Toro VR-2650 User manual

FormNo.3382-922RevA

VR-2650,VR-3100,andVR-3500

RammerCompactor

ModelNo.68034—SerialNo.313000001andUp

ModelNo.68035—SerialNo.313000001andUp

ModelNo.68036—SerialNo.313000001andUp

Registeratwww.Toro.com.

OriginalInstructions(EN)*3382-922*A

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

GenuineTorosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

Theenclosed

Engine Owner's Man ual

issuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Introduction

Thismachineisdesignedtocompactawidearrayofsoil

substances,includinglumpsofclay,silt,gravel,sand,loam,

andothergranularobjects.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1illustratesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

G022333

1

Figure1

1.Modelandserialnumberplate

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN554202

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Introduction..................................................................2

Safety...........................................................................3

SafeOperatingPractices...........................................3

SafetyandInstructionalDecals.................................5

ProductOverview..........................................................6

Controls................................................................6

Specications.........................................................8

Operation.....................................................................8

PreparingtoUsetheMachine....................................8

AddingFuel............................................................8

CheckingtheEngine-oilLevel..................................10

CheckingtheSpring-housingOil..............................11

StartingandStoppingtheEngine..............................11

TransportingtheMachine........................................12

OperatingTips......................................................12

Maintenance.................................................................13

RecommendedMaintenanceSchedule(s)......................13

PremaintenanceProcedures........................................13

DisconnectingtheSpark-plugWire...........................14

EngineMaintenance..................................................14

ServicingtheAirCleaner.........................................14

ServicingtheEngineOil..........................................16

ServicingtheSpring-housingOil..............................17

ServicingtheSparkPlug..........................................18

CompactorShoeMaintenance.....................................19

CheckingtheCompactorShoe.................................19

Cleaning...................................................................19

RemovingDebrisfromtheMachine..........................19

Storage........................................................................20

............................................................................20

RemovingtheMachinefromStorage.........................20

Troubleshooting...........................................................21

Safety

Improperlyusingormaintainingthemachinecanresult

ininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeans:

Caution

,

W ar ning

,

or

Danger

—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonalinjury

ordeath.

SafeOperatingPractices

Thisproductiscapableofcausingseriousinjury.Always

followallsafetyinstructionstoavoidseriousinjuryordeath.

WARNING

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadorunderstand

theinformation,itistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringpeopleordamageto

property.

Preparation

•Wearappropriateclothingincludinghardhat,faceshield,

safetyglasses,longpants,steel-toeshoes,andhearing

protection.Longhair,looseclothing,orjewelrymayget

tangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toys,andwirewhichcan

bethrownbythemachine.

•Useextracarewhenhandlinggasolineandotherfuels.

Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer

–Neverremovethegascaporaddfuelwiththeengine

running.Allowtheenginetocoolbeforerefueling.

Donotsmoke.

–Neverfuelordrainthemachineindoors.

3

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Neverliftthemachineonyourown.Makesuretohaveat

leasttwopersonstoliftthemachine.

•Besurethatalldrivesareintheslowpositionbefore

startingtheengine.Starttheenginefromtheoperator's

positiononly.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Keephandsandfeetawayfromtheshoeofthe

compactor.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Usecarewhenapproachingblindcornersorobjectsthat

mayobscurevision.

•Ensurethattheareaisclearofotherpeoplebefore

operatingthemachine.Stopthemachineifanyoneenters

thearea.

•Neverleavearunningmachineunattended.Alwaysstop

theengineandverifythatthecompactingshoehasbeen

completelystopped.

•Neverjerkthecontrols;useasteadymotion.

•Watchfortrafcwhenoperatingnearroadways.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservicethemachine.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Tominimizefuelandoilleakage,transportthemachine

eitheruprightortippedforward,nottippedtotheside.

Beforetransportingthemachine,ensurethattheengine

on/offswitchisinthestopposition.

•Useproperlyratedstrapsorchainstosecurethemachine

beforetransportingit.

MaintenanceandStorage

•Stoptheengine.Waitforallmovementtostopbefore

adjusting,cleaning,orrepairingthemachine.

•Ensurethattheengineon/offswitchisinthestop

positionbeforestoringthemachineorperforming

maintenance.

•Cleandebrisfromthedrives,mufer,andenginetohelp

preventres.Cleanupoilorfuelspillage.

•Lettheenginecoolbeforestoringanddonotstoreneara

ame.

•Donotstorefuelnearamesordrainfuelfromthe

machineindoors.

•Parkthemachineonlevelground.Neverallowuntrained

personneltoservicethemachine.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Removethesparkplugwirebeforemakinganyrepairs.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Keepnutsandboltstight.Keepequipmentingood

condition.

•Nevertamperwithsafetydevices.

•Keepthemachinefreeofdebrisbuildup.Cleanupoilor

fuelspillage.Allowthemachinetocoolbeforestoringit.

•Useextracarewhenhandlinggasolineandotherfuels.

Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethefuelcaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

fueling.Donotsmoke.

–Neverfuelthemachineindoors.

–Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Neverllacontainerwhileitisinsideavehicle,trunk,

pick-upbed,oranysurfaceotherthantheground.

–Keepthefuel-containernozzleincontactwiththe

tankduringlling.

•Stopandinspectthemachineifyoustrikeanobject.Make

anynecessaryrepairsbeforestartingtheengineagain.

•UseonlygenuineTororeplacementpartstoensurethat

originalstandardsaremaintained.

•Tominimizefuelandoilleakage,donotlaythemachine

ontotherightorleftside.

•Storethemachineupright.

