–6 –

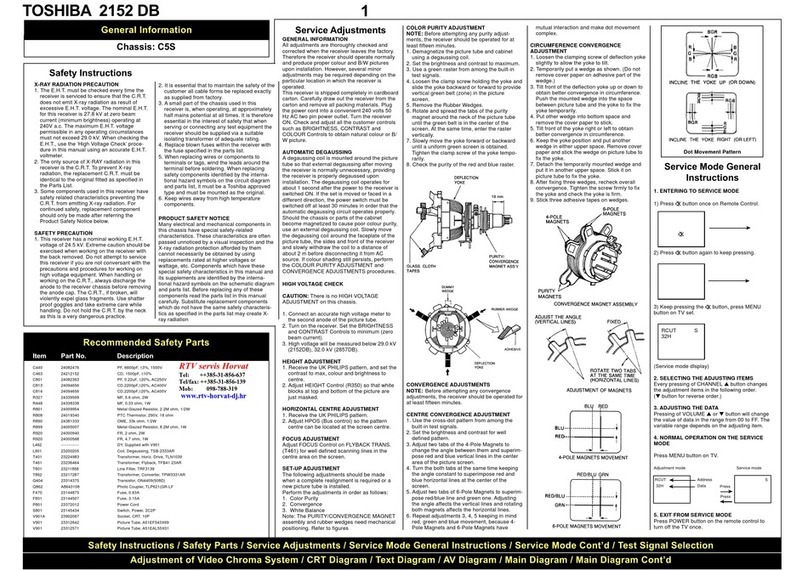

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE "X-RAY RADIATION PRECAUTION", "SAFETY PRE-

CAUTION" AND "PRODUCT SAFETY NOTICE" ON PAGE 3 OF THIS MANUAL.

PICTURE TUBE COMPONENTS ADJUSTMENT

ADJUSTING PROCEDURE IN REPLACING CRT

User convergence center check

Lens focus

Electrical focus

Cutoff

Centering (PAL)

Convergence adjustment

(PAL/NTSC)

