Contents

Safety.......................................................................4

GeneralSafety...................................................4

Engine-EmissionCertication.............................4

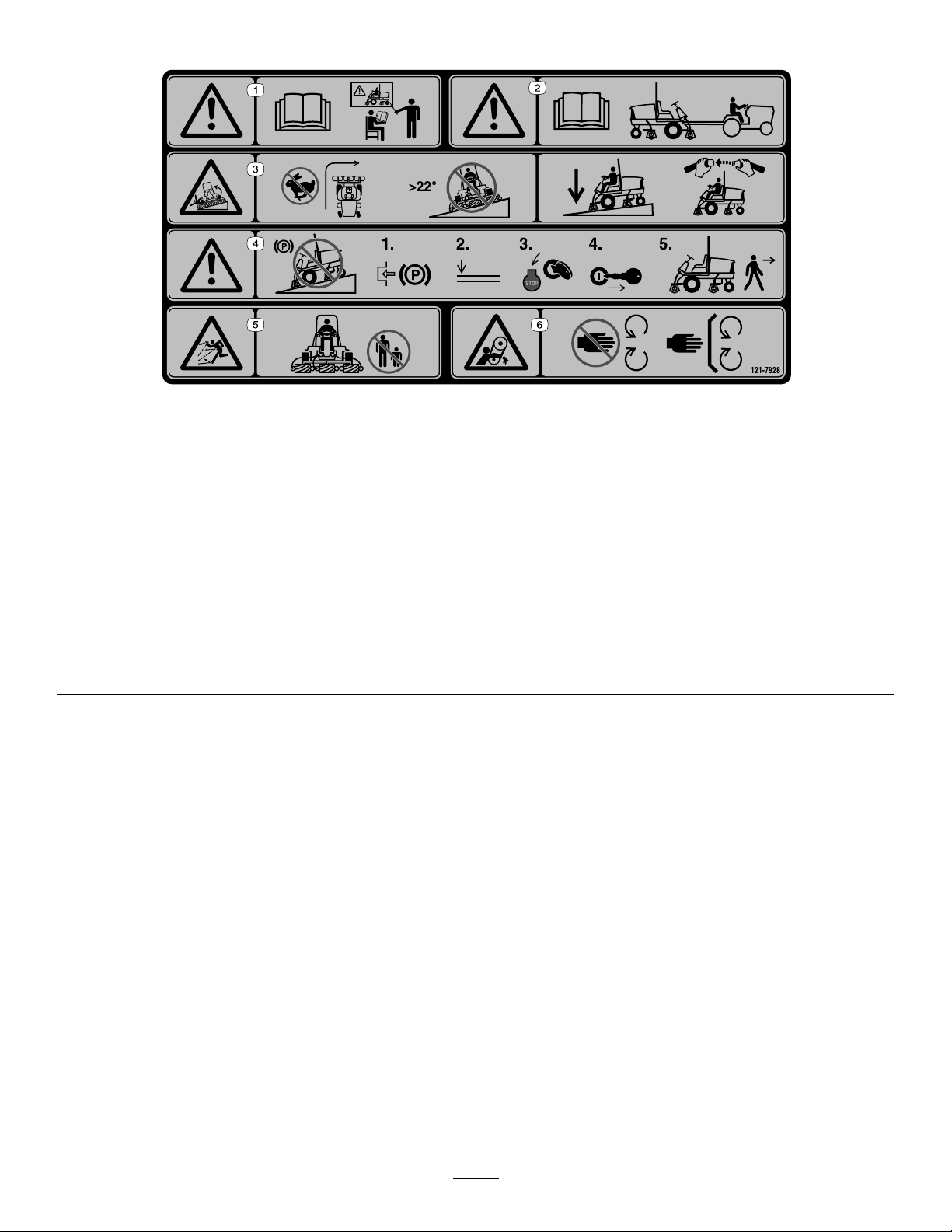

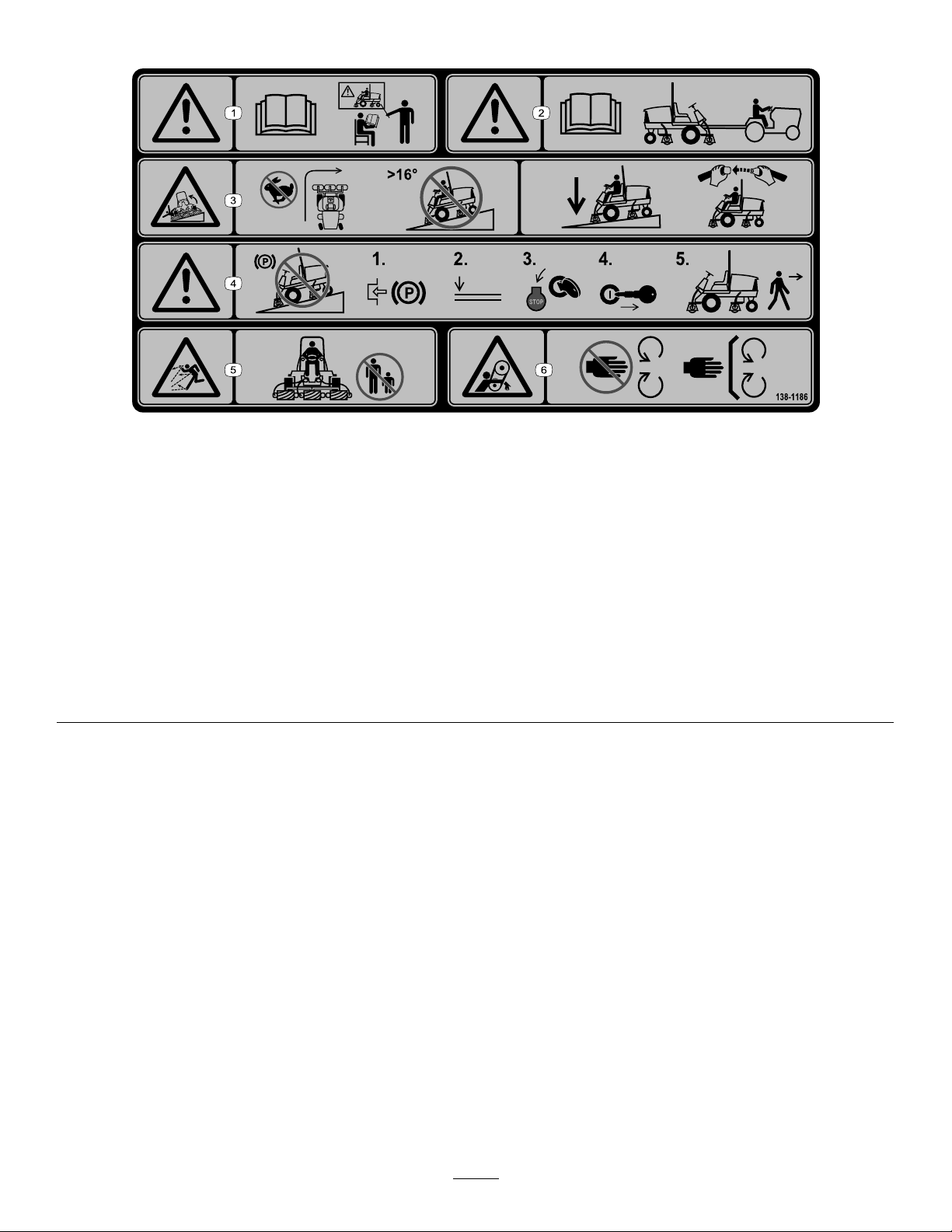

SafetyandInstructionalDecals..........................5

Setup......................................................................13

1InstallingtheCuttingUnits..............................14

2AdjustingtheTurfCompensation

Spring...........................................................16

3InstallingtheCEDecals.................................17

4InstallingtheHoodLatch(CEOnly)................17

5ReducingtheTirePressure............................18

6UsingtheCutting-UnitKickstand....................18

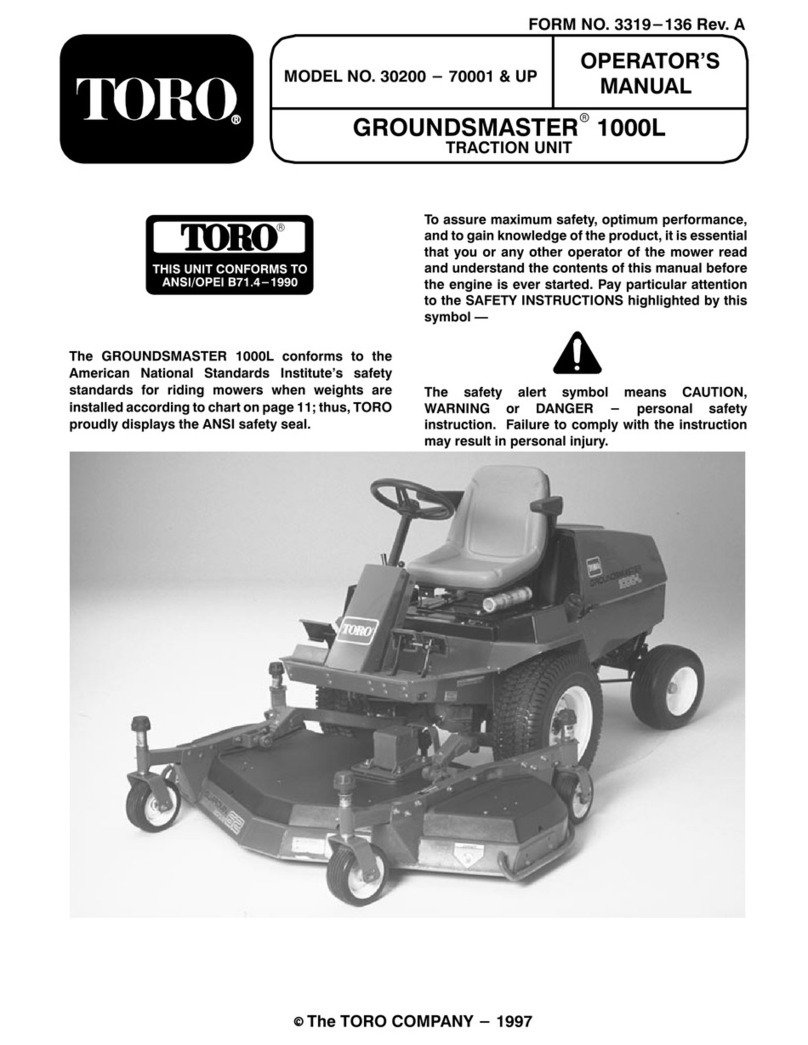

ProductOverview...................................................19

Controls...........................................................19

Specications..................................................23

Attachments/Accessories.................................23

BeforeOperation.................................................24