4

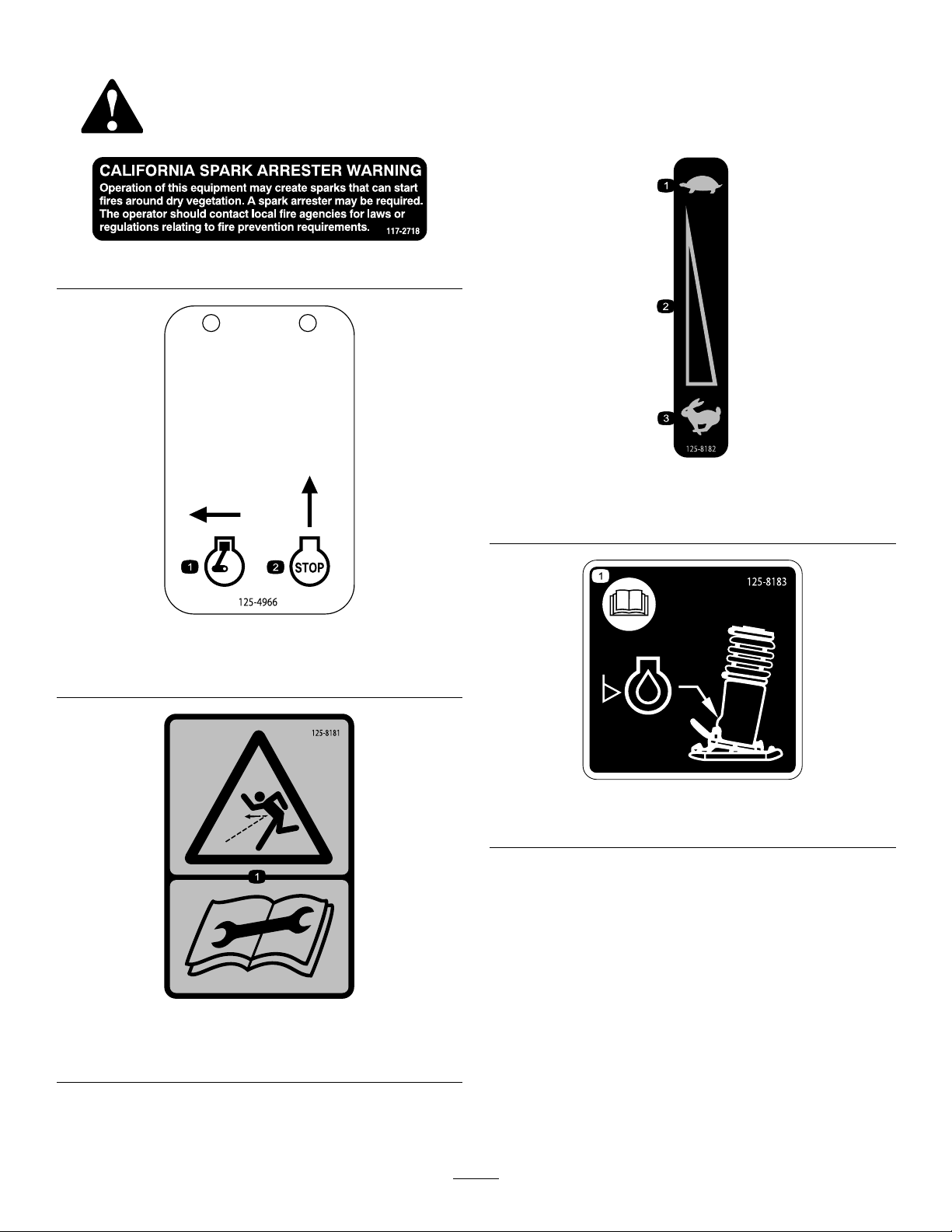

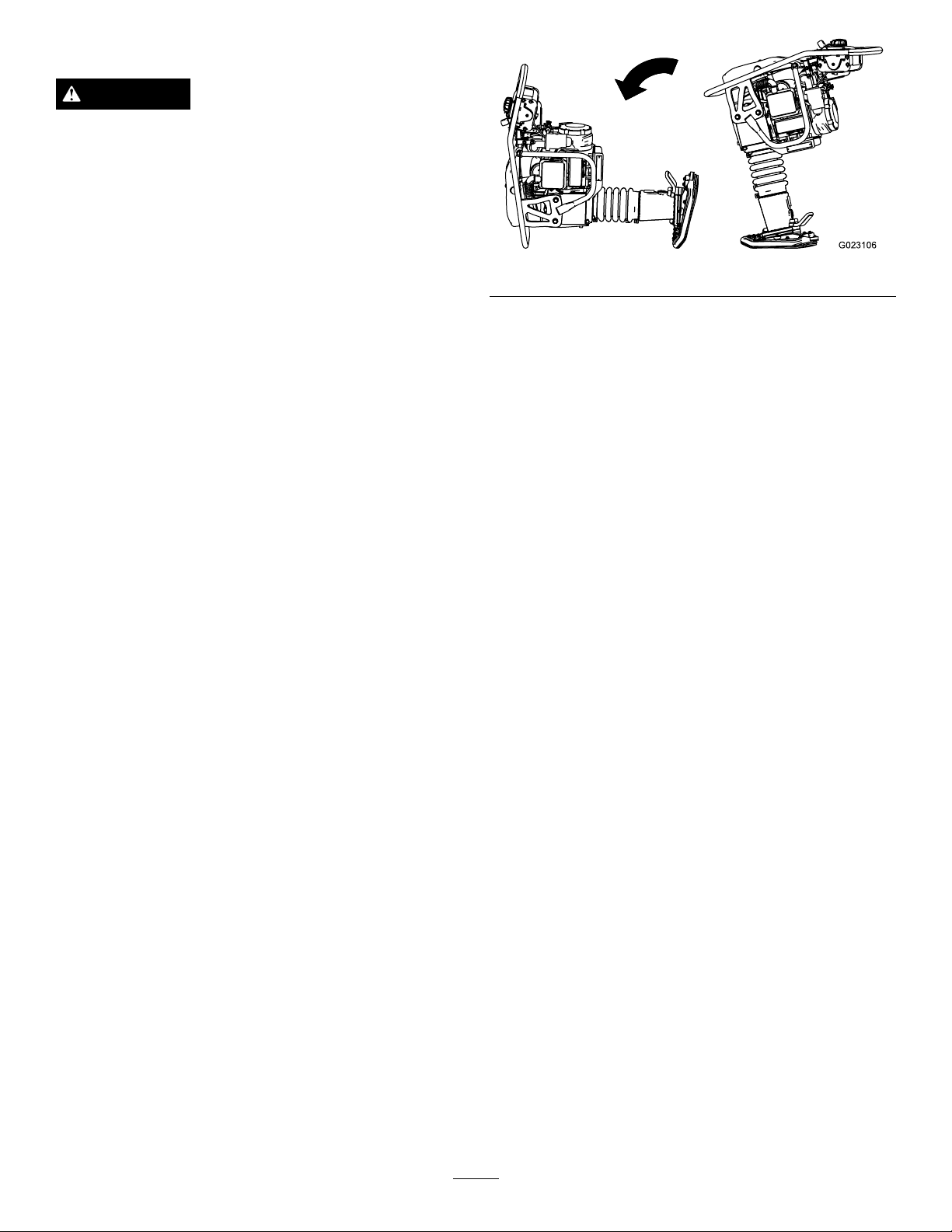

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

117-2718

125-4966

1.Movelefttostartthe

engine.

2.Moveuptostopthe

engine.

125-8181

1.Kickbackhazard—readtheOperator’sManualbefore

performingmaintenance.

125-8182

1.Slow3.Fast

2.Variablespeedcontrol

125-8183

1.ReadtheOperator’sManual—checktheoillevel.

5

125-8191

1.ReadtheOperator’sManualforinformationonstartingthe

engine—1)Turnlevertotheenginestartposition;2)Closethe

choke;3)Pulltherecoilstarter;4)Openthechoke.

5.Warning—keepbystandersawaywhenoperatingthe

machine.

2.ReadtheOperator’sManualforinformationonstoppingthe

engine—turnlevertoenginestopposition.

6.Chokinghazard—donotruntheengineinanenclosed

location.

3.Warning—readtheOperator’sManual;wearhearing

protection.

7.Explosionhazard—stoptheengineandextinguishallames

beforerefuelingthemachine.

4.Warning—keepawayfrommovingparts;keepallguardsand

shieldsinplace.

ProductOverview

1

2

3

456

7

9

8

10

G023144

Figure3

1.Compactorshoe6.Handle

2.Oilllplugandsightgauge7.Fueltank

3.Throttlelever8.Recoil-starterhandle

4.Lifteye9.Springhousing

5.Fuel-tankcap10.Lifthandle

Controls

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine.

EngineOn/OffSwitch

Theengineon/offswitchallowstheenginetorunwhenit

isintherunposition.Inthestopposition,itstopsthefuel

fromowingtotheengineandpreventstheenginefrom

running(Figure4orFigure5).

12

34

G023108

Figure4

Models68034and68035

1.Switchintherunposition3.Stop

2.Switchinthestopposition4.Run

6

12

34

G0231 13

Figure5

Model68036

1.Switchinrunposition3.Stop

2.Switchinstopposition4.Run

ChokeLever

Usethechokelever(Figure6orFigure7)tostartacold

engine.Beforepullingtherecoil-starterhandle,movethe

chokelevertotheclosedposition.Oncetheengineis

running,movethechokelevertotheopenposition.Donot

usethechokeiftheengineisalreadywarmeduporifthe

airtemperatureishigh.

1 2 3

G023107

Figure6

Models68034and68035

1.Openposition3.Chokelever

2.Closedposition

G023112

2

1

Figure7

Model68036

1.ChokeleverintheOpen

position

2.ChokeleverintheClosed

position

ThrottleLever

Thethrottlelevercontrolstheenginespeed.Whenthelever

