Torrey EchoTherm HP60 SERIES User manual

OPERATING MANUAL

EchoTherm™

PROGRAMMABLE HOT PLATES AND

STIRRING HOT PLATES

HP60 AND HS60 SERIES

DOCUMENT NUMBER HP60/HS60-1

Revised 17 January 2011

TORREY PINES SCIENTIFIC, INC.

2713 Loker Ave. West

Carlsbad, CA 92010

TELEPHONE: (760)-930-9400

Toll Free: 866-573-9104

FAX: (760)-930-9480

WEB SITE: www.torreypinesscientific.com

TABLE OF CONTENTS

PAGE

I. INTRODUCTION 3

II. WARRANTY 3

III. RETURN OF ITEMS 3

IV. LABELS 3

V. CAUTIONS 4

VI. GENERAL DESCRIPTION 5

VII. FRONT AND REAR PANEL CONTROLS 6, 7

VIII. SET UP INSTRUCTIONS 8

IX. DISPLAY AND KEYBOARD DESCRIPTION 9, 10, 11

X SIMPLE OPERATIONS 11, 12, 13

XI. PROGRAM OPERATIONS 13, 14, 15

XII TEMPERATURE CALIBRATION 15, 16

XIII CLEANING 17

XIV. ADDITIONAL SYMBOLS 18

XV. RS232 SERIAL INTERFACE SPECIFICATION ADDENDUM

2

I. INTRODUCTION

Congratulations on your purchase of an EchoTherm™ Programmable Hot Plate or Hot Plate/

Stirrer. Please read the instructions carefully to insure that you receive the maximum benefit

from it. Also, be sure to fill out and return the enclosed warranty registration card.

II. WARRANTY

Torrey Pines Scientific warrants this product to be free from defects in material and

workmanship for a period of one year from the date of purchase. If repair or adjustment is

necessary and has not been the result of abuse or misuse within the one year period, please

return---freight prepaid--and correction of the defect will be made without charge.

Out-of-warranty products will be repaired on a charge basis.

III. RETURN OF ITEMS

Authorization must be obtained from our Customer Service Department before returning

items for any reason. When applying for authorization, please include data regarding the

reason the items are to be returned. For your protection, items must be carefully packed to

prevent damage in shipment and insured against possible damage or loss. Torrey Pines

Scientific will not be responsible for damage resulting from careless or insufficient packing. A

15% restocking charge will be made on all unauthorized returns.

NOTE: Torrey Pines Scientific reserves the right to make improvements in design, construction,

and appearance without notice.

IV. LABELS

There are various labels on the body of this unit. Listed below are the labels and their meanings.

This symbol means: Attention. The instruction manual is to be consulted for

further information. Attention: Lire ce manuel pour des informations

complémentaries.

This symbol means: Warning, Hot Surface. Attention, surface chaude.

This symbol means: Ground or earth connection. Connexion á la terre.

3

V. CAUTIONS

HEATER PLATE SURFACE

The Torrey Pines Scientific HP60 & HS60 Programmable Hot Plates & Hot Plate/Stirrers are

capable of temperatures in excess of 450ΕC at the plate surface. Touching the heated surface

will cause severe burns. USE EXTREME CAUTION AT ALL TIMES. Never leave your hot

plate accessible to others while it is hot. Although the unit is equipped with a AHOT

WARNING@indicator on the front panel, do not rely on this alone. It is good practice to never

touch the heater surface.

NOTE: DO NOT INSTALL THIS UNIT CLOSER THAN SIX (6) INCHES (15.24 CM)

TO A WALL OF COMBUSTIBLE MATERIAL. ALSO, THIS UNIT IS NOT FOR USE

WITH FLAMMABLE SUBSTANCES.

TEMPERATURE PROBE

When attempting to control PROBE TEMPERATURE, plug in the temperature probe and place

it in the sample AT ALL TIMES. If not placed into the sample and plugged into the rear of the

hot plate, the unit will not be able to sense the temperature of the sample as heat is being applied.

This will result in driving the heater to its maximum and could result in ruining the sample.

Temperature probes vary in size and material. The most commonly used probe is the stainless

steel 6-inch immersion probe (part number HS30-600). For other probes available in other

lengths and materials, call the factory or consult your price list. All probes come with 3-foot

(91.44 cm) interconnect cable and are 3/16th (47.6 mm) in diameter. Stainless steel probes work

best with all but the most aggressive chemicals. Solid Teflon will work with the most aggressive

chemicals, but only to about 260ΕC. Glass probes are available for use with aggressive

chemicals at higher temperatures.

