TOUGH-WORKS SSA16V User manual

16 IN. SCROLL SAW

WITH PINLESS BLADE HOLDER

INSTRUCTION

MANUAL

IMPORTANT:

For your own safety, read and follow all of the Safety

Guidelines and Operating Instructions before operating

this product.

SSA16V

2

TABLE OF CONTENTS

SPECIFICATIONS

TABLE OF CONTENTS

BD4603

TABLE OF CONTENTS ...............................................................................................

2

SAFETY GUIDELINES ................................................................................................

5

7

PACKAGE CONTENTS ..............................................................................................

8

KEY PARTS DIAGRAN

..................................................................................................

9

ASSEMBLY/MOUNTING

........................................................................................

12

OPERATION .................................................................................................................

16

MAINTENANCE ............................................................................................................

17

TROUBLESHOOTING GUIDE .....................................................................................

18

EXPLONED VIEW .........................................................................................................

19

PARTS LIST ..................................................................................................................

22

WARRANTY ..................................................................................................................

23

ELECTRICAL SAFETY .................................................................................................

SSA16V

Input 120 VAC ,AC Only, 60Hz / 1.2 A

No Load Speed 550-1,650 r/min(RPM)

Throat

Blade Length

SPECIFICATIONS .......................................................................................................

2

16 in.

5 in.pin or plain

BD4603

SAFETY GUIDELINES

3SSA16V

SAFETY ALERT:

Precautions that involve your safety.

Indicates an imminently hazardous situation

which, if not avoided, will result in death or se-

Indicates a potentially hazardous situation

which, if not avoided, could result in death or

Indicates a potentially hazardous situation

which, if not avoided,may result in minor or

moderate injury.

Used without the safety alert symbol indic-

ates potentially hazardous situation which, if

not avoided, may result in property damage.

WARNING

DANGER!

CAUTION

!

NOTICE

PROHIBITION

WEAR EYE PROTECTION:

Always wear safety goggles or safety

glasses with side shields.

WEAR RESPIRATORY AND HEARING

PROTECTION:

Always wear respiratory

and hearing

READ AND UNDERSTAND INSTRU-

CTION MANUAL:

To reduce the risk of injury, user and all

bystanders must read and understand

instruction manual before using this

product.

KEEP HANDS AWAY FROM THE MO-

VING PART AND CUTTING SURFACE:

Failure to keep your hands away from

the moving part and cutting surface

will result in serious personal injury.

SUPPORT AND CLAMP WORK

SAFETY GUIDELINES

Your power tool and its Instruction Manual

may contain “WARNING ICONS”(a picture)

symbol intended to alert you to and/or instruct

you how to avoid a potentially hazardous co-

ndition). Understanding and heeding these

symbols will help you operate your tool better

and safer. Shown below are some of the sy-

mbols you may see.

WARNING

!!

protection.

rious injury.

serious injury.

Some dust created by power sanding, sawing,

grinding,drilling and other construction ac-

tivities contains chemicals known to the

state of California to cause cancer, birth

defects or other reproductive harm. Some

examples of these chemicals are:

Lead from lead-based paints.

Crystalline silica from bricks and cement

and other masonry products.

Arsenic and chromium from chemically-

treated lumber.

WARNING

!

Your risk from these exposures varies, depe-

nding on how often you do this type of work.

To reduce your exposure to these chemicals:

work in a well ventilated area and work with

approved safety equipment such as dust masks

that are specially designed to filter out mi-

croscopic particles. Avoid prolonged contact

with dust from power sanding, sawing, gri-

nding, drilling, and other construction activi-

ties. Wear protective clothing and wash exposed

areas with soap and water. Allowing dust to

get into your mouth, eyes, or lay on the skin

may promote absorption of harmful chemicals.

WARNING

!

To avoid electrical hazards, fire hazards or damage

to the tool, use proper circuit protection.This tool

is wired at the factory for 110-120 Volt operation.

It must be connected to a 110-120 Volt /15 Ampere

time delay fuse or circuit breaker. To avoid shock

or fire, replace power cord immediately if it is worn,

cut or damaged in any way.

Before using your tool, it is critical that you read

and understand these safety rules. Failure to follow

these rules could result in serious injury to you

or damage to the tool.

4

SSA16V

GENERAL SAFETY INSTRUCTIONS

BEFORE USING THIS POWER TOOL

Safety is a combination of common sense,

staying alert and knowing how to use your

power tool.

To avoid mistakes that could cause serious

injury, do not plug the tool in until you have

read and understood the following.

Read all instructions before operating

product.Failure to follow all instructions listed

below may result in electric shock, fire and

/or serious injury.

1. READ and become familiar with the

entire Instruction Manual. LEARN

the tool’s application, limitations and

and possible hazards.

2. KEEP GUARDS IN PLACEand in working

order.

3. KEEPWORK AREACLEAN. Cluttered

areas and benches invite accidents.

4. DO NOT USE IN DANGEROUS

ENVIRONMENTS. Do not use power tools

in damp locations, or expose them to rain

or snow. Keep work area well lit.

5. KEEP CHILDREN AWAY. All visitors and

bystanders should be kept a safe distance

from work area.

6. DO NOT FORCE THE TOOL. It will do the

job better and safer at the rate for which it

was designed.

7. WEAR PROPER APPAREL.Do not wear

loose clothing, gloves, neckties, rings,

bracelets or other jewelry which may get

caught in moving parts. Nonslip footwear

is recommended. Wear protective hair

covering to contain long hair.

8. ALWAYS WEAR EYE

PROTECTION. Any power tool can

throw foreign objects into the eyes

ALWAYS wear Safety Goggles (not

glasses) that comply with ANSI Safety

standard Z87.1. Everyday eyeglasses

have only impact–resistant lenses. They

ARE NOT safety glasses. NOTE:Glasses

or goggles not in compliance with ANSI

Z87.1 could seriously injure you when

they break.

9. WEAR A FACE MASK OR

DUST MASK.Sanding operation

produces dust.

10. DISCONNECT TOOLS FROM POWER

SOURCE before servicing, and when

changing accessories such as blades,

bits and cutters.

WARNING

!

12. USE RECOMMENDED ACCESSORIES.

Consult this Instruction Manual for

recommended accessories. The use of

improper accessories may cause risk of

injury to yourself or others.

13. NEVER STAND ON THE TOOL. Serious

injury could occur if the tool is tipped

or if the cutting tool is unintentionally

contacted.

14. MAINTAIN TOOLS WITH CARE. Keep

tools sharp and clean for best and safest

performance. Follow instructions for

lubricating and changing accessories.

and could cause permanent eye damage.

11.USE PROPER EXTENSION CORDS.

Make sure your extension cord is in

good condition.When using an extension

cord, be sure to use one heavy enough

to carry the current your product will draw.

An undersized cord will result in a drop

in line voltage and in loss of power

which will cause the tool to overheat.

The table on page 8 shows the correct

size to use depending on cord length

and nameplate ampere rating. If in

doubt, use the next heavier gauge.

The smaller the gauge number, the

heavier the cord.

15.CHECK FOR DAMAGED PARTS.

Before further use of the tool, a guard or

other part that is damaged should be

SAFETY GUIDELINES

5SSA16V

18.

