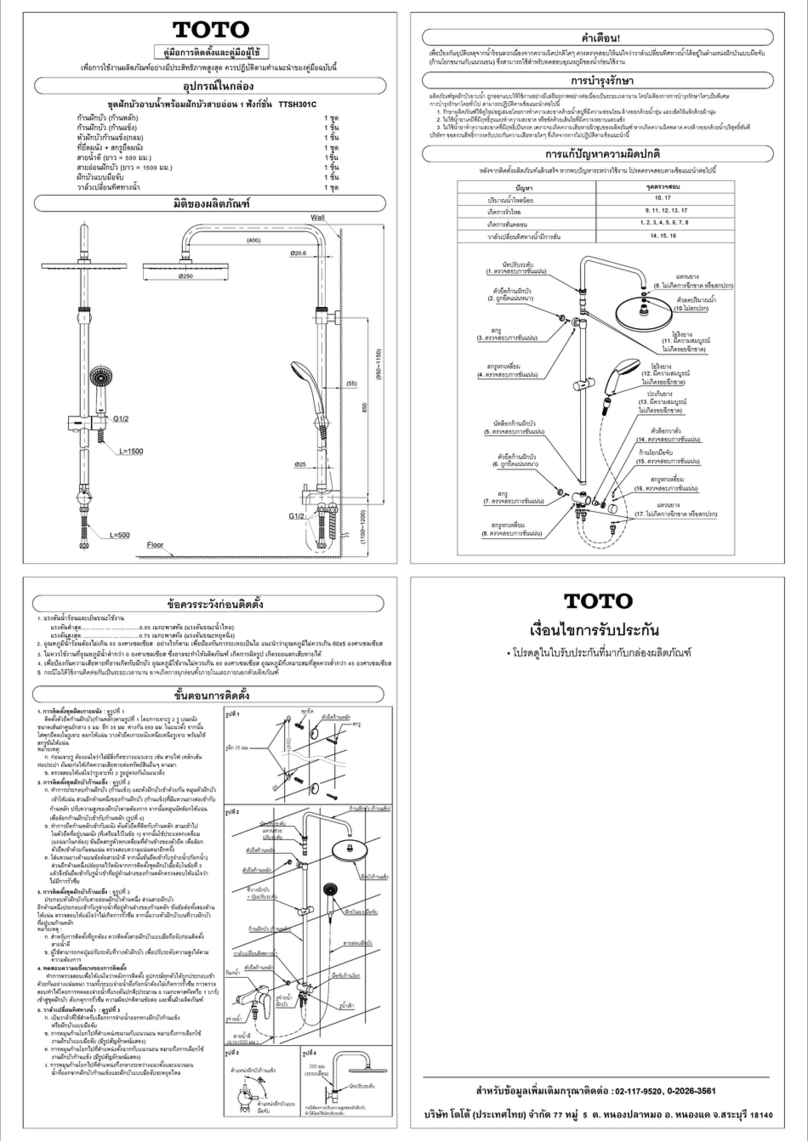

10

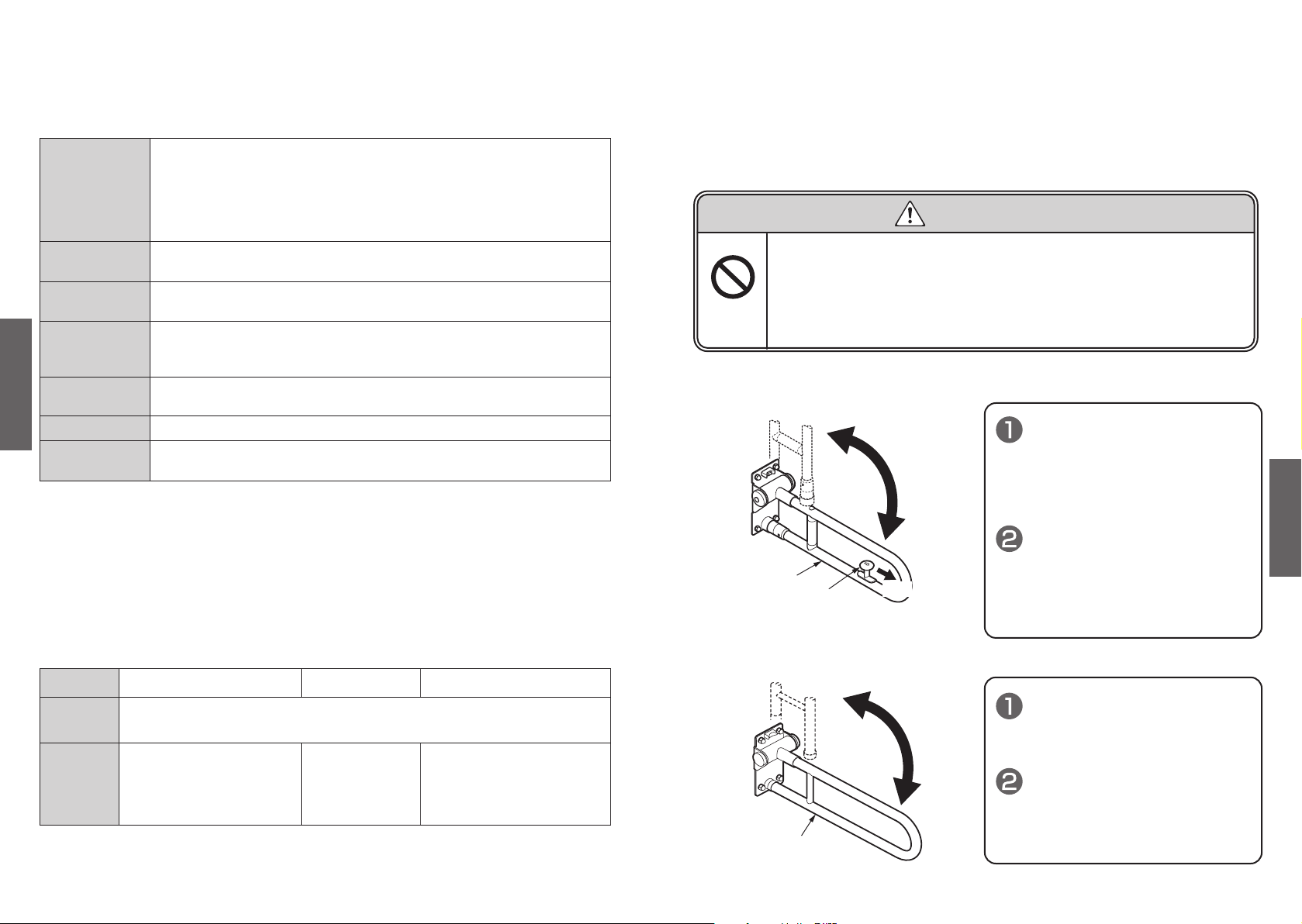

Cleaning

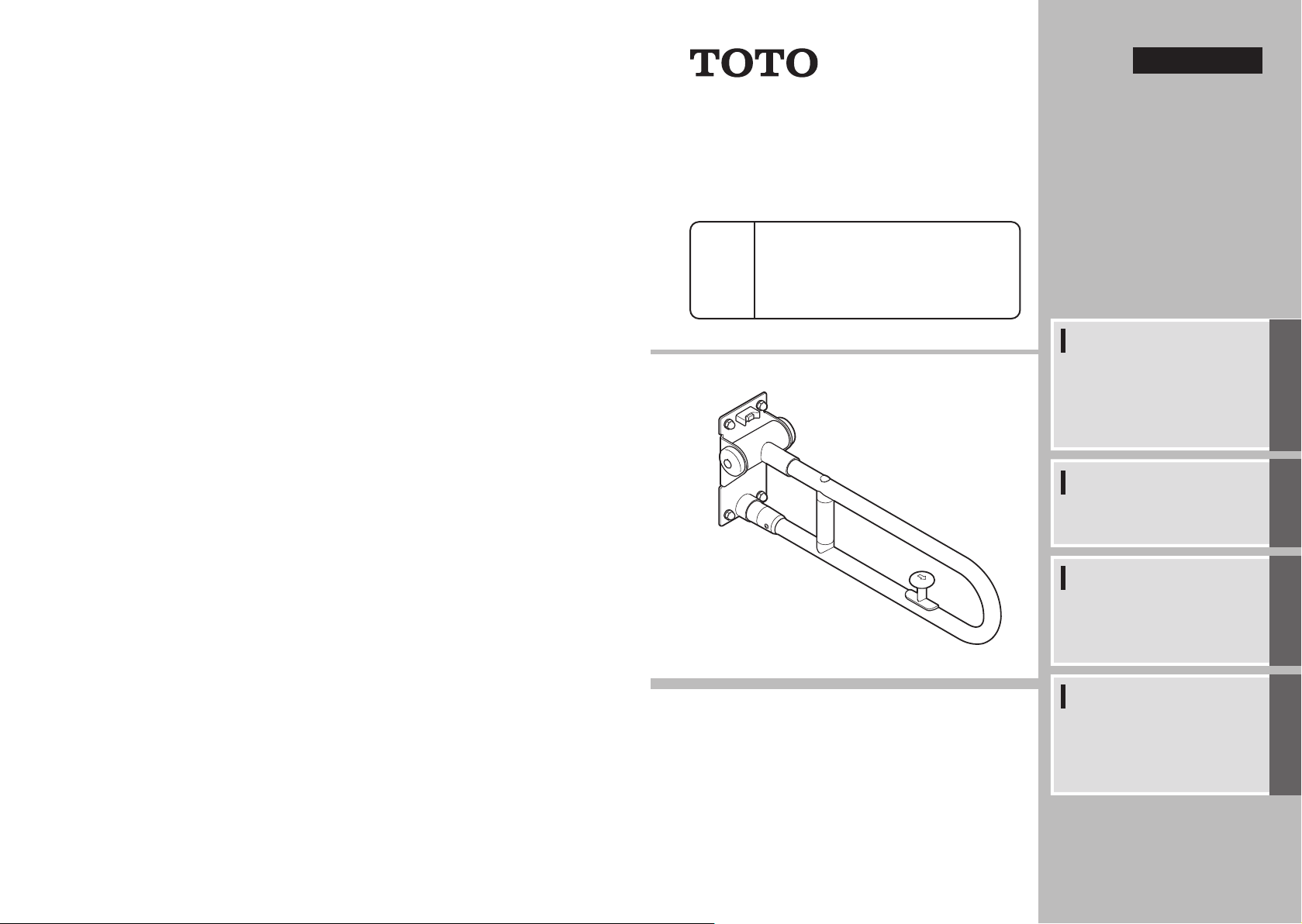

④Operation lever

③Grip bar

②Fixed part on the wall

①Grip bar

②Fixed part on the wall

Operation lever

④The operation lever won’t move. A user hits the body against the

handrail and falls, resulting in injury.

Deterioration (ageing degradation) caused by long-term use of the product may

cause safety problems. In order to prevent serious accidents due to aging

deterioration and ensure that the product can be used for a longer period of

time safely and comfortably, customers are requested to perform the following

inspections at least once a month.

If you find any problem, stop using the product and contact the installation

service shop or the sales shop where you purchased the product.

Fixed part

on the wall

Grip bar

Wall

Grip bar

No.

Inspection area, etc.

(See the figures.)

Deterioration check item

Specific phenomena expected

due to aging deterioration

(Harm information, etc.)

①

②

-

③

It has deformation or cracks.

If you shake the handrail, it rattles.

If you shake the handrail, it rattles.

The grip bar cannot lock when the handrail is

in the horizontal position.

(Applicable only to the flip-up type (lock type))

There are loose or missing screws.

(Applicable only to movable handrails)

There are cracks.

There are cracks in the wall near

the fixed part.

There is power that has come out of

the wall around the fixed part.

If you let go of the grip bar while the handrail

is moving, the handrail falls with a bang.

The grip bar flips up suddenly.

If you shake the handrail, the wall

shakes together.

The handrail gets damaged and a

user falls, resulting in injury.

The handrail comes off the wall

and a user falls, resulting in injury.

A user hits the body against the

handrail and falls, resulting in injury.

A user fails to grasp the handrail

and falls, resulting in injury.

Sign

Yes

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

No

Implement at least

once/month

The handrail comes off the wall

and a user falls, resulting in injury.

A user hits the body against the

handrail and falls, resulting in

injury.

