elobau eloProtect M 165MSK Series Quick guide

Art.-Nr./Art. No./Réf./N° art/N° art.: 9010002B01M Version: 1.1 Date: 11.04.2016 1/11

165MSK...

Safety sensor series 165MSK...

Translation of the original operating instructions

Table of contents

1 About these operating instructions .................................................... 1

2 Designated use.................................................................................. 1

3Approvals........................................................................................... 1

4 Safety instructions ............................................................................. 2

5 Warning against misuse .................................................................... 2

6 Exclusion of liability ........................................................................... 2

7Function............................................................................................. 2

8 Technical specifications..................................................................... 2

9Installation ......................................................................................... 2

10 Adjustment......................................................................................... 3

11 Electrical connection.......................................................................... 3

12 Commissioning .................................................................................. 3

13 Maintenance ...................................................................................... 3

14 Dismantling........................................................................................ 3

15 Disposal............................................................................................. 3

16 Information on the manufacturing date.............................................. 6

Declaration of conformity ........................................................................... 20

1 About these operating instructions

The following standard models are described:

165MSK00.1.

Data sheets can also be requested from elobau for customer-specific safety

sensors. The information specified in the data sheet applies for customer-

specific models if this information deviates from the operating instructions.

The person installing the safety sensor is to be provided with the operating

instructions.

The operating instructions must be kept in a legible condition and in an

accessible location.

Meaning of the symbols used:

Warning

Failure to observe this warning may result in faults or malfunc-

tions.

Failure to observe this warning may result in personal injury

and/or damage to the machine.

Information

Indicates available accessories and useful additional informa-

tion.

GB 165MSK...

Type key safety sensor

Type key actuator

165MSK00.1.

A = N.O. contact / N.O. contact

B = N.O. contact / N.O. contact / LED

C = N.O. contact / N.O. contact / control contact N.O. contact

D = N.O. contact / N.O. contact / control contact N.O. contact /

LED

E = N.O. contact / N.O. contact / lateral control

F = N.O. contact / N.O. contact / lateral control / LED

G = N.O. contact / N.C. contact

H = N.O. contact / N.C. contact / LED

I = N.O. contact / N.C. contact / control contact N.O. contact

J = N.O. contact / N.C. contact / control contact N.O. contact /

LED

K = N.O. contact / N.C. contact / lateral control

L = N.O. contact / N.C. contact / LED / lateral control

H = Plug M12x1 4-pole Pigtail

J = Plug M12x1 8-pole Pigtail

K = Cable

165MBK.01

0 = standard (non-reinforced); end face

1 = reinforced, end face

2 = standard (non-reinforced); 90°

3 = reinforced, 90°

4 = special design

2 Designated use

In combination with the elobau safety control units or similar safety controllers,

the safety sensors and actuator 165MBK... are exclusively used to monitor

moving, isolating safety devices.

The safety control units (or similar) detailed in chapter 7 “Function” on page 4

achieve PDF-M / PDF-S-classification according to EN 60947-5-3 in combin-

ation with the safety sensors and actuators.

The overall control concept in which the safety sensor is incorporated, must be

validated, for example, according to EN ISO 13849-2.

3 Approvals

[INDUSTRIAL CONTROL SWITCH]

E336137

(Tested according to ECOLAB

standard)

Test media:

- Distilled water

- P3-topax 66

- P3-topactive 200

- P3-topax 52

- P3-topax 990

Art.-Nr./Art. No./Réf./N° art/N° art.: 9010002B01M Version: 1.1 Date: 11.04.2016 2/11

4 Safety instructions

5 Warning against misuse

6 Exclusion of liability

No liability shall be accepted for any damage or operational faults caused by a

failure to observe these operating instructions. All further liability of the

manufacturer is excluded in the case of damage caused by the use of

replacement and accessory parts that have not been authorized by the

manufacturer.

No unauthorized repairs, conversions or modifications are permitted for reasons

of safety and the manufacturer shall not be liable for any damage resulting

therefrom.

7 Function

A coded magnetic safety sensor with a non-contact activation through a coded

actuator.

(Type 4; low coding level according to EN ISO 14119)

An elobau safety control unit or similar safety processing unit / safety controller

analyses the switching state of the safety sensor. PDF-M and PDF-S is

achieved only in combination with the elobau safety control units listed below or

comparable safety control units / safety controllers.

