TableofContents

Preface................................................................................................................5

Chapter1:Safety............................................................................................1–1

SafetyInstructions.......................................................................................1–2

JackingInstructions.....................................................................................1–6

SafetyandInstructionalDecals....................................................................1–8

Chapter2:SpecicationsandMaintenance....................................................2–1

Specications...............................................................................................2–2

TorqueSpecications...................................................................................2–4

ShopSupplies..............................................................................................2–9

SpecialT ools..............................................................................................2–11

Chapter3:DieselEngine.................................................................................3–1

Specications...............................................................................................3–2

GeneralInformation.....................................................................................3–3

ServiceandRepairs.....................................................................................3–8

Chapter4:HydraulicSystem...........................................................................4–1

Specications...............................................................................................4–3

GeneralInformation.....................................................................................4–4

HydraulicSchematics.................................................................................4–13

SpecialT ools...............................................................................................4–23

Troubleshooting..........................................................................................4–28

TestingtheHydraulicSystem......................................................................4–31

ServiceandRepairs...................................................................................4–57

Chapter5:ElectricalSystem...........................................................................5–1

GeneralInformation.....................................................................................5–3

SpecialTools.................................................................................................5–9

InfoCenterDisplay......................................................................................5–11

Troubleshooting..........................................................................................5–16

ElectricalSystemQuickChecks..................................................................5–20

TestingtheElectricalComponents..............................................................5–23

Adjustments...............................................................................................5–54

ServiceandRepairs...................................................................................5–56

Chapter6:Chassis..........................................................................................6–1

Specications...............................................................................................6–2

GeneralInformation.....................................................................................6–3

ServiceandRepairs.....................................................................................6–4

Chapter7:CuttingDeck..................................................................................7–1

GeneralInformation.....................................................................................7–2

FactorsThatCanAffectCuttingPerformance...............................................7–3

ServiceandRepairs.....................................................................................7–4

AppendixA......................................................................................................A–1

HydraulicSchematic.....................................................................................A–3

ElectricalSchematic-Platform.....................................................................A–4

ElectricalSchematic-Engine.......................................................................A–5

ElectricalSchematic-Cab(1of2)................................................................A–6

ElectricalSchematic-Cab(2of2)................................................................A–7

WireHarnessDrawing-Platform(1of2)......................................................A–8

WireHarnessDrawing-Platform(2of2)......................................................A–9

WireHarnessDrawing-Engine(1of2).......................................................A–10

WireHarnessDrawing-Engine(2of2).......................................................A–11

WireHarnessDrawing-CabPower............................................................A–12

WireHarnessDrawing-CabHeadliner.......................................................A–13

WireHarnessDiagram-CabHeadliner......................................................A–14

WireHarnessDrawing-CabPowerPointKit..............................................A–15

WireHarnessDrawing-AuxiliaryPowerModel30382................................A–16

WireHarnessDrawing-LightKitModel30374...........................................A–17

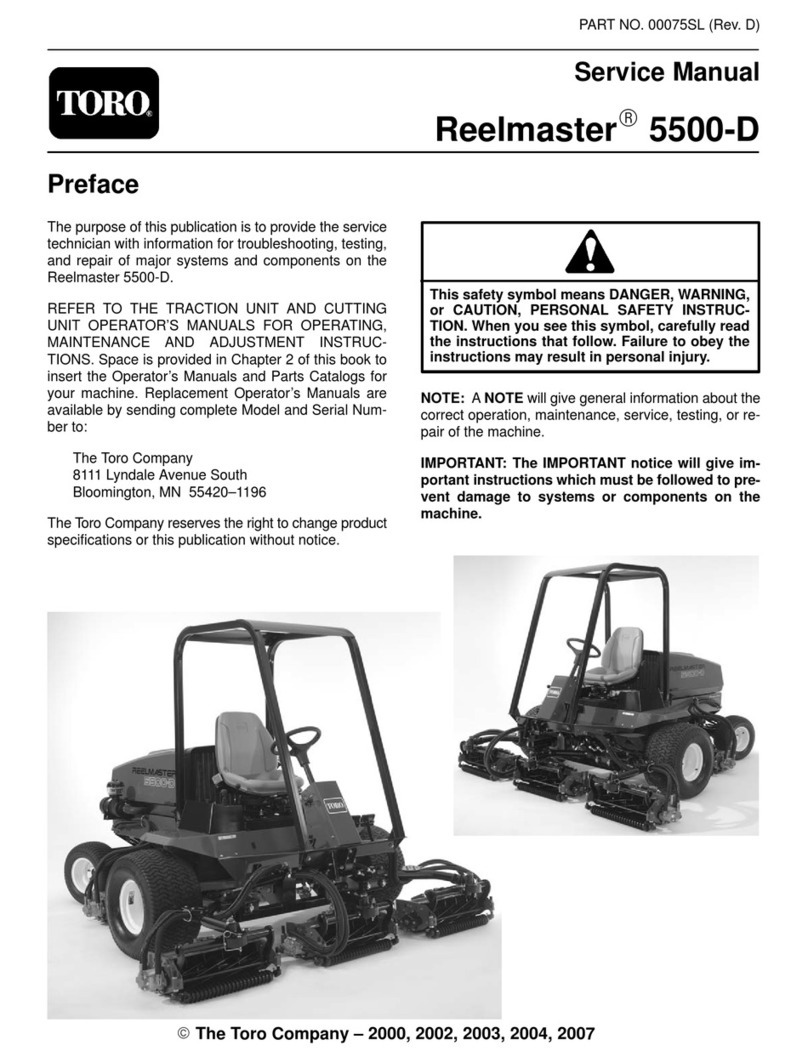

Groundsmaster7210Page7Preface

16222SLRevC