isintheslowposition,theenginerunsatidlespeed.Thisis

alsothestartingposition.Whenyoumovethelevertothe

fastposition,thecentrifugalclutchengages,andtheshoeof

themachinevibratesandcompacts.

40 00 +/-50 R PM

1

3

G020101

2

Figure8

1.Fastposition3.Slowposition

2.Variablecontrolspeed

7

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Model680346803568036

Weight60kg(132lb)65kg(144lb)70kg(154lb)

Length77cm(30.6

inches)

75cm(29.7

inches)

85cm(33.8

inches)

Width34cm(13.5

inches)

37cm(14.9

inches)

41cm(16.4

inches)

Height106cm(42

inches)

106cm(42

inches)

111cm(44

inches)

EngineHonda®

GX100

Honda®

GX100

Honda®

GX120

ImpactForce1205kg(2650

lb)

1409kg(3100

lb)

1591kg(3500

lb)

Maximum

Blows/Minute

727690655

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Important:Beforeoperating,checkthefuelandoil

levelsandremovedebrisfromthemachine.Also,ensure

thattheareaisclearofpeopleanddebris.Youshould

alsoknowandhavemarkedthelocationsofallutility

lines.

PreparingtoUsetheMachine

•Checkthatthegroundisfreeofforeignobjects,suchas

electricalcables,barbedwire,etc.

•Reviewallthesafetydecalsonthemachine.

•Usesteel-toeshoes,ahard-hat,hearingprotection,and

eyeprotection.Ameshvisoralonedoesnotprovide

sufcienteyeprotection;supplementwithprotective

glasses.

•Ensurethatyouarefamiliarwithsafetyregulationsand

shutdownproceduresdescribedintheOperator’sManual.

•Ensurethatallguardsareinplaceandingoodcondition.

•Ensurethatthecompactorshoeisinplaceandingood

condition.

•Ensurethateveryone,includingchildrenandanimals,

maintainadistanceofatleast15m(50feet)fromthe

machine.

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

8

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditionerbottleopening.

•Avoidcontactwithskin;washoffspillagewith

soapandwater.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefueltank

bedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditionerto

thegas.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.Tominimizethechance

ofvarnishdepositsinthefuelsystem,usefuelstabilizer

atalltimes.

9

FillingtheFuelTank

1.Parkthemachineonalevelsurfaceandstoptheengine.

2.Allowtheenginetocool.

