TC3, 4, 5000 GAS TRIMMER, MODELS 51643, 51644, 51645

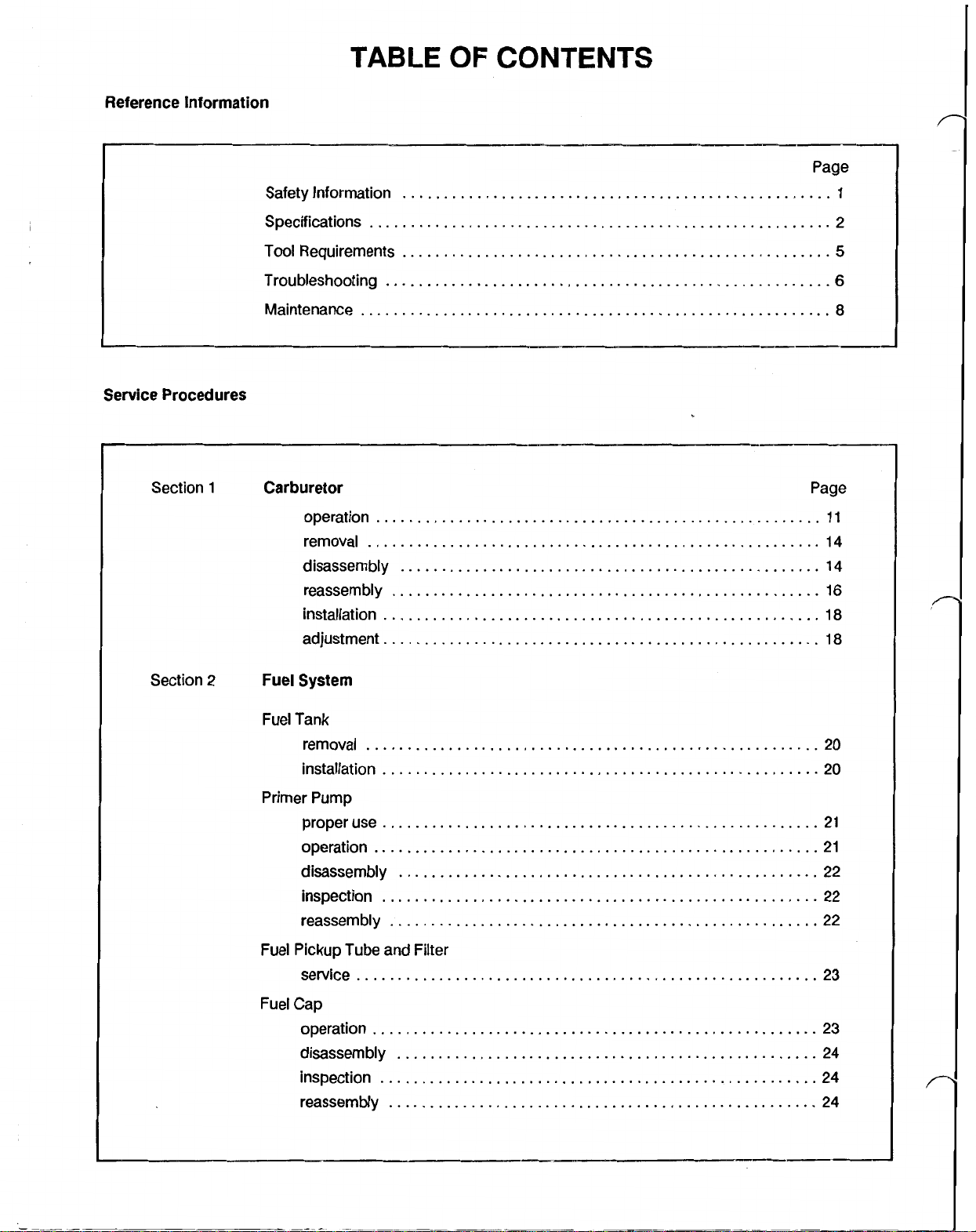

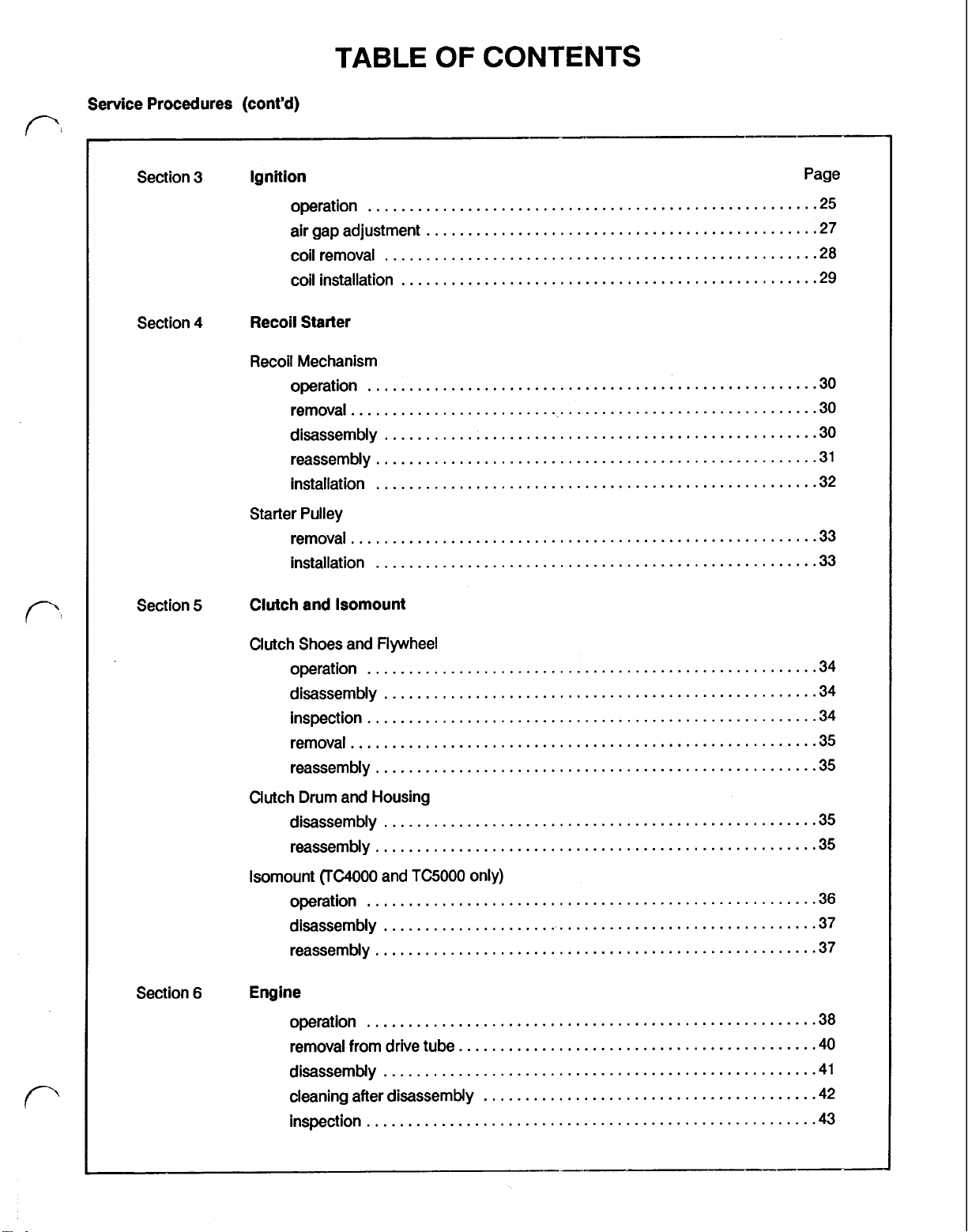

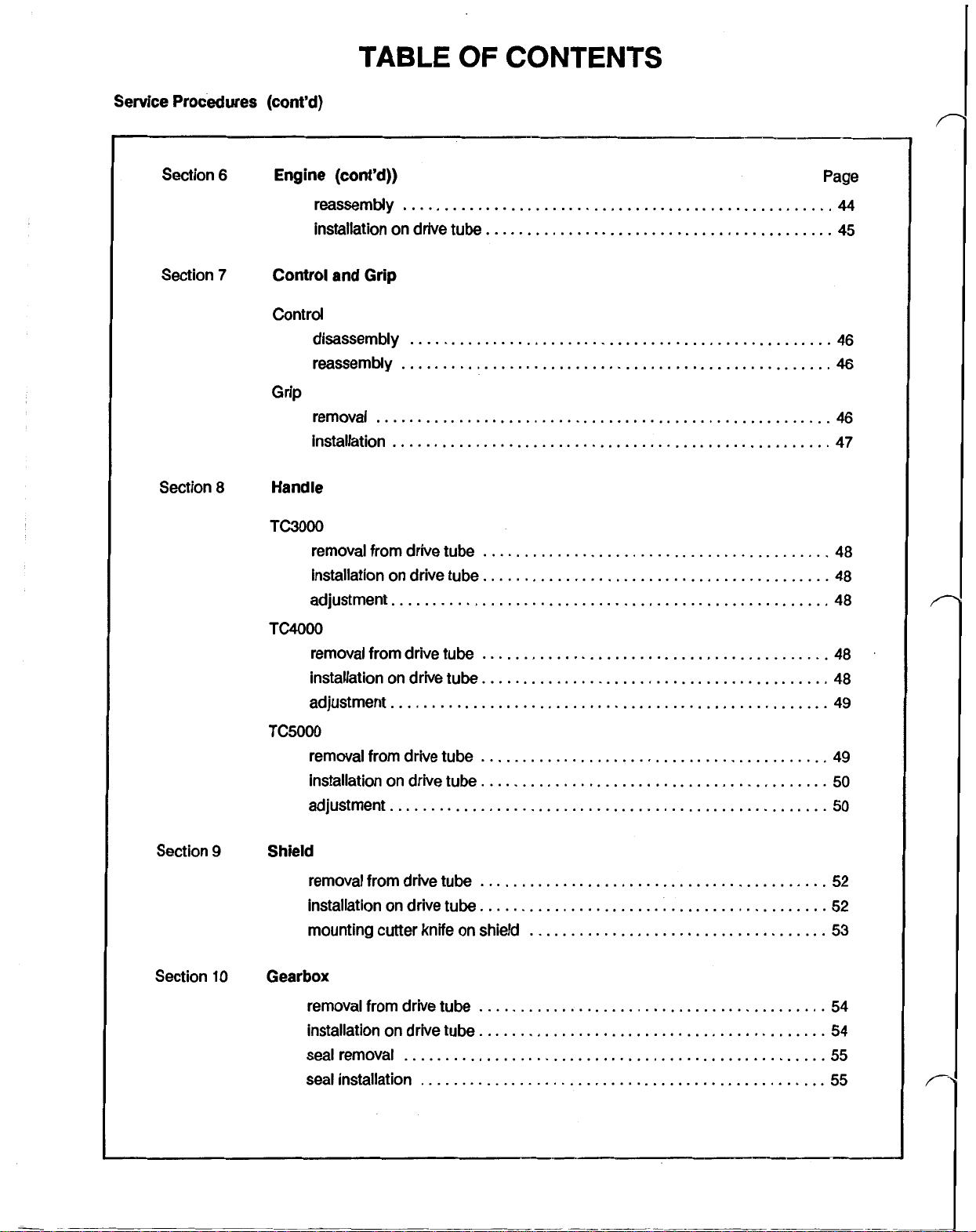

Table of Contents – Page 2 of 4

SECTION 2 FUEL SYSTEM - Continued

FUEL CAP - DISASSEMBLY

FUEL CAP - INSPECTION

FUEL CAP - REASSEMBLY

SECTION 3 IGNITION

IGNITION OPERATION

IGNITION OPERATION - FLYWHEEL

IGNITION OPERATION - IGNITION COIL

IGNITION OPERATION - TRIGGER MODULE

IGNITION OPERATION - SPARK PLUG

AIR GAP ADJUSTMENT

