Toyo CV-3010 User manual

SERIAL to BCD CONVERTOR

MODEL CV-3010

OPERATION MANUAL

TOYO SOKKI CO.,LTD.

964-24 Nippa-cho Kohoku-ku, Yokohama 223-0057 Japan

TEL +81-45-540-8353

FAX +81-45-544-8354

MA4-00300-R1(2023/5)

MA4-00300-R1

- 2 -

-- Table of contents -- Page

§1. SUMMARY ..................................................................................................... 3

§2. APPEARANCE AND EACH PART NAME.................................................................. 3

§3. FUNCTION & OPERATION ................................................................................. 4

3-1) General .................................................................................................... 4

3-2) Input / Output interface .............................................................................. 4

3-3) Each function ............................................................................................ 5

3-4) Timing of acquisition of BCD data ................................................................. 7

3-5) Operation at abnormal ................................................................................ 8

§4. TROUBLESHOOTING........................................................................................ 9

4-1) Basic check point ....................................................................................... 9

4-2) Troubleshooting when the desired operation cannot be achieved. ....................... 9

§5. METHOD OF INSTALLATION AND CONNECTION .................................................. 10

5-1) Installation environment of this unit ............................................................ 10

5-2) Terminal/Connector connection .................................................................. 10

5-3) Precautions of wiring ................................................................................ 11

§6. DIMENSIONAL DRAWING ............................................................................... 12

※This operation manual is applied to the product shipped after Sep/2015

Revision history:

Rev.1 (2/Oct/2015)

Addition of explanation of Connectable indicator,

Details of I/F and Pulse width of STROBE signal

Rev.2 (26/May/2023)

Revision of explanation of Connectable indicator

This document is translated from MA4-00148-R2 (Japanese)

MA4-00300-R1

- 3 -

§1.Summary

This unit is a convertor to transform serial data which are transmitted from TOYO digital

indicator to BCD data. BCD data is output through Open Collector signal which is isolated from

an inner circuit by a photo coupler.

This unit has functions of Data hold and Logic inversion, etc. which are controlled by external

command input.

The power supplied voltage is DC24V which is isolated from an inner circuit by insulated DC/DC

convertor.