Dust generated from certain materials

can be hazardous to your health. Always

operate saw in well-ventilated area and

provide for proper dust removal.

19.

People with electronic devices, such as

pacemakers, should consult their ph-

ysician(s) before using this product.

close proximity to a heart pacemakercould

cause interference or failure of the pacemaker.

20. WEAR HEARING PROTECTION

to reduce the risk of induced hearing

loss.

WARNING

!

DANGER

!

carefully checked to determine that it

will operate properly and perform its

intended function– check for alignment

of moving parts, binding of moving parts,

breakageof parts, mounting and any other

conditions that may affect its operation.

A guard or other part that is damaged

should be properly repaired or replaced.

16. NEVER LEAVE THE TOOL RUNNING

UNATTENDED. TURN THE POWER “OFF”.

Do not walk away from a running tool until

the blade comes to a complete stop and the

tool is unplugged from the power source.

17. DO NOT OVERREACH. Keep proper footing

and balance at all times.

SPECIFIC SAFETY RULES

1. FIRMLYCLAMP OR BOLT the tool to a

workbench or table at approximately hip

height.

2. KEEP HANDS AWAY FROM CUTTING AREA.

Do not reach underneath work or in blade

cutting path with hands and fingers for any

reason. Always turn the power off.

3. BE SURE THE BLADE CLEARS THE

WORKPIECE.

Never start the saw with the blade touching the

workpiece.Allow motor to come up to full speed

before starting cut.

4. MAKE SURE THE WORK AREA HAS

AMPLE LIGHTING

to see the work and that no obstructions will int-

erfere with safe operation BEFORE performing

any work using the saw.

5. ALWAYS TURN OFF THE SAW

before disconnecting it to avoid accidental starting

when reconnecting to power supply. NEVER

leave the saw unattended while connected to a

power source.

6. TURN OFF TOOL and wait for saw blade to

come to a complete stop before moving work-

piece or changing settings.

7. IF THE POWER SUPPLY CORD IS DAMAGED,

it must be replaced only by the manufacturer or

by an authorized service center to avoid risk.

8. ALWAYS SUPPORT LARGE WORKPIECES

while cutting to minimize risk of blade pinching

and kickback. Saw may slip, walk or slide while

cutting large or heavy boards.

9. SAVE THESE INSTRUCTIONS.

Refer to them frequently and use them to instruct

other users. If you loan someone this tool, loan

them these instructions also.

SAFETY GUIDELINES

6

SSA16V

ELECTRICAL SAFETY

C

EXTENSION CORDS

Use only 3-wire extension cords that have 3-prong

grounding plugs and 3-pole receptacles that accept

the tool's plug. When using a power tool at a co-

nsiderable distance from the power source, use an

extension cord heavy enough to carry the current

that the tool will draw.An undersized extension cord

will cause a drop in line voltage, resulting in a loss

of power and causing the motor to overheat. Use

the chart provided below to determine the minimum

wire size required in an extension cord. Only round

jacketed cords listed by Underwriter's Laboratories

(UL) should be used.

When working with the tool outdoors, use an ext-

ension cord that is designed for outside use. This

is indicated by the letters “W-A” or “W” on the cord’s

jacket.

Before using an extension cord, inspect it for loose

or exposed wires and cut or worn insulation.

Keep the extension cord clear of the working area.

Position the cord so that it will not get caught on

lumber, tools or other obstructions while you are

working with a power tool. Failure to do so can result

in serious personal injury.

WARNING

!

Check extension cords before each use. If da-

maged replace immediately. Never use product

with a damaged cord since touching the damaged

area could cause electrical shock resulting in serious

injury.

This product is powered by a precision built electric

motor. It should be connected to a power supply

that is 120 V, AC only (normal household current),

60 Hz. Do not operate this product on direct current

(DC). A substantial voltage drop will cause a loss

WARNING

!

ELECTRICAL CONNECTION

of power and the motor will overheat. If the

saw does not operate when plugged into an

outlet, double check the power supply.

SPEED AND WIRING

The no-load speed of this tool is approximately

1,600 spm. This speed is not constant and

decreases under a load or with lower voltage.

For voltage, the wiring in a shop is as important

as the motor’s horsepower rating. A line intended

only for lights cannot properly carry a power

tool motor. Wire that is heavy enough for a short

distance will be too light for a greater distance. A

line that can support one power tool may not be

able to support two or three tools.

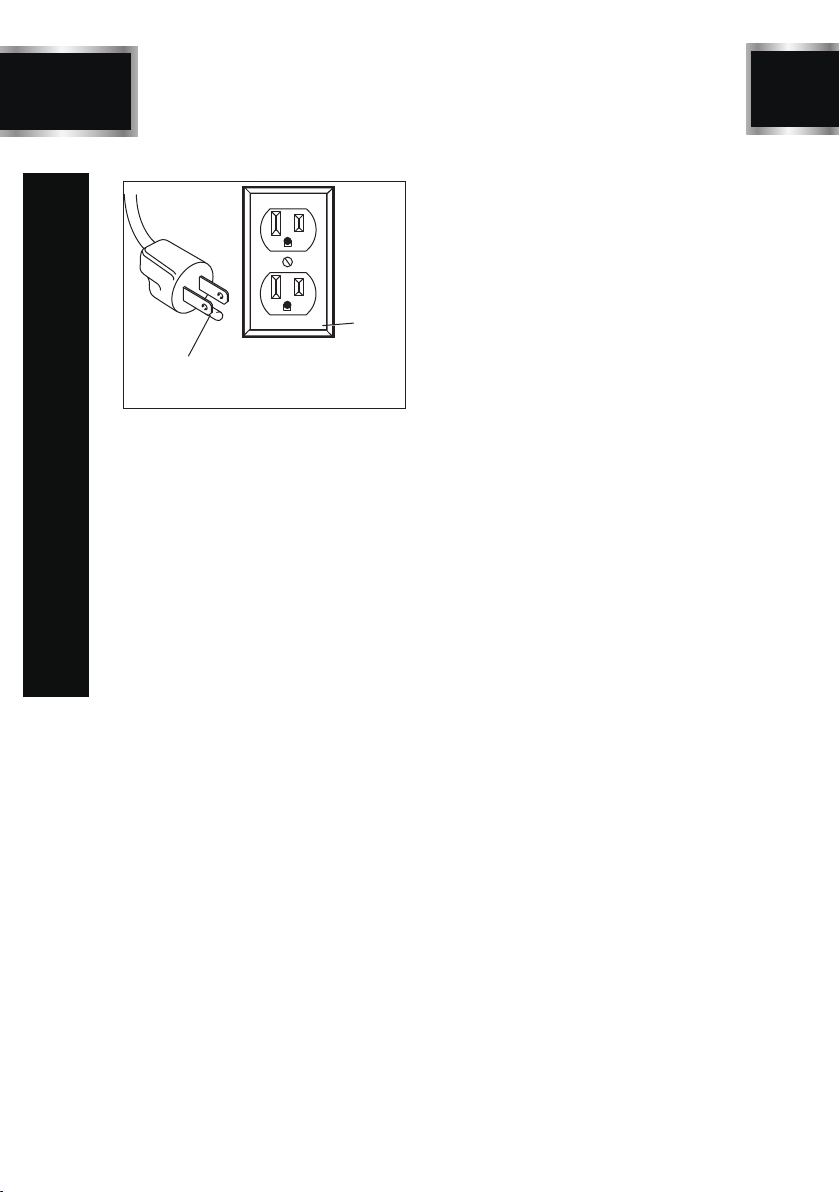

GROUNDING INSTRUCTIONS

This product must be grounded. In the event

of a malfunction or breakdown, grounding pr-

ovides a path of least resistance for electric

current to reduce the risk of electric shock. This

tool is equipped with an electric cord having

an equipment-grounding conductor and a

grounding plug.The plug must be plugged into

a matching outlet that is properly installed and

grounded in accordance with all local codes and

ordinances.

