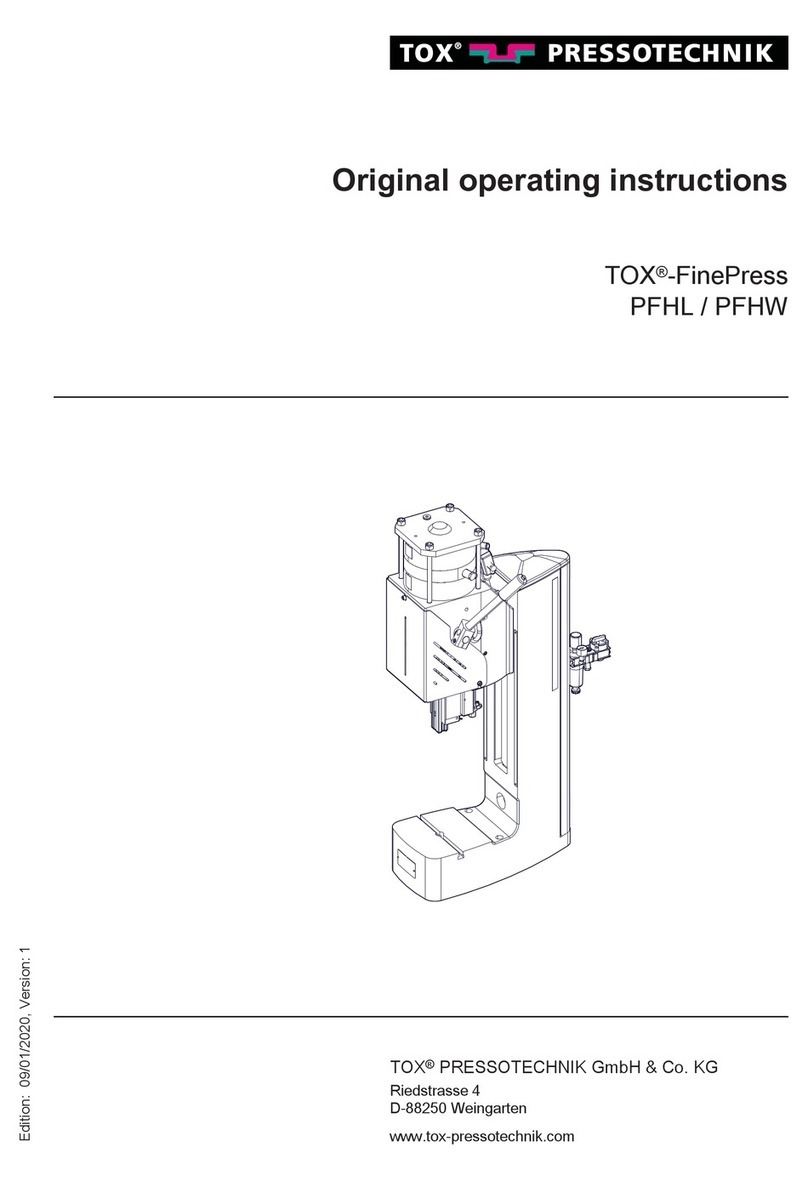

TOX PRESSOTECHNIK FinePress PFHL Series User manual

TOX PRESSOTECHNIK GmbH & Co. KG Riedstraße 4 D-88250 Weingarten

Phone +49 (0) 751/5007-0 Fax +49 (0) 751/52391 www.tox-de.com E-Mail: info@tox-de.com

Operating manual

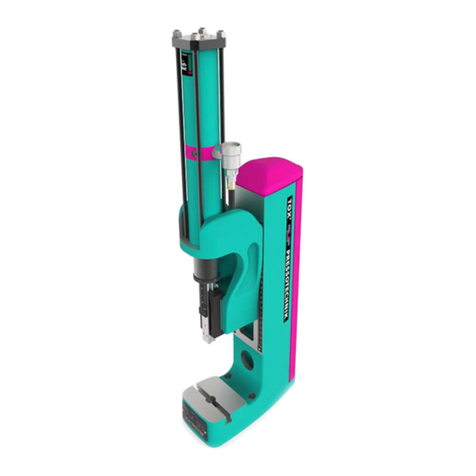

TOX-FinePress

Pneumatic press with manual approach

Type PFHL /PFHW

Pneumatic press PFHL/PFHW

2 OM 45.PFHL-PFHW.201803.en

Pneumatic press PFHL / PFHW

OM 45.PFHL-PFHW.201803.en 3

Content

Available accessories ............................................................... 4

1Technical data .................................................................... 5

