SETTING MANUAL

Multi function sensor (CO2/ PM)

Model name: TCB-SFMCA1V-E

* This product is used in combination with a heat recovery ventilation unit. Do not use the multi function sensor on its own or in combination

with other companies’ products.

Thank you for purchasing the “Multi function sensor” for

TOSHIBA Air Conditioner.

Before starting the installation work, please read this manual

carefully and install the product properly.

DN

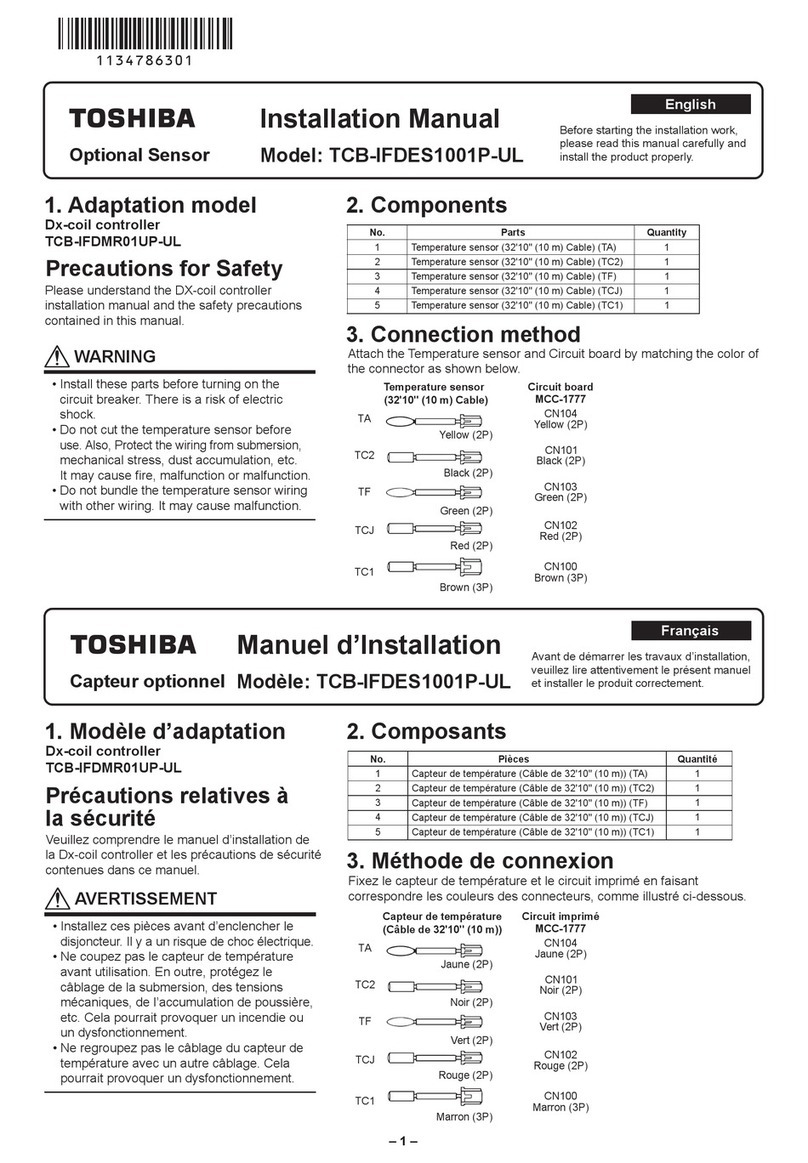

code Description SET DATA and description Factory default

560 CO2concentration control 0000: Uncontrolled

0001: Controlled 0001: Controlled

561 CO2concentration remote

controller display

0000: Hide

0001: Display 0001: Display

562 CO2concentration remote

controller display correction

0000: No correction

-0010 - 0010: Remote controller display value (no correction)

+ setting data × 50 ppm

0000: No correction

563 CO2sensor altitude correction 0000: No correction (altitude 0 m)

0000 - 0040: Setting data ×100 m altitude correction

0000: No correction

(altitude 0 m)