Do not modify the plug provided. If it will not

fit the outlet, have the proper outlet installed

by a qualified electrician.

Improper installation of the grounding plug can

result in a risk of electric shock. When repair

or replacement of the cord is required, do not

connect the grounding wire to either flat blade

terminal. The wire with insulation having an outer

surface that is green with or without yellow

stripesis the grounding wire.

Check with a qualified electrician or service

personnel if the grounding instructions are

not completely understood, or if in doubt as

to whether the tool is properly grounded.

Repair or replace a damaged or worn cord

immediately.

This product is for use on a nominal 120 volt

circuit and has a grounding plug similar to

the plug illustrated in figure 1.

WARNING

!

**Ampere rating (on tool faceplate)

0-2.0 2.1-3.4 3.5-5.0 5. 1-7.0 7. 1-12.0 12.1-16.0

Cord Length Wire Size (A.W.G.)

25' 16 16 16 16 14 14

50' 16 16 16 14 14 12

100' 16 16 14 12 10 —

**Used on 12 gauge - 20 amp circuit.

NOTE: AWG = American Wire Gauge

7SSA16V

ELECTRICAL SAFETY

A

B

Figure1

Grounding pin

Ground fault

outlet

8

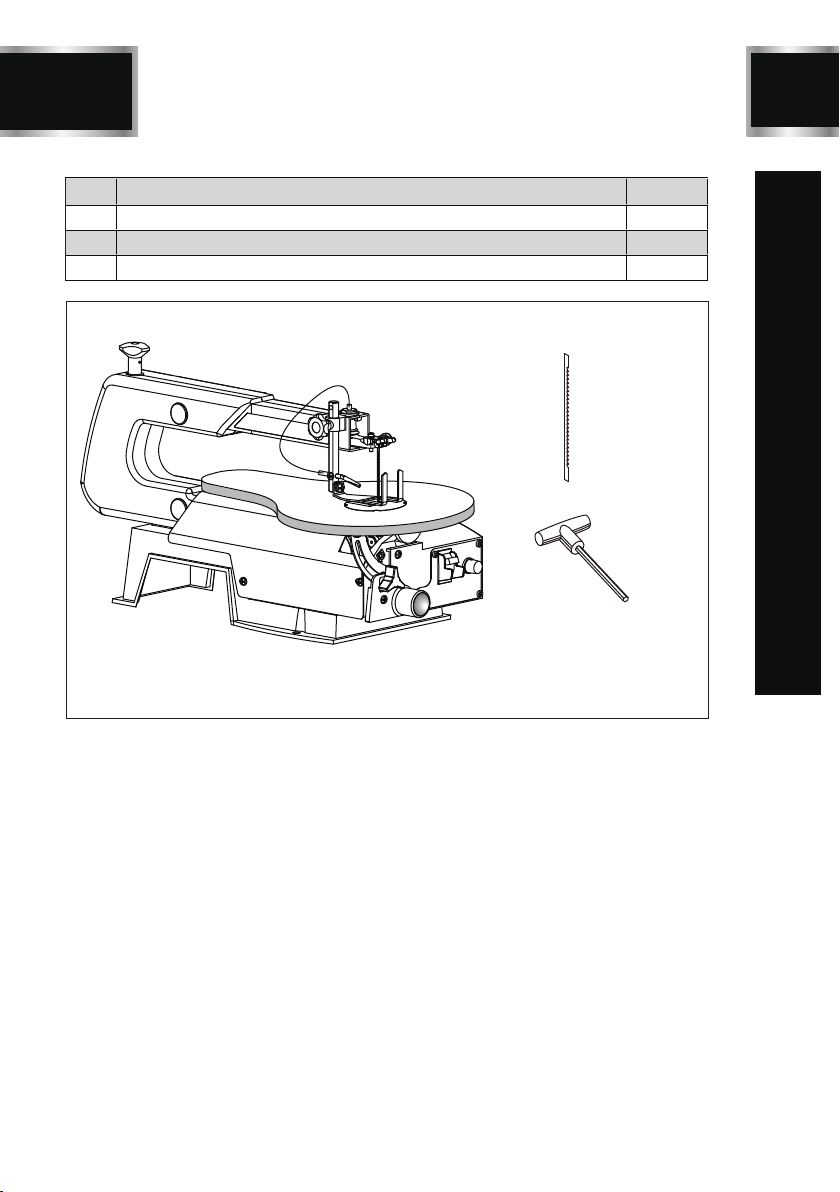

SSA16V

1

2

3

No. Description Qty.

1Scroll saw 1

2Blade(s) 1

3T-handle hex key 1

PACKAGE CONTENTS

BD4603

9SSA16V

KEY PARTS DIAGRAN

J

B

N

C

A

H

G

F

E

I

D

K

L

M

A - Blade tension knob

B - Drop foot lock knob

C- Saw dust blower

D- Saw blade

E - Saw table

F - Throat plate

G- Variable speed knob

H- Switch and switch key

I- Sawdust exhaust

J - Bevel lock knob

K - Bevel scale

L - Drop foot

M- Blade(s)

N- T-handle hex key

10

SSA16V

ASSEMBLY/ MOUNTING

Do not use this product if any parts on

the Loose Parts List are already asse-

mbled to your product when you unpack

it. Parts on this list are not assembled

to the product by the manufacturer and

require customer installation.Use of a

product that may have been improperly

assembled could result in serious per-

sonal injury.

