Contents

Safety.......................................................................3

GeneralSafety...................................................3

CuttingUnitSafety..............................................4

BladeSafety.......................................................4

SafetyandInstructionalDecals..........................4

Setup........................................................................6

1PreparingtheMachine.....................................6

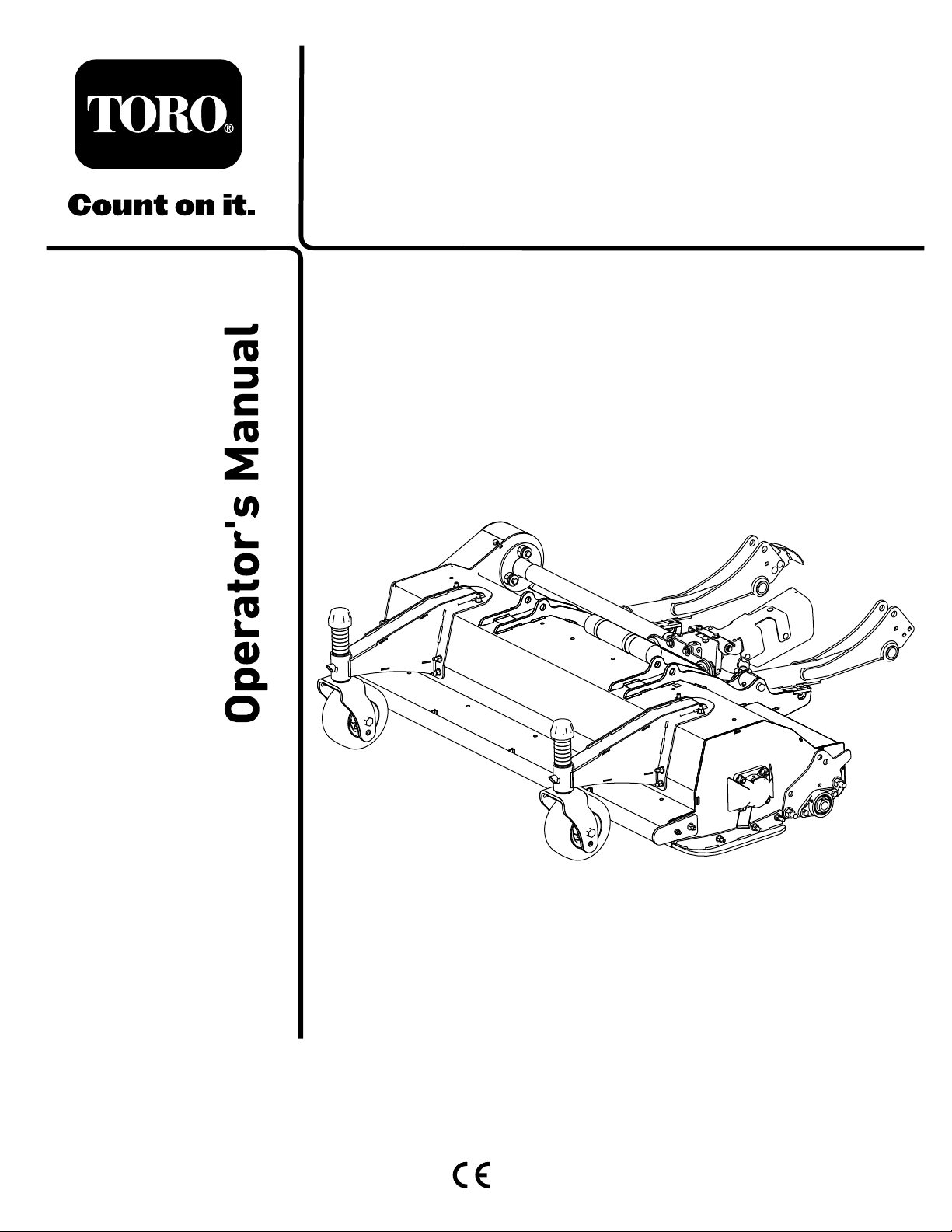

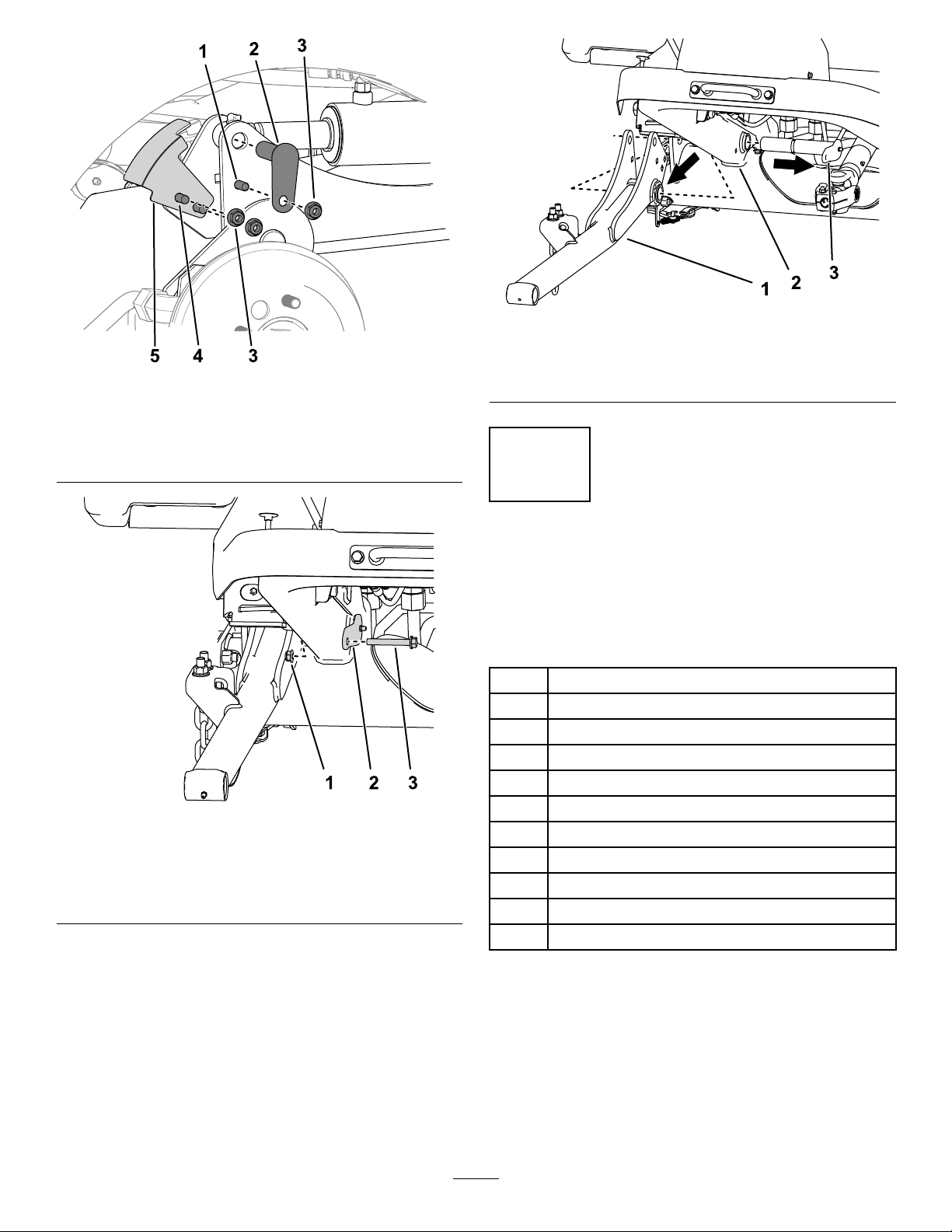

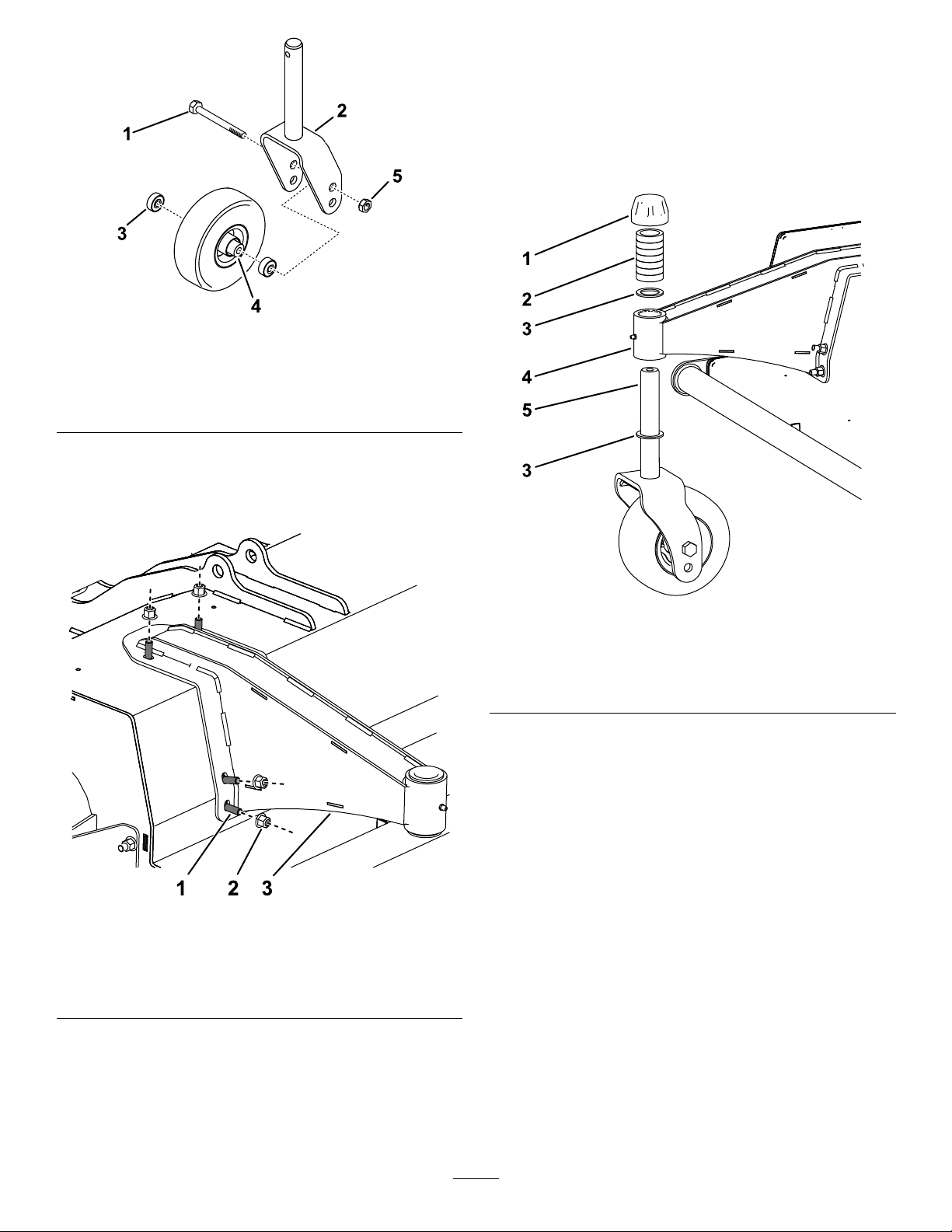

2AssemblingtheCasterArmsandCasters

totheCuttingUnit...........................................7

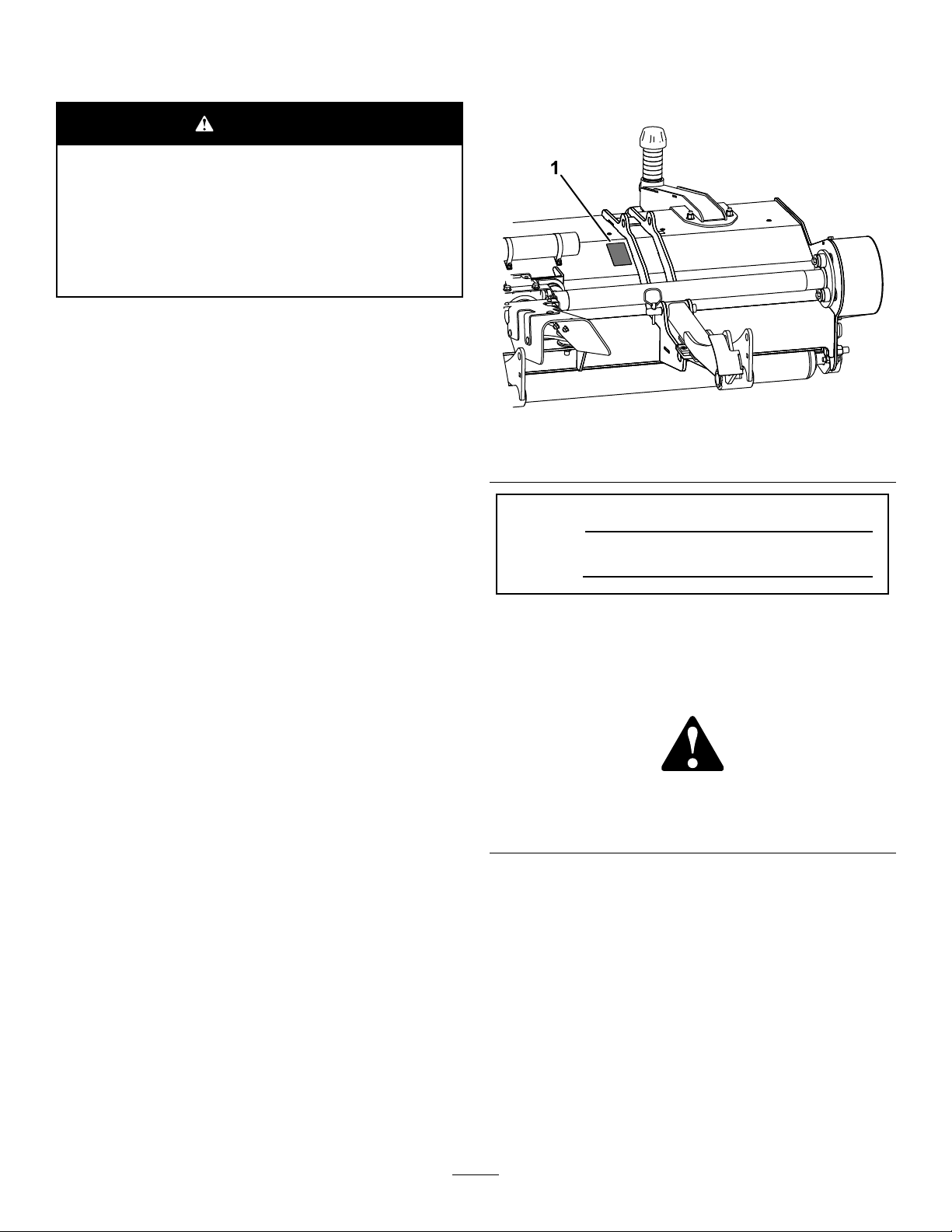

3InstallingtheDebrisGuardtotheFront