Overview Pneumatic press with manual approach PFHL /

PFHW 6

2About this manual ............................................................... 7

Copyright, warranty 7

Legends of illustrations and position numbers 8

Explanation of symbols 8

3Safety ................................................................................. 9

Safe use of the machine 9

Organization measures to be taken by the user 9

Transport, assembly and operation 10

Maintenance and repair 10

Protective guards 11

Environmental protection 11

Warning and information signs 12

Danger points and notes 12

4Description of the press .................................................... 13

Intended use 13

Conditions for use 13

Storage conditions 13

Press functioning 14

5Transport .......................................................................... 14

Delivery of the machine 14

Transport of the machine 15

6Assembly .......................................................................... 16

Mounting of the press 16

Assembly of the accessories 17

Connection of compressed air supply 20

Control elements maintenance unit 20

Setting up the press 21

Compressed air-press force table for TOX®-FinePress type

PFHL / PFHW 24

7Operation.......................................................................... 25

Safety during operation 25

8Inspection / Maintenance .................................................. 26

Inspection and maintenance rates 27

9Failures: Causes and their elimination .............................. 28

10 Ordering spare parts / Repair ........................................... 29

Notes regarding repairs 29

Declaration of knowledge of the charged staff Master copy......

Pneumatic press PFHL/PFHW

4 OM 45.PFHL-PFHW.201803.en

Available accessories

Press type

PFHL

larger open height

PFHW

larger throat depth

Accessories

Counter

ZPZ 001

Force sensor

ZAK K08.000

ZAK K16.000

ZAK K34.000

ZAK K57.000

Travel sensor

ZWPH 060.000

Slide tables

ZHST 080.160

(Manual operation)

ZHST 080.160 P

(Pneumatic drive)

ZHSTP 001.000

(Position sensor)

Pressing moni-

tor

EPWL

CEP

Universal base

frame

UUF 1-45

(Standard with levelling

feet)

ZUUF 1-45 R

(+ swivel casters)

ZUUF 1-45 A

(+ adjustable foot rest)

*

Force range of the press

+

Tool hold-

ing fixture

+

Tool hold-

ing fixture

Pneumatic press PFHL / PFHW

OM 45.PFHL-PFHW.201803.en 5

1 Technical data

PFHL

Hand-lever press with pneumatic approach and in-

creased open height

PFHW

Hand-lever press with pneumatic approach and in-

creased throat depth

Press type

Force

range at 6

bar air

pressure

[kN]

Working

stroke

A[mm]

Throat

depth

C [mm]

Open

height, ad-

justable

S [mm]

Base

height

K[mm]

Overall

height

M[mm]

Base

size

W x D

[mm]

Re-

quired

space

L

[mm]

Table

bore

Ø [mm]

Net.

weight

approx

[kg]

Max. de-

flection

*

[mm]

Moy

(permiss.

moment)

**

static [Nm]

PFHL 008.002

8.5 60 120 30

-

265 95 674 150x125 339 20 61 0.10 25

PFHL 013.002

13.5

60

165

35

-

375

115

800

200x180

439

20

95

0.20

25

PFHL 022.002

22.5 60 165 25

-

330 115 800 200x180 439 20 120 0.35 70

PFHL 033.002

34.5

60

200

35

-

355

125

820

240x220

534

25

157

0.45

70

PFHL 056.002

57.5 60 240 55

-

340 160 860 260x220 614 30 232 0.70 70

PFHW 008.002

8.5 60 300 205

-

285 150 745 200x200 624 20 115 0.20 25

PFHW 013.002

13.5

60

300

200

-

280

180

775

240x230

654

20

177

0.20

25

PFHW 022.002

22.5 60 300 190

-

240 180 775 240x230 654 20 200 0.25 70

PFHW 033.002

34.5

60

300

210

-

275

190

805

300x250

674

25

234

0.35

70

PFHW 056.002

57.5 60 355 185

-

245 215 825 300x280 789 30 308 0.45 70

All dimensions in mm * Press head in topmost position ** Ram in BDC

Codes of the press types

PFHL

008.001 +options e.g. + ZAK 000 End position sensor

Version +ZPZ 001 Stroke counter

Press force

Hand-lever press

+ Complete pneumatics

Pneumatic press PFHL/PFHW

6 OM 45.PFHL-PFHW.201803.en

Overview Pneumatic press with manual approach PFHL / PFHW

Broken line: Element is hidden

Accessories

The accessories will be

shown in the chapter 6 'As-

sembly'.

