TPI 709R User manual

TPI 709R

Combustion Analyser

Contents

1. Introduction

2. Instrument Overview

2.1 Front View

2.2 Back View

2.3 Side Views

2.4 Top View

3. Turning On & Fuel Selection

3.1 Turning On

3.2 Fuel Selection

4. The 5 Functions

4.1 Function 1: - Flue Gas Analysis

4.2 Function 2: - Temperature Reading

4.3 Function 3: - Pressure Testing

4.4 Function 5: - Date/Time

5. Saving Data

6. Reviewing Data

7. Printing Data

8. Turning Off & Charging

9. Holding Data on Screen

Appendix A Specifications

Appendix B Calibration & Service

Appendix C Guarantee

Appendix D Troubleshooting Guide

Appendix E Index

1. Introduction

Thank you for purchasing TPI brand products. The TPI 709R Combustion

Analyser is a state of the art, easy to use analyser designed not only to display

and calculate the required readings from a flue but also to cover most of the other

desirable parameters associated with appliance installation and maintenance.

The instrument is ruggedly constructed and comes with a limited 3 Year

Warranty.

This manual will guide you through the functions of the TPI 709R, which will give

you many years of reliable service. The TPI 709R software has in-built self-

diagnostics that can easily be interrogated by our fully qualified and professional

engineers should an error occur. Please call the number below before returning

your instrument to your distributor should an error occurs. We can rectify over

75% of proposed faults over the phone.

TPI HELPLINE

01293 530196

Your TPI 709R Combustion Analyser comes complete with the following items as

standard: -

TPI 709R Instrument

Rubber Boot

Soft Carrying Case

Sampling Probe (c/w Type “K” Thermocouple)

In-Line Water Trap Bowl Filter (c/w Spare Particle Filter)

Battery Charger

Mini In-Line Pump Protection Filter (c/w 5 spare filters)

Exhaust Spigot (removable)

Pressure Tubing (2 x 1 metres)

GK11M Air Probe

Instruction Manual

Your TPI 709R Combustion Analyser has the following options available: -

Infrared Printer (see Appendix B)

Various Temperature Probes (see Appendix B)

Oil Filter (see Appendix B)

Smoke Test Pump (see Appendix B)

