!

0*,0(

Manufacturer Ċ Mitsubishi.

Horsepower Ċ 22 (16 w) @ 3000 RPM.

Torque Ċ 40 ft-lb (54.2 Nm) @ 2400 RPM.

Displacement Ċ 58.1 cu in. (952 cc).

Crankcase Capacity Ċ 3.8 qt. (3.6 L).

Governor Ċ Mechanical.

Governor Limit Ċ 3100Ć3250 RPM.

Idle Speed Ċ 1700 RPM.

,3 .(%0(3 Donaldson heavy duty with precleaner.

Remote mounted.

6(. !%0- %2%&,5: 8.5 gal. (32 l).

6(. ,.5(3$%5(3 (2%3%513 3 micron spinĆon type

element. Replaceable (Toro Part No. 63-8300).

6(. 6/2 12 volt electric (transistor type)

w/replaceable fuel filter (Toro Part No. 43-2550).

11.,0* :45(/

Radiator Ċ Approx. 6 qt (5.7 l) capacity.

Expansion Tank Ċ Remote mounted; 1 qt (0.946 l)

capacity. System contains a 50/50 mix of ethylene

glycol antiĆfreeze and water.

.(&53,&%. Battery Ċ 12 volt, BCI group size 26,530

Amp at 0 F. 35 amp alternator with regulator/rectifier.

3,7( 162.,0* Transmission driven by steel shaft

with flexible rubber couplings at each end.

!3%04/,44,10

Manufacturer & Type Ċ Sundstrand hydrostatic,

Type U15.

Normal Charge Pressure Ċ 70Ć150 psi

(483Ć1034 kPa).

Implement Relief Setting Ċ 700Ć800 psi

(4 826 Ć 5 516 kPa).

:'3%6.,& ,.5(3 25 micron mounted directly to

transmission. Replaceable (Toro Part No. 23-2300).

3,7( 9.( Manufacturer Ċ Dana Corp., Model GTĆ20.

Axle serves as a hydraulic fluid reservoir and mates

directly with the transmission. Approximately 5 qt (4.7 l)

capacity.

3%-(4 Mechanical drum type, 7 in. (17.8 cm) dia. x

1Ć3/4 in. (45 mm) wide. Individually controlled by two

pedals connected by cable and conduit for steering

assist. Pedals may be latched together for two wheel

braking. Lever provided for parking brake.

!,3(4 $+((.4 3(4463(

Front Tires Ċ 23 x 8.50 - 12

Rear Tires Ċ 16 x 6.50 - 8

All tires 4 ply rating, tubeless type.

(Pressure Ċ 20 psi (138 kPa).

5((3,0* 13 in. (33 cm) steering wheel. TRW power

steering valve.

%,0 3%/( Frame is welded, formed steel.

04536/(05%5,10 Fuel gauge, water temperature

gauge, hour meter and warning lights for high

temperature shutdown, oil pressure, amperage and

glow plug are mounted on the console.

10531.4 Throttle, PTO switch, parking brake,

implement lift, ignition switch and glow plug switch are

all handĆoperated. Forward/reverse traction pedal and

turning brakes are foot operated.

! 3,7( Splined PTO shaft is clutched by a

torqueĆteamed HA Section, spring tensioned VĆbelt

directly from engine output shaft. PTO shaft engaged

by electric clutch/brake assembly. PTO speed Ċ 2200

RPM @ 3250 RPM engine speed.

/2.(/(05 100(&5,10 Ċ Universal joint and

telescoping shaft assembly.

,)5 :.,0'(34 Two, with 2 in. (51 mm) bore, 3.5 in. (89

mm) stroke.

05(3.1&- 8,5&+(4 Prevents engine starting if traction

pedal or PTO switch are engaged. Stops engine if

operator leaves seat with either traction pedal or PTO

switch engaged.