Screwing advance stroke

17

Crank

19

Crank bolt, screw bar

20

Clamping plate

21

Fastening screws

XX

press head

22

Compressed air supply 6 bar

23

Rear cover of press

XX

frame (slipped on)

24

5

Top cover

6

Pneumatic valve

7

Start button pneumatic

power stroke

8

Hand lever

9

Maintenance unit /

Compressed air connection

11

Scale height adjustment

10

mm

11

inch

12

Press frame

13

Bores for frame fastening

14

Press bed with groove for

11

fastening the tools

11

and feed aids

Type PFHL (basic de-

vice, valid for all types)

15

Screw fitting for return stroke throttle

16

Connection for counter

18

Threaded bore for counter

Pneumatic cylinder

1

Cover for press head

2

Guide rail / ram

3

Tool holding fixture (option)

4

Pneumatic press PFHL / PFHW

OM 45.PFHL-PFHW.201803.en 7

2 About this manual

The operating manual should help you to use the

TOX-FinePress as intended. It contains im-

portant instructions for a safe, appropriate and

economical operation of the press. The ob-

servance of the manual helps to avoid risks, to

reduce repair costs and downtimes, and to in-

crease the reliability and the service life of the

machine.

Duty to inform the staff

All persons charged by the user

with the transport, mounting, opera-

tion, maintenance and repair of the

press must have read and under-

stood the operating manual, espe-

cially chapter "Safety" before start-

up.

Keep the operating manual

Keep the operating manual near

the machine and always available

for the personnel.

The type sheet 'TOX-FinePress' also includes in-

formation on the pneumatic presses and their ac-

cessories described in this manual. If this type

sheet is not attached to the operating manual,

you can download it from the Internet under

www.tox-en.com.

Besides the operating manual and the manda-

tory regulations valid on site for the prevention of

accidents, also the applicable technical regula-

tion for safety and qualified working must be ob-

served.

The handling of the machine depends on its in-

tended purpose, the construction of the whole

production line, the working process and the in-

stalled tools.

Copyright, warranty

This operating manual as well as any attached

documents are protected by copyright. They are

entrusted to our customers and the users of our

products.

Copyright:

TOX®PRESSOTECHNIK GmbH & Co. KG

This operating manual represents the state of

the issue date.

Edition: 2018-03-29

Subsequent modifications or conversions to the

machine by the user are not covered.

This operating manual is part of the scope of de-

livery and must be passed on to the new owner

in the event of a resale of the machine.

We guarantee for the machine in accordance

with our terms and conditions. The guarantee will

not apply in the event of

−damages caused by improper use or han-

dling,

−repairs or modifications made by persons not au-

thorized to do so,

−using accessories and spare parts which are

not designed to be used with this machine,

−not repairing defect parts immediately, in or-

der to minimize the extent of the damage and

to avoid impairing the safety of the machine

(repair obligation).

Damages to the machine

Report any failures as soon as they

are detected to the competent dis-

tribution partner or direct to TOX®

PRESSOTECHNIK:

TOX®PRESSOTECHNIK

Riedstraße 4

D - 88250 Weingarten

Phone: +49 (0) 751/5007-0

Fax: +49 (0) 751/52391

E-Mail: info@tox-de.com

Pneumatic press PFHL/PFHW

8 OM 45.PFHL-PFHW.201803.en

This machine is designed and manufactured ac-

cording to the state of the art and the applicable

German standards and specifications. The fol-

lowing norms and guidelines are met:

–Guideline 2006/42/EG

–DIN EN ISO 12100: 2011-03

–DIN EN 13736 :2009-11

–DIN EN ISO 4414: 2011-04

Subject to technical changes.

Declaration of conformity

The declaration of conformity con-

tained in this operating manual is

valid for all machines without pro-

cess monitoring. If a separate dec-

laration of conformity is delivered

with the machine, only this special

document is valid.

Legends of illustrations and position

numbers

The illustrations in this part of the operating

manual are provided with a title and an illustra-

tion number. Important system or device parts

shown on the illustrations are provided with com-

ponent numbers.

The reference in the text to a component allows

an easy allocation.

The technical drawings besides the legend and

the notes in clear text include also position num-

bers. These position numbers are also used for

the identification of the spare parts.

Explanation of symbols

This arrow at the beginning of a paragraph

draws attention to the action steps you must

follow.

This hook at the beginning of a paragraph

draws attention to a condition to be met be-

fore beginning the next step.

Danger notes:

Safety

Here you will find instructions for

the prevention of damages.

These safety notes must be strictly

observed by the employer and user

of the machine.

Danger

Warns of mechanic dangers which

can lead to personal injury or risk to

life.

Operating notes:

Note

Informs on work sequences and

methods which facilitate the han-

dling of the machine.