The safety sensors are suitable for the following elobau safety control units:

- Ensure that the safety sensors are only mounted and put into

operation by specially-trained and authorised personnel.

- Only install and put the device into operation once you have

read and understood the operating instructions and are familiar

with the applicable regulations on occupational safety and

accident prevention.

- The safety sensor may only be activated by a correctly mounted

actuator on the safety device. Actuation by a spare actuator that

is not mounted to the safety device is prohibited.

- The safety sensors may only be operated in a perfect function-

ing condition.

- Ensure that the safety sensors are exclusively used to protect

against risks.

- Ensure that all of the valid safety regulations for the respective

machine are complied with.

- Ensure that all of the valid laws and directives are complied with.

- Connecting safety sensors in series can, under certain

circumstances, reduce their performance level according to

EN ISO 13849-1 standards due to a lower detection of errors.

- There are no known residual risks, if all of the information

contained in these operating instructions is complied with.

- In case of incorrect or unintended use or manipulation, the use

of the safety sensors does not exclude risks to persons or

damage to machine or system components.

Please also observe the relevant information stipulated in

EN ISO 14119.

- Please ensure that when using safety control units that have not

been supplied by elobau, no current or voltage peaks which are

higher than the specified electrical data of the safety sensor are

generated by these devices. Current or voltage peaks are

produced, for example, by capacitive or inductive loads.

- The safety sensor is not short-circuit proof.

- An exceeding of the electrical data of the safety sensor (e.g. in

the event of incorrect wiring or short-circuits) may cause

irreparable damage to the sensor.

- The safety sensor may only be activated in the approved control

options (see Technical specifications).

Non-compliance with this information may result in reduced

service life of the safety sensor.

PDF-M according to EN 60947-5-3:1999 + A1:2005

(corresponds to PLe /Cat.4) for:

470... 470EFR3E11K_

470EFR3E12K_

471... 471M41H31

471EFR3E11K_

471EFR3E12K_

471EFR3E13K_

471EFR3E14K_

eloProg 485EPB

485EPE08A02

485EPE08

4854EPE12

485EPE16

PDF-S according to EN 60947-5-3:1999 + A1:2005

(corresponds to PLd /Cat.3) for:

463... 463111B1

463111B2

463114B1

463114B2

463111B101

463114B101

463121B1

463124B1

470... 470111B1

470115B1

470121B1

470125B1

470EFR2D12K_

471... 471EFR2D14K_

8 Technical specifications

See Technical specifications beginning on page page 14.

9 Installation

- Safety sensor and actuator

do not use as end stops

do not install in strong magnetic fields

do not expose to any strong shocks or vibrations

keep away from iron filings

- The safety sensor and the accompanying actuators may only be mounted in

a voltage-free state.

- Ensure that all safety sensor and actuator markings are congruently

opposed to one another.

- The installation position is arbitrary. The safety sensor and actuator must

however be mounted in parallel, facing each other.

- Please note the specified installation tolerances and the approved control

options.

- Since the safety sensor is a non-embeddable proximity switch (in

accordance with EN 60947-5-2), the safety sensor and the actuator should

be mounted on non-ferromagnetic material. A free zone of 25 mm is required

in the event that this cannot be avoided.

- Where possible, the safety sensor and actuator should not be mounted on

ferromagnetic material. Changes to the switching distances are to be

expected. A non-ferromagnetic spacer with a thickness of at least 10 mm

must be used in order to avoid influencing the switching distances. The

above-mentioned free zone still applies to the safety sensor and actuator.

- The mounting distance between two safety sensor and actuator systems

must be at least 50 mm.

- Tightly fasten the safety sensor and actuator to the safety device.

Suitable spacer plates for the

safety

sensor and actuator are

available from elobau under order number 350008.

Art.-Nr./Art. No./Réf./N° art/N° art.: 9010002B01M Version: 1.1 Date: 11.04.2016 3/11

165MSK...

- Only M4 flat head screws (e.g. M4 cylinder head screws ISO 4762) may be

used for mounting the safety sensor and actuator. Max. tightening torque

0.7 Nm. Screws made from non-ferromagnetic material (e.g. brass) must be

used.

- The safety sensor may only be mounted on an even surface as failure to do

so may lead to tension which could damage the safety sensor or alter the

switching distances.

- The connection cable of the safety sensor must be protected against

mechanical damage.

- During the assembly process, the requirements according to EN 14119

should be taken into consideration.