ELECTRICAL

These hot plate/stirrers are made in models that operate at 100, 115, and 230 volts AC ∀10%.

Be certain that your voltage matches the unit you receive. Check the nameplate on the bottom

for the voltage setting on your unit. Be certain to use a three-wire, properly grounded AC input.

Take the normal care and precaution one would use with any electrical appliance. Be careful to

keep the AC line cord away from the hot plate. Be certain to use a line cord of the same type

and rating as the one supplied with this unit. Note: all fuses are fast blow.

Bien vérifier que le cordon utilisé est du même type que celui livré avec l=unité. Note: tous les

fusibles sont à action rapide.

4

VI. GENERAL DESCRIPTION

The Torrey Pines Scientific HP60/HS60 Series Programmable Hot Plates & Hot Plate/Stirrers

are general purpose digital/programmable units. They are available with a solid ceramic top or

milled-flat cast aluminum top. All functions are settable from the digital front panel and display.

These units when received display temperature in ºC. They may be switched to read in ºF. See

page 6.

HEATER

Either the plate surface temperature or the actual sample temperature may be set. A sensor in the

plate is used to monitor surface temperature, or, alternately, a 100-ohm, 3-wire, platinum RTD

temperature probe may be connected to the rear of the unit and inserted into the sample to

measure sample temperature. When a temperature is set, power is applied to the heater to

precisely control the temperature at the plate surface or at the sample, as directed by the user.

An optional ramp value may be entered into the unit which causes the temperature to approach

the target value at a controlled rate of temperature change. This can be either an increase or

decrease in temperature. Ramp temperature is always displayed in degrees centigrade.

TIMER

All models come with a count down timer that is settable and displays in hours, minutes and

seconds. The timer can be set to 99:59:59 hours. When the timer is set it starts to count down to

zero. At zero the timer will sound an audible alarm that will ring five times. In addition to the

timer, the unit has an AUTO-OFF function. When the AUTO-OFF function is activated the

heater and stirrer will turn off at the end of any count down timer setting.

ALARMS

In addition to the audible alarm associated with the count down timer, all models have an over

temperature alarm that activates at 455ΕC on ceramic topped units and 405ºC on aluminum

topped units. If, for any reason, the plate surface temperature runs away and exceeds either

value, the units will turn on the over temperature alarm LED, sound an audible alarm, and shut

the heater off. If or when the heater plate surface cools to below 450ºC for ceramic tops or

400ºC for aluminum tops, the heater will turn on again, and the alarm LED and audible alarm

will turn off. NOTE: Failing to place the temperature probe in the solution and then setting

a probe temperature will cause the heater to heat to over 455ΕC and set off the OVER

TEMPERATURE ALARM. Also, the OVER TEMPERATURE ALARM may come on if a

very large sample is placed on the unit and a probe temperature is set. This setting can

cause the heater surface to go over 455ΕC to achieve the probe temperature set to heat the

large sample.

STIRRERS

All stirrers are a motor driven magnet which revolves directly under the heater plate. It is

normal to stir a solution while heating. A stir bar is used in the solution and couples with the