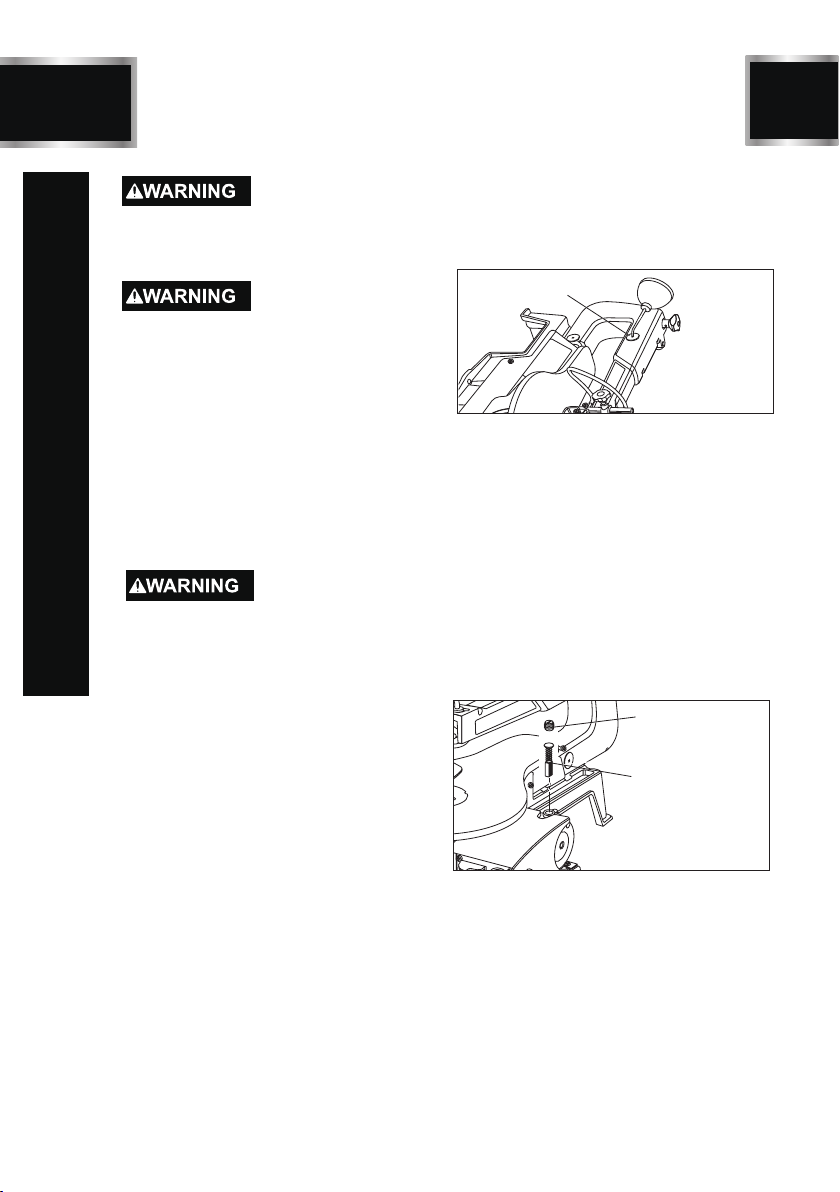

MOUNTING SCROLL SAW TO WORKBENCH

If the scroll saw is to be used in a permanent appli-

cation, we recommend that you secure it in a

permanent location such as a workbench. When

mounting the saw to a workbench, holes should

be drilled through the supporting surface of the

workbench.

Each hole in the base of the saw should be bolted

securely using machine bolts, washers, and nuts

(not included). Bolts should be of sufficient length

to accommodate the saw base,washers,nuts, and

the thickness of the workbench.

Place scroll saw on workbench. Using the saw

base as a pattern, locate and mark the holes

where the scroll saw is to be mounted.

Drill four holes through the workbench.

Place scroll saw on workbench aligning holes in

the saw base with the holes drilled in the wor-

kbench.

Insert all four bolts (not included) and tighten

securely with washers and nuts (not included).

●

●

●

●

NOTE: All bolts should be inserted from the top.

Install the washers and nuts from the underside

of the bench.

Supporting surface where scroll saw is mounted

should be examined carefully after mounting to

insure that no movement during use can result.

If any tipping or walking is noted, secure workbe-

nch or supporting surface before beginning cutting

operations.

CLAMPING SCROLL SAW TO WORKBENCH

(In Figure 2)

If the scroll saw is to be used in aportable appli-

cation, it is recommended that you fasten it perma-

nently to a mounting board that can easily be cla-

Mount saw to board using holes in saw base as a

template for hole pattern. Locate and mark the

holes where scroll saw is to be mounted.

Follow last three steps in previous section called

“Mounting Scroll Saw to Workbench”.

If lag bolts are being used, make sure they are long

enough to go through holes in the saw base and

the material the saw is being mounted to.

If machine bolts are being used, make sure they

are long enough to go through holes in the saw

base,the material the saw is being mounted to,and

the washers and nuts.

mped to a workbench or other supporting surface.

The mounting board should be of sufficient size to

avoid tipping of saw while in use. Any good grade

plywood or chipboard with a 3/4 in. thickness is re-

commended.

4.Mounting board

1.

2.Saw base

3. Workbench

C-clamp

1.C-clamp

Figure2

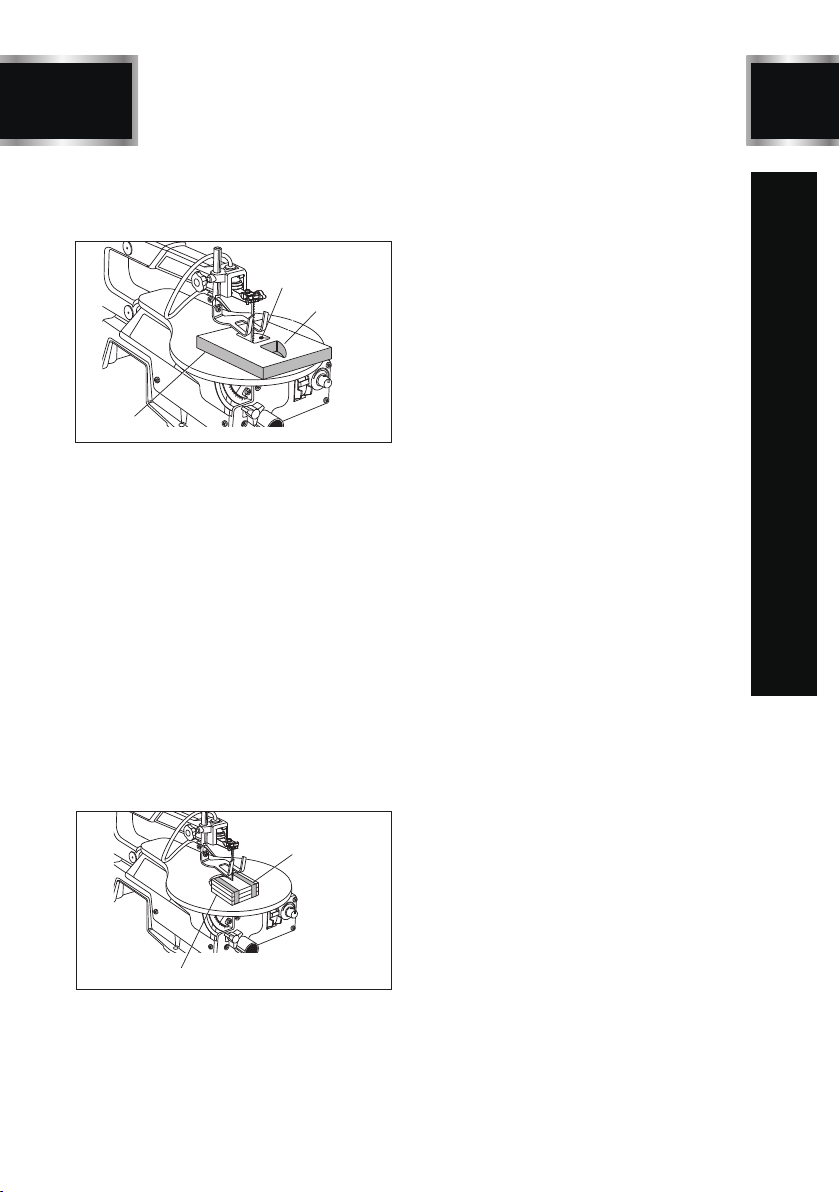

SAWDUST BLOWER(In Figure3)

●

The sawdust blower is designed and preset to

direct air to the most effective point on the cutting

line. Be sure drop foot is properly adjusted to

secure workpiece and direct air to the cutting

surface.