3.Cleanaroundthefueltankcapandremoveit(Figure9).

G020337

1

2

3

Figure9

1.Fillwithgasolinehere3.Gasolinecan

2.Gasolinecap

4.Addunleadedgasolinetothefueltank,untilthelevel

is6to13mm(1/4to1/2inch)belowthebottomof

thellerneck.

Important:Thisspaceinthetankallowsgasoline

toexpand.Donotllthefueltankcompletelyfull.

5.Installthefueltankcapsecurely.

6.Wipeupanygasolinethatmayhavespilled.

CheckingtheEngine-oilLevel

OilType:4-cycleengineoilthatmeetsorexceedsthe

requirementsforAPIservicecategorySJ,SL,SM,orhigher.

CrankcaseCapacity:

•0.28L(0.30USqt)formodels68034and68035

•0.40L(0.37USqt)formodel68036

Viscosity:SAE10W-30isrecommendedforgeneraluse.

1.Stoptheengineandallowittocool.

2.Tiltthemachinesothattheengineislevel.

Important:Proporleanthemachineagainst

somethingtoensurethatitdoesnotfallover.

3.Cleanaroundtheoildipstick.

4.Removethedipstickandwipetheendclean.

5.Slidethedipstickfullyintothedipsticktubewithout

threadingitintothellerneck.

6.Pullthedipstickoutandlookattheend.

Theoilshouldbelevelwiththeupper-limitmark

(Figure10).

12

3

4

g019686

5

Figure10

1.Fillertube4.Lowerlimit

2.Dipstick5.Oil-drainbolt

3.Upperlimit

Important:Runningtheenginewithalowoil

levelcancauseenginedamage.Thistypeof

damageisnotcoveredbywarranty.

7.Iftheoillevelislow,slowlypouronlyenoughoilinto

thecrankcasetoraisetheleveltotheupperlimit.

Important:Donotoverllthecrankcasewithoil

becausetheenginemaybedamaged.

8.Installandsecurethedipstick.

10

CheckingtheSpring-housing

Oil

ServiceInterval:Beforeeachuseordaily

OilType:4-cycleengineoilthatmeetsorexceedsthe

requirementsforAPIservicecategorySJ,SL,SM,orhigher.

Capacity:0.47L(0.5USqt)

Viscosity:SAE10W-30isrecommendedforgeneraluse.

Checkthespring-housingoilasfollows:

1.Carefullytipthemachineslightlybackward,sothatit

standscompletelyuprightandvertical.

Important:Proporleanthemachineagainst

somethingtoensurethatitdoesnotfallover.

2.Checktheoilsightplug(Figure11),andensurethat

theoillevelishalfwaybetweenthetopandbottom

oftheoilsightplug.

1

G023141

Figure11

1.Oilsightplug

3.Iftheoillevelislow ,addoil;refertoAddingOiltothe

SpringHousing(page17).

StartingandStoppingthe

Engine

StartingtheEngine

1.Movetheengineon/offswitchtotherunposition

(counterclockwise);refertoEngineOn/OffSwitch

(page6).

2.Movethechokelevertotheclosedpositionifyouare

startingacoldengine;refertoChokeLever(page7).

Note:Awarmorhotenginemaynotrequirechoking.

3.Movethethrottlelevertotheslowposition;referto

ThrottleLever(page7).

4.Pulltherecoil-starterhandlelightlyuntilyoufeel

resistance,thenpullthehandlebriskly.Gentlyreturn

thehandletotheoriginalposition.

5.Aftertheenginestarts,graduallymovethechoke

leverbacktotheopenposition.Iftheenginestalls

orhesitates,movethechokeleverbacktotheclosed

positionagainuntiltheenginewarmsup.Thenmove

ittotheopenposition.

StoppingtheEngine

1.Movethethrottlelevertotheslowposition.Ifthe

enginehasbeenworkinghardorishot,letitrunfora

minute.Thishelpstocooltheenginebeforestopping.

Important:Tostoptheengineimmediately,you

canmovetheengineon/offswitchtothe

stop

positionbeforemovingthethrottlelevertothe

slo w

position.

2.Movetheengineon/offswitchtothestopposition

(clockwise).