motor driven magnet and stirs the solution. 5

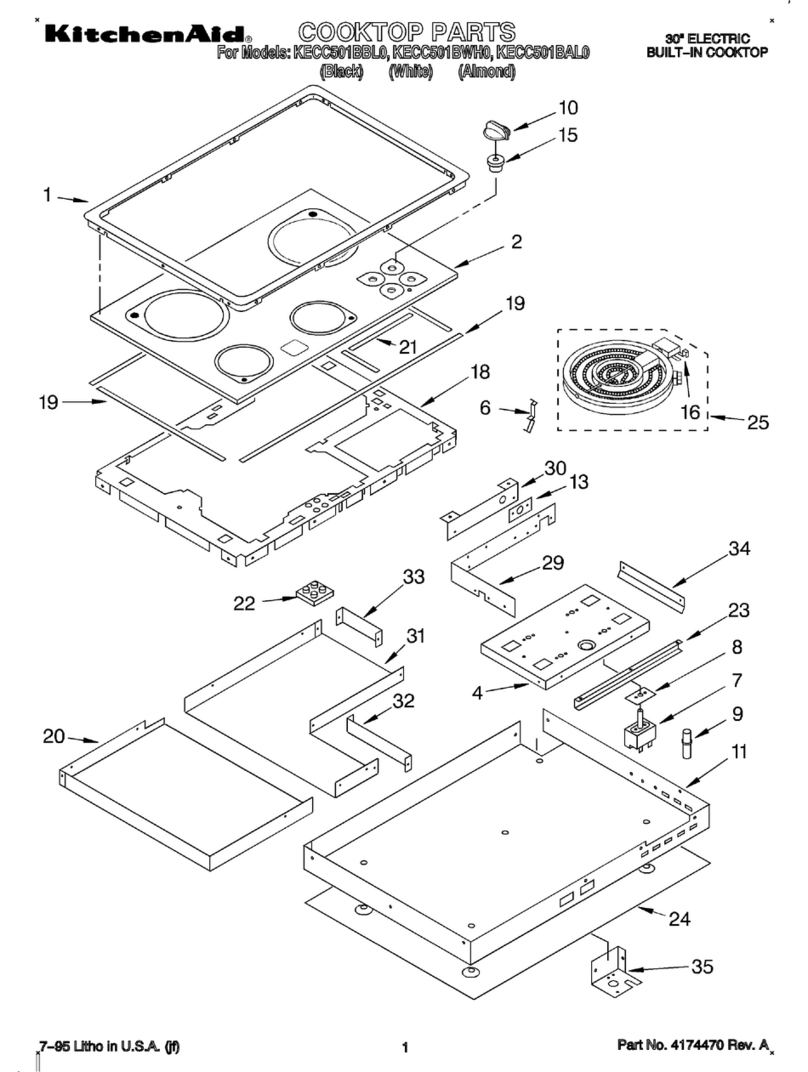

VII. FRONT AND REAR PANEL CONTROLS

FRONT PANEL

Shown above are the keyboard and display for the HS65 Programmable Digital Hot Plate/Stirrer.

This unit has 5-stirring positions and is the most complex unit in the series. Other models in the

series will have a single stirring position or no stirrer at all. The keypads will vary depending

upon the keys needed for the units in this series with less functions.

The front panel has a tactile touch membrane keyboard with audible feedback. The keyboard is

used to set all operating parameters. The display is a LCD type made up of rows of numbers and

several icons which function to display all parameters when the unit is running and during

setting. When the unit is turned on, the display will come on and show the actual plate surface

temperature. If a probe is used, it will display the probe temperature. The timer and stirrer

functions will show zeros.

There is a red LED on the front panel. It is actuated when the plate surface goes over 50ΕC to

remind the user that the plate surface is hot enough to cause burns. Also, it will flash when the

over temperature alarm is activated.

To change the unit from reading in ºC to reading in ºF or vise-versa hold the HEAT OFF button

down for 3 seconds. The display will switch over. The RAMP value is always set in ºC/hour

via the keypad or RS232 I/O port.

6

REAR PANEL

The AC power connector jack and fuse holder are a module mounted on the rear of the unit. The

temperature probe jack and RS232 I/O port jacks are on the rear panel as well. Note the polarity

on the probe jack. Be sure not to force this connection when plugging in the temperature probe.

The AC power jack is a three-prong, male plug combining the snap-in fuse holder. The fuse

types used appear on the label on the rear of the unit.

CAUTION: If the fuses blow repeatedly, contact your dealer or the manufacturer.

ATTENTION: Si les fusibles sautent de manière répétitive, contacter votre distributeur

habituel ou le fabricant.

The temperature sensor jack is a 5-pin DIN jack which is used with a 100-ohm at 0ΕC platinum

RTD temperature probe. Only pins 1, 3 and 5 are used.

7

VIII. SET UP PARAMETERS AND INSTRUCTIONS

The HP60 & HS60 Programmable Ho t Plates & Hot Plate/Stirrers are very simple instruments

to use. Follow the instructions below.

SET UP PARAMETERS

1. Ambient operating temperature range is from 5ΕC to 40ΕC.

2. Maximum altitude of operation should not exceed 2000 meters.

3. Maximum ambient operating relative humidity should not exceed 80% at 31ΕC decreasing

linearly to 50% relative humidity at 40ΕC.

SET UP INSTRUCTIONS

1. Place the unit on a level, dry bench or surface.

2. Plug the unit into a properly grounded, three-wire outlet of proper voltage.

3. Plug the temperature probe (if used) into the jack on the rear of the unit.

4. Place the sample on the heater plate and put the temperature probe (if used) into the sample

container.