Plastic tubing should be connected to the bellows

tube before starting the saw.

3. Bellows tube

1. Sawdust blower

2. Plastic

tubing

4. Drop foot

5.Drop foot lock knob

Figure3

11

ASSEMBLY/ MOUNTING

SSA16V

DROP FOOT (In Figure 3)

To prevent workpiece from lifting, the drop

foot should be adjusted so it just rests on the

top of the workpiece. The drop foot should

not be adjusted so that the workpiece drags.

Always retighten the drop foot lock knob after

each adjustment has been made.

The tall, front part of the drop foot acts as a

blade guard to prevent accidental contact

with the blade.

Loosen the drop foot lock knob.

Lower or raise the drop foot to the desired

position.

Retighten the drop foot lock knob.

●

●

●

SQUARING THE SAW TABLE TO THE BLADE

(In Figure 4-5)

2.Drop foot

3.Drop foot rod

5. Table lock knob

1.Drop foot

lock knob

4.

Combination

square

Figure4

Loosen the drop foot lock knob and move

drop foot rod all the way up. Retighten drop

foot lock knob.

Loosen the table lock knob to tilt the saw

table until it is approximately perpendicular

or at right angle to the blade.

Place a small square on the saw table next

to the blade.

Loosen the screw holding the scale indicator.

Move indicator to the 0° mark and securely

tighten screw. Remember, the bevel scale

is a convenient guide but should not be relied

upon for precision. Make practice cuts on

scrap material to determine if your angle

settings are correct.

Adjust the drop foot to desired position and

securely retighten the drop foot lock knob.

●

●

●

●

●

45

30

15

0

ON

OFF

1. Bevel

scale

2. Scale

indicator

3. Table lock knob

4. Screw

Figure5

A bevel scale is located under the saw table

as a convenient guide for setting the app-

roximate saw table angle for bevel cutting.

When greater precision is required, make

practice cuts on scrap material and adjust

the saw table as necessary for your requi-

rements.

SETTING THE TABLE FOR HORIZONTAL

OR BEVEL CUTTING(In Figure 5)

NOTE: When cutting at angles, the drop foot

should be tilted so it is parallel to the saw

table and rests flat against the workpiece.

To tilt the drop foot, loosen phillips screw,

tilt drop foot to the proper angle, then ret-

ighten screw.

Loosen the drop foot lock knob.

Center the drop foot around the saw blade

to the desired position.

Tighten the drop foot lock knob.

●

●

●

ADJUSTING BLADE TENSION(In Figure 6)

1.To tighten

(pour serrer, para

apretar)

Blade tension knob

To loosen

Figure6

Turning the blade tension knob counterclo-

ckwise decreases (or loosens) blade tension.

Turning the blade tension knob clockwise

increases (or tightens) blade tension.

●

●

12

SSA16V

ASSEMBLY/ MOUNTING

NOTE: Adjustments to blade tension can be

made at any time.Check tension by the sound

the blade makes when plucked like a guitar

string. This method of adding tension to the blade

can be developed with practice and requires

knowing the scroll saw.

Pluck the back straight edge of blade while turning

tension adjusting knob. Sound should be a

musical note.Sound becomes less flat as tension

increases. Sound decreases with too much tension.

●

NOTE: Be careful not to adjust blade too tight.

Too much tension may cause the blade to break as

soon as you start cutting. Too little tension may

cause the blade to bend or break before the teeth

wear out.

BD4603

13

OPERATION

SSA16V

Do not allow familiarity with products to make

you careless. Remember that a careless fra-

ction of a second is sufficient to inflict serious

injury.

Always wear eye protection with side shields

marked to comply with ANSI Z87.1. Failure to do

so could result in objects being thrown into your

eyes, resulting in possible serious injury.

Do not use any attachments or accessories not

recommended by the manufacturer of this prod-

uct. The use of attachments or accessories not

recommended can result in serious personal

injury.

APPLICATIONS

You may use this product for the following

purposes:

Cutting wood, wood composition products,

plastic, and other fibrous material up to 2 in.

thick

●

BASIC OPERATION OF THE SCROLL SAW

Before starting a cut, watch the saw run.If you

experience excessive vibration or unusual noise,

stop immediately.Turn the saw off ,remove the

switch key, and unplug the saw. Do not restart

until locating and correcting the problem.

NOTE: After the saw is turned ON, a hesitation

before blade movement is normal.

CUTTING PROCEDURES

There is a learning curve for each person who

wants to use this saw. During that period of

time it is expected that some blades will break

until you learn how to use and adjust the saw.

Plan the way you will hold the workpiece from

start to finish.

Keep your hands away from the blade.Do not

hand hold pieces so small your fingers will

go under the blade guard.

Hold the workpiece firmly against the saw

table.

●

●

●

●

The blade teeth cut material only on the down

stroke.

Use gentle pressure and both hands when

feeding the work into the blade. Do not force

the work.

Guide the workpiece into the blade slowly be-

cause the teeth of the blade are very small and

can only remove material on the down stroke.

●

●

●

Avoid awkward operations and hand positions

where a sudden slip could cause serious injury

from contact with the blade. Never place hands

in blade path.

To get accurate cuts,compensate for the blade’s

tendency to follow the wood grain as you are

cutting wood.

Use extra supports (tables, saw horses, blocks,

etc.) when cutting large, small or awkward wor-

kpieces.

Never use another person as a substitute for

a table extension or as additional support for

a workpiece that is longer or wider than the

basic saw table.

When cutting irregularly shaped workpieces,

plan your work so it will not pinch the blade.

Workpieces must not twist, rock or slip while

being cut.

●

●

●

●

●

REMOVING JAMMED MATERIAL

When backing out the workpiece, the blade may

bind in the kerf (cut). This is usually caused by

sawdust clogging the kerf or when the blade

comes out of the blade holders. If this happens:

Wait until the saw has come to a full and co-

mplete stop.

Place the switch in the OFF position, remove

the switch key from the switch assembly.Store

key in a safe place.

Unplug the saw from the power source.

Remove the saw blade and the workpiece, see

section on Installing and Removing the Blades.

Wedge the kerf open with a flat screwdriver or

wooden wedge then remove the blade from the

workpiece.

●

●

●

●

Before removing loose or jammed pieces from the

table, turn saw off and wait for all moving parts to

stop to avoid serious personal injury.

14

SSA16V

OPERATION

AVOIDING INJURY

Make sure saw is level and does not rock. Saw

should always be on a firm, level surface with

plenty of room for handling and properly sup-

porting the workpiece.

Bolt saw to the support surface to prevent slip-

ping, walking or sliding during operations like

cutting long, heavy boards.

Turn saw off, remove switch key, and unplug

cord from the power source before moving the

saw.

Do not remove jammed cutoff pieces until blade

has come to a full and complete stop.

Choose the right size and style blade for the

material and type of cut you plan to do.

Use only recommended accessories.

With the exception of the workpiece and related

support devices, clear everything off the saw

table before turning the saw on.

