4

WARNING

WARNING

SECTION 1 – GENERAL

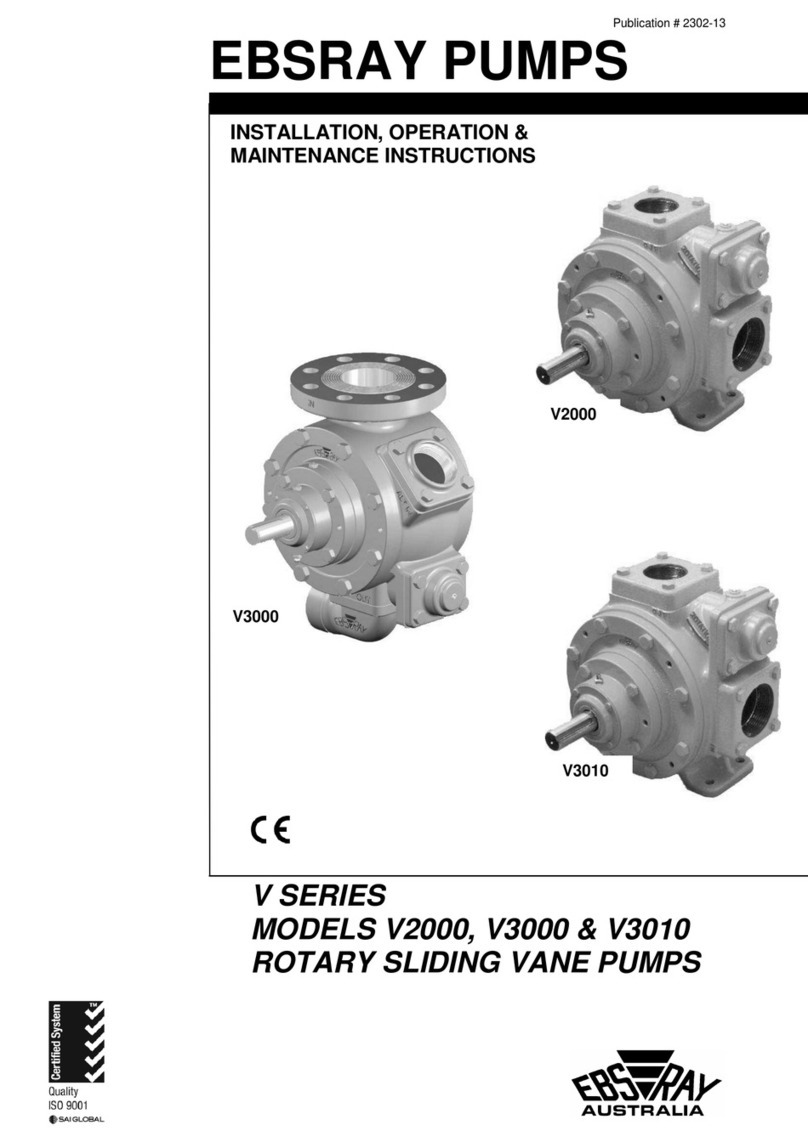

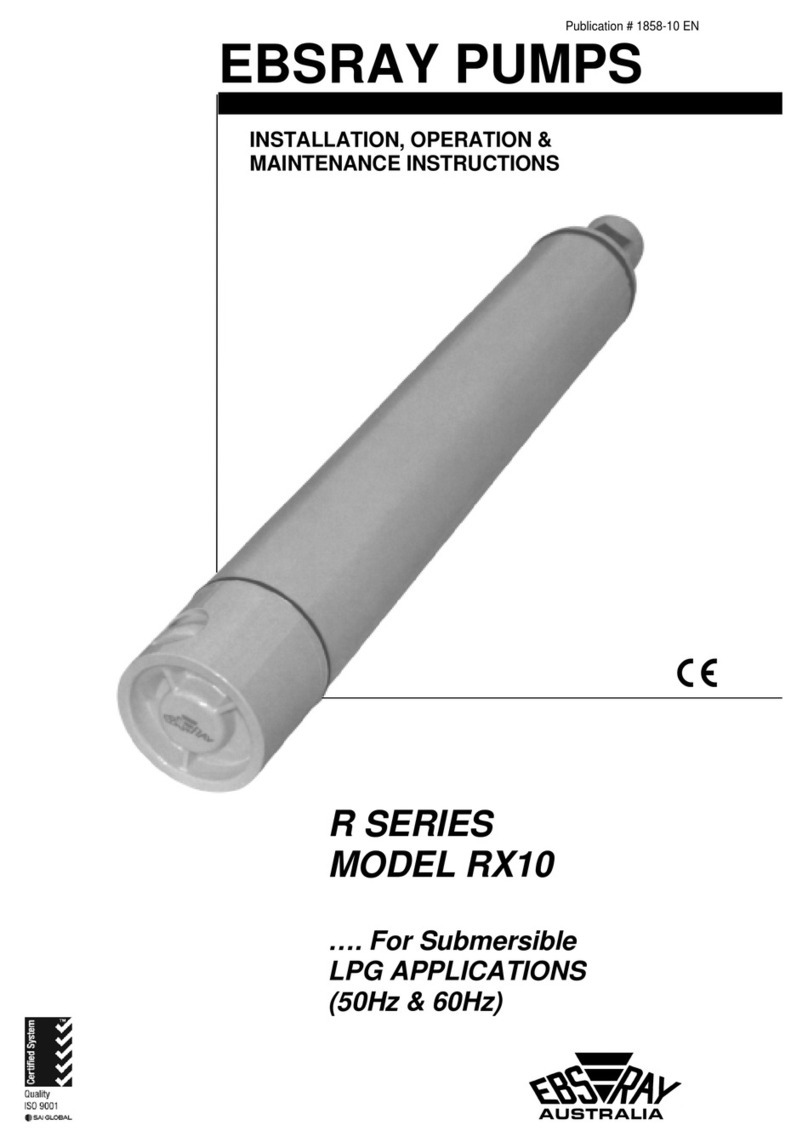

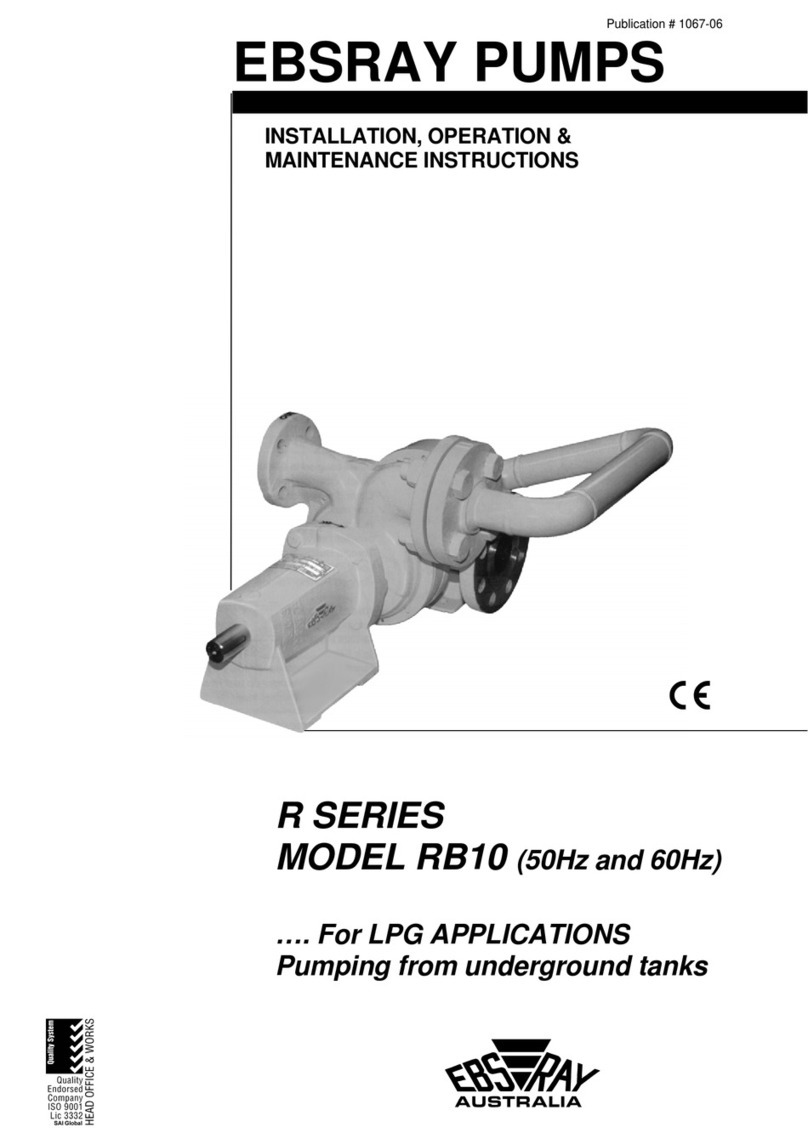

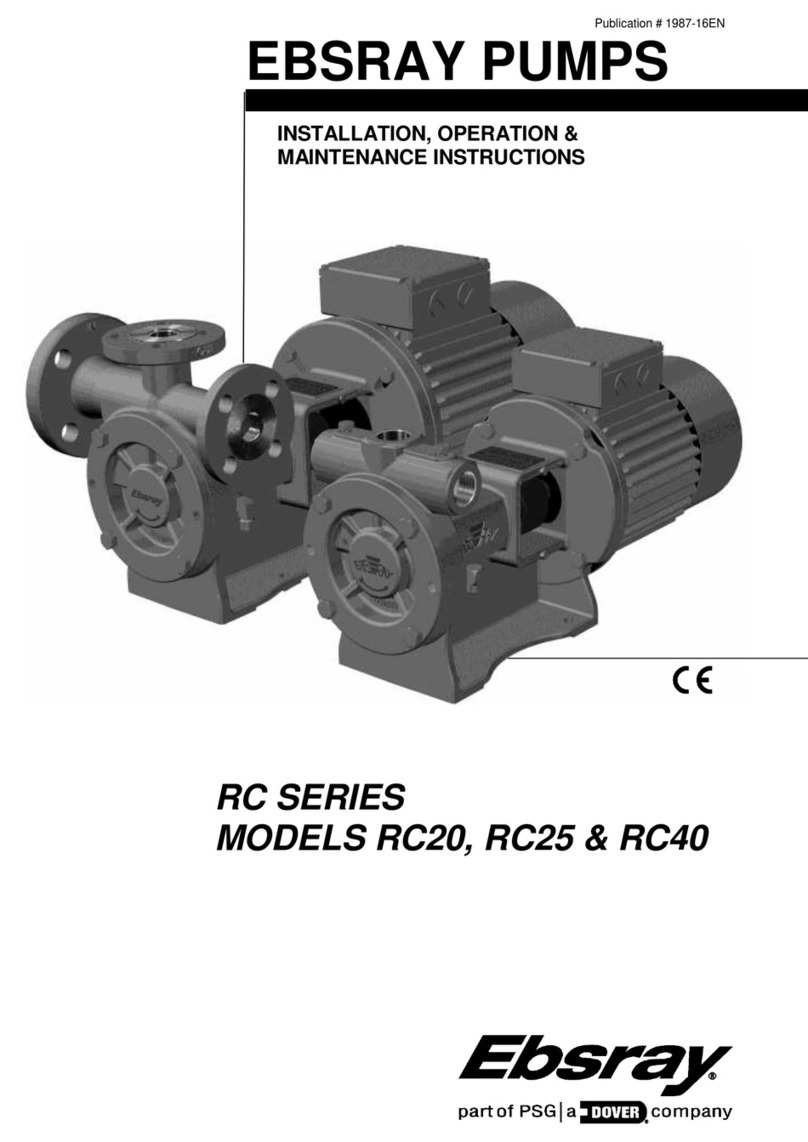

1.1 INTRODUCTION

This publication is intended to assist those involved

with the installation, operation and maintenance of

EBSRAY RC Series Regenerative Turbine Pumps and

related pumping systems.

Before starting any work, this publication should

be completely read/reviewed by all persons

involved with the work. If any part of this

publication is unclear, obtain clarification before

proceeding with any work.

As LPG (Propane and Butane) is regarded as a

flammable liquid, extreme caution must be taken to

ensure total compliance with all necessary

Directives, Statutory Standards, Codes and

Regulations is fully understood and exercised in

the installation, operation and maintenance of

Ebsray RC Series pumps.

These instructions are intended to assist correct

pump installation, operation and maintenance

requirements. They are additional to, and do not

supersede or override any applicable statutory,

legal or regulatory requirements.

CAUTION

Installation and servicing of this equipment should

be performed by qualified competent personnel in

accordance with relevant Directives, Standards,

Codes, Regulations and site requirements, in