5. Turn on the unit by the key on the front panel. The unit will beep once and the display will

light up. At this point the user can set or view any of the parameters of the unit.

6. Set either the plate or probe target temperature, stirrer, timer, ramp rate, or program according

to the instructions given in the following sections.

Note: Do not use this equipment in any manner not specified by the manufacturer.

Note: Ne pas utiliser cet équipement si vous ne pouves pas respecter les conditions

d=utilisation spécifiées par le fabricant.

ENVIRONMENTAL INFORMATION

1. This unit is for installation category II.

2. This unit is rated pollution degree 2.

8

IX. DISPLAY AND KEYBOARD DESCRIPTIONS

DISPLAY

The display has three rows of numbers and some icons. From the top they are as follows.

Plate/Probe Temperature: The icon to the left of the numbers will switch from a picture of a

probe in a vessel when the probe is in use to a flat surface with heat rays radiating up from the

surface when the probe is removed and the plate surface is being controlled. The row of

numbers to the right shows the temperature of either the plate or probe. These numbers are

normally followed with AºC@which denotes that the temperature reading is in degrees

centigrade. However, the display can be made to read in degrees Fahrenheit by holding the

HEATER key depressed for 3 seconds. When a target temperature is set into the unit, the

temperature values in the display will toggle from the target temperature to the actual

temperature. When the actual temperature is displayed, the symbol to the left of the display will

illuminate.

Stirrer: There are units in this series without stirrers (HP60 & HP61), and units with one stirrer

(HS60 and HS61), and units with five stirrers (HS65). The units without stirrers will not have a

numerical value displayed in the middle row of the display. The units with a single stirrer will

display the value of the stirrer in RPM with “RPM” to the right of the numbers. The units with

5-stirrers will display the value of the stirrer in RPM with “RPM” below a box to the right

showing which stirrer of the 5 is being displayed. The STIRRER SELECT key next to the

display can be used to move a dot around in the box next to the numerical values displayed to

choose the stirrer position being monitored. All stirrer positions can be checked this way.

Ramp: When the RAMP key is depressed the ºC symbol to the right of the top line of the display

with convert to “ºC/hr”. (The number value set in the display is always in degrees centigrade per

hour). When the value is entered for a ramp, the word “RAMP” will appear vertically on the left

of the display and it will remain illuminated as long as a ramp value is being used. This tells the

user that the target temperature as set for the probe or plate is moving from its starting point to

the target temperature at a fixed rate in degrees centigrade per hour. The ºC/Hr icon will convert

back to ºC and will be displaying only the actual and target temperatures set for either the plate

or probe. To view the ramp rate set, depress RAMP.

Timer: The bottom line of the display is the timer. The timer is displayed and can be set to

99:59:59 maximum (99 hours, 59 minutes, 59 seconds). The timer will count down to zero from

its setting and sound an audible alarm.

Auto-Off: The count-down timer can be used with an auto-off function that will turn off the

heater and stirrer when the timer counts down to zero. This function is not for use in a program,

but for use in non-programmed operation. When the AUTO-OFF key is depressed the words

AAUTO-OFF@will appear to the right of the timer value set. When this function is actuated, the

timer will count down to zero, sound the audible alarm, and turn the heater and stirrer off.

9

Program: The words PROG and a number value from 1 to 10 will be displayed to the left of the

timer value when setting a program into memory.

KEYBOARD

Power Button: This button is for turning the power to the unit on and off.

Up/Down, Right/Left Arrows: The UP and DOWN arrows to the right of the display are used to

set numeric values for the probe temperature, plate temperature, stirrer, ramp, timer, and

progressing within the steps of a program when writing or editing the program. Pushing the

RIGHT and LEFT arrows are for selecting the digit to be set.

Heater button: Touching the HEATER button is for selecting the value to be set into the heater

plate or probe. Touch HEATER then the RIGHT/LEFT/UP/DOWN arrows to set the target

temperature

Ramp Button: Touch the RAMP button is for selecting values to be entered into the ramp

function. Touch RAMP then the UP/DOWN/RIGHT/LEFT arrows to set the ramp value. To turn

off the ramp value set it to zero.

Stirrer Button (on units that have stirrers only): Touch the STIRRER button to set the value of

the stirrer. Touch STIRRER button then the UP/DOWN/RIGHT/LEFT arrows to set the

STIRRER value.