564 CO2sensor calibration

function

0000: Autocalibration enabled, Force calibration disabled

0001: Autocalibration disabled, Force calibration disabled

0002: Autocalibration disabled, Force calibration enabled

0000: Autocalibration

enabled,

Force calibration

disabled

565 CO2sensor force calibration 0000: No calibrate

0001 - 0100: Calibrate with setting data × 20 ppm concentration 0000: No calibrate

566 PM2.5 concentration control 0000: Uncontrolled

0001: Controlled 0001: Controlled

567 PM2.5 concentration remote

controller display

0000: Hide

0001: Display 0001: Display

568 PM2.5 concentration remote

controller display correction

0000: No correction

-0020 - 0020: Remote controller display value (no correction)

+ setting data × 10 μg/m3

0000: No correction

5F6

Multi function sensor

(CO2/ PM)

connection

0000: Without connection

0001: With connection 0000: Without connection

790 CO2target concentration

0000: 1000 ppm

0001: 1400 ppm

0002: 800 ppm

0000: 1000 ppm

793 PM2.5 target concentration

0000: 70 μg/m3

0001: 100 μg/m3

0002: 40 μg/m3

0000: 70 μg/m3

796 Ventilation fan speed [AUTO]

fixed operation

0000: Invalid (according to fan speed in remote controller settings)

0001: Valid (fixed at Fan speed [AUTO])

0000: Invalid

(according to fan speed

in remote controller

settings)

79A Fixed ventilation fan speed

setting

0000: High

0001: Medium

0002: Low

0000: High

79B

Concentration-controlled

minimum ventilation fan

speed

0000: Low

0001: Medium 0000: Low

CO2/ PM2.5 sensor DN code setting list

Refer to How to set each setting for the details of each item.

Refer to the installation manual of the heat recovery ventilation unit for other DN codes.

How to set each setting

Configure the settings when the heat recovery ventilation unit is stopped (Be sure to stop the heat recovery ventilation unit).

Refer to the installation manual of the heat recovery ventilation unit (“7 Installation method for each system configuration”) or the installation

manual of the remote controller (“9. DN setting” in the “7 Field setting menu”) for details on how to set the DN code.

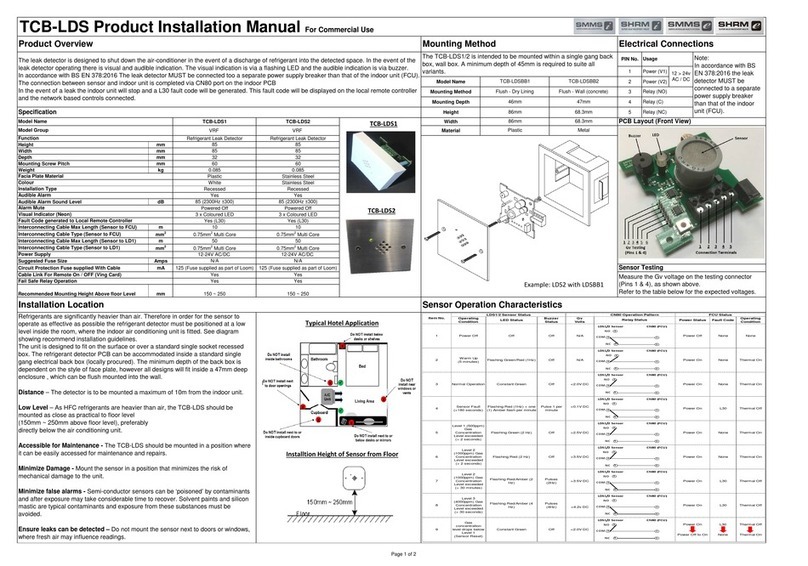

1 Sensor connection settings (be sure to implement)

To perform automatic fan speed control using the CO2/ PM2.5 sensor, change the following setting (0001: With connection).

DN code SET DATA 0000 0001

5F6 Multi function sensor (CO2/ PM)

connection

Without connection

(factory default) With connection

2 CO2 / PM2.5 target concentration setting

Target concentration is the concentration at which the fan speed is the highest.

The fan speed is changed automatically in 7 stages according to the CO2concentration and PM2.5 concentration.

The CO2target concentration and PM2.5 target concentration can be changed in the settings below.

