3

SAFETY INSTRUCTIONS

7. Do not operate machine while wearing sandals,

tennis shoes, sneakers or shorts. Also, do not wear

loose fitting clothing which could get caught in moving

parts. Always wear long pants and substantial shoes.

Wearing safety glasses, safety shoes and a helmet is

advisable and required by some local ordinances and

insurance regulations.

8. Fill fuel tank with gasoline before starting the en

gine. Avoid spilling gasoline. Since gasoline is flam

mable, handle it carefully.

A. Use an approved gasoline container.

B. Do not fill tank while engine is hot or running.

C. Do not smoke while handling gasoline.

D. Fill fuel tank outdoors and up to about one inch

(25 mm) from top of the tank, not the filler neck.

E. Wipe up any spilled gasoline.

WHILE OPERATING

9. Start engine when parking brake is set, blade is

disengaged, and transmission is in neutral.

10. Do not run the engine in a confined area without

adequate ventilation. Exhaust fumes are hazardous

and could possibly be deadly.

11. Using the machine demands attention, and to pre

vent loss of control:

A. Mow only in daylight or when there is good artifi

cial light.

B. Watch for holes or other hidden hazards.

C. Do not drive close to a sand trap, ditch, creek or

other hazard.

D. Reduce speed when making sharp turns and

when turning on hillsides.

12. Do not operate unless grass deflector, Recycler

cover or entire grass collector is installed. The grass

deflector must always be installed and in lowest posi

tion on the side discharge cutting unit. This product is

designed to drive objects into the ground where they

lose energy quickly in grassy areas. However, don't

take an injury risk!! When a person or pet appears un

expectedly in or near the mowing area, STOP MOW

ING. Careless operation, combined with terrain

angles, ricochets, or improperly positioned guards,

can lead to thrown object injuries. Do not resume mow

ing until area is cleared.

13. Never raise the cutting unit while the blades are ro

tating.

14. If the cutting blades strike a solid object or the ma

chine vibrates abnormally, shut the engine off. Remove

spark plug wire from spark plug to prevent possibility of

accidental starting. Check cutting unit and traction unit

for damage and malfunctioning parts. Repair any dam

age before restarting the engine and operating the cut

ting unit. Be sure blades are in good condition and

blade bolts are tight.

15. Cut grass slopes carefully. Do not start, stop, or

turn suddenly.

16. Do not touch engine or muffler while engine is run

ning or soon after it is stopped. These areas couId be

hot enough to cause a burn.

17. Before leaving the operator's position behind

handle or leaving mower unattended, shift transmis

sion into NEUTRAL, apply parking brake, release con

trol bail and shut OFF engine.

MAINTENANCE

18. Remove key from switch and disconnect spark

plug wire from spark plug to prevent accidental starting

of the engine when servicing, adjusting or storing the

machine.

19. If traction unit and mower must be tipped to per

form maintenance or an adjustment, drain gasoline

from fuel tank and oil from crankcase.

20. When driving unit forward, always use upper For

ward" traction drive handle. When backing up, always

use lower Reverse" traction drive handle.