11

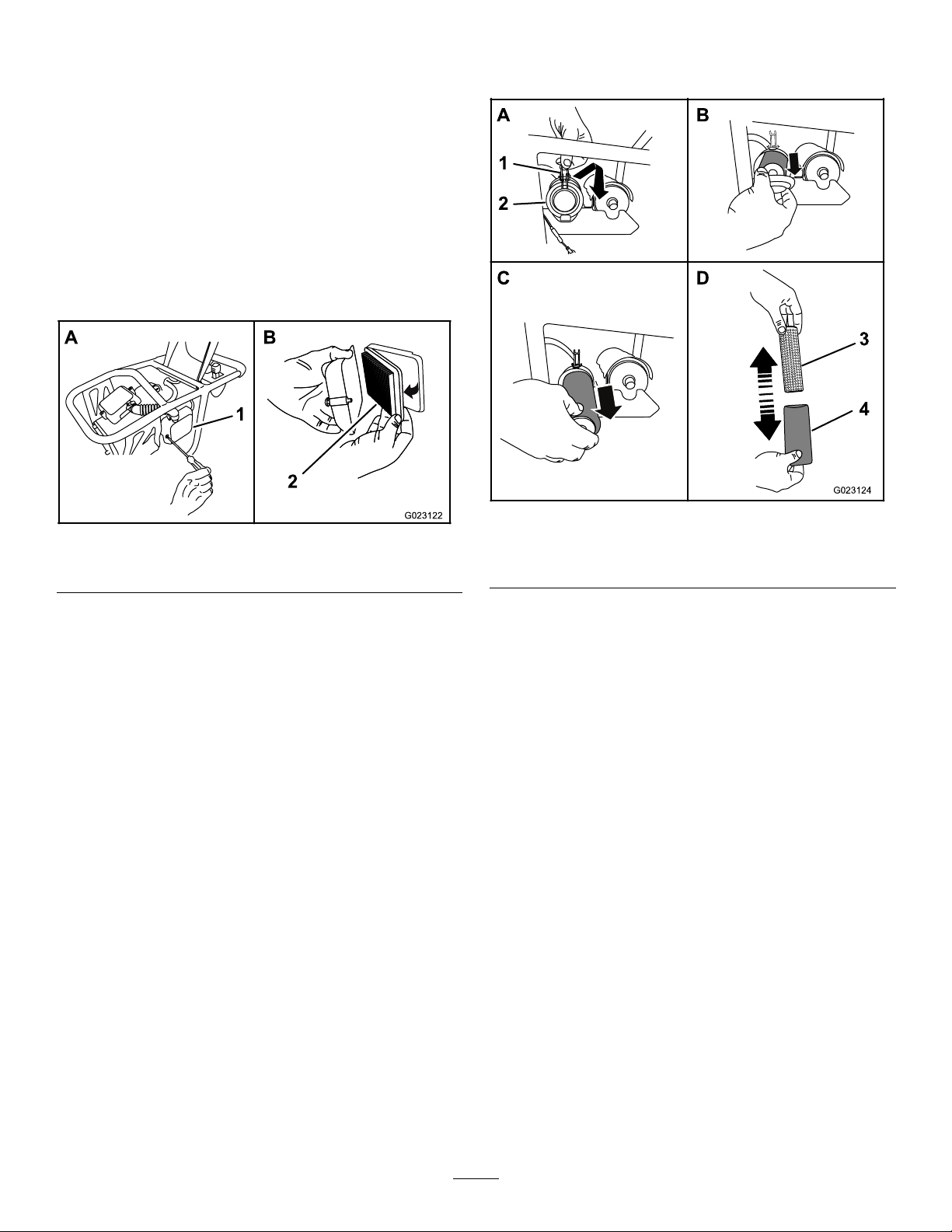

TransportingtheMachine

CAUTION

Ifyoutipthemachinewhentheengineon/off

switchisinthe

r un

position,fuelcanleakoutofthe

fueltank.Afuelleakcouldleadtoareandcause

seriouspersonalinjury.

Drainthefueltankorensurethattheengineon/off

switchisinthe

stop

positionbeforetippingthe

machine.

Important:Beforetransportingthemachine,secureit

withstrapsorchainstopreventitfromfallingortipping

over.

Ensurethattheliftingdeviceandstrapsorchainsare

properlyrated;refertoSpecications(page8).

Ifpossible,keepthemachinestandinguprightwhen

transportingit.Secureitwithstrapsorchains;donotletit

fallover.

Ifyoumusttransportthemachinehorizontally,dosoas

follows:

1.Stoptheengineandallowittocoolfor15minutes.

Ensurethattheengineon/offswitchisinthestop

position.

Theengineon/offswitchisalsoafuelvalve.Ensuring

thatitisinthestoppositionpreventsfuelfromleaking

outofthefueltank.

2.Usealiftingdevicewithadequateliftingcapacity(at

least75kg,or165.3lb)toliftthemachineintothe

transportvehicle.

Important:Attachchainsorotherlifting-device

componentstoonlythelifteyeofthemachine;

refertoFigure3.

3.CarefullypositionthemachineasshowninFigure12,

andsecureitwithstrapsorchainstopreventitfrom

movingortipping.

Important:Donotlaythemachineontotheright

orleftside,ortheengineoilcanleakintotheair

intakeortheexhaustsystem.Laythemachine

tippedforwardonly,sothatitrestsonthefrontbar.

G023106

Figure12

4.Aftertransportingthemachine,standituprightto

allowtheoiltodrainthroughtheengineandsettle

backintothecrankcase.

Important:Allowtheoiltosettleforatleast2

minutesafterstandingthemachineuprightbefore

startingtheengine.

OperatingTips

•Keepthemachineuprightsothatitcontactstheground

withtheentireshoe,ratherthanwithjustthefrontor

backedgeoftheshoe.

•Allowthemachinetodothework;pushingdownwardon

thehandlelimitstheeffectivenessofthemachine.

•Onlevelsurfaces,themachinemovesforwardinrapid

jumps.Onunevensurfaces,tiltthemachineasnecessary

toassisttheforwardmovement.

•Thejumpheightofthemachineincreasesastheground

becomesmorecompacted.

12

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Important:Youmaytipthemachineforward,ifyoudrainthefueltankormovetheengineon/offswitchtothe

stop

position,tomakecleaningorservicingthemachineeasier.Ifyoulaythemachineontotheside,oilcandrainout

ofthecrankcase,intotheaircleanerorthemufer.

Allowtheoiltosettleforatleast2minutesafterstandingthemachineuprightbeforestartingtheengine.

RecommendedMaintenanceSchedule(s)

MaintenanceService

IntervalMaintenanceProcedure

Aftertherst25hours•Changetheengineoil.

•Changethespring-housingoil.

Beforeeachuseordaily

•Checkthespring-housingoil.

•Checktheairlter.

•Checkthecompactorshoe.

•Removedebrisfromthemachine.

Every50hours•Cleantheair-lterelements(morefrequentlyifconditionsaredustyorsandy).

•Cleantheprelter(models68034and68035).

Every100hours

•Changetheengineoil(morefrequentlyiftheoperatingconditionsareextremely

dustyorsandy).

•Changethespring-housingoil.

•Checkthesparkplug.

Every200hours•Replacethepaperair-lterelement(morefrequentlyifconditionsaredustyorsandy).

Yearlyorbeforestorage•Changetheengineoil.

•Changethespring-housingoil.

Important:Refertoyour

Engine Operator's Man ual

foradditionalmaintenanceprocedures.

Premaintenance

Procedures

Beforeperformingmaintenanceonthemachine,dothe

following:

1.Ensurethattheengineandmuferarecool.

2.Disabletheenginebydisconnectingthespark-plug

wire;refertoDisconnectingtheSpark-plugWire(page

14).