Properly support round materials such as dowel

rods or tubing because they have a tendency

to roll during a cut causing the blade to “bite.”

To avoid this, always use a “V” block or clamp

workpiece to a miter gauge.

Before removing loose pieces from the saw table,

turn saw off and wait for all moving parts to stop.

●

●

●

●

●

●

●

●

●

●

LOCKING THE SWITCH(In Figure 7)

Wait until the saw has come to a full and co-

mplete stop.

Place the switch in the OFF position, then remove

the switch key from the switch assembly. Store

key in a safe place.

●

●

Switch on

Switch off

Switch key removed

Figure7

INSTALLING AND REMOVING BLADES

(In Figure 8)

Scroll saw blades wear out quickly and must be

replaced frequently for best cutting results. Ex-

pect to break some blades while you learn to

use and adjust the saw. Blades generally stay

sharp for 1/2 hour to 2 hours of cutting, dep-

ending on the type of material and speed of

operation.

Throat plate

Drop foot lock knob

Blade clamp screw

Blade clamp screw

Saw blade

Saw blade

Figure8

REMOVING THE SAW BLADE

Turn off and unplug the saw from the power

source.

Turn blade tension knob counterclockwise to

decrease (or loosen) blade tension.

Pushing up from under the saw table, remove

the throat plate.

Loosen both the upper and lower blade clamp

screws.

Pull up on the blade and push down on the saw

arm to disengage the upper pin in the V-notch

of the upper blade holder. Push the blade do-

wnward to disengage the lower pin in the V-

notch of the lower blade holder.

Remove the blade.

●

●

●

●

●

●

PIN END BLADES

Turn off and unplug the saw from the power

source.

Remove the blade.

Place the new blade through the opening in

the saw table with the teeth to the front of the

saw and pointing down toward the saw table.

The pins on the blade go under the blade holder

in the V-notch of the lower blade holder.

Pull up on the blade and press the upper arm

down to position the upper end of the blade in

the V-notch in the upper blade holder.

Securely tighten the upper and lower blade

clamps by tightening the blade clamp screws.

●

●

●

●

●

●

BD4603

15

OPERATION

SSA16V

NOTE: If the blade touches the drop foot on either

side then the drop foot must be adjusted. See se-

ction on “Drop Foot.”

Turn the blade tension knob clockwise until the

blade has the desired amount of tension.

Replace the throat plate.

●

●

PLAIN END BLADES

Turn off and unplug the saw from the power

source.

Remove the blade.

Place the new blade through the opening in the

saw table with the teeth to the front of the saw

and pointing down toward the saw table.

Position blade in the lower blade holder and

tighten the blade clamp screw securely.

Press the upper arm down to position the upper

end of the blade in the upper blade holder.

Securely tighten the upper blade clamp screw.

Turn the blade tension knob clockwise until the

blade has the desired amount of tension.

Replace the throat plate.

●

●

●

●

●

●

●

NOTE:If the blade touches the drop foot on either

side then the drop foot must be adjusted. See

section Drop Foot.

BLADE INFORMATION

Scroll saw blades wear out and must be repla-

ced frequently for best cutting results. Scroll

saw blades generally stay sharp for 1/2 hour to

2 hours of cutting, depending on type of ma-

terial and speed of operation.

In cutting wood, best results are achieved when

cutting wood less than one inch thick.

When cutting wood thicker than one inch, the

user must guide the workpiece very slowly into

the blade and take extra care not to bend or

twist the blade while cutting.

When choosing a blade, carefully consider the

following:

1)Very fine, narrow blades should be used to

scroll cut in thin material 1/4 in. thick or less.

2)Most blade packages state the size or thic-

kness and type of material which that blade is

intended to cut.The package should also state

the radius or size of curve that can be cut with

that blade size.

3)Wider blades cannot cut curves as tight or

as small as thinner blades.

●

●

●

●

●

Blades wear faster when:

1)Cutting plywood, hardwood, and other la-

minates.

2)Cutting material thicker than 3/4 in.

3)Side pressure is applied to the blade.

●

CHOICE OF BLADE AND SPEED

The scroll saw accepts a wide variety of blade wi-

dths and thicknesses for cutting wood and other

fibrous materials. The saw uses 5 in. long blades

of either the pin end or the plain end style.The blade

width and thickness and the number of teeth per

inch to use are determined by the type of material

and the size of the radius being cut.

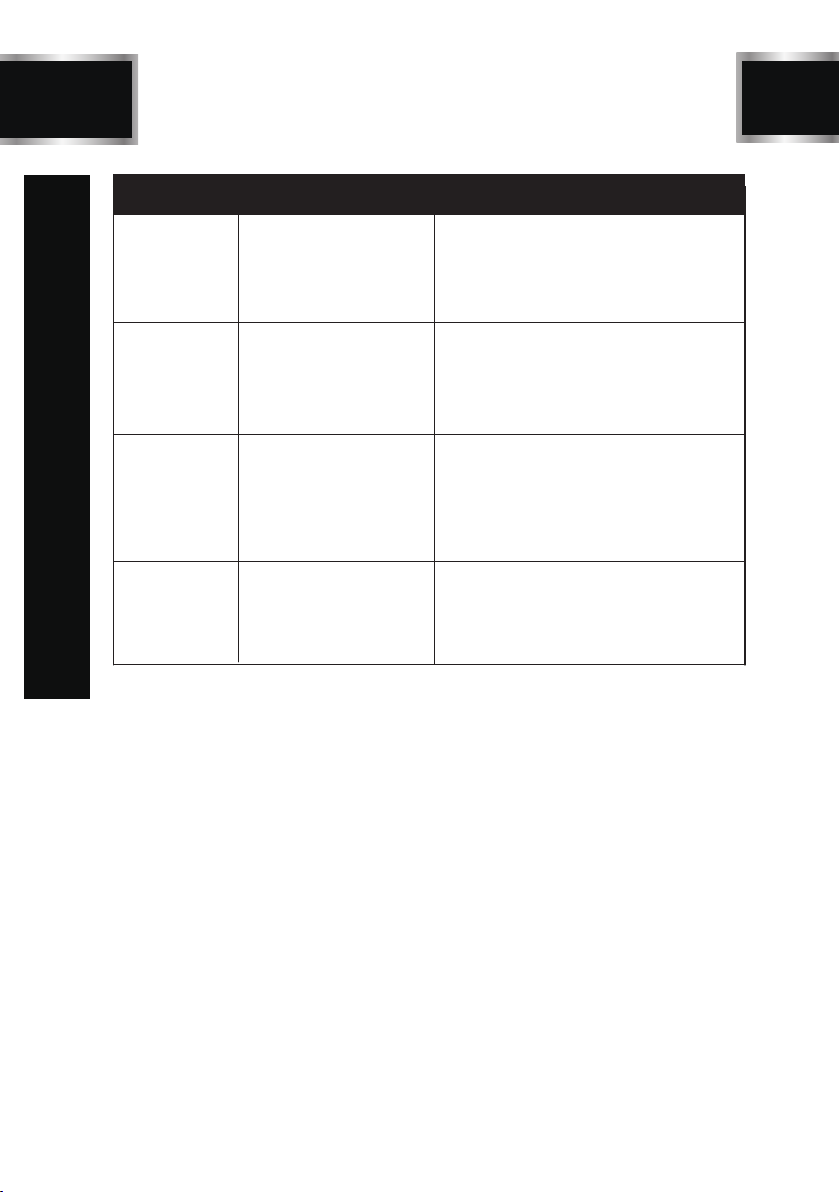

Teeth/Inch Width Thickness Speed or

Strokes Per Minute

Material Cut

10 .110 in. .020 in. 1,200 - 1,600

15 .110 in. .020 in. 600 - 1,200

18 .095 in. .010 in. 550 - 600

Popular size for cutting

hard and soft woods 3/16

in. up to 2 in. Plastics,

paper, felt, bone, etc.