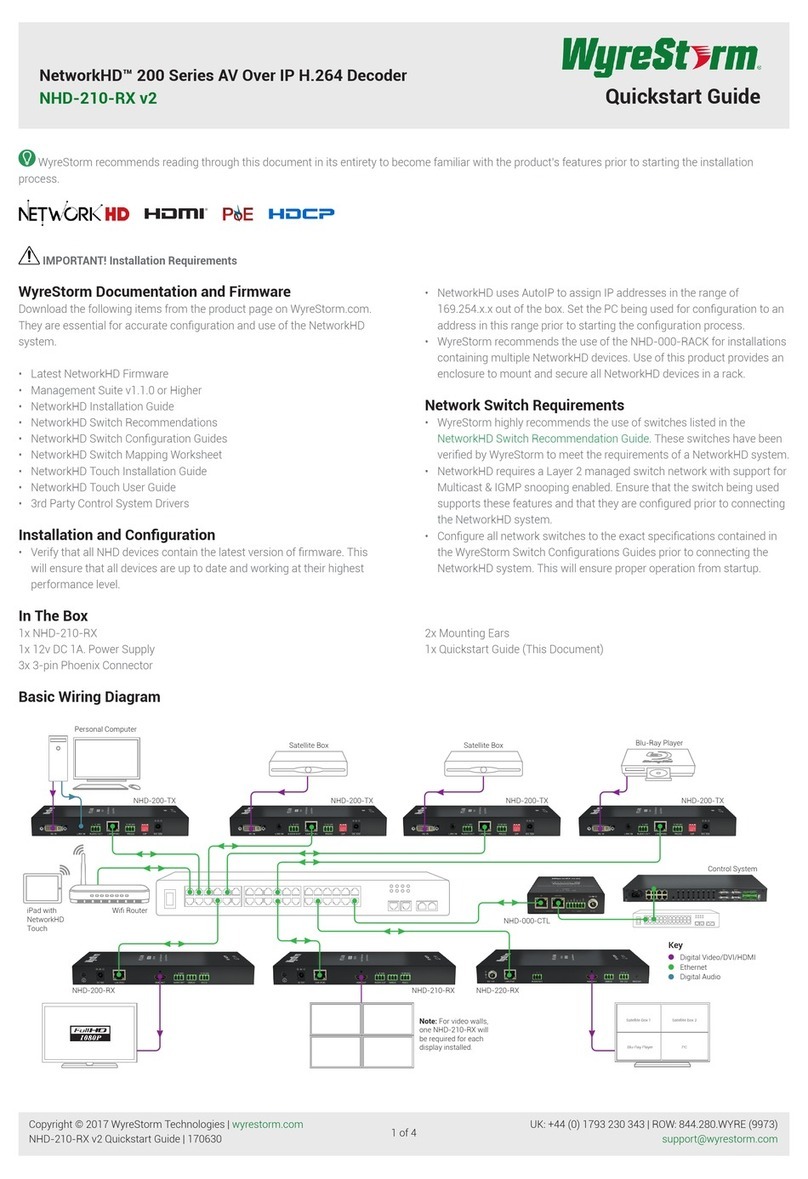

§2.Appearance and Each part name

Appearance of the unit

① SERIAL MONITOR (LED) LED for indicating that serial data is transmitting/receiving

② TERMINAL 5mm pitch screw-less terminal for serial I/O and power line

③CONNECTOR 36pin-Amphenol for BCD output and external command input

④ MOUNTING HOLE Use 4-M3 screw to fix this unit

Attached accessories

① Operation Manual 1 copy

② Connector (DDK 57-30360 or the equivalent) 1 pc

MA4-00300-R1

- 4 -

§3.Function & Operation

3-1)General

This unit is a convertor to transform 0~20mA current loop(as ‘C/L’ thereafter) or RS-232C

serial data which are transmitted from TOYO digital indicator to BCD data which is output

through Open Collector signal.

1). Connectable digital indicators

TOYO’s digital indicator equipped with C/L or RS-232C output can connect to CV-3010.

・TOYO’s digital indicator equipped with C/L output as standard are:

DLS-5028A,DLS-5025B,DLS-5037,DLS-5026B,DLS-5031A

・TOYO’s digital indicator equipped with C/L output as option are:

DLS-5033A(OP-4),TI-703(OP-4)

・TOYO’s digital indicator equipped with RS-232C as standard is:

DLS-5031A

・TOYO’s digital indicator equipped with RS-232C interface as option. It should connect to

CV-3010 through C/L signal if equipped with C/L as standard:

DLS-5028A(OP-3),DLS-5025B(OP-3),DLS-5037(OP-3),DLS-5026B(OP-3),TI-703(OP-3)

Cable length of RS-232C should be less than 15m. But cable length of C/L signal is up to 100m

because C/L signal is transmitted by current.

Input signal to this unit is either C/L signal or RS-232C signal. Cannot accept both signal at the

same time.

To enable addition of external connected device, either C/L or RS-232C input serial signal is

delivered to output port of RS-232C and C/L terminal.

2). BCD signal and accompanied signal

BCD output is 24bit Open Collector signal which is isolated by photo coupler.

BCD data : 5digit (4bitx5), Polarity(+), Overflow

STROBE : Timing signal of acquisition data

RUN : Alert signal for power failure, detecting abnormal of input signal

Above data will be updated each time receiving data through C/L or RS-232C signal.

This unit accepts 4 input signals to control conversion.

Data Hold : Update of BCD data is hold

Logic inversion of data : Invert of BCD data, Polarity(+), Overflow

Logic inversion of STROBE : Invert of STROBE signal

Pulse width of STROBE : Pulse width of STROBE is 100msec or 20msec.

3-2)Input / Output interface

1). Serial data input (RS-232C or C/L)

Digital indicator equipped with C/L output is connected to C/L input of this unit.

Digital indicator not equipped with C/L output but RS-232C interface as option is connected to

RS-232C input of this unit

Receivable data protocol of RS-232C is fixed as the followings.

Communication speed 2400bps

Communication protocol Start-stop synchronous (Asynchronous)

Communication format Data bit:7bit, Stop bit:2bit, Parity:Even, Data:ASCII code

MA4-00300-R1

- 5 -

2). Serial data output (RS-232C or C/L)

When C/L signal or RS-232C signal is input to this unit, same signal is transmitted from both

C/L and RS-232C port of this unit, which help to add external connected devices. But when

receiving error has been detected, the detected data is not transmitted. (including: flaming

error, parity error, over-run error)

Transmitting data protocol of RS-232C is same as the receiving data protocol.

