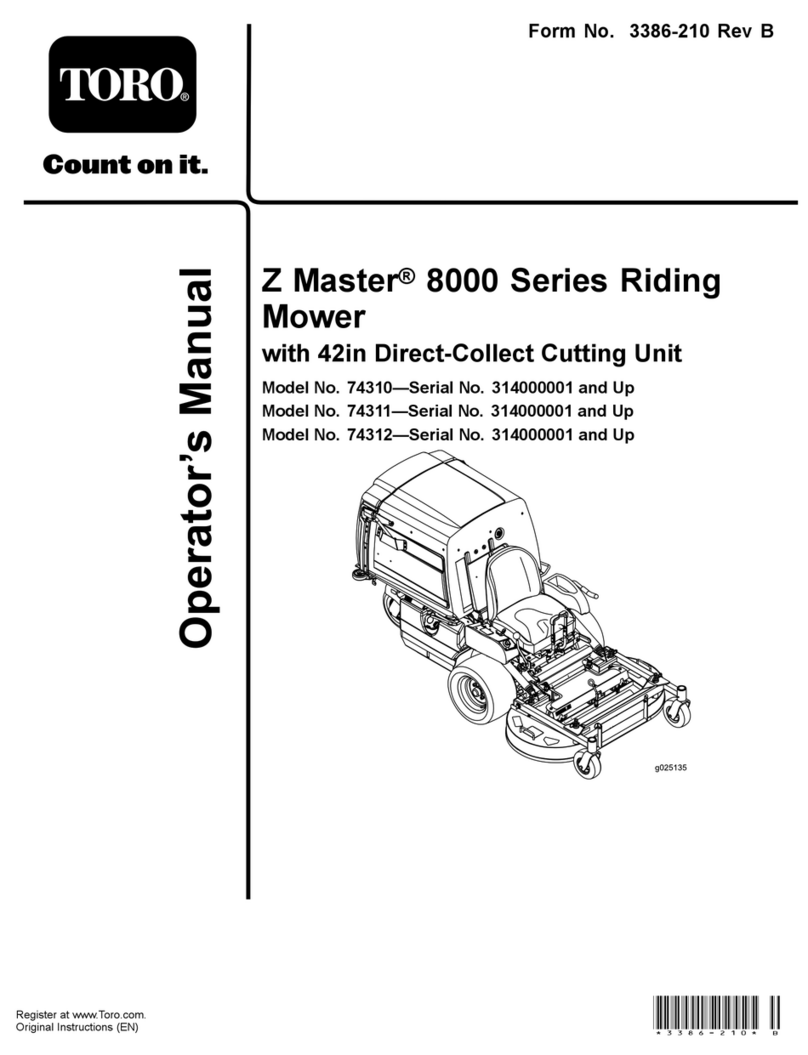

ProductOverview......................................................16

Controls.............................................................16

Specications.....................................................19

Attachments/Accessories...................................19

Operation...................................................................19

ThinkSafetyFirst...............................................19

CheckingtheEngineOil.....................................19

FillingtheFuelTank...........................................20

CheckingtheHydraulicFluidLevel.....................21

CheckingtheTirePressure.................................22

CheckingtheTorqueoftheWheel

Nuts...............................................................22

Break-inPeriod..................................................22

StartingtheEngine.............................................22

CheckingtheSafetyInterlockSystem..................23

CheckingtheLeakDetector................................23

SettingtheReelSpeed.........................................25

PreparingtheMachineforMowing.....................25

TrainingPeriod...................................................26

BeforeMowing..................................................26

Mowing..............................................................26

LeakDetectorOperation....................................27

TransportOperation..........................................27

InspectionandCleanupAfterMowing................27

TowingtheTractionUnit....................................28

Maintenance...............................................................29

RecommendedMaintenanceSchedule(s)................29

DailyMaintenanceChecklist...............................30

PremaintenanceProcedures....................................31

RemovingtheSeat..............................................31

JackingtheMachine............................................31

Lubrication.............................................................32

GreasingtheMachine.........................................32

EngineMaintenance...............................................34

ServicingtheAirCleaner....................................34

ChangingtheEngineOilandFilter.....................34

AdjustingtheThrottleControl............................35

AdjustingtheChokeControl..............................35

AdjustingtheCarburetorandSpeed

Control..........................................................35

ReplacingtheSparkPlugs...................................36

FuelSystemMaintenance.......................................36

ReplacingtheFuelFilter.....................................36

FuelLinesandConnections................................36

ElectricalSystemMaintenance................................37

ServicingtheBattery...........................................37

ServicingtheFuses.............................................37

DriveSystemMaintenance.....................................38

AdjustingtheTransmissionforNeutral...............38

AdjustingtheTransportSpeed............................38

AdjustingtheMowingSpeed..............................39

BrakeMaintenance.................................................39

AdjustingtheBrakes...........................................39

ControlsSystemMaintenance.................................40

AdjustingtheCuttingUnitLift/Drop.................40

AdjustingtheLiftCylinders................................40

HydraulicSystemMaintenance...............................41

ChangingtheHydraulicOilandFilter.................41

CheckingtheHydraulicLinesandHoses.............41

CuttingUnitMaintenance.......................................42

Backlapping........................................................42

Storage.......................................................................43

Schematics.................................................................44

3