- Consider the requirements of EN 60204-1 when mounting, in particular with

regard to appropriate laying. It is recommended to conceal the safety sensor

lead.

10 Adjustment

- Always test the correct functionality with one of the approved safety control

units.

- The specified switching distances (see Technical specifications from

page 14) only apply for mounting on non-ferromagnetic material if the safety

sensor and actuator are mounted in parallel and facing each other. Other

layouts may lead to deviating switching distances.

11 Electrical connection

- Electrical connection is permitted in voltage-free state only.

- Connect the safety sensor according to the specified wire colours or pin

assignment (see Technical specifications from page 14).

- Please ensure that the voltage does not fall below the required minimum

input voltage of the downstream safety processing unit. For that reason

observe the voltage drop at the safety sensor (series resistor) and in the

connection cable.

- The voltage drop for the internal LED circuit is to be considered additionally

for LED safety sensors (see Technical specifications).

- For series connection of the safety sensors (verify approval in advance) their

respective NO paths must be connected in series and the respective NC

paths must be connected in parallel.

12 Commissioning

When commissioning, the following points must be ensured in advance:

- The safety sensor and actuator are positioned correctly and mounted in a

fixed position.

- The supply line is intact.

- There are no iron filings on the safety sensor and actuator.

The safety sensor and the connected control unit must then be tested for correct

functionality.

13 Maintenance

If the safety sensor is mounted and used correctly, no maintenance measures

are be necessary.

We recommend a visual and functional inspection carried out at regular

intervals:

- Check that the safety sensor and actuator are firmly seated.

To secure the mounting screws against easy disassembly, we

recommend using the screw covers included.

For safety sensors with connection plugs, suitable cable sets and

connectors for assembly are directly available from elobau (see

Technical specifications from page 14

).

The control contact is not a safety contact.

It may not be incorporated into a safety circuit.

Use the control contact for non safety-relevant signal and control

functions only.

If several safety sensors with LED are used, the brightness of the

LEDs can decrease with an increasing number of closed safety

doors.

14 Dismantling

The safety sensor may only be dismantled in a voltage-free state.

15 Disposal

Dispose of packaging and used parts in accordance with the regulations of the

country in which the device is installed.

16 Information on the manufacturing date

The manufacturing date can be seen on the safety sensor casing

in the form of "week/year":

e.g. 37/14 = week 37/ year 2014

165MSK...

Art.-Nr./Art. No./Réf./N° art.: 9010002B01M Version: 1.1 Date: 11.04.2016 4/11

Technical specifications

Electrical data 165MSK00.1.

Switching voltage U1) 24 V DC +/- 20 %

Max. switching current safety

contact

- without LED

- with LED (green colour)

For UL approval: resistive

200 mA (-25°C...+80°C)

10 mA (-25°C...+70°C)

5 mA (>70°C...+80°C)

Max. switching current control

contact 50 mA

Series resistor safety contact

- without LED

- with LED (green colour)

For UL approval: resistive

10 Ω(0,75 W)

10 Ω(0,10 W)

Series resistor control contact 10 Ω(0,25 W)

Max. voltage drop additionally

for LED Ud3,7 V

Max. frequency of operating

cycles 5 Hz

Max. rated insulation voltage Ui300 V DC / 250 V AC

Rated impulse withstand voltage

Uimp 0,8 kV

Degree of pollution 3

Usage category DC 12

Type key actuator 165MSK00.1.

Standard actuator 165MBK001 / 165MBK201

Amplified actuator for larger

operating distances 165MBK101 / 165MBK301

Secured operating distance Sao

Standard

Reinforced

5 mm

8 mm

Safe distance for switching off Sar

Standard

Reinforced

14 mm

18 mm

Repeat accuracy [R]

Differential travel [H] / standard /

reinforced

< 0,2 mm

3,5 mm

Minimum air gap Somin 0,5 mm

165MSK...

Art.-Nr./Art. No./Réf./N° art.: 9010002B01M Version: 1.1 Date: 11.04.2016 5/11

Environmental data 165MSK00.1.

Ambient temperature

(connection cable in a fixed

position)

For UL approval:

- 25 °C ... +80 °C

- 25 °C ... +55 °C

- 25 °C ... +65 °C

- 25 °C ... +40 °C

1

- 25 °C ... +80 °C

30 g / 11 ms

10 Hz ... 55 Hz

1 mm

IP67

IP6K9K

Mechanical specifications 165MSK00.1.