A serial signal monitor LED which places close to the input terminal is flushing when

transmitting/receiving a serial signal.

3). BCD data output

BCD data is output through 24bit Open Collector output, which consists of NPN transistor and

photo coupler, TOSHIBA TLP627, and is isolated from an inner circuit. BCD data are output

from 36pin-Amphenol connector, Emitter is common to pin#13,#14,#31 and #32 of the

connector.

Rated output is DC30V, 30mA (resistive load). Saturation voltage between Collector and

Emitter is 1.2V or less at the rated load.

Output logic is selectable. Status between Collector and Emitter against negative/positive logic

are shown in a Table below.

Output data

Negative logic

Positive logic

Status Collector -

Emitter

Output level at

pull up end

Status Collector -

Emitter

Output level at

pull up end

0

Open

High

Short

Low

1

Short

Low

Open

High

4). External command input

There are 4 external commands, as Data Hold, Logic inversion of data, Logic inversion of

STROBE and Pulse width of STROBE, which are set by external Relay contact MAKE input. Each

contact current consumption should be approximately 5mA (at applied voltage 5V).

Ground of external input is common to the ground of inner circuit. The external Relay contacts

and this unit are supposed to build in the same control box, so that the cable length between

contacts and this unit should be less than 10m.

When the ground of external input is connected to Emitter of BCD output, external command

is not accepted because it is isolated from BCD output.

3-3)Each function

1). BCD data output

This unit outputs 5digit BCD signal which are converted from serial data of the measured value

comprised of ASCII code transmitted from TOYO’s digital indicator.

Decimal point is ignored if it is attached.

When a digital indicator indicates overflow, 4bit data of each digit output ‘1’. (5digit BCD

output ‘FFFFF’ in result). Using this function, it is possible to detect overflow without addition

of a bit as a discriminator.

2). Overflow output

When a connected digital indicator indicates overflow (All digits are flushing), output ‘1’.

3). Polarity output

Output ‘1’ when BCD data is plus.

Output ‘0’ when BCD data is minus.

4).STROBE output

BCD data is updated whenever the measured value data comprised of ASCII code is received .

STROBE signal is set ‘1’ after 10msec from when BCD data is updated and is set ‘0’ after

100msec after setting ‘1’.

Timing of acquisition of BCD data is to detect a rise edge of the STROBE signal first and capture

BCD data within 100msec.

MA4-00300-R1

- 6 -

5). RUN signal

RUN signal output ‘1’ after receiving the first serial data from powered ON.

All the most of TOYO’s digital indicator transmit data 4times/second or 16times/second. If

receiving data is stopped for 1 second, treat as abnormal of indicator or disconnection of cable,

RUN signal output ‘0’ until the next data is received.

Logic of RUN signal is fixed to the negative logic. Status between Collector - Emitter is OFF

when powered OFF. RUN signal can be used as detecting abnormal of indicator or power

failure.

6). Data Hold signal

When making electrical short between #16 and #18(D.COM) of 36pin-Amphenol connector,

update of BCD data is stopped within 50msec. BCD data and STROBE signal is not updated

while electrical short between them.

In case of being impossible to utilize STROBE signal, capture BCD data after 50msec from

when Data Hold signal is input to this unit.

7). Logic inversion of data signal

When making electrical short between #34 and #36(D.COM) of 36pin-Amphenol connector,

invert the logic of BCD data, Polarity, Overflow

Open : Negative logic (at the time of shipment)

Short : Positive logic

8). Logic inversion of STROBE signal

When making electrical short between #17 and #18(D.COM) of 36pin-Amphenol connector,

invert the logic of STROBE signal

Open : Negative logic (at the time of shipment)

Short : Positive logic

9). Pulse width changing of STROBE signal

When making electrical short between #35 and #36(D.COM) of 36pin-Amphenol connector,

pulse width of STROBE signal is changed.

Set 100msec when transmitting data of the connected digital indicator is 4 times/second.

Set 20msec when transmitting data of the connected digital indicator is 16 times/second.

Open : Pulse width 100msec. (at the time of shipment)

Short : Pulse width 20msec.