Function

Explains the functioning of the ma-

chine or the sequence of a working

process.

Settings

Draws attention to important infor-

mation on setting the operating pa-

rameters.

Mounting / Maintenance

Offers instructions regarding

individual working steps during

mounting or maintenance of the

machine.

Pneumatic press PFHL / PFHW

OM 45.PFHL-PFHW.201803.en 9

3 Safety

Safe use of the machine

This machine is designed and built according to

the state of the art and the applicable safety reg-

ulations. It is tested for type examination and

compliant to CE. The operational safety is en-

sured. Nevertheless risks for personnel and ma-

chine may arise from the machine if

•it is not operated as intended,

•it is not operated by trained staff,

•it is changed or modified improperly,

•the safety instructions are not observed.

The machine must only be operated in perfect

technical condition. All provided protective

guards must be mounted and in good functional

condition. The instruction and warning plates at-

tached to the machine must be observed.

Independent of the instructions given in this op-

erating manual, the legal safety and accident

prevention regulations in the country as well as

generally recognized rules of safety technology

and industrial medicine must be observed.

Organization measures to be taken

by the user

The user is responsible for

•the observance of the commissioning, oper-

ating and maintenance conditions described

in the operating manual of TOX®PRES-

SOTECHNIK,

•the appropriate operation, checking and

maintenance of the machine and the clear

definition of responsibilities and competence

for the work,

•the familiarization of the operating staff by

suited training with the due handling of the

machine and its safety devices,

•the immediate replacement of damaged or re-

moved instruction or warning plates,

•the existence and operability of the provided

safety guards.

Using the machine as a plant

component

If the machine is not delivered

ready for use, the employer or the

charged plant constructor are re-

sponsible for the observance of the

prescribed safety measures during

planning, installation and comple-

tion of the production line.

Depending on the intended applica-

tion, the mounting of further protec-

tive gears might be necessary.

The operator should draw up internal job instruc-

tions for the machine taking into account the spe-

cific regulations of the country and the known

qualifications of the staff.

Instruction and training

The operator should obtain written

confirmation of participation of the

staff in introduction, training, semi-

nars etc. for learning about the safe

operation, maintenance and repair

of the machine.

For this purpose, the operator can

copy and have filled in the print

"Declaration of knowledge of the

charged personnel' (in the annex of

these manual).

Obligatory safety checks

Please observe the national regula-

tions of the country for the execu-

tion of safety checks.

Pneumatic press PFHL/PFHW

10 OM 45.PFHL-PFHW.201803.en

Transport, assembly and operation

During transport and assembly of the machine,

the indicated part dimensions and part weights

of the machine including tool and accessories

must be observed.

The machine must only be mounted by author-

ized and briefed staff.

Check the machine and the accessories for dam-

ages. A defective machine must be immediately

stopped and the plant must be secured against

reclosing.

A defective machine must only be repaired by

specialists or by TOX®PRESSOTECHNIK.

Before beginning work, check all supply pipes for

damages. If any damage is detected, depressur-

ize the pipe or the pneumatic system and have

the damaged pipes changed by authorized spe-

cialists.

Observe machine data

The technical data stated in the

data sheet and the settings must

be observed.

Observe the information in the op-

erating manual as well as the in-

struction and warning plates on the

machine.

Danger to persons

During the operation of the ma-

chine the user must ensure that no-

body is at risk due to potentially

dangerous actions.

The machine must only be oper-

ated, if nobody stays within the

danger area.

Individual protective equipment

Depending on the intended use of the

press, personal protective equipment

(PPE) might be necessary.

According to the national regula-

tions for working safety, the PPE to

be used for the intended use must

be defined in the operator's work-

ing instruction.

Maintenance and repair

Safety regulations

When working on the machine, al-

ways observe the applicable safety

regulations and the legal condi-

tions.

Keep the recommended intervals for mainte-

nance and inspection work.

The qualified repair of products from TOX®

PRESSOTECHNIK requires trained specialized

personnel. The operator or the persons charged

with the repair must take care that the staff is

specially trained for the repair of the product.

Persons engaged in repairing the machine are

always responsible for the working safety.

Do not start repair and maintenance work until it has

been ensured that

•the machine is separated from the com-

pressed air supply,

•the machine is switched off and protected

against restarting,

•dangerous motions have come to a stop,

•an unauthorized, accidental or unexpected

putting into operation and an initiation of dan-

gerous motions due to latent energies is pre-

vented.

Only use original spare parts from TOX® PRES-

SOTECHNIK.