Stirrer Select Button (on multi-position stirring units only): The STIRRER SELECT button is

for use with the 5-position stirrers only. It is used with the box to the right of the stirrer numeric

values to select the stirrer to be controlled. The stirrers can all be set to one value or each to a

separate value as needed. Press STIRRER SELECT over and over and the dot in the box to the

right of the stirrer value will move around showing each stirrer position. Stop on the one to be

set and use the UP/DOWN/RIGHT/LEFT arrows to set the stirrer speed in RPM.

Timer Button: The TIMER is for setting the value of the timer. Use the

UP/DOWN/RIGHT/LEFT arrows to select the value to be set into the timer.

Auto-Off Button: Touching and releasing this button activates the AUTO-OFF function. It is

used in conjunction with the count-down timer. When activated, this will shut off the heater and

stirrer when the timer counts down to zero. This function can be turned off by touching the

AUTO-OFF button at any time during a timed event. When activated, the words AAUTO-OFF@

will be illuminated on the display.

Heater Off Button: Touching and releasing the HEATER OFF button will turn off the heater.

The HEAT OFF button also is used to change the unit temperature display from ºC to ºF and

vise-versa. Holding the key down for 3 seconds will cause the display to change.

10

Stirrer Off Button (on units with stirrers only): Touching and releasing the STIRRER OFF

button will turn off the stirrer. In the 5-position stirrer this will turn off the stirrer position

selected with the dot in the box to the right of the stirrer speed display. Depressing STIRRER

SELECT will allow the user to scroll around the box to set the dot to the selected stirrer position.

To turn off all 5 stirrers at the same time, press and hold the STIRRER OFF button until it beeps.

Edit Button: The EDIT button is used to enter the program memory to write or edit a program.

Cancel Button: The Cancel button is used to cancel a program step while writing or editing a

program or to cancel any setting if made in error.

Run Button: The Run button is used to start running a program in memory.

Enter Button: The Enter button is used to enter a value setting into the unit in manual operation

or in a program.

X. SIMPLE OPERATION

The HP/HS60 Series units are fully programmable. They have the ability to write and store in

memory ten programs of as many as ten steps each for instant recall and later use. Also, these

units can be used to set a single temperature, temperature ramp, stirring speed and timer function

without going into the memory. The memory is used for complex routines where all the

parameters of the sample can be changed automatically to other values without user attention.

TEMPERATURE

The user may enter either a target probe temperature or a target plate temperature. Only one

target temperature is allowed at one time. Setting a target probe temperature will erase any

target plate temperature previously set and vice versa. Target temperatures may be set anywhere

in the range from ambient to 450ΕC or 842ºF in ceramic topped units, or from ambient to 400ºC

or 752ºF in aluminum topped units. The unit comes with the display reading in degrees C. To

change to ºF depress and hold the HEATER OFF button until the display changes. To change

back to ºC repeat the process.

Setting Solution Temperature: When setting a solution temperature, plug the probe into the jack

on the rear of the unit and place it into the solution. With the probe plugged in, the unit will only

set and control the solution temperature as controlled by the probe. With the probe unplugged,

only the plate surface temperature is sensed and controlled by the unit. Next, touch the

HEATER button and use the UP, DOWN. RIGHT, LEFT arrows to enter the value of the

temperature wanted. Then press ENTER. The unit will now turn the heater on and drive the

solution to the target temperature. Note that the temperature display will toggle between the

target and the actual temperatures. When the target temperature is reached, the display will still

toggle but the numerical value will remain the same.

11

CAUTION: Be certain the temperature probe is in the solution when a solution

temperature target has been entered. Failure to do so could damage your sample because

the hot plate will drive to maximum while seeking a temperature it cannot find.

PRÉCAUTION D=EMPLOI: Bien vérifier que la sonde de température plonge dans le

liquide et qu=elle est connectée dans la fiche située à l=arrière de l=appareil lorsque vous

sélectionnez une température. L=échantillon risque d=être endommagé si la sonde n=est

pas connectée car la plaque va monter au maximum de sa température en recherchant une

température qui n=aura pas été.

Setting Plate Temperature: To set a plate temperature the probe must not be plugged into the rear

of the unit. With the probe unplugged, the unit will control the plate surface using a sensor built

into the heater plate and the display will show only the target and actual heater plate surface

temperatures. To set the plate temperature press HEATER and then use the UP, DOWN,

RIGHT, LEFT arrows to set the target temperature value into the display. Then press ENTER.