MA4-00300-R1

- 7 -

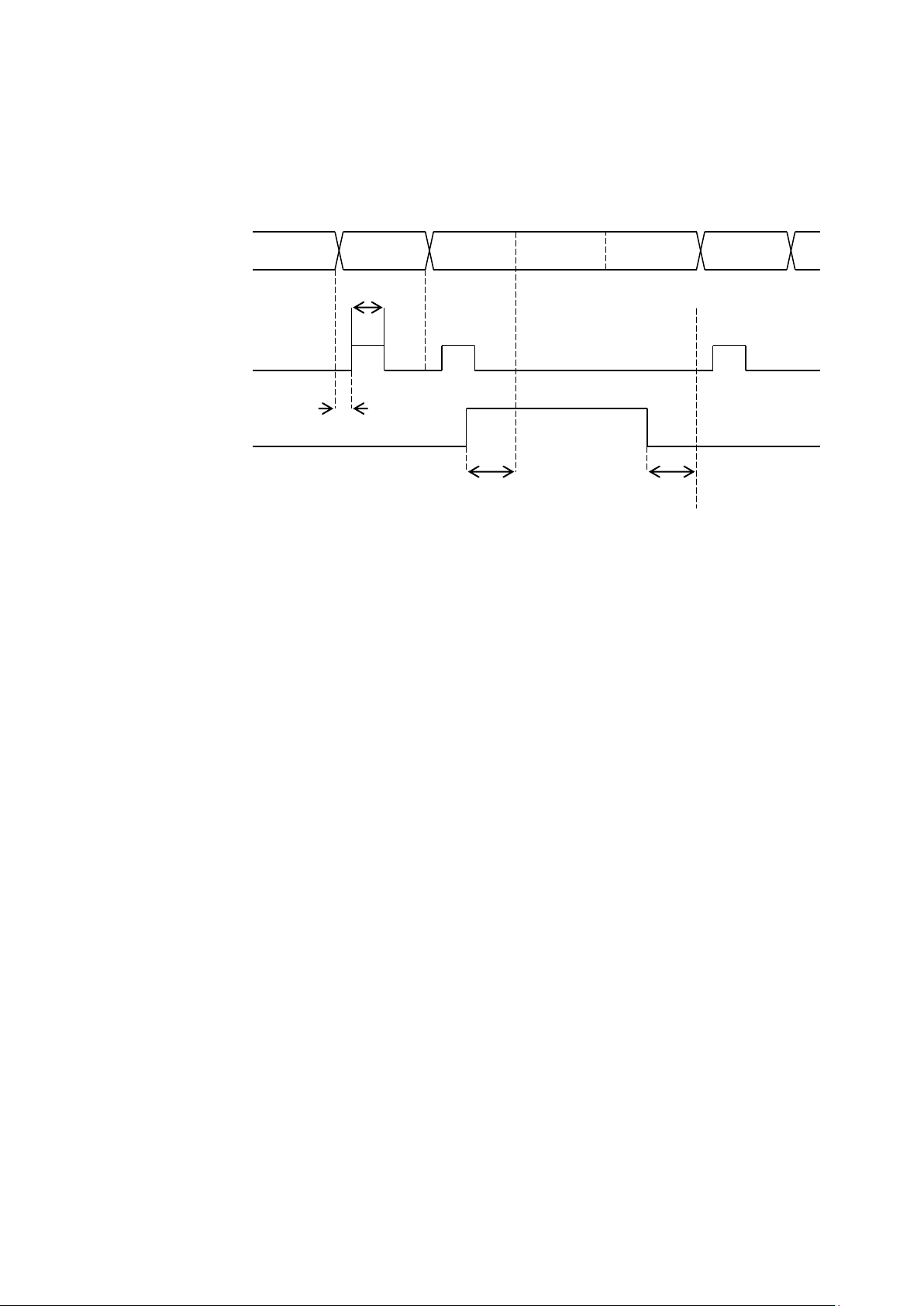

10ms

100ms (or 20ms)

50ms

max

50ms

max

250ms (or 60ms) update cycle

3-4)Timing of acquisition of BCD data

1). Timing chart of BCD data output sequence

This unit is operated according to the following timing at most cases.

After a serial data has been received, BCD data is updated.

After 10msec from an update of BCD data, STROBE signal is transmitted for 100msec or

20msec time length.

After 50msec from input of Hold signal, BCD data is hold and not updated. After 50msec from

release of Hold signal, BCD data is updated again.

2). Methods of acquisition of BCD data

BCD data is unstable during updating period. Transition time to turn ON of output transistor

(including photo coupler) is approximately tens of μsec. But transition time to turn OFF of it is

approximately up to hundreds of μsec depending on a load.