13

DisconnectingtheSpark-plug

Wire

Pullthespark-plugwireofftheterminalofthesparkplug

(Figure13orFigure14).

1

G0231 19

Figure13

Models68034and68035

1.Spark-plugwire

1

G023120

Figure14

Model68036

1.Spark-plugwire

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Checktheair

lter.

Every50hours—Cleantheair-lterelements(more

frequentlyifconditionsaredustyorsandy).

Every200hours—Replacethepaperair-lterelement

(morefrequentlyifconditionsaredustyorsandy).

Important:Donotoperatetheenginewithoutthe

air-lterassembly;extremeenginedamagewilloccur.

Note:Iftheengineislowonpower,producesblacksmoke,

orrunsunevenly,theairltermaybeclogged.

CleaningthePrelter—Models68034

and68035

ServiceInterval:Every50hours

1.Openthecoverofthemachine(Figure15).

1

2

G020404

Figure15

2.Removethescrewsthatsecurethecovertotheprelter

housing(Figure16),andremovethecover.

A B

2

1

G023121

Figure16

1.Prelterhousing2.Prelter

3.Removetheprelter.

4.Cleantheprelterasfollows:

A.Washtheprelterusingamilddetergentand

water.

B.Squeezeitdrywithacleancloth.

C.Soakitwithnewengineoil.

14

D.Gentlywindtheprelterinanabsorbentcloth,

andsqueezeouttheexcessoil.

5.Installtheprelterasfollows:

A.Aligntheprelterinsideofthecover.

B.Alignthepreltercovertothehousing.

C.Securethecovertothehousingwiththescrews.

ServicingtheAirFilter—Models68034

and68035

1.Removethescrewsthatsecurethecovertotheair-lter

housing(Figure17)

A B

2

1

G023122

Figure17

1.Air-lterhousing2.Airlter

2.Removetheairlterfromthehousingasshownin

Figure17.

3.Inspecttheairlterandreplaceitifitisdamaged,

excessivelydirty,orsaturatedwithoilorfuel.

4.Aligntheairlterinsideofthecover.

5.Aligntheairltercovertothehousing.

6.Securethecoverhousingwiththescrews.

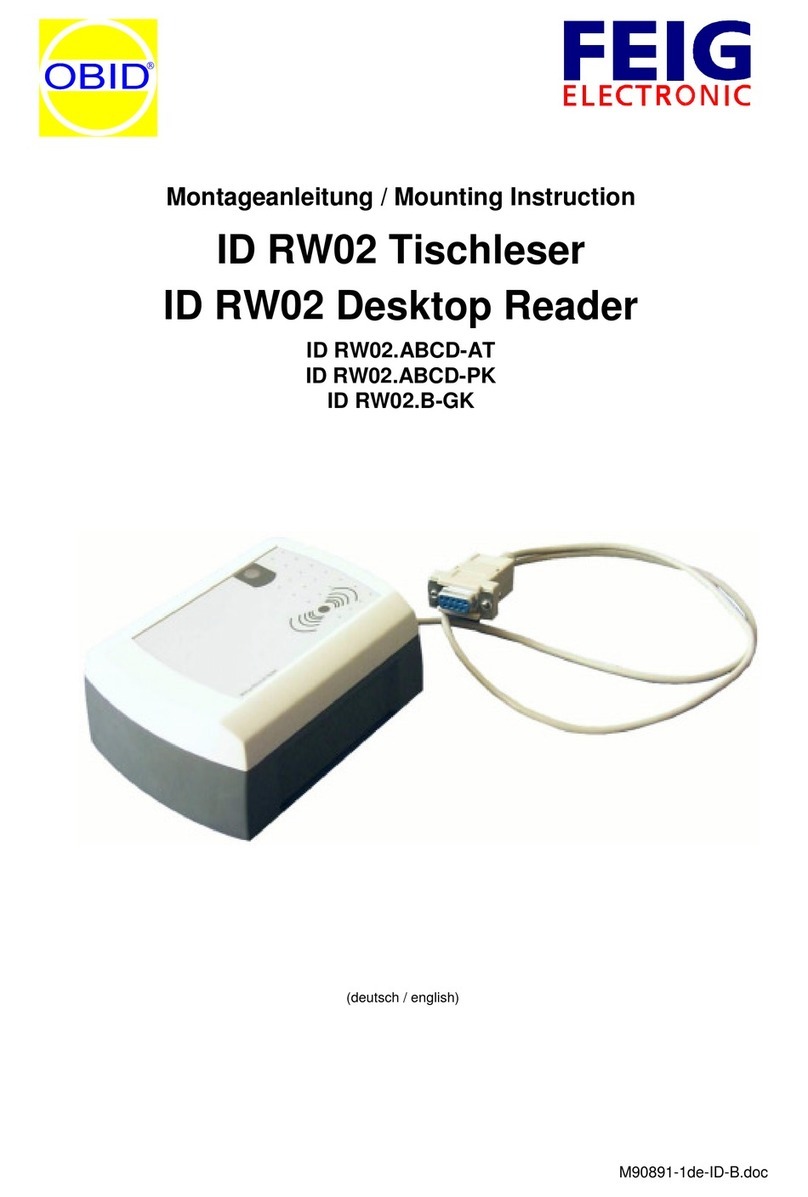

ServicingtheAirFilter—Model68036

1.Openthelatchoftheair-ltercover(Figure18).

G023124

AB

C D

3

4

1

2

Figure18

1.Latch3.Paperelement

2.Cover4.Foamelement

2.Removetheairlterfromthehousingasshownin

Figure18.

3.Removethefoamelementfromthepaperelement.

4.Inspecttheelementsandreplacethemiftheyare

damagedorexcessivelydirty.

Note:Ifthepaperelementissaturatedwithoilor

fuel,replaceit.

5.Tapthepaperelementseveraltimesonahardsurface

toremovethedirt.

6.Cleanthefoamelementinwarm,soapywaterorin

anonammablesolvent.