Mounting position arbitrary —

Non-flush mountable —

Housing material

PBT colour: grey

PC colour: black

✓

✓

Max. torque for fastening screw 0,7 Nm

Dimensions 88 mm x 25 mm x 13 mm

Weight approx.

- Safety sensor with 1m/3m /5m/

10m connection piping

- Safety sensor with plug

- Actuator

145 g / 345 g / 545 g / 1045 g

45 g

35 g

-

-

-

without LED

with LED (green colour)

plug version

(without/with LED)

Area type class

Storage and transport

temperature

Shock resistance EN 60947-5-2

Vibration resistance according

to EN 60947-5-2

Amplitude

Protection class in accordance

with EN 60529

Degree of protection according to

ISO 20653:2013

(excluding plugs)2)

165MSK...

Art.-Nr./Art. No./Réf./N° art.: 9010002B01M Version: 1.1 Date: 11.04.2016 6/11

Connection types 165MSK00.1.

Connection cable grey PVC LiYY 4x0,25mm² / 6x0,25mm²

(AWG 24)

Connector with Pigtail

(according to

EN 61076-2-101:2012)

- M12x1, 4-pole, black/grey

- M12x1, 8-pole, black/grey

PVC LiYY M12x1 4x0,25mm² (AWG 24)

PVC LiYY M12x1 8x0,25mm² (AWG 24)

Mating plug available for

- M12x1, 4-pole, black/grey

- M12x1, 8-pole, black/grey

(elobau article number)

K14G00.K

K18G00.K

Cable diameter (± tolerance)

4-core / 4-pole

6-core / 8-pole

Ø 4,7 mm ± 0,25 mm

Ø 6,0 mm ± 0,30 mm

Max. torque for plug 0,6 Nm

Max. cable length 30 m

1) The safety sensor must be

supplied directly or indirectly to a

SELV / PELV power supply unit.

2) Only for use in industrial

equipment in accordance with

NFPA 79

Safety parameters 165MSK00.1.

B10d according to

EN ISO 13849-1:2008

Appendix C

(at max. 20% contact load)

20.000.000

Service life in years 20

An individual safety sensor can

be used up to 1)

Kat.4 / PL e (EN ISO 13849-1)

SILCL 3 (IEC/EN 62061)

SIL 3 (IEC/EN 61508)

2

1

7

6

5

43

2

8

3

1

4

165MSK...

Art.-Nr./Art. No./Réf./N° art.: 9010002B01M Version: 1.1 Date: 11.04.2016 7/11

Specifications in accordance

with EN 61508

165MSK00.1.

Classification in accordance with

EN 60947-5-3:1999+A1:2005

2)

PDF-M PDF-S

Diagnostic Coverage (DC)

min. high (PDF-M)

min. medium (PDF-S) ✓

✓

Min. Safe Failure Fraction

(SFF) 99,5% 95%

Min. category/PL in accordance

with EN ISO 13849-1:2008 4/PL e 3/PL d

SIL in accordance with

(IEC/EN 62061)

SIL in accordance with

(IEC/EN 61508)

SILCL 3

SIL 3

MTTFd (years) 2707

PFHd(1/h) 8,43 x 10-9 8,44 x 10-9

1)

- For this, at least the following

measures are required:

- Short circuit recognition

through differing voltages

or pulsed signals

- Two-channel structure

(see EN ISO 13849-1:2008)

2)

- The usable safety control units

can be found in chapter 7,

"Function" of this manual

165MSK...

Art.-Nr./Art. No./Réf./N° art.: 9010002B01M Version: 1.1 Date: 11.04.2016 8/11

1 6 5 M S K 0 0 . 1 . 1 6 5 M S K 0 0 . 1 .

165MBK001 / 165MBK101 165MBK001 / 165MBK101

AA

165MBK201 / 165MBK301 165MBK201 / 165MBK301

Somin

Sao

Sar

A

B

C

D

G

H

I

J

H

J

K

E

F

K

L

H

J

K

Somin

Sao

Sar

Somin

Sao

Sar

Somin

Sao

Sar

Active surface marked with ▲

Actuator operating directions

frontal lateral

Dimensions

165MSK... 165MBK...

9,5

18,5

25

4,5Ø

25

7,6Ø

8888

78

78

18,5

5,1

13

5,1

13

4,5Ø

7,6Ø

LIYY 4x0,25mm² / 6x0,25mm² / 8x0,25mm²

For further information on actuators, please contact elobau for appropriate datasheets

A

165MSK...