conjunction with these instructions.

When the equipment supplied utilises components

other than those manufactured by EBSRAY e.g.

electrical equipment, switches, fittings, valves, etc

reference should be made to the original

manufacturer's data before installation or servicing is

commenced.

Failure to observe these details could result in

equipment failure and void the Warranty.

The pumpset must be operated within the original

selected design parameters of pumped product,

flow, pressure, temperature, voltage and current.

Should ANY change from original specification be

contemplated, please confer with Ebsray or

appointed Representative in order to verify the

suitability of such a change.

Standard domestic packing is suitable for shipment in

covered transports. Pump ports must be adequately

sealed to exclude ingress of condensation, moisture or

foreign material. When received on site the pump must

be stored in a dry covered area.

NOTE

If Pump is not installed and commissioned

immediately, special preservative techniques will

be required. (Refer to EBSRAY or appointed

Representative).

e.g. If the pump is installed, but not

commissioned, low pressure nitrogen can be used

to purge, seal and protect pump from the effects of

condensation and atmospheric corrosion.

NEVER allow water or any corrosive product to

enter the pump (e.g. for hydrostatic testing of

pipework). Severe internal damage may result and

will void the Warranty.

1.3 RECEIVING INSPECTION

SHORTAGES and/or DAMAGE

On receipt of equipment, check all items against the

dispatch documents and inspect for damage. Any

damage or shortage incurred during transit should be

noted on the Packing Note and on both your own and

the carrier's copy of the Consignment Note. A claim

should be made immediately on the transport

company.

Also advise EBSRAY or appointed Representative.

Should a shortage be evident on receipt, notify

EBSRAY immediately giving full details and Packing

Note number.

1.4 HANDLING

Do not drop or damage Pumpset! Care should be

taken in moving/handling pumps/pumpsets in order to

minimise stress on the internal components.

The pump/pumpset should be lifted ensuring

compliance with the relevant lifting codes.

Severe internal pump/pumpset damage may result

if correct handling and due care is not taken.

1.5 WARRANTY

1. All EBSRAY manufactured pumps and equipment

are warranted as standard for one (1) year against

faulty workmanship and/or materials. Refer

EBSRAY appointed representative for details.

2. Ancillary equipment supplied by EBSRAY but

manufactured by others will be in accordance with

those manufacturer's written warranty conditions.

1.2 TRANSPORTATION AND STORAGE

DANGER

DANGER