Note:Donotusefueltocleanthefoamelement

becauseitcouldcreateariskofreorexplosion.

7.Rinseanddrythefoamelementthoroughly.

8.Dipthefoamelementincleanengineoil,thensqueeze

outtheexcessoil.

Note:Excessoilinthefoamelementrestrictstheair

owthroughtheelementandmayreachthepaper

lterandclogit.

9.Wipedirtfromthehousingandthecoverwithamoist

rag.

Note:Becarefultopreventdirtanddebrisfrom

enteringtheairductleadingtothecarburetor.

15

10.Installtheair-cleanerelementsandensurethattheyare

properlypositioned(Figure19).

Important:Ensurethattheopenendofthe

air-cleanerelementsarefacinginwardtoward

themachine,asthemachinewillnotrunif

theelementsarenotplacedintheproperair

orientationduetoairrestriction(Figure19).

Figure19

1.Openendofthepaper

element

2.Openendofthefoam

element

11.Securethecovertothehousingwiththelatch.

ServicingtheEngineOil

OilType:4-cycleengineoilthatmeetsorexceedsthe

requirementsforAPIservicecategorySJ,SL,SM,orhigher.

CrankcaseCapacity:

•0.28L(0.30USqt)formodels68034and68035

•0.40L(0.37USqt)formodel68036

Viscosity:SAE10W-30isrecommendedforgeneraluse.

ChangingtheEngineOil

ServiceInterval:Aftertherst25hours

Every100hours

Yearlyorbeforestorage

ToroPremiumEngineOilisavailablefromyourAuthorized

ToroDealer.

1.Starttheengineandletitrunfor5minutes;referto

StartingtheEngine(page11).

2.Stoptheengine;refertoStoppingtheEngine(page11).

3.Tiltthemachinesothatthedrainsideisslightlylower

thantheoppositesidetoensurethattheoildrains

completely.

4.Placeadrainpanundertheoil-drainhole.

5.Removethedrainplug,anddraintheoilfromthe

engine(Figure20).

3

2

1

G020104

Figure20

1.Oilpan3.Oil-llhole

2.Oil-drainhole

6.Whentheoilhasdrainedcompletely,installtheplug

andwipeupanyspilledoil.

Note:Disposeoftheusedoilatacertiedrecycling

center.

7.Removethedipstickandslowlypourapproximately80

percentofthespeciedamountofoilintotheengine

(Figure20).

8.Slowlyaddadditionaloiltobringtheoilleveltothe

upper-limitmarkonthedipstick;refertoCheckingthe

Engine-oilLevel(page10).

9.Installandsecurethedipstick.

16

ServicingtheSpring-housing

Oil

OilType:4-cycleengineoilthatmeetsorexceedsthe

requirementsforAPIservicecategorySJ,SL,SM,orhigher.

Capacity:0.47L(0.5USqt)

Viscosity:SAE10W-30isrecommendedforgeneraluse.

ChangingtheSpring-housingOil

ServiceInterval:Aftertherst25hours

Every100hours

Yearlyorbeforestorage

Changethespring-housingoilasfollows:

1.Starttheengineandletitrunfor5minutes;referto

StartingtheEngine(page11).

2.Stoptheengine;refertoStoppingtheEngine(page11).

3.Ensurethattheengineon/offswitchisinthestop

positionsothatthefueldoesnotleakoutofthefuel

tank.

4.Tiltthemachinesothattheoilsightplugfaces

downwardtoensurethattheoildrainscompletely

(Figure21).

G023142

1

2

Figure21

1.Oilsightplug2.Drainpan

5.Placeadrainpanundertheoilsightplug(Figure21).

6.Removetheoilsightplug(Figure21).

7.Draintheoiloutoftheholeinthehousing(Figure21).

8.Cleanthethreadsontheoilsightplug,andapply3

layersofPTFEthread-sealingtape.

9.Addoiltothespringhousing;refertoAddingOilto

theSpringHousing(page17).

10.Installandtorquetheoilsightplugto54N-m(39.8

ft-lb).

Important:Allowtheoiltosettleforatleast2minutes

afterstandingthemachineuprightbeforestartingthe

engine.

AddingOiltotheSpringHousing

Addoiltothespringhousingasfollows:

1.Tiltthemachinesothattheoilsightplugisfacing

upward(Figure22).

1

G023143

Figure22

1.Openingfortheoil

2.Removetheoilsightplug.

3.Cleanthethreadsontheoilsightplug,andapply3

layersofPTFEthread-sealingtape.

4.Addtheoiltothespringhousinginincrementsto

ensurethatyoudonotoverllthemachine;referto

CheckingtheSpring-housingOil(page11)toensure

thattheoilisatthecorrectlevel.

Note:Theoilcapacityofthespringhousingis0.47

L(0.5USqt);addthefullamountonlyifthespring

housingisempty.

5.Installandtorquetheoilsightplugto54N-m(39.8

ft-lb).

Important:Allowtheoiltosettleforatleast2minutes

afterstandingthemachineuprightbeforestartingthe

engine.

17

ServicingtheSparkPlug

ServiceInterval:Every100hours—Checkthesparkplug.

Ensurethattheairgapbetweenthecenterelectrodeandthe

sideelectrodeiscorrectbeforeinstallingthesparkplug.Usea

spark-plugwrenchforremovingandinstallingthesparkplug

andagappingtool/feelergaugetocheckandadjusttheair

gap.Installanewsparkplugifnecessary.

Models68034and68035:UseaDENSOU16FSR-UBor

anNGKCR5HSBsparkplug.

Model68036:UseaDENSOW14EPR-UoranNGK

BP4ESsparkplug.

RemovingtheSparkPlug

1.Ensurethatthemachineisstoppedandthattheengine

isoff,andletthemachinecool.

2.Disconnectthewirefromthesparkplug(Figure23).

Figure23

1.Sparkplug2.Wire

3.Cleanaroundthesparkplug.

4.Useaspark-plugwrenchtoremovethesparkplugand

themetalwasher.