Art.-Nr./Art. No./Réf./N° art.: 9010002B01M Version: 1.1 Date: 11.04.2016 9/11

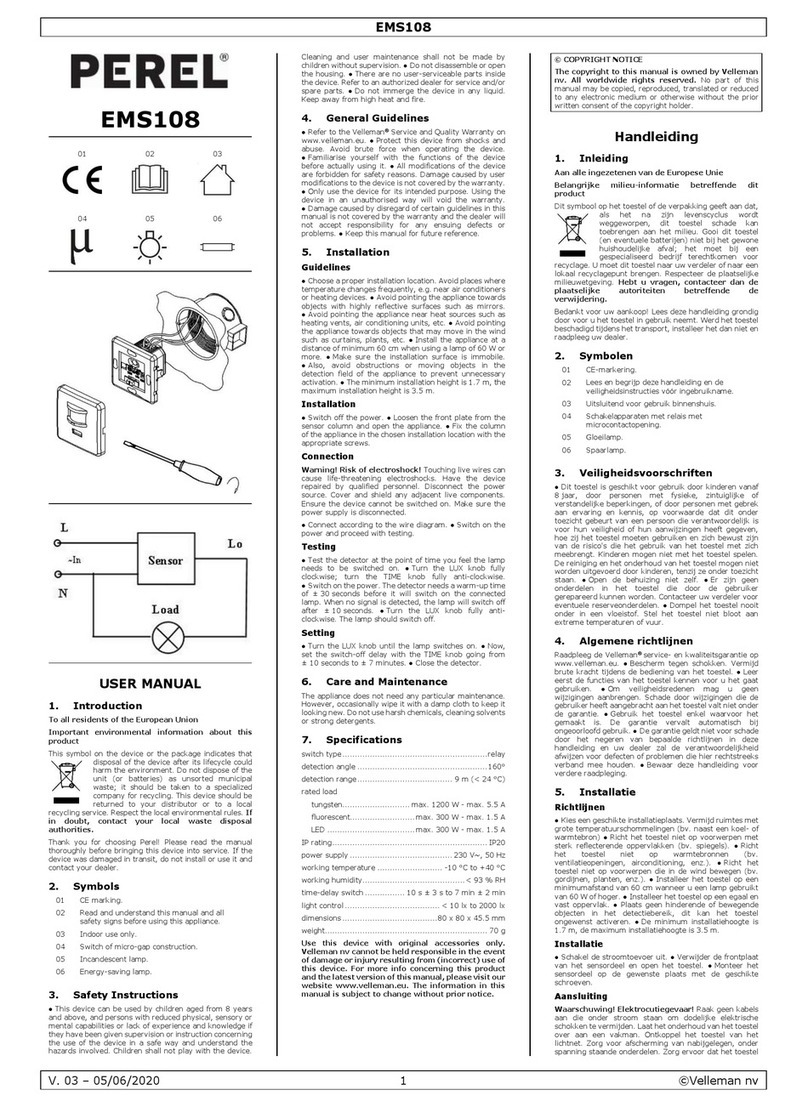

2

1

4

A

G

C

3

12

1(+)

3

21

3

5

2 1(+)

6

3

5

2

4

1

3

2 1(+)

3

BDE

4

1(+) 21

3

2

5

21

34

2 1(+)

3

BN(+)

BK

BN

BU

WH WH

BU

BN

BU

GY

WH BN(+)

PK

WH

GY

BK BU

BN WH BN(+)

BK

BN

BU

WH

BK

BN(+)

BU

WH

BK

BN

BU

GY PK

BK

BN(+)

BU

GY

WH

BK

BN

BU BK

BN(+)

BU

BU

BU

IJ

CD

IJ

control contact control contact

control contact control contact

control contact control contact

control contact control contact

A

G

B

H

EF

BK

WH

BK

PK

K

BK

WH

L

WH

WH

BK

PK

1(+)

3

5

4

6

K

2

4

L

4

3

H

4

F

4

2

6

44

4

3

6

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

10˖

A

B

C

D

E

F

G

H

I

J

K

L

1 6 5 M S K 0 0 . 1 .

165MSK00K1. 165MSK00H1.

165MSK00J1.