Wood,plastics, extremely

thin cuts on materials 3/32

in.to 1/2 in. thick.

For tight radius work in

thin materials 3/32 in. to

1/8 in. Wood, veneer,bone,

fiber, ivory, plastic, etc.

USING VARIABLE SPEED(In Figure 9)

45

30

15

0

ON

OFF

1.Variable speed knob

2.To increase

(pour augmenter,

para aumentar)

3.To decrease

(pour réduire, para

disminuir)

By turning the variable speed knob, the saw’s

speed may be adjusted from a high speed of

approximately 1,650 SPM (Strokes Per Minute)

to a low speed of approximately 550 SPM.

To increase the strokes per minute, turn the va-

riable speed knob clockwise or to the right.

To decrease the strokes per minute,turn the va-

riable speed knob counterclockwise or to the left.

●

●

●

Figure9

SCROLL CUTTING

For general type scroll cutting, follow the pattern

lines by pushing and turning the workpiece at the

same time. Do not try to turn the workpiece while

16

BD4603

3. Workpiece

1.Arm bearing

INTERIOR SCROLL CUTTING(In Figure 10)

engaged in the blade without pushing it – the

workpiece could bind or twist the blade.

SSA16V

0

30

15

L

1.

Drill hole

(percer un trou, taladrar

agujero)

Figure10

2.Interior cut

One feature of a scroll saw is that it can be used

to make scroll cuts on the interior of a workp-

iece without breaking or cutting through the

edge or perimeter of the board.

To make interior cuts in the workpiece,remove

the scroll saw blade as explained in the section

on Installing and Removing Blades.

Drill a 1/4 in. hole in the workpiece.

Place the workpiece on the saw table with the

drilled hole over the access hole in the table.

Install blade through the hole in the workpiece;

adjust the drop foot and blade tension.

When finished making the interior scroll cuts,

simply remove the blade from the blade hold-

ers as described in the section on Installing

and Removing Blades and remove the work-

piece from the saw table.

●

●

●

●

●

●

STACK CUTTING(in Figure 11)

0

30

15

L

2.lMotor brush Figure11

After becoming well acquainted with the saw

through practice and experience, you may

wish to try stack cutting. Stack cutting may

be used when several identical shapes need

to be cut. Several pieces of wood may be st-

acked on top and secured to each other before

cutting. The wood pieces may be joined to-

gether by placing double sided tape between

each piece or by wrapping masking tape

around the corners or ends of the stacked

wood. You must attach the stacked pieces

of wood to each other so they will move on

the table as a single piece of material.

OPERATION

BD4603

17

MAINTENANCE

SSA16V

When servicing, use only identical replace-

ment parts. Use of any other parts can create

a hazard or cause product damage.

Always wear eye protection with side shields

marked to comply with ANSI Z87.1. Failure

to do so could result in objects being thrown

into your eyes, resulting in possible serious

injury.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic

parts. Most plastics are susceptible to dam-

age from various types of commercial solvents

and may be damaged by their use. Use clean

cloths to remove dirt, dust, oil, grease, etc.

Do not at any time let brake fluids, gasoline,

petroleum-based products, penetrating oils,etc.,

come in contact with plastic parts. Chemicals

can damage, weaken, or destroy plastic which

could result in serious personal injury.

Keep the saw clean.

After cleaning the table top initially, apply a

thin coat of automobile type (paste) wax to

the table top so the wood slides easily while

cutting.

Do not allow pitch to accumulate on the saw

table. Clean with gum and pitch remover. Do

not use gasoline.

●

●

●

Electric tools used on fiberglass material, wa-

llboard, spackling compounds, or plaster are su-

bject to accelerated wear and possible prem-

ature failure because the fiberglass chips and

grindings are highly abrasive to bearings, brushes,

commutators, etc. Consequently, we do not

recommended using this product for extended

work on these types of materials. However, if

you do work with any of these materials, it is

extremely important to clean the product using

compressed air

ARM BEARINGS(In Figure 12)

Lubricate the arm bearings after the first 10

hours of use. Oil after every 50 hours of use

or whenever there is a squeak coming from

the bearings.

0

30

15

L

Figure12

1.Arm bearing

(roulement du bras,

cojinete del brazo)

Carefully place the saw on its side as shown.

Remove the rubber cap from the upper and

the lower arm of the saw.

Squirt a few drops of SAE20 oil around the

shaft end and arm bearings. Let oil soak in

overnight, remaining in this position.

●

●

NOTE: Lubricate the bearings on the other side

of the saw in this same manner.

MOTOR BRUSHES(In Figure 13)

The saw has externally accessible motor brush

assemblies that should be checked periodically

for wear. When one of the two brushes becomes

worn, replace both brushes.

Unplug the saw from the power source.

Carefully place the saw on its side exposing

the underside of the saw housing.

Using aflat blade screwdriver,remove the bottom

brush assembly cap through the access hole

in the base and the top brush assembly cap

from the top of the motor. Gently pry the brush

assemblies out using a small screwdriver, point

of a nail, or paper clip.

If one motor brush is worn down shorter than

1/4 in. (6 mm), replace both motor brushes.

Figure13

2.Motor brush

(charbon de moteur,

escobilla del motor)

1.Brush cap (bouchon

de porte-charbon, tapa

de la escobilla)

●

●

●

●

18

Problem Likely Solutions

Motor will not run

Blades breaking

Vibration

(there is always some

vibration when the

saw is running)

Problem Possible Causes Likely Solutions

SSA16V

TROUBLESHOOTING

Problem with ON-OFF switch,

power cord, or outlet.

Motor defective.

Have worn parts replaced before using scroll saw

again. Have the proper outlet installed by a qualified

electrician.

Do not attempt any repair. Have repaired by a

qualified service technician.

Too much tension.

Feeding too quickly.

Wrong blade.

Blade twisting in wood.

Adjust tension.

Reduce feed rate.

Narrow blades for cutting thin wood or tight corners

and turns, wide blades for thicker wood or wide turns.

Reduce side pressure on blade; check blade tension.

Improper mounting of saw.

Mounting surface.

Loose table or table resting

against motor.

Loose motor mounting.

Check mounting.

Check mounting in manual.

Tighten table lock knob.

Tighten mounting screws.

Blade runout

(blade not properly

aligned with arm

motion)

Blade holders out of line. Realign blade.