2. Instrument Overview

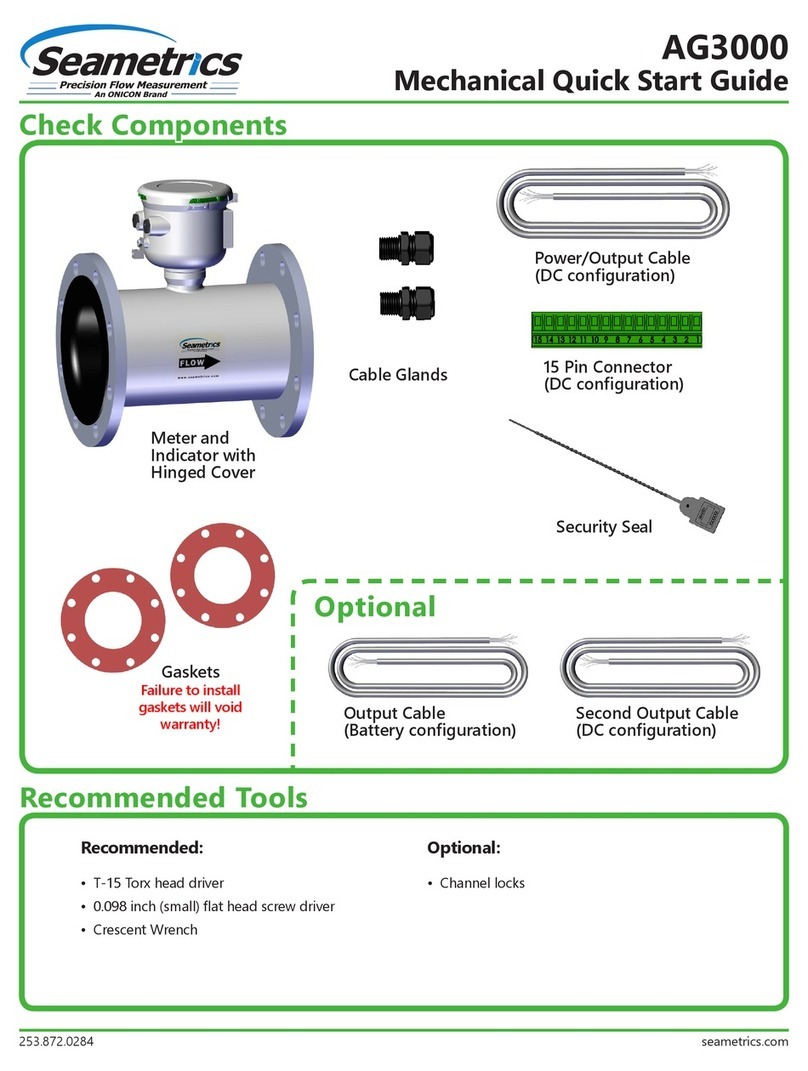

2.1 Front View

Rubber Boot Protects the instrument from accidental damage

Display Large 3 Parameter Backlit Display

Battery Indicator Showing battery life

Selected Fuel Type N Gas, LPG, Light Oil or Heavy Oil

Scrolls through selectable fuels (see 3.2)

Switches between Gross and Nett Efficiency (see 4.1.4)

Switches between ºC and ºF (see 4.2.1)

Scrolls through mbar, kPa and inH2O (see 4.3.1)

Moves up through the Stored Data Addresses (see 5, 6 & 7)

Zeroes pressure reading (see 4.3.1)

Moves down through the Stored Data Addresses (see 5, 6 & 7)

Scrolls through Flue Gas Analysis Function Screens (see 4.1)

Turns ch2 temperature ON/OFF (see 4.3.1)

Allows you to change the Date and Time (see 4.4)

Allows you to choose a Stored Data Address (see 5, 6 & 7)

Sends stored data to a separate infrared printer (see 7)

Allows you to view stored data on the display (see 6)

Stores readings to memory (see 5)

Moves you through the 4 Functions (see 4)

Turns Backlight ON and OFF (see 4)

Turns the instrument ON and OFF (see 3.1 & 8)

2.2 Back View

Gas and Pressure Inlet Ports Connection for In-Line Pump Protection Filter

(see 2.4 & 3.1)

Connections for Pressure Tubing (see 2.4 & 4.3)

Calibration and Info Label Displays calibration information

Displays serial number

Battery Compartment Holds rechargeable battery

Rubber Boot Protects the instrument from accidental damage

2.3 Side Views

Exhaust Port Port for connection of Exhaust Adaptor

Infrared Window Window for sending stored data to IR Printer (see 7)

Rubber Boot Protects the instrument from accidental damage

2.4 Top View

Charger Socket Connection for 220V/115V charger (see 10.1)

Thermocouple (ch1) Connection for thermocouple plug on probe (see 4.1)

T1 Socket Connection for any ‘K’ type thermocouple probe (see 4.2)

Thermocouple (ch2) Connection for any ‘K’ type thermocouple probe (see 4.2)

T2 Socket

Gas Inlet Port Connection for In-Line Pump Protection Filter (see 3.1)

Pressure (+) Port Connections for Pressure Tubing (see 4.3)

Pressure (-) Port Connections for Pressure Tubing (see 4.3)

3. Turning On & Fuel Selection

3.1 Turning On

Always: - Before turning on please ensure

that the In-Line Pump Protection Filter

(shown across) is connected to the Gas

Sample Port (see 2.2 or 2.4).

**THIS MUST REMAIN ON THE UNIT

AT ALL TIMES.**

Failure to do so may result in pump failure

and will invalidate the warranty.