Contact types

All safety sensor contacts are presented in a deactivated state (open protective door). For safety sensors with connecting cable and plug the pin assignment is specified (see plug diagram page 16). Wire colours are stated

for safety sensors with connection cable. The first (1/2 or BN / WH) and the second (3/4 or BU / BK) contacts are safety contacts. The third contact (GY / PK or 5/6) is the control contact.

EU-Konformitätserklärung

EU- Declaration of Conformity

Hiermit erklären wir, dass das nachfolgend aufgeführte Produkt aufgrund der Konzipierung und

Bauart den Sicherheits- und Gesundheitsanforderungen der unten genannten EU-Richtlinien

entspricht.

Hereby we officially validate that the below listed component comply with the requirements of the following European Directive because of their

design and construction:

Einschlägige EG-Richtlinien:

relevant EC-Directives:

Maschinenrichtlinie 2006/42/EG

bis 19.04.2016: EMV-Richtlinie 2004/108/EG

von 20.04.2016: EMV-Richtlinie 2014/30/EU

Machine Safety Directive 2006/42/EC

to 04/19/2016: EMC Directive 2004/108/EC

from 04/20/2016: EMC Directive 2014/30/EU

Bezeichnung und Beschreibung der Produktkomponenten des Sicherheitsbauteils:

Designation and description of the product components of the safety-relevant component:

Sicherheitssensor:

Safety sensor:

elobau Artikel-Nr.: 165 MSK *

elobau item - no.:

codierter magnetisch wirkender Sicherheitssensor

coded, magnetically acting safety sensor

Betätiger:

Actuator:

elobau Artikel-Nr.: 165 MBK *

elobau item - no.:

Betätigungsmagnet für benannten Sicherheitssensor

switching magnet for named safety sensor

Sicherheitsauswerteeinheit:

Safety control unit:

Sicherheitsauswerteeinheit der Firma elobau oder eine

vergleichbare Sicherheitsauswerteeinheit /

Sicherheitssteuerung, die den Anforderungen der DIN EN

ISO 13849-1 oder der DIN EN 62061 genügt.

Safety control unit by elobau or any comparable Safety Control Unit / Safety Control that

complies with the requirements of DIN EN ISO 13849-1 or of DIN EN 62061

Die CE-Kennzeichnung von Sicherheitssensor und Betätiger hat nur in kombinierter

Anwendung Gültigkeit.

The CE marking of safety sensor and actuator is only valid if the units are used in combination.

998H0004K0006

Die Übereinstimmung eines Baumusters des bezeichneten Produkts mit der oben benannten

Richtlinie wurde bescheinigt durch:

The consistency of a production sample with the marked product in accordance with the above named Directive has been

certified by:

Name und Anschrift

benannte Stelle:

TÜV Product Service GmbH

Ridlerstraße 65

D-80339 München

Kennnummer: 0123

Nummerierung der

Bescheinigung:

Certification number:

Z10 14 09 20166 030

Änderungsindex:

Modification Index: B

Leutkirch, den 11.04.2016 Sandrina Fehrs

CE-Beauftragte /

EC authorized Representative

Dokumentation Bevollmächtigte /

Documentation Representative

Sa

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

Sa

Sa

Sa

Sa

a

a

a

a

a

a

Sa

Sa

Sa

a

a

a

a

Sa

a

a

S

a

a

a

a

a

a

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

nd

d

d

d

nd

d

nd

nd

nd

d

d

d

nd

d

d

ri

ri

ri

ri

ri

i

ri

r

ri

ri

ri

ri

r

r

ri

r

r

ri

ri

r

ri

ri

r

ri

ri

ri

r

r

na

a

a

a

na

na

na

na

na

na

na

n

na

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

F

eh

eh

eh

eh

h

eh

eh

eh

eh

eh

eh

eh

eh

eh

eh

h

eh

eh

e

e

e

e

e

e

e

e

e

rs

CE

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

Beauftragte /

EC th

This manual suits for next models

12

Table of contents

Other elobau Security Sensor manuals

elobau

elobau 114 Series Quick guide

elobau

elobau 120 2 Series User manual

elobau

elobau 153 Series Quick guide

elobau

elobau 1655 V Series Quick guide

elobau

elobau N3 Series User manual

elobau

elobau 122 Series Quick guide

elobau

elobau eloProtect E 165ESK Series Quick guide

elobau

elobau UD30 350S Series User manual

elobau

elobau 153MSK Series User manual

elobau

elobau 165 Series User manual