Yoke horizontal

End

Sub bright adjustment

White balance

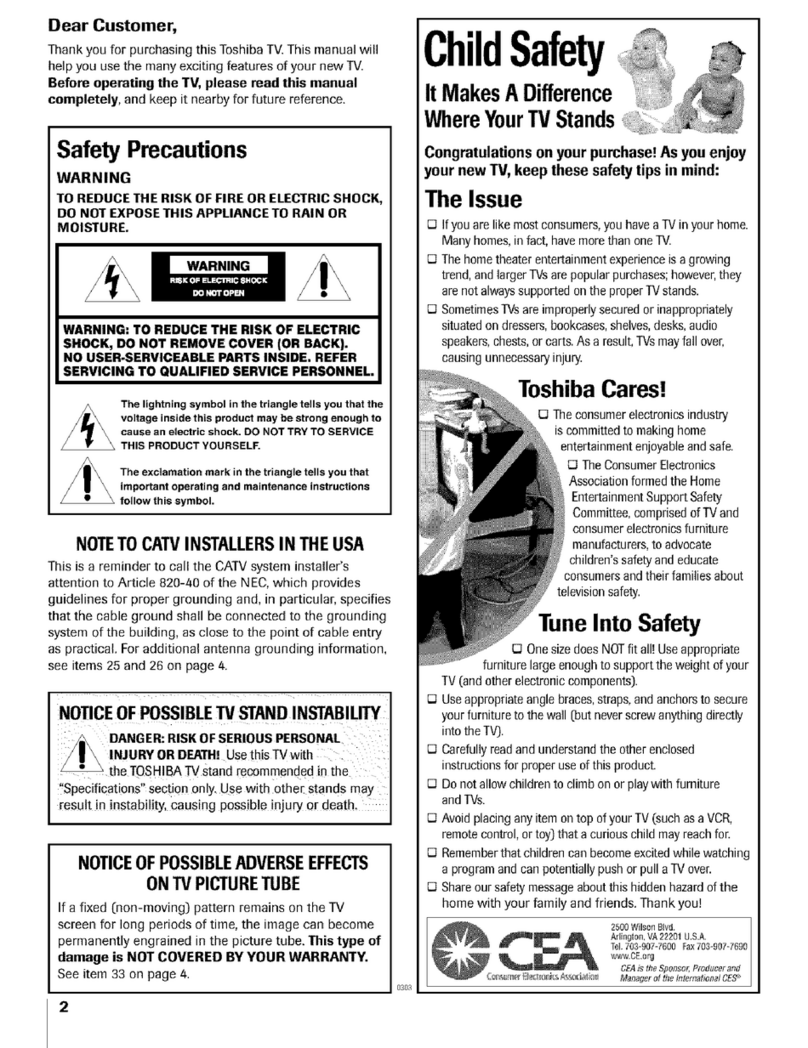

DESCRIPTION OF NECK COMPONENTS

1Deflection yoke and convergence yoke.

The position on the neck is required most front (CRT fun-

nel side) and the screw is fastened after rotating yoke

adjusting picture tilt.

2Centering magnet

After adjusting picture tilt, picture position is finally fixed

by this magnet.

In order to get maximum margin of user convergence con-

trol for center of screen, this magnet have to be used for

center convergence adjustment.

PREPARATION

Operate the receiver for at least 5 minutes.

R, G, B CUTOFF (SCREEN VR) ADJUSTMENT

1. Adjust before replace the screen assembly.

2. Set user control to reset position.

(CONTRAST →Max

BRIGHTNESS, COLOR, TINT →Center. )

3. Call up the adjustment mode display, then select the

item RCUT.

4. Adjust the data of items RCUT,GCUT, and BCUT to

"40H".

5. Press the -/-- button on Remote. (Y-MUTE : ON)

6. Gradually rotate R, G and B screen volume of FOCUS

PAC clockwise or counterclockwise until the raster

appears slightly on the CRT through the each lens, and

leave them.

(Lookin to the lens in order to check the raster.)

7. Press the -/-- button on Remote. (Return to Normal

Picture)

1

2

S.V.M. COIL

RGB FOCUS ADJUSTMENT

1. Connect a VIDEO signal generator which generates a

cross-hatch pattern.

2. Receive a white cross-hatch pattern by pressing the signal

slection key on the VIDEO signal generator.

3. Expose only RED by covering the GREEN and BLUE

lenses with caps.

4. Loosen the RED lens fixing screws (refer to Fig. a), and

adjust the RED lens focus to obtain the sharpest point

while observing the middle and peripheral sections of the

screen.

Fig. a

5. Use the focus VR of “R”of the focus pack in order to adjust

the electric focus in the middle and peripheral sections of

the screen to its sharpest level.

6. Check the RED focus of the whole screen and if necessary

repeat steps 4 and 5.

7. Fix the RED lens by tightening its fixing screws.

8. Expose only GREEN by covering the RED and BLUE

lenses with caps.

9. Display the internally-generated cross-hatch signal.

10. Adjust the GREEN lens focus on the left border of the

screen to its sharpest level, then check the focus on the

right border, and if it is at its sharpest level, fix it in that

position by tightening the lens screws.

(1) If the horizontal line toward the right border is red-

flared, turn the lens screw slightly right in order to

balance it with the left border. (After adjustment, the

left border tends to be slightly green-flared, and the

right border tends to be slightly red-flared.)

(2) If the horizontal line toward the right border is green-

flared, turn the lens screw slightly left in order to

balance it with the left border. (After adjustment, the

left border tends to be slightly red-flared, and the

right border tends to be slightly green-flared.)

Note: The aim of the above-described adjustment procedure

for the Green lens focus is to obtain the best lens focus

after 2 - 3 hours of warming up taking into account the

focus drift; it applies if the warming up time before the

adjustment is less than 30 minutes. (The horizontal line

in the screen middle section tends to be slightly red-

flared.)