E6582148

I. Safety precautions I-2

I

3

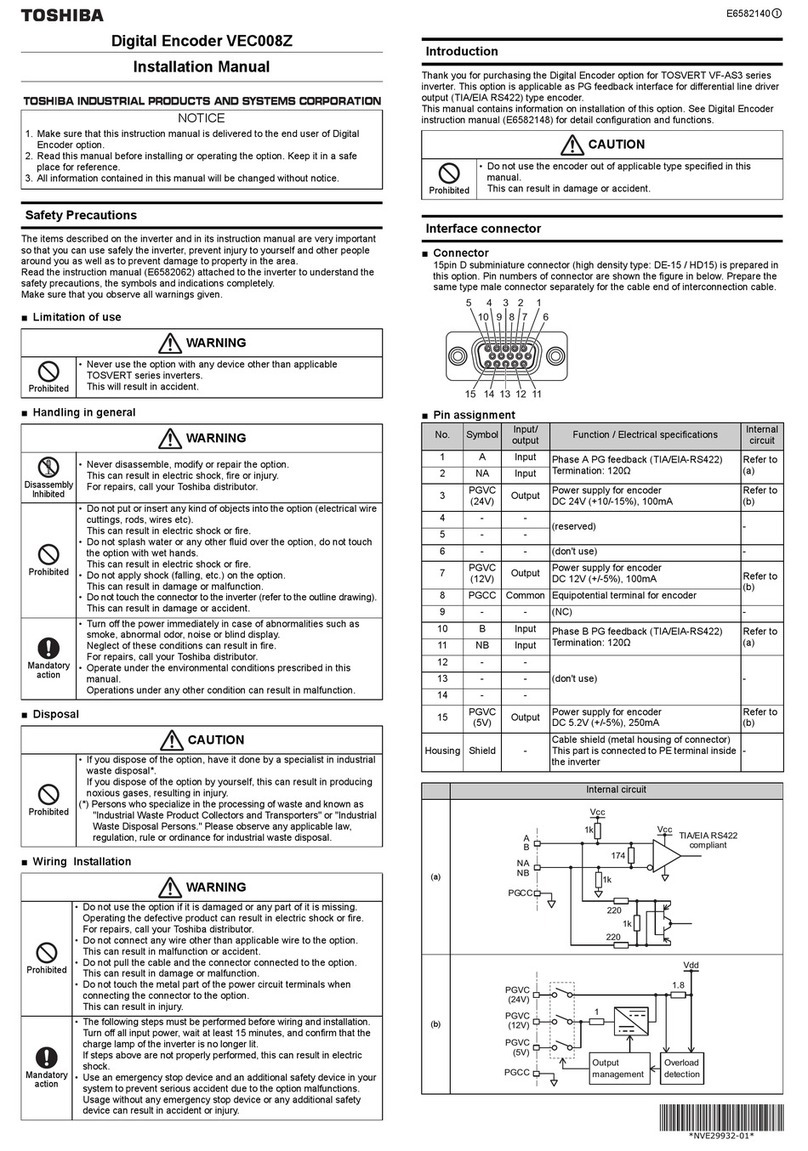

■Limitation of use

■Handling in general

■Disposal

WARNING

Prohibited

• Never use the option with any device other than applicable TOSVERT series inverters.

This will result in accident.

WARNING

Disassembly

inhibited

• Never disassemble, modify or repair the option.

This can result in electric shock, fire or injury.

For repairs, call your Toshiba distributor.

Prohibited

• Do not put or insert any kind of objects into the option (electrical wire cuttings, rods, wires etc).

This can result in damage or fire.

• Do not splash water or any other fluid over the option, do not touch the option with wet hands.

This can result in damage or fire.

• Do not apply shock (falling, etc.) on the option.

This can result in damage or malfunction.

• Do not touch the connector to the inverter (refer to the outline drawing).

This can result in damage or accident.

Mandatory

action

• Turn off the power immediately in case of abnormalities such as smoke, abnormal odor, noise

or blind display.

Neglect of these conditions can result in fire.

For repairs, call your Toshiba distributor.

• Operate under the environmental conditions prescribed in this manual.

Operations under any other condition can result in malfunction.

CAUTION

Prohibited

• If you dispose of the option, have it done by a specialist in industrial waste disposal*.

If you dispose of the option by yourself, this can result in producing noxious gases, resulting in

injury.

(*) Persons who specialize in the processing of waste and known as "Industrial Waste Product

Collectors and Transporters" or "Industrial Waste Disposal Persons." Please observe any

applicable law, regulation, rule or ordinance for industrial waste disposal.