Transition time can vary depending on the individual of transistor or load differences or

surrounding temperature.

Thus, if connected equipment try to capture all the 24bit data at same time while data is

updating, it will result in capture data error.

For example, when capturing data while it is transiting from 19999 to 20000, BCD data might

be 29999 or 10000, which is capture data error.

To prevent such capture data error, please capture data by one of the following method.

① Method to utilize STROBE signal

STROBE signal is high level ‘1’ and BCD data is stable after 10msec from updating BCD data.

STROBE signal is ‘1’ for 100msec (or 20msec). Because an update data cycle of a connected

digital indicator is 250msec (or 60msec), after STROBE signal turns to low level ’0’ there is no

possibility to update the next data at least for 100msec (or 20msec).

Thus, to capture BCD data, first detect a rise edge of the STROBE pulse to ‘1’, and next capture

all the 24bit data within 100msec (or 20msec).

The value inside () is the one at pulse width of STROBE signal=20msec when transmitting data

of connected digital indicator is 16times/second.

This method makes the delay time of data acquisition be shortest compared to the other two

methods.

② Method to utilize Data Hold command

When making electrical short between #16 and #18(D.COM), update of BCD data is stopped

within 50msec and BCD data is stable.

After 50msec from input of Data Hold command, capture all the 24bit data.

BCD data

STROBE signal

Hold signal

MA4-00300-R1

- 8 -

③Method to capture data more than 2 times

Capture all the 24bit data 2 times with interval more than 10msec. Compare both data and if

they coincide, regard as correct data. If not coincide, consider that the first data is captured

before update and the second data is captured after update, or data are captured while in

transition state of unstable. In that case, capture data again after 10msec or more.

Use this method, capturing data at least 3 times, judge the correct data to prevent a capture

data error.

3). Recommended logic and RUN signal

This unit can invert output of BCD data (5digit data, polarity (+), over) and STROBE signal

independently.

Because BCD data is output by Open Collector, status between Collector–Emitter is OFF when

powered OFF. Thus, it is recommended to use negative logic of both BCD data and STROBE

signal.

When using positive logic, it is impossible to distinguish the state of plus side overflow (5digit

data and polarity are all ‘1’) and state of powered OFF. Also STROBE signal becomes ‘1’ when

powered OFF.

If using positive logic, it is recommended to utilize RUN signal. Status between

Collector-Emitter of this signal is OFF only when powered OFF or receiving data from digital

indicator is stopped for more than one second. Treat RUN signal as an alert to help to prevent

such trouble.

When using negative logic, to monitor RUN signal, it is easy to detect an alert.

3-5)Operation at abnormal

All the 24bit output between Collector-Emitter are OFF when powered OFF, also they are OFF

until the first serial signal coming in from powered ON.

When receiving data is stopped for more than 1 second caused by disconnection of cable or

receiving error, BCD data output ‘-00000’ regardless specified logic. Because zero output from

digital indicator is only ‘+0’, it is easy to distinguish that ‘-0’ is abnormal. STROBE signal is not

output in this case. RUN bit between Collector-Emitter is OFF

MA4-00300-R1

- 9 -

§4.Troubleshooting

If this unit does not work properly, please take the following measures. If the trouble still

cannot be solved, then please contact our company.

At query, please inform us the model name, product serial number, and conditions of this unit

as detailed as possible.

4-1)Basic check point

1). Please check if using a correct power supply.

This unit is supplied voltage with DC24V±10% (100mA typ.).

2). Please check that wires are connected to the terminal and connector properly and firmly.

4-2)Troubleshooting when the desired operation cannot be achieved.

1). Check input of serial signal

Check whether the serial signal monitor LED is flushing regularly. That LED is blinking

ON/OFF 4 times per second when the serial data is received normally.

When the LED is not flushing, please check the wiring of input signal of the terminal. Check

whether there is no disconnection of wires or each signal line of RS-232C or C/L is wired to

appropriate terminal.

C/L signal has no polarity.

Check whether RXD and D.COM of RS-232C signal is wired correctly.

Either RS-232C or C/L should be connected to the input terminal. If both are connected, it

is unable to receive serial data.

2). BCD data is not output even the serial monitor LED is flushing.

Check the subsequent wiring of BCD output. It is unable to detect ON/OFF of Emitter –

Collector by a tester because it is Open Collector output.