TC3000/TC4000 AIR GAP ADJUSTMENT - PREPARATION

TC3000/TC4000 AIR GAP ADJUSTMENT

TC3000/TC4000 AIR GAP ADJUSTMENT - REASSEMBLY

TC5000 AIR GAP ADJUSTMENT - PREPARATION

TC5000 AIR GAP ADJUSTMENT

TC5000 AIR GAP ADJUSTMENT - REASSEMBLY

COIL- COIL - REMOVAL

COIL - INSTALLATION

SECTION 4 RECOIL STARTER

RECOIL STARTER - OPERATION

RECOIL MECHANISM - REMOVAL

RECOIL MECHANISM - DISASSEMBLY

RECOIL MECHANISM - REASSEMBLY

RECOIL MECHANISM - INSTALLATION

STARTER PULLEY - REMOVAL

STARTER PULLEY - INSTALLATION

SECTION 5 CLUTCH SHOES AND FLYWHEEL

CLUTCH SHOES AND FLYWHEEL - OPERATION

CLUTCH SHOES AND FLYWHEEL - DISASSEMBLY

CLUTCH SHOES AND FLYWHEEL - INSPECTION

CLUTCH SHOES AND FLYWHEEL - REMOVAL

CLUTCH SHOES AND FLYWHEEL - REASSEMBLY

CLUTCH DRUM AND CLUTCH HOUSING - CLUTCH DRUM AND CLUTCH HOUSING -

CLUTCH DRUM AND CLUTCH HOUSING - REASSEMBLY

ISOLATION MOUNT (TC4000 AND TC5000 ONLY) - ISOLATION MOUNT -

ISOLATION MOUNT - DISASSEMBLY

ISOLATION MOUNT - REASSEMBLY

SECTION 6 ENGINE

ENGINE - OPERATION

ENGINE - REMOVAL FROM DRIVE TUBE