Assemble the press completely

After repair or maintenance work,

duly remount all covers dismounted

before. Check also the screwing

and the tightness of all connections

of pneumatically driven accesso-

ries.

Do not modify the machine!

Arbitrary conversions or alterations

(of mechanics, hydraulics, or pneu-

matics) endanger the safety of per-

sonnel, of the whole machine, or of

other material assets.

Pneumatic press PFHL / PFHW

OM 45.PFHL-PFHW.201803.en 11

Protective guards

When using the press according to its intended

use, danger to the operating staff is largely ex-

cluded by protective guards. Even predictable

misbehaviour was taken into account.

Due to the working cycles, however, the machine

has some areas and parts which cannot be pro-

tected without impairing its function and opera-

tion. Thus, in spite of constructive safety

measures and mounted safety guards a residual

risk remains

•to life or health of the user or third persons,

•to the tool or other material assets,

•to the efficient operation of the machine.

Crushing hazard in the tool area

When operating the press, there

exists the risk of crushing by the

tool. If necessary, take the appro-

priate protective measures in order

to exclude the risk of injury.

During the operation of the press,

the workpiece must not be held by

hand. Provide a fixed deposit of the

workpiece.

Cover for press head

The press must only be used, if the

cover of the press head is mounted

tightly. This cover must not be cir-

cumvented or put out of function.

Safety regulations for pneumat-

ics

Observe the valid national safety

regulations. Especially pay atten-

tion to the pneumatics and the

pneumatic pipes.

Special risks

– Injuries caused by the bursting

of a pneumatic pipe.

– Crushing of limbs if not

properly handled

In the event of injuries or accidents,

consult a doctor immediately!

Environmental protection

Observe the regulations

During all work on the machine, the

applicable national noise and envi-

ronmental protection regulations

must be observed.

Already when selecting the required operating

material (e.g. lubricants, lubrication oils, filter

cartridges, cleansing agents), the factors of en-

vironmental safety, health risks and the valid dis-

posal regulations have to be considered.

Disposal

When disposing the pneumatic

press and all its accessories, the

national applicable environmental

regulations must be observed. For

the disposal of the wear and spare

parts, the toggle press and its ac-

cessories, the valid national envi-

ronmental protection regulations at

the moment of disposal must be

observed.

Pneumatic press PFHL/PFHW

12 OM 45.PFHL-PFHW.201803.en

Warning and information signs

Compressed air supply: Maximum operating

pressure

Observe the maximum operating

pressure

The operating pressure of

max. 6 bar must not be exceeded,

otherwise the operational reliability

of the appliance cannot be longer

guaranteed.

In case of compressed air supplies > 6 bar, a

pressure reducing valve must be superposed to

limit the operating pressure to the max. permitted

value.

Maximum press force

Observe maximum press force

The indicated press force must

never be exceeded, otherwise the

operational safety of the device is

no longer guaranteed.

CE mark

Type plate:

In case of queries please state the following

data:

Type: _____________________

Serial number: _____________________

You will find these information on the type plate

of the press which is attached to the press frame.

The code of the press types is described in chap-

ter 1 'Technical data'.

Instructions for ordering wear and spare parts

are given in chapter ‘Ordering of spare parts / re-

pair’.

Danger points and notes

Example: Press type PFHL,

drawing without tools

Accordingly applies to all other types

Maintenance unit, drive

Danger due to the high pressure in the pneumatic

system. Service work must only be realized by au-

thorized specialists.

Observe the maximum operating pressure.

Risk of shearing and crushing

Observe the safety distance up to the limit of

danger point (1) (observe DIN EN 349).

Exclude the risk of danger to other persons.

Resetting the machine in case of injuries:

Release start button "pneumatic support" and

move hand lever to the top.

Tool setting, maintenance and repair work must

only be executed by authorized specialists.

1

Pneumatic press PFHL / PFHW

OM 45.PFHL-PFHW.201803.en 13

4 Description of the press

Intended use

The pneumatic presses with manual approach of

the series TOX®-FinePress can be used in com-

bination with the provided tool holding fixture and

tools for the following applications according to

the specifications of TOX®PRESSOTECHNIK:

Clinching, Assem-

bling, TOX sheet

metal joining

Pressing, Com-

pressing

Edging, Bending,

Shearing

Coining, Marking

Punching,

Piercing

Riveting, Crimping,

Caulking

Tensioning, Clamp-

ing, Caulking

Strech forming,

Flanging

Make sure the press has enough press force for

the intended application.

The press must only be used for the intended

working process. Any other use is considered to

be a not intended application. The manufacturer

is not liable for damages arising from use that is

not as intended - this is at the risk of the user.