Periodic Inspection

9

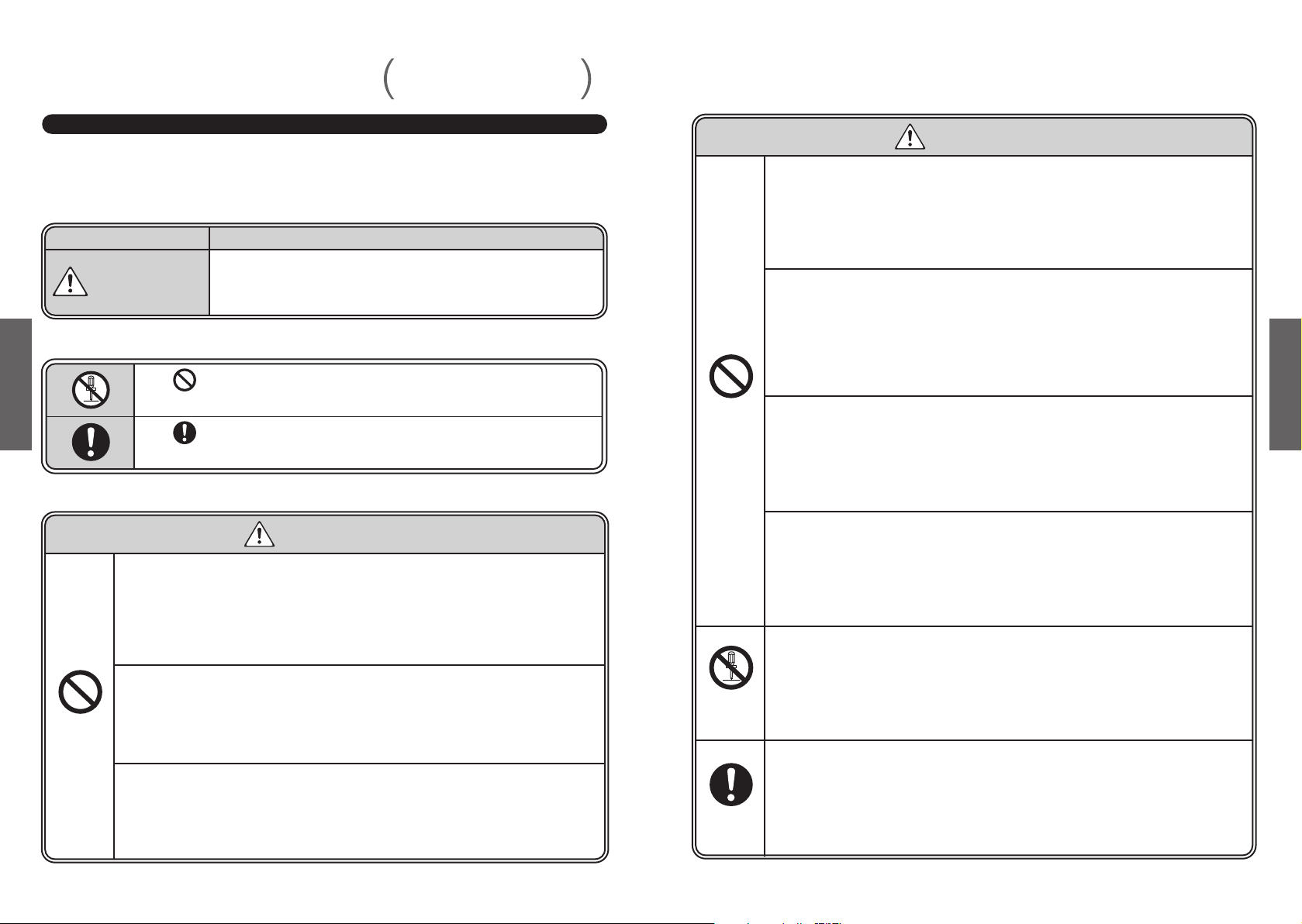

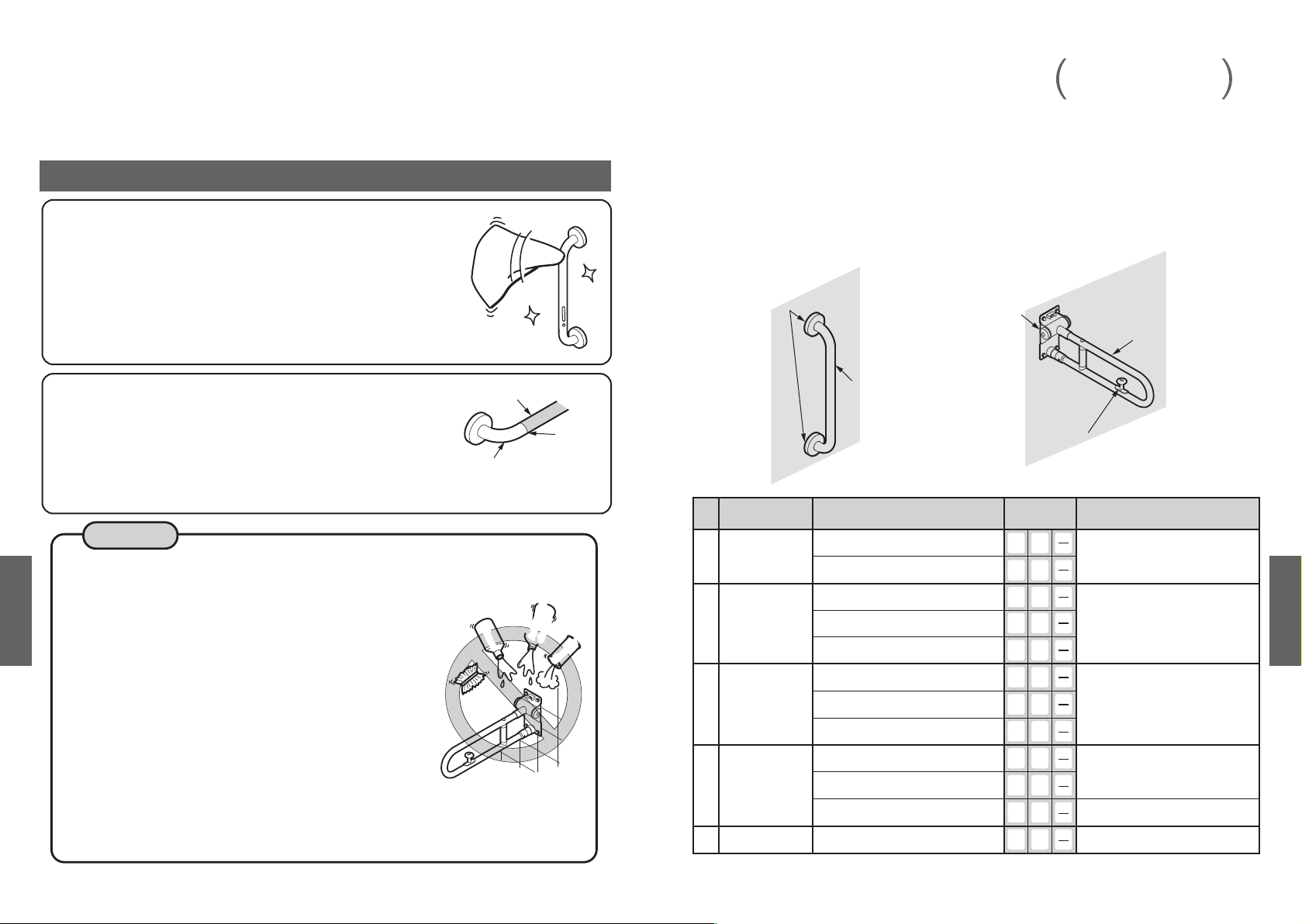

Cleaning

Resin-coated part

Juncture

Stainless steel part

Thinner

Acid/Alkaline

cleaner

Cleanser

Daily Cleaning

Please clean this product on a regular basis in order to exert its functions

sufciently and to be able to use cleanly and hygienically.

Cleaning with cloth

Request

Never use anything that can damage the surface of the product.

●Acid cleaner, chlorine bleach, alkaline cleaner, acid

disinfectant, and alkaline disinfectant

These cleaners could cause the surface of the handrail

to be discolored (including rusting) or damaged.

●Cleaners containing rough particles such as cleanser

and polishing powder

●Nylon scrubbing brush, other scrubbing brushes,

brushes, etc.

These brushes could damage the surface of the handrail.

●Medicines such as ointment, hair growing agent, hair

dye, cleansing agent, hair dressing agent, etc.

●Organic solvents such as thinner, benzine, and oils

These solvent could cause the surface of the handrail to

be discolored or rubber and resin parts to be damaged.

・ If acid or alkaline detergent, chlorine bleach, acid or alkaline disinfectant, or

organic solvent is attached to the handrail, immediately wring a cloth dampened

with water, wipe with it, and then wipe off moisture clean with a dry cloth.

●T114 type

●Normal cleaning

●Cleaning when the product is very dirty

After wetting a cloth with water or lukewarm water, wring it

out thoroughly and then use it to wipe the product.

Wipe with a cloth dampened with appropriately-diluted neutral

detergent. Then wring a cloth dampened with water and wipe

with it. After that, wipe off moisture clean with a dry cloth.

T114 type may have dust accumulated at the juncture

between the resin-coated part and stainless steel part. In

this case, soak the cotton thread with neutral detergent

and rub all the way down to the bottom of the juncture with

the thread to remove the dust.