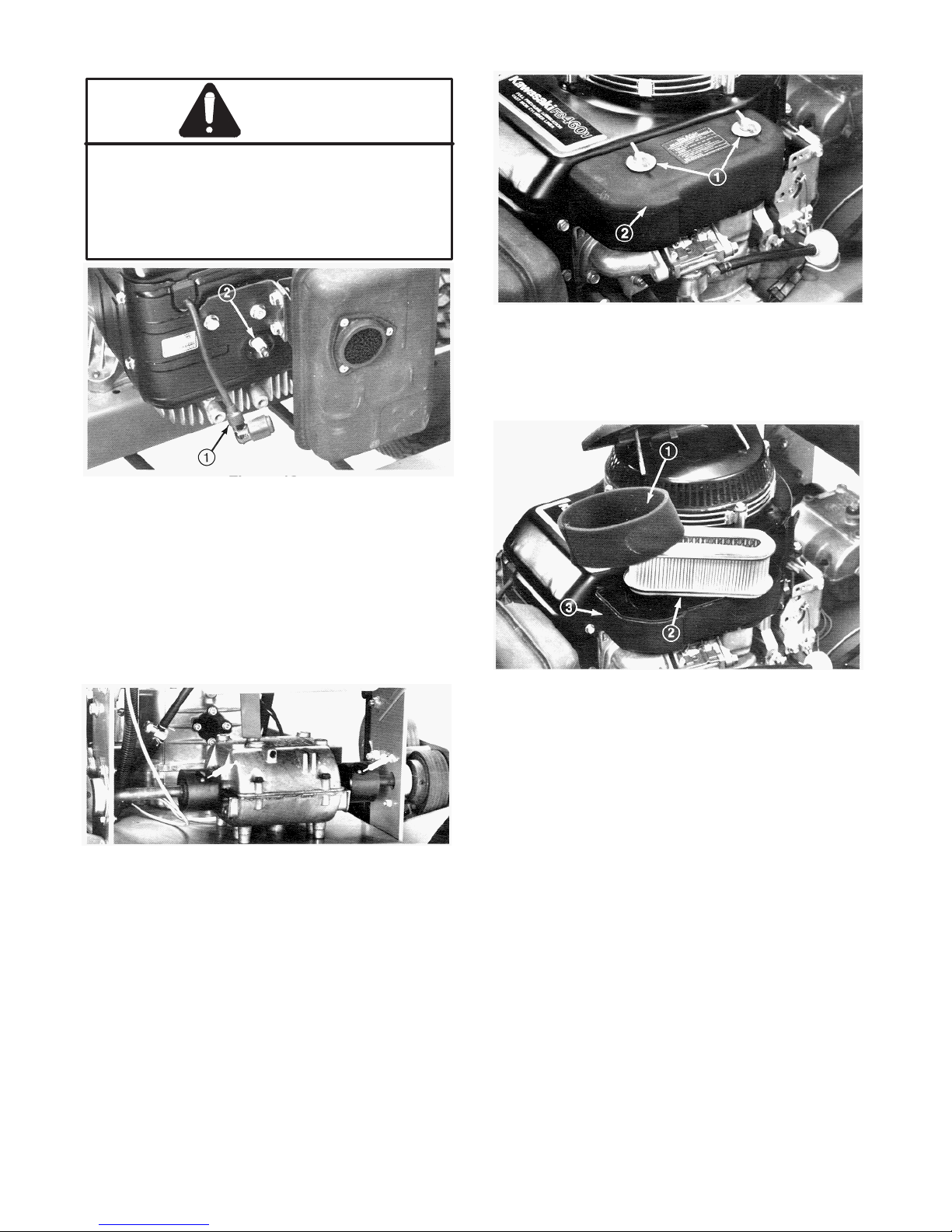

21. To reduce potential fire hazard, keep the engine

free of excessive grease, grass, leaves and accumula

tions of dirt.

22. Be sure machine is in safe operating condition by

keeping nuts, bolts and screws tight. Check the blade

mounting bolts and nuts frequently to be sure they are

tightened to specification.

23. If the engine must be running to perform a mainte

nance adjustment, keep hands, feet, clothing and oth

er parts of the body away from the cutting unit blades

and other moving parts.

24. Do not overspeed the engine by changing gover

nor settings. To be sure of safety and accuracy, have an

Authorized TORO Proline Service Dealer check maxi

mum engine speed with a tachometer.

25. Engine must be shut off before checking oil or add

ing oil to the crankcase.

26. Allow engine to cool before storing mower in any

enclosure such as a garage or storage shed. Make

sure the mower fuel tank is empty if machine is to be

stored in excess of 30 days. Do not store mower near

any open flame or where gasoline fumes may be ig

nited by a spark. Always store gasoline in a safety-ap

proved, red metal container.

27. Perform only those maintenance instructions de

scribed in this manual. If major repairs are ever needed

or assistance is desired, contact an Authorized Toro

Proline Service Dealer. To ensure optimum perfor

mance and continued safety conformance of the ma

chine, use genuine TORO replacement parts and ac

cessories. Replacement parts and accessories made

by other manufacturers may result in nonconfor

mance with safety standards and could void the war

ranty.