The unit will now drive the plate surface to the target temperature while toggling the temperature

display between the target and actual plate surface temperatures. When the target temperature is

reached, the display will still toggle between the target and actual temperatures, but the display

will read the same values.

Setting Ramp: NOTE: IF A RAMP VALUE IS TO BE USED, THE RAMP VALUE MUST

ALWAYS BE SET BEFORE SETTING A TARGET TEMPERATURE. To set a ramp

value, press the RAMP button. The display to the right of the temperature value will show

ºC/Hr. Use the RIGHT, LEFT, UP, DOWN arrows to set the selected value of ramp rate in

ºC/hr. After a target temperature is set the heater will now drive the temperature from its current

value to the target temperature, either plate or solution, at the rate just instructed. The ramp

value is always in degrees centigrade per hour even if the temperature display has been set to

read in degrees F. The RAMP rate is settable from 1ºC/Hour to 450ºC/Hour. Note that the unit

will heat fastest when not using a ramp rate setting, even 450ºC/Hour. The ramp rate

should only be used to slow the heating rate.

It is valuable to note that the ramp can be set to go up to a target temperature or down

from a higher temperature to a lower one. However, the unit can never ramp down any

faster than the sample can cool naturally. When ramping down, the heater is used to slow

a cooling rate only.

Setting Stirrer: To set a stirrer speed on single stirrer units, press STIRRER and the use the UP,

DOWN, RIGHT, LEFT arrows to set the value of the stirrer speed into the display. Then press

ENTER. The stirrer will now start to run and will display the speed in RPM on the second line

of the display.

To set the HS65, 5-position stirrer, the user can select to have all stirrers run at the same speed or

each stirrer position can be set to its own individual speed. To select the stirrers to be set use

press the STIRRER SELECT button repeatedly until the dot in the box to the right of the stirrer

12

speed display is on the stirrer position to be set. Then enter the value for that position by using

the UP, DOWN, RIGHT, LEFT arrows and press the ENTER button. That will set the selected

stirrer. Repeat this process for each position. To set all stirrers to the same speed use the

STIRRER SELECT button to scroll the dots in the box to the right of the display until all 5 dots

are illuminated. The use the UP, DOWN, RIGHT, LEFT arrows to enter the stirrer speed value,

and press the ENTER button.

Setting Timer: To set a timer value press the TIMER button and use the UP, DOWN, RIGHT,

LEFT arrows to set the value in hours, minutes and seconds. Then press the ENTER button. The

timer will now start to count down toward zero. When the timer reaches zero it will sound the

audible alarm. To stop the alarm press CANCEL.

Setting Auto-Off: The auto-off function is used with the timer. When activated, the unit will

turn off the heater and stirrer when the timer counts down to zero. To set the auto-off function,

press the AUTO-OFF button. The display will illuminate the words AAUTO-OFF@to the right

of the timer telling the user that the auto-off function is set. To turn off the auto-off function,

touch the AUTO-OFF button again. The words, AAUTO-OFF@will no longer be illuminated in

the display. Remember that when AUTO-OFF is on, the unit will automatically turn off the

heater and stirrer when the timer counts down to zero.

XI. PROGRAMMABLE OPERATION

The HS60 series have the ability to store ten programs in memory for instant recall and use.

Each program has ten steps maximum where one step is a temperature, stirring speed, ramp

function (if wanted), and time. At the end of each program there is a cycle step that can be

selected to repeat the program up to 98 times. Setting cycles to 99 makes the program repeat

infinitely. These programs are stored in CMOS and cannot be lost by a power failure or by

turning the unit off. However, if power fails during a program run, when power returns, the unit

will have lost its instructions and will be sitting with the same information on the display as

when the unit was first turned on. To stop a program while it is running touch CANCEL.

Some rules for programming:

To erase all programs in memory, depress and hold the EDIT key for about 5 seconds. The

display will be all blank. When the EDIT key is released, after a few seconds or, the

display will return to the normal screen and the programs will be erased. This erases ALL

programs in memory. To change or erase one program the user must go into the program

and remove each step.