Press the Power Key for approximately 2 seconds and the TPI 709R will

start up and display ALL Segments on the display for approx. 1 second. The

709R will then enter its 30-second purge period countdown with the following

screen being displayed.

The instrument should ALWAYS be turned

on in a clean air environment as the 30

second purge will attempt to set the Carbon

Monoxide level to 0 ppm and the Oxygen to

20.9%.

If there is insufficient clean air in the sensor

chamber after the 30 second purge period an

error indicating this may be displayed, please

see troubleshooting guide (appendix D) for

appropriate remedy. If the error is still present

after attempting the suggested remedy please

call the TPI HELPLINE

01293 530196

3.2 Fuel Selection

During the last 20 seconds of the 30 second purge time (i.e. as the 709R counts

down from 19 to 0) the user can scroll through the following Fuels: - Natural Gas,

LPG, Light Oil & Heavy Oil by repeatedly pressing the

Up Arrow Key to select the Fuel they are working with.

4. THE 4 FUNCTIONS

After the 30-second countdown the instrument is ready to take Flue Gas,

Temperature or Pressure readings and will Display the following Screen.

You are now ready to take Flue Gas Analysis

Readings. Please continue on with the manual from

Section 4.1 (below) which will guide you through the

various Analysis Screens.

However, if you do not wish to perform a Flue Test at

this moment Press the Func/Backlight Key

and move onto Section 4.2 of the manual.

At any time you can activate the Backlight by holding down the

Func/Backlight Key for 2 seconds.

4.1 Function 1: - Flue Gas Analysis

Ensure you have connected the Temperature Sampling Probe complete with

In-Line Water Trap Bowl Filter to the In-Line Pump Protection Filter (See 3.1)

which should ALWAYS be connected to the Gas Sample Port (see 2.2 or 2.4)

and that the ‘K’ Type Thermocouple Plug is in Thermocouple Socket (ch1)

(see 2.4). Also ensure that a ‘K’ Type Air Probe is connected to

Thermocouple Socket (ch2) (see 2.4) in order to calculate efficiency.

Your temperature-sampling probe comes complete with an In-Line Water Trap

Bowl Filter as standard.

This consists of a Particle Filter in

the Bowl Compartment and a Disc

Filter in the Lid (as shown in the

diagram across). The Disc Filter in

Lid will prevent any excessive water

from entering the 709R Combustion

Analyser if used correctly.

If you are working with OIL then you MUST ensure that you also use the optional

Oil Filter as shown below. Failure to do so will result in erroneous readings.

If any of the filters become excessively dirty or blocked then the

following screen will be displayed as a warning and no further

readings will be able to be taken until either the dirty filters are

replaced or the blockage removed:-

The 709R will also give off an audible Beeping Alarm

to warn that a “FLo Err” is being detected

WARNING: - Ensure that the In-Line Water Trap Bowl Filter hangs in a vertical

position whilst readings are being taken, particularly if water is visible (see below).

Failure to comply may result in damage to the instrument and will invalidate

the warranty.

WARNING: - There is ONLY one correct way to connect the

‘K’ type thermocouple plug into the socket (see 2.4). The

thermocouple plug is designed with one thick (negative) and

one thinner (positive) prong. Forcing the plug into the socket

the wrong way round may result in damage to the instrument.

Failure to comply may result in damage to the instrument

and will invalidate the warranty.

Pressing the Scroll/Enter Key will take you through the following Flue Gas

Analysis Screens

4.1.1 Screen 1

Displays Carbon Monoxide (CO) reading in parts per

million (ppm)

Displays calculated Carbon Dioxide (CO2) figure in

percentage (%)

Displays calculated CO/CO2(Ratio) figure

4.1.2 HIGH CO ALARM

Should the CO reading rise above 2,000ppm a continuous series of Alarm Beeps

will be heard. This Alarm alerts the user that there is a high concentration of CO

and that there may be a potential problem with the appliance. The instrument will

continue to monitor CO up to 10,000ppm but the longer the probe is left attached

to the instrument sampling at these high levels the longer the recovery time back

to ambient air before the instrument will be able to be switched off (see 4.1.8 –

Failsafe Turn Off).