The permission for an application not mentioned

here must be agreed with TOX®PRESSOTECH-

NIK.

The small presses of the series TOX®-FinePress

are built exclusively for industrial applications.

Conditions for use

Ambient temperature

The operation of the TOX-press is

only permitted within Tmin = 10°C

and Tmax = 60°C.

When operated outside these tem-

perature limits, function troubles or

sealing damages may occur.

Preparation of compressed air

The machine must only be used

with filtered and dried compressed

air. The max. admissible particle

size is 40 µm.

When operated with unfiltered com-

pressed air, a premature damage

of the sealings may occur.

The machine can also be operated

with slightly oiled compressed air.

In this case, it is absolutely neces-

sary to adjust the lubrication unit to

an economical setting.

Special working environment

If you want to use the machine in a

special working environment (e.g.

outdoor or in dusty or humid envi-

ronment, in food industry or under

special chemical or physical condi-

tions), please contact our service

department and ask for the condi-

tions.

Storage conditions

Store the press in a dry and dust-proof place.

Cover the machine with an applicable dust

cover. Store the machine at an ambient temper-

ature between -10 and 60°C.

Pneumatic press PFHL/PFHW

14 OM 45.PFHL-PFHW.201803.en

Press functioning

The working ram at presses of the series TOX®-

FinePress PFHL / PFHW is moved out by a hand

lever via a knuckle joint. If the limit switch is

reached at this position, a pneumatic power

stroke of 6 mm is activated after pressing the

start button at the lever grip. After resetting the

lever or releasing the start button, the return

stroke of the ram is initiated.

The pneumatic cylinder is mounted directly to the

press frame.

The piston of the pneumatic cylinder generates

a power which is proportional to the pressure.

The nominal force is reached a the maximum op-

erating pressure of 6 bar. At proportionally de-

creasing force it is, however, possible to operate

the presses up to approx. 3 bar (see compressed

air / press force table).

This press series provides an integrated control

system including maintenance unit.

A ball monorail guidance system with a linear

guided working ram ensures the precise guid-

ance of the tool.

Due to their manifold shifting and adjusting pos-

sibilities, the machines of series TOX®-Fine-

Press can be easily adapted to the desired ap-

plications.

Technical data, machine dimen-

sions and description

The technical data can be found in

chapter 1.

Detailed information on machine

dimensions, a brief description of

the press series and of the availa-

ble accessories can be found in

type sheet 'TOX®-FinePress'.

5 Transport

Delivery of the machine

The TOX®-toggle press will be delivered ready

for erection. The press must not be dismounted

for transport.

If accessories are also supplied, they must be

mounted during the erection of the press. Please

observe the instructions given in this operating

manual or in instructions delivered separately.

During transport take always care that the TOX®-

press is appropriately handled. The means of

transport must be designed for the weight of the

press including tool and accessories.

Checking the delivery

Check the delivery for completeness with the

help of the shipping note.

Check the machine for damages during

transport.

Report transport damages imme-

diately

If you detect any transport dam-

ages, advise us immediately on the

kind and extent of damages

(please state number of shipping

note, machine type, and serial

number):

TOX®PRESSOTECHNIK

Riedstraße 4

D - 88250 Weingarten

Tel. +49 (0) 751/5007-0

Fax +49 (0) 751/52391

E-Mail info@tox-de.com

Pneumatic press PFHL / PFHW

OM 45.PFHL-PFHW.201803.en 15

Transport of the machine

Risks during transport

The means of transport must be

designed for the press weight in-

cluding tools and accessories.

Do not lift the press frame by fixing

the means of transport in the tool

room or at add-on parts.

Any loose parts on the press must

be fixed and/or secured.

Check after each transport whether

all machine parts are undamaged.

Risk of crushing when lowering

the press to the ground

During the transport of the machine

there is the risk of pinching when

lifting up and specially when setting

down the press.

Transport by lifting device or crane

For lifting the rack and pinion press a bore hole

for an ring bolt is provided. The threaded bores

(1) are located under the lid of the press frame.

Bore hole provided for ring bolt

Screw in the ring bolt at the pro-

vided position at the press frame

only. If other threaded bore holes

are used, the drive or add-on

pieces can be damaged.

Do not fix the ring bolts at the

pneumatic cylinder!

Take off the lid of the press frame and attach

the ring bolt.

Take the crank handle out of the press frame

(they might fall out during transport).

Attach the transport gear to the ring bolt.

Be careful when lifting up the

machine

Pay attention to the gravity centre

of the machine:

– the press might slightly swing

out.

The transport gear may tear. Al-

ways keep a safety distance to the

means of transport.