Each output of Collector side should be connected to the plus side of external DC supply

through a load. Each output of Emitter side should be connected to the minus side of

external DC supply.

Also check whether the external DC supply is satisfied with the rated output of photo

coupler in this unit. (Max. DC30V, 30mA, resistive load).

3). BCD data does not coincide with data of connected digital indicator all the time, or several

times in a day.

① Check the logic inversion of BCD data (Negative logic at the time of shipment).

② Check the logic inversion of STROBE signal (Negative logic at the time of shipment).

③ When capturing BCD data without condition, capture it when it is stable by using the

method of 3-4) 2). ‘Methods of acquisition of BCD data’

MA4-00300-R1

- 10 -

§5.Method of Installation and Connection

5-1)Installation environment of this unit

1) Operation temperature range of this unit is 0 to +40℃.

Please install this unit in a place not exposed to direct sunlight and condensation.

Consider ventilation when installing inside a control box which has possibility of filled up

heat. (This unit does not generate large amount of heat by itself)

2) The power supplied voltage is DC24V±10%.

Using an improper power supply may cause overheating, damage, malfunction, etc.

3) This unit is designed to fix by wall-mount. Please make use of holes 4-Φ4.0 of a cover and

fix with M3 screw.

There is no restriction of installation of direction.

5-2)Terminal/Connector connection

Serial signal is wired to 5mm pitch, 12pin screw-less terminal.

The shield line of each cable shall be grounded by either this unit or each connected

instrument, so that there is no ground loop.

Terminal #9(Shield) and #10(E) are connected inside of this unit.

Power supplied voltage is DC24V, which is isolated from an inner circuit by DC/DC

converter.

Serial signal from a digital indicator should be wired to the terminal as follows

・C/L signal C/L signal from a digital indicator is wired to the terminal

#1,#2 (C/L input), with no polarity.

・RS-232C signal TXD signal from a digital indicator is wired to the terminal

#5 (RXD).

COM signal from a digital indicator is wired to the terminal

#6 (D.COM).

Open Collector output is isolated from an inner circuit by photo coupler.

External command input, RS-232C input and C/L input are not isolated from inner circuit.

Ground of external input is common to the ground of RS-232C input. Thus it is

recommended to prepare external Rely contact to drive external input of this unit.

Meanwhile, C/L output of this unit is isolated from an inner circuit by photo coupler.

Wiring to BCD data connector should be done through a shielded cable.