DN code SET DATA 0000 0001 0002

790 CO2target concentration 1000 ppm

(factory default) 1400 ppm 800 ppm

793 PM2.5 target concentration 70 μg/m3

(factory default) 100 μg/m340 μg/m3

* Although the fan speed is switched automatically using the set CO2concentration or PM2.5 concentration as a target, the detection

concentration differs depending on the operating environment and product installation conditions etc., so the concentration may go above

the target concentration depending on the operating environment.

* As a general guideline, the CO2concentration should be 1000 ppm or less.

(REHVA (Federation of European Heating Ventilation and Air Conditioning Associations))

* As a general guideline, the PM2.5 concentration (daily average) should be 70 μg/m3or less.

(Ministry of Environment of China)

* The concentration at which the fan speed is the lowest will not change even if the settings above are configured, with the CO2concentration

being 400 ppm, and the PM2.5 concentration being 5 μg/m3.

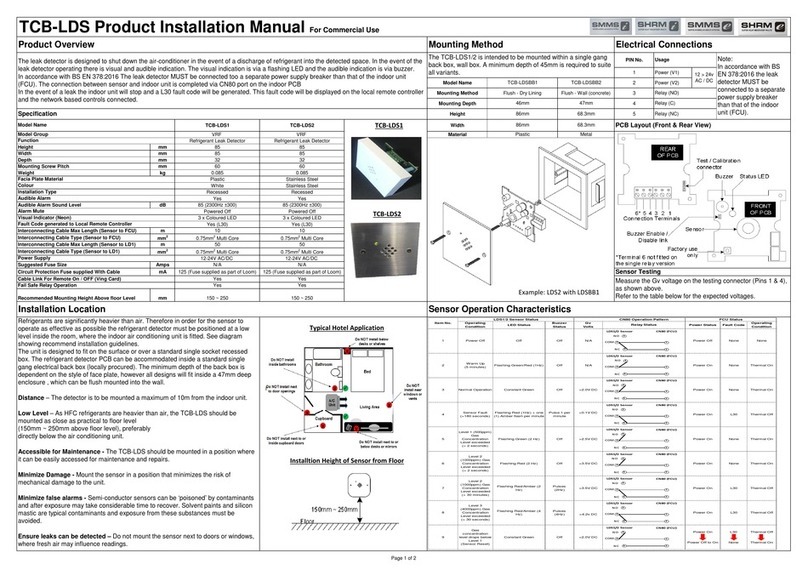

3 Remote controller display settings

The display of the CO2concentration and PM2.5 concentration on the remote controller can be hidden with the following settings.

DN code SET DATA 0000 0001

561 CO2concentration remote controller display Hide Display

(factory default)

567 PM2.5 concentration remote controller display Hide Display

(factory default)

* Even if the concentration is hidden in the remote controller display, when DN code “560” and “566” control is enabled, automatic fan speed

control is performed.

Refer to section 5 for DN code “560” and “566”.

* If the concentration is hidden, in the event of a sensor failure, the CO2concentration “- - ppm”, PM2.5 concentration “- - μg/m3” will also not

be displayed.

* The display range of the concentration is as follows: CO2: 300 - 5000 ppm, PM2.5: 0 - 999 μg/m3.

* Refer to section 6 for details on the remote controller display in a group connection system.

4 Remote controller concentration display correction

Detection of the CO2concentration and PM2.5 concentration is performed at the RA air path of the heat recovery ventilation unit main body.

As unevenness will also occur in the indoor concentration, a difference between the concentration displayed in the remote controller and the

environmental measurement etc. may result. In such a situation, the concentration value displayed by the remote controller can be corrected.

DN code SET DATA -0010 - 0010

562 CO2concentration remote controller display

correction

Remote controller display value (no correction) + setting data × 50 ppm

(factory default: 0000 (no correction))

DN code SET DATA -0020 - 0020

568 PM2.5 concentration remote controller display

correction

Remote controller display value (no correction) + setting data × 10 μg/m

3

(factory default: 0000 (no correction))

* The CO2concentration will appear as “- - ppm” if the corrected value is too low.

* If the corrected PM2.5 concentration is negative, it will appear as “0 μg/m3”.

* Correct only the concentration display value displayed by the remote controller.

* Refer to section 6 for details on the remote controller display in a group connection system.

English

1 2