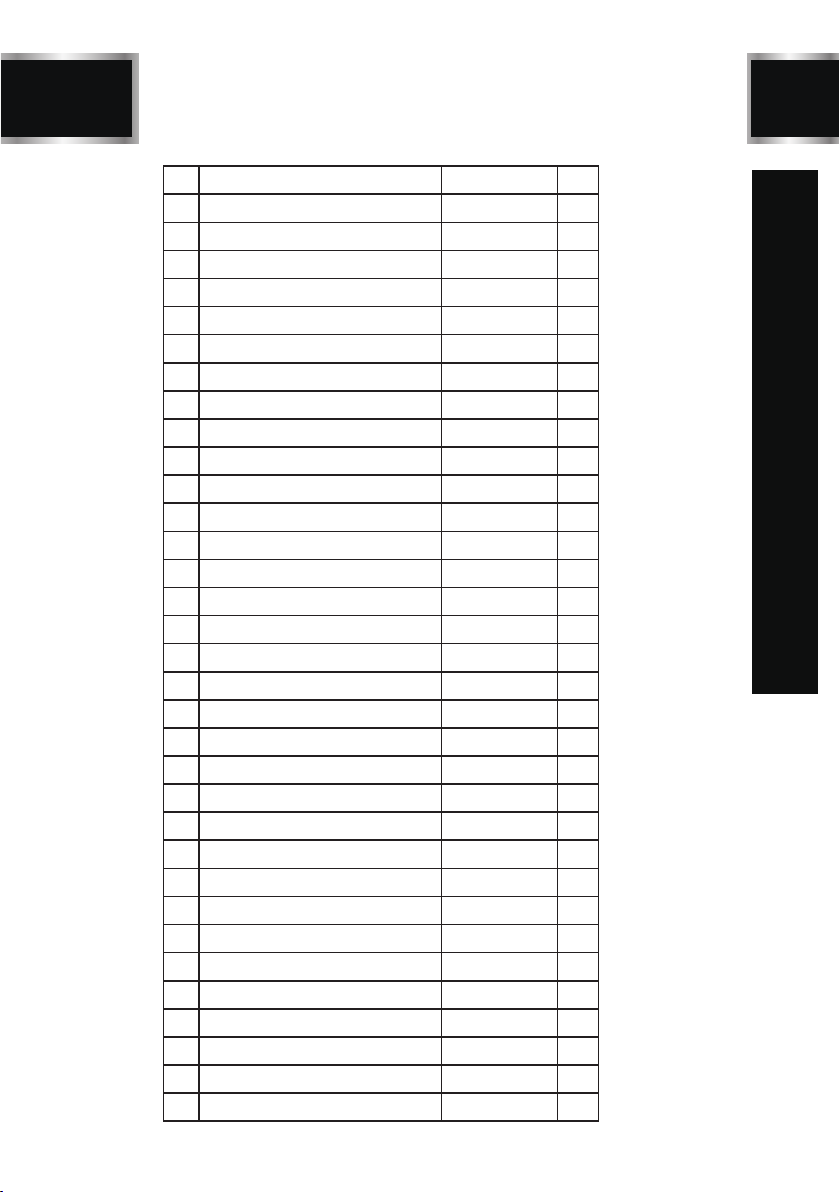

EXPLODED VIEW

BD4603

19 SSA16V

20

BD4603

SSA16V

PARTS LIST

Hose

57 Big flat washer Washer 6

58 Compression spring 65Mn 1

Item Description Specification Qty

Item Description Specification Qty

1 Philips Screw M5X8 2

41 Eccentric connector plate Q235 1

2 Handle ABS 1

42 Philps screw ST4.2X9.5 5

3 Side Cover Q235 1

43 Small spacer Powder metal 1

4 Hex nut, I type M6 5

44 Hex screw+spring washer M5X16 1

5 Spring washer Washer 6 4

45 L wrench S3 1

bonkratS64

1051THesaB6

7 Dust cap NR 4

47 Drop foot guide post 45 1

8 Left Arm housing ZL105 1

48 Philips Screw+spring washer M5X30 2

9 Tension lever assembly 1

49 Circuit Board E 1

toofporD05

1nM56gnirpS01

rehsawtalF15

2etalP11

12 Spring washer Washer 4 1

52 Philips Screw+spring washer M6X10 1

13 Hex screw+spring washer M4X10 2

53

14 Lower Arm ZL105 1

54 PVC bushing Washer 6 1

15 Upper Arm ZL105 1

55 Hex screw M6X40 1

hsawgnirps+tlobxeH65

4gniraebeveelsliO61

17 Air Nozzle Q235 1

18 Philips Screw M5X6 1

19 Right Arm housing ZL105 1

59 Hex screw M6X

20 Spring washer Washer 5 2

60 Table Mounting Bracket HT150 1

retnioP16

553X5Mrehsawgnirps+wercSspilihP12

22 Spring Washer 5 1

62 Miter Gauge Q235 1

23 Bellow Cover ABS 1

63 Work Table ZL105 1

24 Philips Screw+spring washer M5X28 1

64 Table insert ABS 1

25 Locking knob ABS 1

65 Variable speed Knob ABS 1

26 Switch box cover ABS 1

66 Hex screw M5x6 1

drocrewoP76

17YHhctiwS72

awtalf+wercSspilihP86

1RNwolleB82

29 Mounting Plate Q235 2

69 Hex screw M8X12 1

30 Carriage screw M6X20 4

70 Eccentric counter wheel Powder metal 1

rotoM17

1troppusedalBreppU13

32 Locking washer Washer 4 4

72 Switch Box ABS 1

33 Hex Screw M4X16 2

73 Cord Clip 6P-4(certificate) 1

1 Philips Screw M5X8 2 41 Eccentric connector plate Q235 1

2 Handle ABS 1 42 Philps screw ST4.2X9.5 5

3 Side Cover Q235 1 43 Small spacer Powder metal 1

4 Hex nut, I type M6 5 44 Hex screw+spring washer M5X16 1

5 Spring washer Washer 6 4 45 L wrench S3 1

HesaB6

7 Dust cap NR 4 47 Drop foot guide post 45 1

8 Left Arm housing ZL105 1 48 Philips Screw+spring washer M5X30 2

9 Tension lever assembly 1 49 Circuit Board E 1

gnirpS01

etalP11

12 Spring washer Washer 4 1 52 Philips Screw+spring washer M6X10 1

13 Hex screw+spring washer M4X10 2 53

14 Lower Arm ZL105 1 54 PVC bushing Washer 6 1

15 Upper Arm ZL105 1 55 Hex screw M6X40 1

gniraebeveelsliO61

Air Nozzle Q235

Philips Screw M5X6

19 Right Arm housing ZL105 1 59 Hex screw M6X

20 Spring washer Washer 5 2 60 Table Mounting Bracket HT150 1

rehsawg

nirps+wercSspilihP12

23 Bellow Cover ABS 1 63 Work Table ZL105 1

24 Philips Screw+spring washer M5X28 1 64 Table insert ABS 1

25 Locking knob ABS 1 65 Variable speed Knob ABS 1

Table of contents

Popular Saw manuals by other brands

Makita

Makita MLS100 instruction manual

Crown

Crown CT15228-110-W Original instructions

Villager

Villager VMS 18020 Original instruction manual

AM TECH

AM TECH Y0200 Instruction manual and safety guide

Scheppach

Scheppach HM254SPX Translation of original instruction manual

DBK

DBK ES 185 C operating instructions