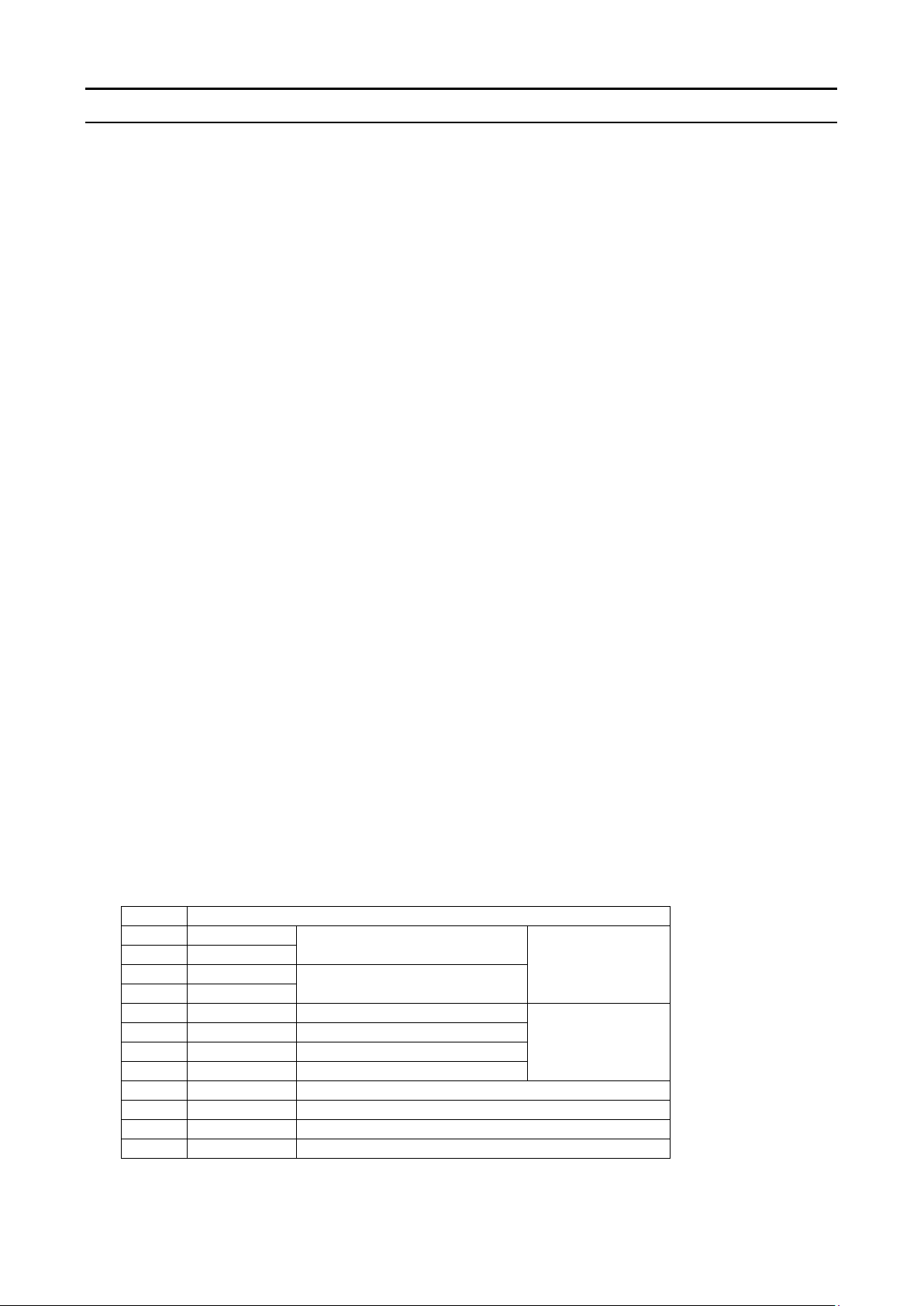

1). Terminal

5mm pitch, 12pin screw-less terminal

No.

Connection signal

1

C/L IN

C/L signal input

(No polarity)

Current Loop

2

C/L IN

3

C/L OUT

C/L signal output

(No polarity)

4

C/L OUT

5

RXD

Receive data

RS-232C

6

D.COM

Digital ground

7

TXD

Transmit data

8

D.COM

Digital ground

9

Shield

Shield of serial signal

10

E

Earth / Ground

11

+24V

Power line (DC+24V)

12

0

Power line (DC+0V)

Applicable wire spec.: Single wire = Φ0.4~1.2mm (AWG26~16),

Strand wire = 0.3~1.25mm2(AWG22~16)

MA4-00300-R1

- 11 -

2). Connector

36pin connector, DDK : 57-40360-7700(D12) or the equivalent

Direction

Connection signal

No.

No.

Connection signal

Direction

OUT

BCD data 100-1

1

19

BCD data 100-2

OUT

BCD data 100-4

2

20

BCD data 100-8

BCD data 101-1

3

21

BCD data 101-2

BCD data 101-4

4

22

BCD data 101-8

BCD data 102-1

5

23

BCD data 102-2

BCD data 102-4

6

24

BCD data 102-8

BCD data 103-1

7

25

BCD data 103-2

BCD data 103-4

8

26

BCD data 103-8

BCD data 104-1

9

27

BCD data 104-2

BCD data 104-4

10

28

BCD data 104-8

OVER

11

29

POL(+)

STROBE

12

30

RUN

Common Emitter

13

31

Common Emitter

14

32

N.C.

15

33

N.C.

IN

Data Hold

16

34

Logic inversion of

Data

IN

Logic inversion of

STROBE signal

17

35

Pulse width changing

of STROBE signal

D.COM

18

36

D.COM

Applicable wire connector: DDK 57-30360 or the equivalent

Connector pin#18,36(D.COM) are common to the terminal#6,8(D.COM) of RS-232C serial

I/O, but are independent from pin#13,14,31,32(Common Emitter) of BCD data output.

5-3)Precautions of wiring

BCD data output of this unit is Open Collector output. External command input of this unit

should be driven by external Relay contact due to not isolated from an inner circuit. The

external Relay contacts and this unit are supposed to build in the same control box, so that the

cable length between Relay contacts and this unit should be less than 10m.

BCD data signal can be extended as long as 100m because they are isolated from an inner

circuit. But it will depend on the surrounding circumstances.