CheckingtheSparkPlug

1.Lookatthecenterofthesparkplug(Figure24).Ifyou

seelightbrownorgrayontheinsulator,theengineis

operatingproperly.Ablackcoatingontheinsulator

usuallymeansthattheaircleanerisdirty.

Important:Donotcleanthesparkplug.Always

replacethesparkplugwhenithasablackcoating,

wornelectrodes,anoilylm,orcracks.

G023105

1 2 43 5

Figure24

1.Sideelectrode4.0.60to0.70mm(0.024to

0.028inch)gap(Models

68034and68035)

2.Centerelectrode5.0.70to0.80mm(0.028

to0.031inch)gap(Model

68036)

3.Insulator

2.Checkthegapbetweenthecenterandsideelectrodes

(Figure24).

3.Ifthegapisnotwithinthespeciedrange,dothe

following:

A.Ifthegapistoosmall,carefullybendtheside

electrodeawayfromthecenterelectrodeuntilthe

gapbetweentheelectrodesiscorrect.

B.Ifthegapistoolarge,carefullybendtheside

electrodetowardthecenterelectrodeuntilthegap

betweentheelectrodesiscorrect.

InstallingtheSparkPlug

1.Threadthesparkplugintothespark-plughole.

2.Tightenthesparkplugto20ft-lb(27N-m).

3.Connectthewiretothesparkplug.

18

CompactorShoe

Maintenance

CheckingtheCompactorShoe

ServiceInterval:Beforeeachuseordaily

Amongthemostcriticalelementsofthemachineisthe

compactorshoe.Itisalsothemostsubjecttodamageand

wear.Inthecourseofcompactingawidearrayofgranular

objects,themachineencountersnumerousabrasivesand

objects,suchasdirt,stones,andoccasionallyalargerockor

buriedscrap.

Thewearofthecompactorshoecansignicantlyimpairthe

efciencyandperformanceofthemachine.Therefore,itis

importanttomakefrequentchecksoftheconditionofthe

compactorshoeforleaksandcracks.(Figure25).

G020338

1

Figure25

1.Compactorshoe

Cleaning

RemovingDebrisfromthe

Machine

Regularcleaningandwashingwillincreasethelifespanofthe

machine.Cleanthemachineimmediatelyafteruse,before

thedirthardens.

Checkbeforecleaningthatthefueltankcapisproperlyin

placetoavoidgettingwaterinthetank.

Usecarewhenusingahigh-pressuresprayerbecauseitcan

damagewarningdecals,instructionsigns,andtheengine.

19

Storage

Forstorageover30days,preparethemachineasfollows:

1.Removedirtandgrimefromtheexternalpartsofthe

entiremachine,especiallytheengine.Cleanallgranular

objectsfromtheoutsideoftheenginecylinder-head

nsandtheblowerhousing.

Important:Youcanwashthemachinewithmild

detergentandwater.

2.Addapetroleum-basedstabilizer/conditionerto

thefuelinthetank.Followthemixinginstructions

fromthestabilizermanufacturer.Donotusean

alcohol-basedstabilizer(ethanolormethanol).

Note:Fuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasolineandusedatalltimes.

Important:Donotstorestabilizer/conditioned

gasolineover90days.

3.Runtheenginetodistributeconditionedfuelthrough

thefuelsystem(5minutes).

4.Stoptheengine,allowittocool,anddrainthefueltank

usingapump-typesiphon.Disposeoffuelproperly;

recycleitaccordingtolocalcodes.

5.Starttheengineandrunituntilitstops.

6.Choketheengine.

7.Startandruntheengineuntilitwillnotstartagain.

8.Servicetheaircleaner;refertoFigure15.

9.Changetheenginecrankcaseoil;refertoFigure20.

10.Removethesparkplugandcheckthecondition;refer

toFigure23andFigure24.

11.Withthesparkplugremovedfromtheengine,pour30

ml(2tablespoons)ofengineoilintothespark-plug

hole.

12.Pulltherecoil-starterhandleslowlytocranktheengine

anddistributetheoilinsidethecylinder.

13.Installthesparkplug,butdonotinstallthewireon

thesparkplug.

14.Checkandtightenallbolts,nuts,andscrews.Repairor

replaceanypartthatisdamaged.

15.Paintallscratchedorbaremetalsurfaces.Paintis

availablefromyourAuthorizedServiceDealer.

16.Storethemachineinaclean,drygarageorstoragearea.

Important:Storethemachineintheupright

position.Donottipthemachineonitsside,or

leavethemachinetippedforwardwiththefront

bardownforalongperiodoftime.

17.Coverthemachinetoprotectitandkeepitclean.

RemovingtheMachinefrom

Storage

1.Checkandtightenallfasteners.

2.Inspectthesparkplugandreplaceitifitisdirty,worn,

orcracked;refertotheengineOperator’sManual.

3.Installthesparkpluguntilitishand-tight,thenan

additional1/2turnifitisnew,otherwise,tightenitan

additional1/8to1/4turn.

4.Performanyneededmaintenanceprocedures.

5.Checktheengine-oillevel;refertoCheckingthe

Engine-oilLevel(page10).

Important:Storethemachineintheupright

position.Donottipthemachineonitsside,or

leavethemachinetippedforwardwiththefront

bardownforalongperiodoftime.

6.Checkthespring-housingoillevel;refertoChecking

theSpring-housingOil(page11).

7.Fillthefueltankwithfreshgasoline;refertoAdding

Fuel(page8).

8.Connectthewiretothesparkplug.

20

Other manuals for VR-2650

1

This manual suits for next models

5

Table of contents

Other Toro Other manuals

Popular Other manuals by other brands

Feig Electronic

Feig Electronic OBID ID RW02 Series Mounting instructions

Black Horse

Black Horse 17FJ26MA installation instructions

Richard Paul Russell

Richard Paul Russell SpaceLogger D10 user manual

Beats

Beats Studio Wireless quick start guide

Skyrc

Skyrc iMax B8+ instruction manual

Panasonic

Panasonic GP-KH232 manual