The timer can be used in two ways in a program. The timer can be used with a ramp

function or without a ramp function. When the timer is used with a ramp function, the

timer does not start to count down until the target temperature is reached. When the timer

is used without a ramp function, the timer starts to count down as soon as the program

starts. If the user wants a timed event to start after the target temperature is reached, but

13

does not want to wait for a ramped approach to the target temperature to take place, set

the ramp to 450. In almost all cases, this ramp rate is faster than the unit can approach the

target temperature, and it will appear as though no ramp rate is being used, and the timer

will start to count down after the target temperature is reached.

RUNNING A PROGRAM STORED IN MEMORY

1. Press RUN. The display will show PROG 1 at the bottom of the display to the left of the

timer. This is program 1.

2. If program 1 is the choice to be run, next press ENTER. Program 1 will now start to run. If

program 1 is not the choice use the UP ARROW to scroll to the program of choice. When the

program is chosen, press ENTER and the program stored in that site will start to run. As the

program starts to run, as the unit progresses through the steps in the program, the audible

alarm will sound five times for each step as the program progresses. As the program moves

through the steps in the program the current step will be displayed to the left of the timer.

HOW TO WRITE A PROGRAM

Remember, a program step is a temperature, stirring speed (if wanted), temperature ramp

(if wanted), and a timer setting. Do not advance to the next step until the current one is

complete.

1 Press EDIT

2 Select the program site (1 through 10) using the UP and DOWN ARROWS.

3 Touch ENTER. The display will show PROG 1 for program one step one.

4 Enter the ramp value if wanted (remember how the timer works with and without a ramp

function) and push the ENTER button. Then enter a temperature and push the ENTER

button, and stirring speed and the ENTER button, and the time function for that step and

ENTER button. This step is now finished.

5 Press the UP ARROW to go to step 2. The display will show 2 for program step two.

Now enter the values for ramp, temperature, stirrer and timer being certain to hit ENTER

after each. Step 2 is now complete.

6 Repeat the steps above until the program is written.

Note: If a mistake is made while entering a program step, just hit CANCEL on that

step and make the new entry. To go back to a prior program step, hit the DOWN

ARROW. Likewise, to go forward to another program step, hit the UP ARROW.

7 After the last program step data has been entered, press ENTER twice. The display will

now show CYC 01. If only one cycle of the program is needed, hit ENTER. If more

than one cycle of the program is wanted, use the UP ARROW to go to the number of

cycles wanted. For example, twenty cycles would appear on the display as CYC 20.

Then press ENTER again and the program is written and stored for use.

14

8 To run a program, press RUN, the display will show PROG 1. To run program 1, press

ENTER. To select and run a different program, use the UP ARROW to scroll to the

program to be run, and press ENTER.

XII. TEMPERATURE CALIBRATION

The HP/HS60 series are designed for accuracy. The temperature calibration designed into the

unit is made to hold for very long periods of time. When calibrated in the factory, it is expected

that the unit will meet the most demanding customers=requirements. However, our standards

for temperature measurement may not be the same as the users. Therefore, the HP/HS60 series

has been designed to be calibrated in the field by the user. Follow the instructions below if

calibration is wanted or needed.

Note: To calibrate the unit the user is advised to remove all previously entered calibration data.

To erase the calibration and return to not calibrated readings, press and hold the HEATER button

for three seconds until the display reads CAL. Then press and hold the CANCEL button for

three seconds. Calibration is erased independently for the probe and the plate depending upon

whether the probe is plugged in or not.

PROBE CALIBRATION

Probe calibration is performed by using an accessory calibration kit which precisely simulates

fixed temperature points. The kit has two dummy probes which, when plugged into the probe

jack, represent the value of resistance equal to the temperature shown on the dummy probe. The

dummy probes represent temperatures of 25ΕC and 400ΕC. These are the probe calibration

points. The kit is available from the manufacturer (HS30-700).

To calibrate the probe temperature, follow these steps.

1. Insert the 25ΕC dummy probe in the probe jack at the rear of the unit. Depress and hold

the HEATER button for 3 seconds until the display reads CAL. Then press ENTER.

Then use the UP/DOWN/RIGHT/LEFT arrows to make the display read 25ºC. Then

press ENTER. The probe low calibration point is now calibrated.

2. Remove the 25ΕC dummy probe and replace it with the 400ΕC dummy probe. Depress

and hold the HEATER button for 3 seconds until the display reads CAL. Then press

ENTER. Use the UP/DOWN/RIGHT/LEFT arrows to make the display read 400ΕC.

Then press ENTER. The probe high calibration point is now set.