Axle.................................................................9

4InstallingtheCuttingUnittothe

Machine..........................................................9

5InstallingthePTOGuard.................................11

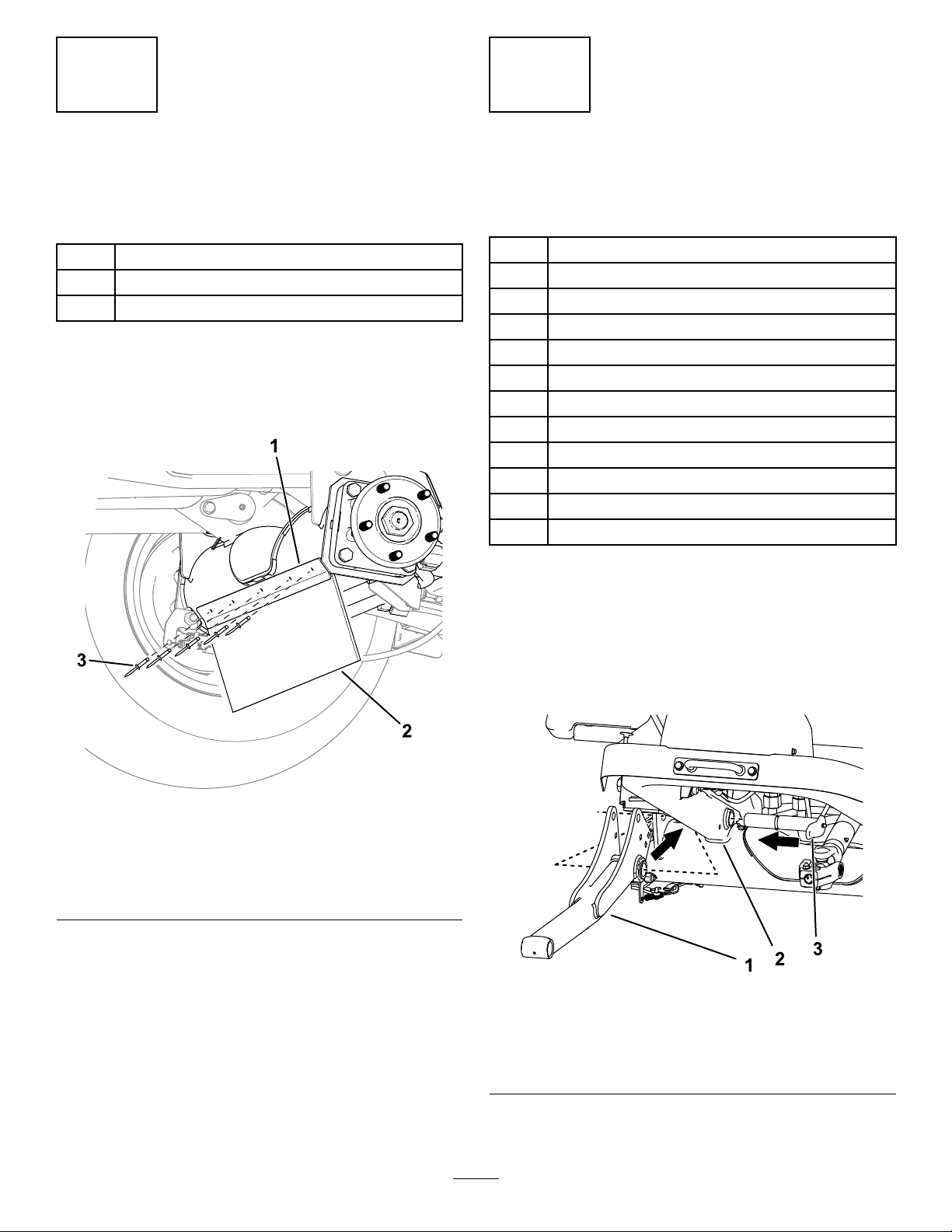

6AdjustingtheSensorBracket..........................11

7AdjustingtheWeightTransfer.........................11

8CheckingtheGearboxOil..............................12

9CheckingtheCasterTirePressure.................12

10GreasingtheMachine..................................12

ProductOverview...................................................12

Specications..................................................12

Attachments/Accessories.................................12

Operation................................................................13