Transport with lifting device (schematic)

Transport by lift truck and forklift

Safety precautions

The TOX®-small press must be ex-

clusively transported on a solid

base (e.g. pallet) and must be pro-

tected against sliding.

Observe the maximum useful load

of the means of transport.

1

Pneumatic press PFHL/PFHW

16 OM 45.PFHL-PFHW.201803.en

6 Assembly

Mounting of the press

The location on site must be determined. The

space requirement of the machine must be

sufficiently calculated.

The required space for the supply pipes must

also be taken into consideration.

Machine weight

The place and the fastening on site

must be designed for the weight of

the press including tool and acces-

sories.

Beside the own weight, also the

load produced by the working pro-

cess (dynamics and vibrations)

must be considered.

The working area must be determined and

configured according to the valid regulations

(specially with regard to ergonomics and

safety).

The frame for the machine must be ready for

mounting.

Risks during erection

Use suitable lifting appliance for lift-

ing up (see chapter 'Transport').

The lifting gear must be designed

for the press weight.

Do not lift the machine by fixing the

means of transport in the tool room

or at add-on parts.

No unauthorized persons must stay

within the danger area.

Noise protection

For noise protection we recom-

mend to place a felt or foam mat

(approx. 1 cm) between the press

frame and the base frame and/or

the table (not obligatory).

Screw-on the press

Before starting operation, the press

must be screwn to the base frame

(option) or to a solid table (e.g.

work bench). Otherwise the opera-

tion of the press is not permitted

Supplied tools

Under the removable top cover of

the press frame, a set of Allan keys,

an additional release spring as well

as the crank for the height adjust-

ment can be found.

Mounting the press

The assembly depends on the type of the press.

The mounting dimensions can be found in type

sheet 'TOX®-FinePress'.

Use an appropriate lifting gear to place the

press on the base frame.

Align the press on the frame.

Fix the press on the provided base frame or

table.

Mounting with base frame (option)

Mount the base frame according to the sepa-

rate mounting instructions.

Use an appropriate lifting gear to place the press

to the intended position.

Align the press.

Check whether the machine is horizontal in

both axes and compensate any unevenness

using the adjustable feet (not in case of a set

of swivel casters).

If the base frame is equipped with a set of

swivel casters (option), the casters must be

mounted instead of the adjustable feet.

Set of swivel casters

Before operation, the swivel cast-

ers must be locked using the fixing

lever.

Pneumatic press PFHL / PFHW

OM 45.PFHL-PFHW.201803.en 17

Assembly of the accessories

Mounting the stroke counter (option)

Separate the coupler (4) on the counter-side

from the plug (5).

Remove the screw provided on the counter

connection (1) of the pneumatic cylinder.

Screw the pressure switch (2) in the counter

connection (1) on the pneumatic cylinder.

Mount the counter housing (3) to the provided

location on the press head using the two

cheese head screws M 5x12 (6).

Connect plug (5) with the coupler (4).

Mounting the force sensor (Option)

Screw the holding device (2) with the two

screws M 5x10 (1) to the side of the press

head.

Dismount the existing tool holding fixture (if

already mounted).

Screw the tool holding fixture and the force

sensor (7) on the press ram o the press.

Fasten the black clamp (6) with screw M 4x8.

Plug the angle plug (8) in the plug of the force

sensor.

For strain relief, clamp the cable into the black

clampFor strain relief, jam the cable into the

black clamp..

Place the straight plug (3) in the mounting clip

(5) and screw the clip with screws M 4x20 (4)

to the holding device (2) using the two lowest

bore holes.

Connect plug (3) with the provided process

control system using an appropriate cable.

Information on force measuring

is given in the corresponding chap-

ters of the operating manual of the

pressing monitor, for example EPW

(accessories).

1

2

3

4

5

6

1

2

3

4

5

4

6

7

8

Pneumatic press PFHL/PFHW

18 OM 45.PFHL-PFHW.201803.en

Mounting the path measuring (option)

Unscrew the cover of the press head (9).

Remove the pin (10): For this purpose un-

screw the lock washer and remove the pin

from the fixing device. Lower the rods to the

front to get more space for mounting the

travel sensor.

Place the travel sensor (1) on the provided lo-

cation of the press head. Pay attention to a

careful threading of the rods of the path travel

sensor.

Fasten the connecting flange (8) of the travel

sensor to the press head using the three

screws (7).

Position the threaded rod of the travel sensor

(1) and fasten it on the ram using the hexagon

nut M 4.

Screw on the holding device (3) with the two

screws M 5x10 (2) to the side of the press

head. After this, fasten the holding device

with the help of the second screw M 5x10 to

the bottom side of the press head.