Micro

computer

BCD output

BCD output

Common Emitter

External

command input

External

command ground

Recommended external Relay contact

Rated out DC5V 10mA or more

OMRON MY2,MY4 etc.

(for DIN rail)

OMRON G5V-1, G6E etc.

(for mount on board)

MA4-00300-R1

- 12 -

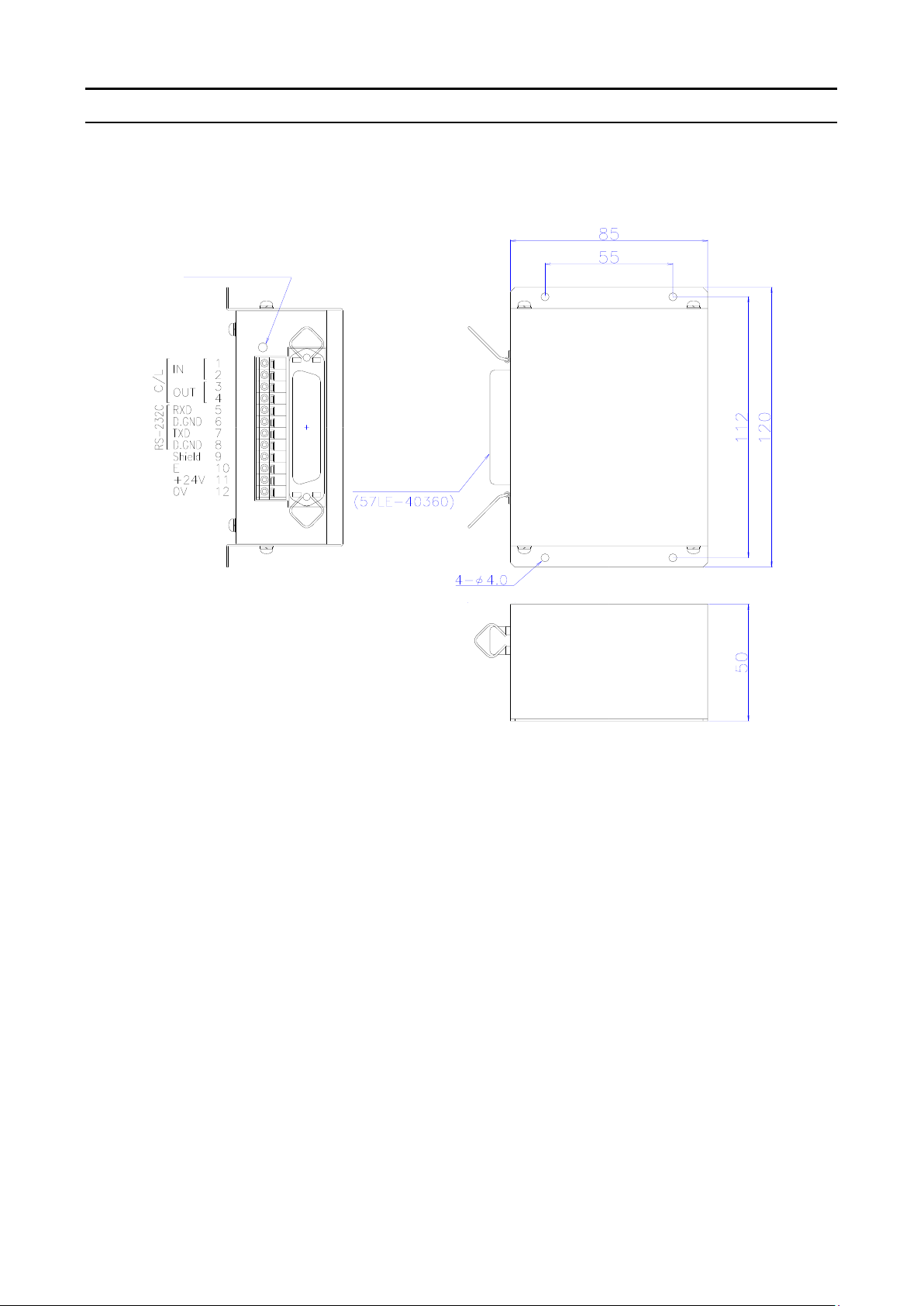

§6.Dimensional drawing

Serial data monitor LED

Connector for

BCD data output

Mounting hole

Table of contents