BeforeOperationSafety...................................24

PerformingDailyMaintenance..........................24

FillingtheFuelTank..........................................24

AdjustingtheSeat............................................25

DuringOperation.................................................26

DuringOperationSafety...................................26

StartingtheEngine...........................................27

ShuttingOfftheEngine.....................................27

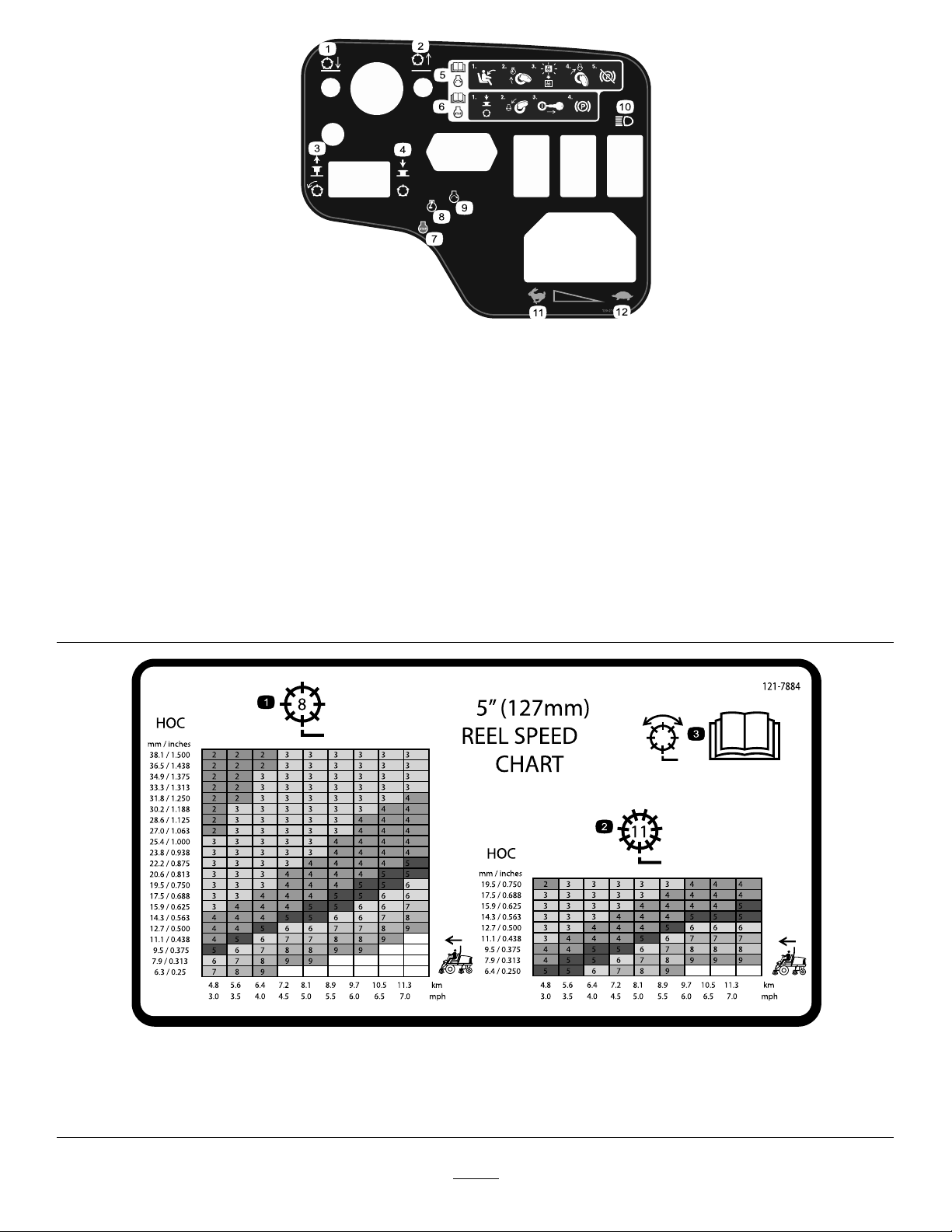

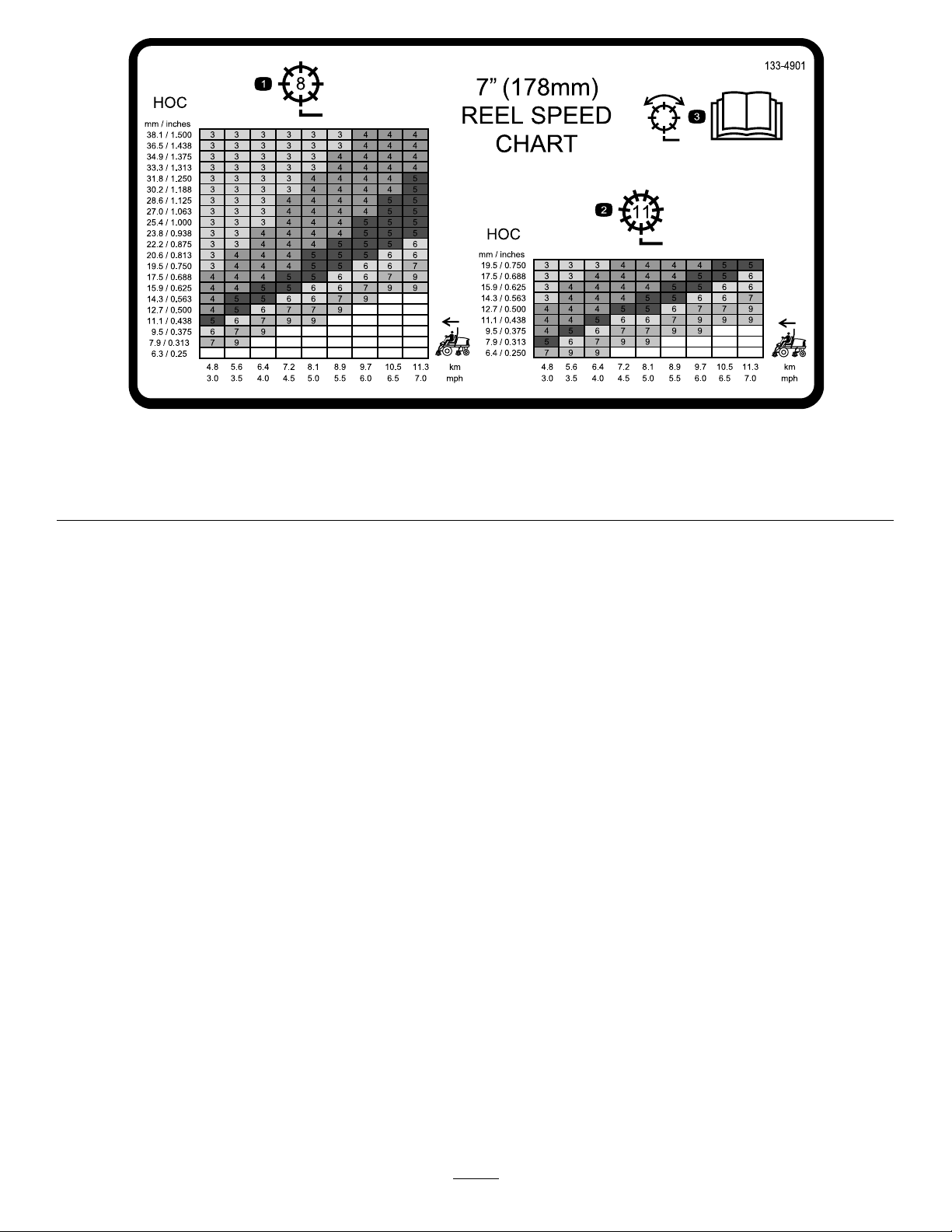

SettingtheReelSpeed.....................................27

AdjustingtheLift-ArmCounterbalance.............29

BleedingtheFuelSystem.................................29

UnderstandingtheDiagnosticLight..................30

UnderstandingtheDiagnosticACE

Display..........................................................30

CheckingtheInterlockSwitches.......................30

OperatingTips.................................................32

AfterOperation....................................................33

AfterOperationSafety......................................33

PushingorTowingtheMachine........................33