Place the plug (4) in the mounting clip (5) and

screw the clip with screws M 4x20 (5) to the

holding device (3) using the two upper bore

holes.

Connect plug (4) with the provided output de-

vice using an appropriate cable.

Information on travel measuring

is given in the corresponding chap-

ters of the operating manual of the

pressing monitor, for example EPW

(accessories).

8 9

8

2

3

5

4

2

7

1

10

7

1

Pneumatic press PFHL / PFHW

OM 45.PFHL-PFHW.201803.en 19

Mounting the sliding table (option)

Legend

1 Base plate (anvil)

6 Handle

2Guide

7 Fastening groove press

3Tool plate

8 Oblong hole for screw fitting

4Set screw for stop

9 Bore hole for screw fitting

5Stop (adjustable)

For precise centring of the slide table you can

use the bore holes (9). There are already

mounted fastening screws and T-groove

nuts. Push the T-groove nuts into the fas-

tening groove of the press and screw the fas-

tening screws tight. If another position of the

slide table is required, it is possible to fasten

the slide table with the help of the oblong

holes (8) using the T-groove nuts and suita-

ble screws.

Align the lower tool on the tool plate (3) and

tighten it in the provided threaded bore holes.

For fine adjustment of the insertion length, it

is possible to shift the stop (5) and to secure

it with the set screw (4).

Slide table with pneumatic cylinder

Retrofitting

If the pneumatic cylinder (12) is

mounted to the slide table at a later

date, first fasten the angle (15) to

the provided location of the base

plate. Then lead the piston through

the opening of the angle and fasten

the cylinder with the nut. Screw

then the coupling of the piston

down to the retainer of the slide ta-

ble (17).

Duly connect the pneumatic cylinder to the

compressed air supply:

−Forward stroke (11): Extension of cylinder

−Return stroke (13): Retraction of cylinder

Use the throttles (10) and (14) to set the

speed for the extension or retraction of the

cylinder.

For fine adjustment of the insertion length, it

is possible to shift the stop (5) and to secure

it with the set screw (4).

Legend

10

Throttle, forward stroke

11

Connection forward stroke

12

Pneumatic cylinder

13

Connection return stroke

14

Throttle, return stroke

15

Angle bracket

16

Coupling cylinder piston

17

Slide table fixing device

Mounting of TDC / BDC sensors

It is possible to screw suitable sen-

sors for TDC/BDC inquiry (acces-

sories) to the pneumatic cylinder

(12).

9 8

7

13 14

15

1 2 3 4 5 6

10 11

12

16

17

Pneumatic press PFHL/PFHW

20 OM 45.PFHL-PFHW.201803.en

Connection of compressed air

supply

On delivery, the press is completely piped and

hosed and is ready to be connected to the com-

pressed air supply of the customer by authorized

staff.

Connect the press to the maintenance unit of

the compressed air supply on site.

Pneumatic connection at the maintenance

unit. 1/4"

Observe specifications

Observe the specifications of TOX®

PRESSOTECHNIK for the connec-

tion to the compressed air supply:

– Preparation of compressed air

(see this manual, chapter 4,

'Conditions for use')

– Maximum compressed air sup-

ply (warning note on pneumatic

cylinder; operating manual,

chapter 3, 'Safety').

Observe the specific safety regula-

tions of the country for pneumatics.

Observe the instruction and warn-

ing plates on the machine.

Control elements maintenance unit

Note: The order of the control elements can vary.

Legend

1Gauge

2Flow control air supply

3 Compressed air supply on /off

4Connection for pneumatics (compressed air

supply)

5Water separator

6Compressed air supply for return stroke

For adjusting the compressed air, pull the turning

handle ofthe flow control (2) and set the required

pressure (read value at gauge). After this, push

the turning handle down again.

Risk of crushing when switch-

ing-off the compressed air

When switching-off the com-

pressed air (3), the ram lowers au-

tomatically.

6

1

2

4

3

5

This manual suits for next models

11

Table of contents

Other TOX PRESSOTECHNIK Power Tools manuals

TOX PRESSOTECHNIK

TOX PRESSOTECHNIK FinePress PFHL User manual

TOX PRESSOTECHNIK

TOX PRESSOTECHNIK FinePress KFS User manual

TOX PRESSOTECHNIK

TOX PRESSOTECHNIK FinePress ZFS User manual

TOX PRESSOTECHNIK

TOX PRESSOTECHNIK FinePress PFS Series User manual

TOX PRESSOTECHNIK

TOX PRESSOTECHNIK TOX-FinePress PFS Series User manual