CuttingUnitGeneralInformation.......................13

AdjustingtheHeightofCut...............................13

InspectingtheBlades.......................................14

OperatingTips.................................................15

Maintenance...........................................................16

RecommendedMaintenanceSchedule(s)...........16

DailyMaintenanceChecklist.............................17

LubricatingtheCuttingUnit...............................18

CheckingtheLubricantintheGearbox..............19

ChangingtheLubricantintheGearbox.............19

CheckingtheBeltTension................................20

CheckingtheBeltDriveandTaperLock

Hardware......................................................21

RemovingtheCuttingUnitfromthe

Machine........................................................21

ServicingtheBushingsintheCaster

Arms.............................................................22

ServicingtheCasterWheelsand

Bearings........................................................22

CheckingtheBladeBolts..................................23

CheckingtheFrontFlaps..................................23

ClearingaBlockedRotor..................................23

CheckingtheCasterTirePressure...................23

CheckingforRotorVibration.............................23

CheckingtheRotorBearings............................24

SharpeningtheBlades.....................................24

ReplacingtheBlades........................................25

CleaningUndertheCuttingUnit........................25

Storage...................................................................26

Safety

Thismachinehasbeendesignedinaccordancewith

ANSIB71.4andMSD.

GeneralSafety

Thisproductiscapableofamputatinghandsandfeet.

Alwaysfollowallsafetyinstructionstoavoidserious

personalinjury.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingthemachine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

functioningproperlyonthemachine.

•Keepclearofanydischargeopening.

•Keepbystandersandchildrenoutoftheoperating

area.Neverallowchildrentooperatethemachine.

•Beforeyouleavetheoperator’sposition,dothe

following:

–Parkthemachineonalevelsurface.

–Lowerthecuttingunit(s).

–Disengagethedrives.

–Engagetheparkingbrake(ifequipped).

–Shutofftheengineandremovethekey.

–Waitforallmovementtostop.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

3