3. Remove the dummy probe. The probe calibration is now complete.

15

PLATE CALIBRATION

The plate calibration does not affect the probe calibration and vice versa. If you are using the

probe temperature control loop only, it is not necessary to calibrate the plate loop. The plate

loop has been factory calibrated and is not likely to change.

To calibrate the plate, an accurate digital temperature meter and a surface temperature probe are

needed. This is a very difficult measurement to make, and not all surface temperature probes

will do the job well. If you need help, please contact the factory. The Plate and Probe

calibration kit #HS30-800 is available from the factory and will contain the temperature meter,

probe, and dummy probes for the probe calibration.

The plate surface calibration procedure cannot be done with the temperature probe

plugged into the rear of the unit.The calibration starts at the low temperatures and goes high.

It is time consuming. Before making an adjustment, be sure that the plate temperature has

stabilized at the point being calibrated. That often takes 20 to 30 minutes after the target

temperature is initially reached. Follow the procedure below.

1. Start at room temperature. Using your temperature meter, read the plate surface

temperature in the center of the heater plate. Press and hold the HEATER button for 3

seconds until the display reads CAL. Then press the ENTER button. Use the

UP/DOWN/RIGHT/LEFT arrows to input the temperature measured for the plate

surface. Then press the ENTER button. The plate low calibration point is set.

2. Set the PLATE temperature to 350ΕC. The plate will start to heat. Give the unit ample

time to reach and stabilize at 350ΕC. When the temperature is stable, measure the plate

temperature with your meter. Press and hold the HEATER button for three seconds until

the display reads CAL. Then press the ENTER button. Use the

UP/DOWN/RIGHT/LEFT arrows as needed to make the plate temperature display read

what is measured on your meter. Then press the ENTER button.

3. Let the unit cool back to room temperature. It will take some time. You can speed the

process by using a fan to help cool the plate. After about an hour measure the plate

surface temperature again. Then reset the plate temperature to what the meter reads as

was done in step 1 above.

The plate surface calibration is now complete.

16

XIII. CLEANING, MAINTENANCE, AND CONSUMABLE PARTS

Cleaning

These units are subject to splashes and spills during normal use. Be sure to clean all spills

quickly. Wipe spills with a soft cloth or paper towel. If a cleaning solution is necessary, use a

mild soap or detergent solution and a soft cloth. Be sure not to use solvents. They could damage

the paint, labels or display window on the unit. A mild abrasive can be used to clean the ceramic

glass heater surface. Do not use abrasives on the cast aluminum heater top. It will scratch the

surface.

Note: When using these units with corrosive liquids, the vapors coming off these liquids

may get into the chassis of the unit and cause damage. This is particularly true on the 5-

position stirring units, the HS65. This unit has a fan on the rear of the unit too cool the

stirrer motors. Vapor can be drawn into the unit by this fan. In any case when using

corrosive chemicals, it is best to try to purge the unit using lab air or an inert gass. Plug as

many holes as is possible and run the gas line into the unit. This causes a positive air

pressure inside the unit and helps keep corrosive vapors out of the unit. On the HS65, the

user may want to deactivate the cooling fan when using a purge gas. When using the unit

with corrosive gasses always work under a fume hood.

CAUTION: Do not attempt to clean the heater surface when it is hot. Burns could occur.

PRÉCAUTION D=EMPLOI: Ne pas nettoyer la surface de la plaque lorqu=elle est chaude

pour éviter toute brûlure accidentelle.

Maintenance

There is no ongoing maintenance program needed with this unit other than the normal care and

cleaning as instructed above and a simple inspection done whenever the unit is to be used. This

simple inspection should include:

1- Checking that the AC line cord is not frayed or burned.

2- Checking that the unit is not dirty to a point where proper performance is impaired. This is

especially important relative to the membrane switch and LCD window.

3- Being certain to store the unit properly when not in use in an area that will not have items

placed on top of the unit. Cover the unit in a way that will keep dirt and other foreign bodies

out.

17

XIV. ADDITIONAL SYMBOLS

The following are additional symbols found on the labels of the instrument.

Symbol Description

V Voltage

~ Alternating Current

A Current

Hz Frequency

W Power

F Fast Acting Fuse

T Time Delay Fuse

I Mains On

O Mains Off

XV. RS232 SERIAL INTERFACE SPECIFICATION

(See the following pages)

18

This manual suits for next models

1

Table of contents