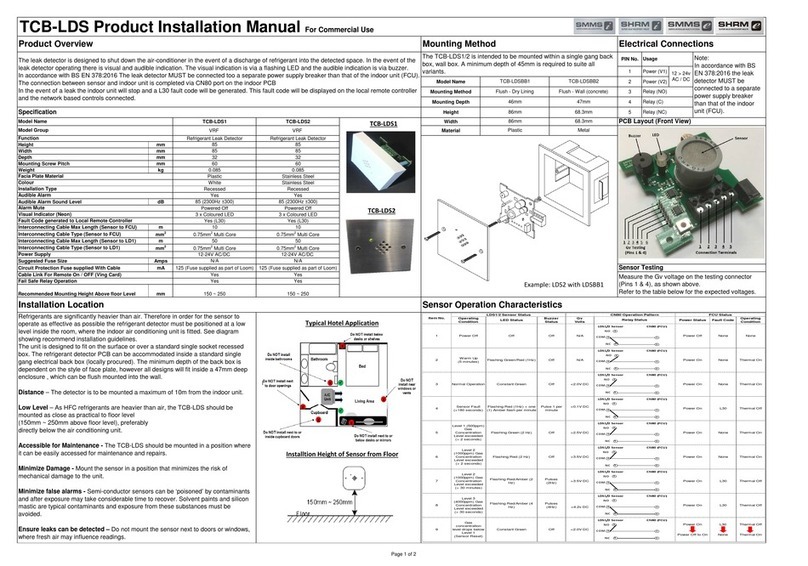

Page 1 of 2

PIN No.

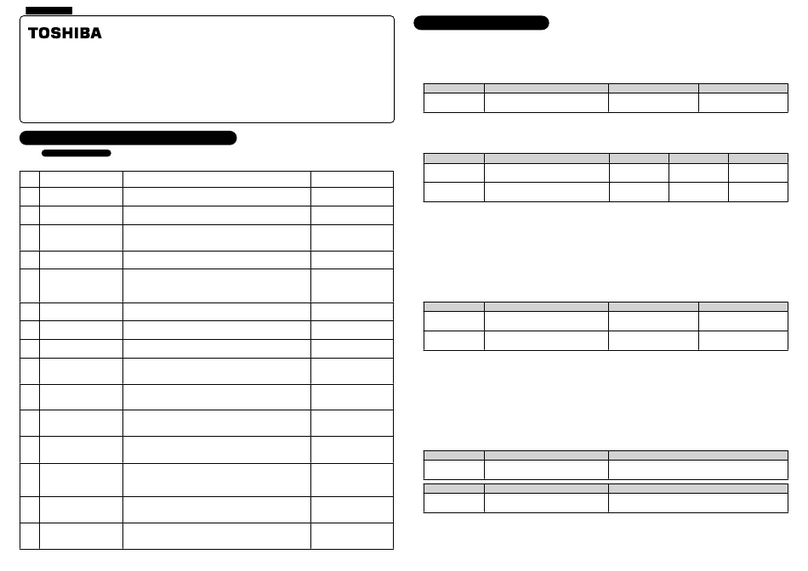

1Power (V1)

Model Name 2Power (V2)

Mounting Method 3

Mounting Depth 4

Height 5

TCB-LDS1 TCB-LDS2 Width

VRF VRF Material

Refrigerant Leak Detector Refrigerant Leak Detector

Height mm 85 85

Width mm 85 85

Depth mm 32 32

Mounting Screw Pitch mm 60 60

Weight kg 0.085 0.085

Plastic Stainless Steel

White Stainless Steel

Recessed Recessed

Yes Yes

Audible Alarm Sound Level dB 85 (2300Hz ±300) 85 (2300Hz ±300)

Powered Off Powered Off

3 x Coloured LED 3 x Coloured LED

Yes (L30) Yes (L30)

Interconnecting Cable Max Length (Sensor to FCU) m10 10

Interconnecting Cable Type (Sensor to FCU)

mm20.75mm2Multi Core 0.75mm2Multi Core

Interconnecting Cable Max Length (Sensor to LD1) m50 50

Interconnecting Cable Type (Sensor to LD1)

mm20.75mm2Multi Core 0.75mm2Multi Core

12-24V AC/DC 12-24V AC/DC

Suggested Fuse Size Amps N/A N/A

Circuit Protection Fuse supplied With Cable mA 125 (Fuse supplied as part of Loom) 125 (Fuse supplied as part of Loom)

Yes Yes

Yes Yes

Recommended Mounting Height Above floor Level mm 150 ~ 250 150 ~ 250

Note:

In accordance with BS

EN 378:2016 the leak

detector MUST be

connected to a separate

power supply breaker

than that of the indoor

unit (FCU).