HaulingtheMachine.........................................34

IdentifyingtheTie-DownPoints........................35

Maintenance...........................................................36

MaintenanceSafety..........................................36

RecommendedMaintenanceSchedule(s)...........36

DailyMaintenanceChecklist.............................38

Pre-MaintenanceProcedures..............................39

RemovingtheHood..........................................39

RemovingtheBatteryCover.............................39

Lubrication..........................................................40

GreasingtheBearingsandBushings................40

EngineMaintenance...........................................41

EngineSafety...................................................41

CheckingtheEngine-OilLevel..........................41

ServicingtheAirCleaner..................................42

ChangingtheEngineOilandFilter....................43

FuelSystemMaintenance...................................43

ServicingtheFuelT ank.....................................43

InspectingtheFuelLinesand

Connections..................................................43

DrainingtheWaterSeparator...........................44

ChangingtheFuelFilterCanister......................44

BleedingAirfromtheInjectors..........................44

ElectricalSystemMaintenance...........................45

ElectricalSystemSafety...................................45

ServicingtheBattery.........................................45

CheckingtheFuses..........................................45

DriveSystemMaintenance..................................46

CheckingtheTirePressure...............................46

TorquingtheWheelNuts...................................46

AdjustingtheTractionDriveforNeutral.............46

CoolingSystemMaintenance..............................47

CoolingSystemSafety.....................................47

CheckingtheCoolingSystem...........................47

CleaningtheEngineCoolingSystem................48

BrakeMaintenance.............................................48

AdjustingtheParkingBrake..............................48

BeltMaintenance................................................49

ServicingtheEngineBelts................................49

ControlsSystemMaintenance.............................50

AdjustingtheThrottle........................................50

HydraulicSystemMaintenance...........................50

HydraulicSystemSafety...................................50

CheckingtheHydraulicLinesand

Hoses............................................................50

CheckingtheHydraulicFluid............................50

HydraulicFluidSpecications...........................51

HydraulicFluidCapacity...................................51

ChangingtheHydraulicFluid............................52

ChangingtheHydraulicFilter............................52

CuttingUnitSystemMaintenance........................53

BladeSafety.....................................................53

CheckingtheReel-to-BedknifeContact............53

UsingtheOptionalGaugeBar..........................54

BacklappingtheCuttingUnits...........................54

Cleaning..............................................................55

WashingtheMachine.......................................55

Storage...................................................................56

StorageSafety..................................................56

PreparingtheTractionUnit...............................56

PreparingtheEngine........................................56

3