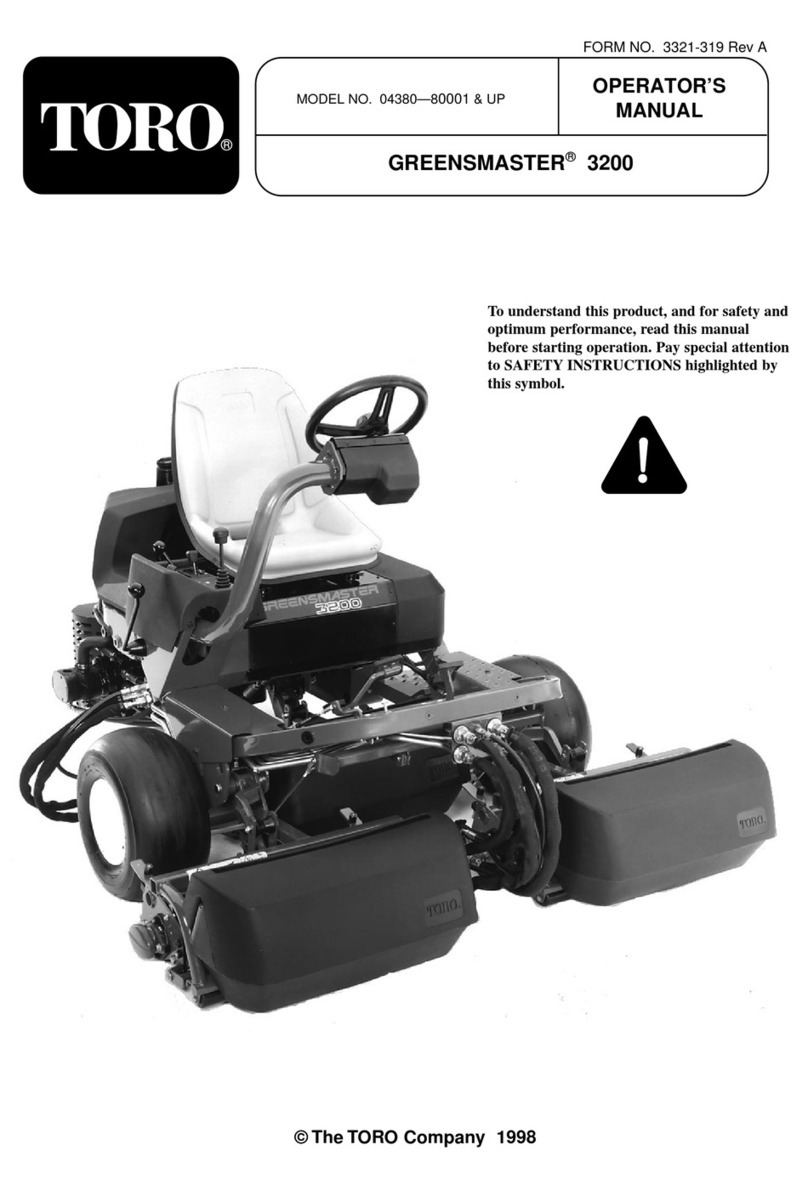

,/(04,104 %0' $(,*+5 %22319

Traction Unit w/Standard Seat

Length: 82 in.

Width: (Rear Wheels) 44 in.

Height: 50 in.

Weight: 1120 lb

! "!

,'( ,4&+%3*( 655,0* "0,5ĊModel No. 30555

(%3 ,4&+%3*( 655,0* "0,5ĊModel No. 30568

,'( ,4&+%3*( 655,0* "0,5ĊModel No. 30564

6%3',%0 (&:&.(3 655,0* "0,5ĊModel No.

30569

,'( ,4&+%3*( 655,0* "0,5ĊModel No. 30575

#;.18 ,5 Ċ Model No. 30750

#;.18 1605,0* ,5 Ċ Model No. 30749. Required

with 30750 VĆPlow. 11Ć0390 Tire Chains

recommended.

3/ (45 ,5 Ċ Model 30707. Fits Models 30769,

30772 Seat its.

(%3 ,4&+%3*( +,(.' ,5 Ċ Model No. 30567.

(%3 $(,*+5 19 ,5 Ċ Part No. 24-5780.

3%44 1..(&5,10 :45(/ Ċ Model No. 30502, 52"

Blower it (for Model 30555 deck) or Model 30503 62"

Blower it (for Model 30564 deck) can be used with

either Model No. 30504, 9 cu. fit. Hopper it or Model

No. 30505, 15 cu. ft. Hopper it.

$,'( !,3(4 83,/ 23 x 10.5 Ć 12, 4 ply Ċ Part No.

62-7020. 23 x 10.5 Ć 12, 6 ply Ċ Part No. 69-9870.