12 > 24v

AC / DC

Relay (NO)

Relay (C)

Relay (NC)

Usage

Model Name

Cable Link For Remote On / OFF (Ving Card)

Fail Safe Relay Operation

Fault Code generated to Local Remote Controller

The TCB-LDS1/2 is intended to be mounted within a single gang

back box, wall box. A minimum depth of 45mm is required to suite

all variants.

68.3mm

86mm

47mm

Flush - Dry Lining

46mm

TCB-LDSBB1

68.3mm86mm

TCB-LDSBB2

Flush - Wall (concrete)

TCB-LDS Product Installation Manual

For Commercial Use

Refrigerants are significantly heavier than air. Therefore in order for the sensor to

operate as effective as possible the refrigerant detector must be positioned at a low

level inside the room, where the indoor air conditioning unit is fitted. See diagram

showing recommend installation guidelines.

The unit is designed to fit on the surface or over a standard single socket recessed

box. The refrigerant detector PCB can be accommodated inside a standard single

gang electrical back box (locally procured). The minimum depth of the back box is

dependent on the style of face plate, however all designs will fit inside a 47mm deep

enclosure , which can be flush mounted into the wall.

Distance – The detector is to be mounted a maximum of 10m from the indoor unit.

Low Level – As HFC refrigerants are heavier than air, the TCB-LDS should be

mounted as close as practical to floor level

(150mm ~ 250mm above floor level), preferably

directly below the air conditioning unit.

Accessible for Maintenance - The TCB-LDS should be mounted in a position where

it can be easily accessed for maintenance and repairs.

Minimize Damage - Mount the sensor in a position that minimizes the risk of

mechanical damage to the unit.

Minimize false alarms - Semi-conductor sensors can be ‘poisoned’ by contaminants

and after exposure may take considerable time to recover. Solvent paints and silicon

mastic are typical contaminants and exposure from these substances must be

avoided.

Ensure leaks can be detected – Do not mount the sensor next to doors or windows,

where fresh air may influence readings.

Sensor Operation Characteristics

Measure the Gv voltage on the testing connector (Pins 1 & 4),

as shown above.

Refer to the table below for the expected voltages.

Installation Location

Electrical Connections

PCB Layout (Front & Rear View)

Product Overview

Specification

Mounting Method

The leak detector is designed to shut down the air-conditioner in the event of a discharge of refrigerant into the detected space. In the event of the

leak detector operating there is visual and audible indication. The visual indication is via a flashing LED and the audible indication is via buzzer.

In accordance with BS EN 378:2016 The leak detector MUST be connected too a separate power supply breaker than that of the indoor unit

(FCU). The connection between sensor and indoor unit is completed via CN80 port on the indoor PCB

In the event of a leak the indoor unit will stop and a L30 fault code will be generated. This fault code will be displayed on the local remote controller

and the network based controls connected.

TCB-LDS1

TCB-LDS2

Installtion Height of Sensor from Floor

Typical Hotel Application

Gv

Volts Power Status Fault Code

Gas

concentration

level drops below

Level 1

(Sensor Reset)

Level 3

(4000ppm) Gas

Concentration

Level exceeded

(> 30 seconds)

Flashing Red/Amber (4

Hz)

Level 2

(1000ppm) Gas

Concentration

Level exceeded

(> 30 minutes)

Flashing Red/Amber (2

Hz)

Level 2

(1000ppm) Gas

Concentration

Level exceeded

(> 2 seconds)

Level 1 (500ppm)

Gas

Concentration

Level exceeded

(> 2 seconds)

Sensor Fault

(>180 seconds)

Flashing Red (1Hz) + one

(1) Amber flash per minute

Example: LDS2 with LDSBB1