4.1.3 Screen 2

Displays Oxygen (O2) reading in percentage (%)

Displays calculated Excess Air (X Air) figure in

percentage (%)

Displays calculated Efficiency (Eff.) figure in percentage

(%)

Pressing the Up Arrow Key will toggle between

Gross & Nett Efficiency

4.1.4 Screen 3

Displays Carbon Monoxide (CO) reading in parts per

million (ppm)

Displays Oxygen (O2) reading in percentage (%)

4.1.5 Screen 4

Displays CO air free calculated reading

4.1.6 Screen 5

Displays Temperature reading of Channel 1 (ch1) in

degrees Centigrade (ºC)

Displays Temperature reading of Channel 2 (ch2) in

degrees Centigrade (ºC)

Displays the Differential Temperature (Diff.) between ch1

and ch2 in ºC

‘oPEn’ will be displayed if no ‘K’ type probe is

connected to the thermocouple socket

4.1.7 CO above 15ppm (Failsafe) Protection Beep

The 709R will not allow the user to either Turn the instrument OFF or to move to

another Function whilst the CO level is above 15ppm. A short beep will be heard

should the user attempt either of the above with the CO above 15ppm.

This is a Failsafe Feature of the 709R to protect the instrument from giving false

readings when next turned on. The 709R should be run in a clean air environment

with just the In-Line Pump Protection Filter attached until the CO level drops

below 15ppm. The 709R will then be able to be moved to a different function

screen or be turned OFF.

4.2 Function 2: - Temperature Reading

The pump will stop running when in this function

Remember:- It was the Function Key that got you here!!!

Ensure you have a ‘K’ type probe connected to one or both of the

thermocouple sockets ch1 or ch2 (see 4.2)

WARNING: - There is ONLY one correct way to connect the

‘K’ type thermocouple plug into the socket (see 2.4). The

thermocouple plug is designed with one thick (negative) and one

thinner (positive) prong. Forcing the plug into the socket the

wrong way round may result in damage to the instrument.

Failure to comply may result in damage to the instrument

and will invalidate the warranty.

4.2.1 Screen 1

Displays Temperature reading of Channel 1 (ch1) in

degrees Centigrade (ºC) or degrees Fahrenheit (ºF)

Displays Temperature reading of Channel 2 (ch2) in

degrees Centigrade (ºC) or degrees Fahrenheit (ºF)

Displays the Differential Temperature (Diff.) between ch1

and ch2 in ºC or ºF

Pressing the Up Arrow Key will toggle between

ºC and ºF

‘oPEn’ will be displayed if no ‘K’ type probe is

connected to the thermocouple socket

4.3 Function 3: - Pressure Testing

The pump will stop running when in this function

Remember:- It was the Function Key that got you here!!!

Ensure you have Pressure Sampling Tube connected to one or both of the

Pressure Ports (see 2.2 or 2.4)

4.3.1 Screen 1

Displays Pressure reading in either millibars (mbar),

kiloPascals (kPa), or inches of Water (inH2O)

Pressing the Up Arrow Key will scroll through

mbar, kPa and inH2O

Pressing the Down Arrow Key will Zero the

Pressure reading

Pressing the Scroll/Enter Key will toggle the ch2

temperature reading ON and OFF

Pressure Resolution

The pressure resolution can be toggled between 0.01mbar & 0.1mbar by pressing

and holding down both the Up & Down Arrow Keys simultaneously.

4.4 Function 5: - Date/Time

The Time, Date and Year can be changed whilst in this function as below:-

4.4.1 Screen 1

1. Press the Scroll/Enter Key once to allow you to change the Time,

Date and Year

2. Press the Up Arrow Key to Increase the Minutes

3. Press the Down Arrow Key to Decrease the Minutes

4. Press the Scroll/Enter Key to confirm the desired Minute and

move onto the Hours

5. Repeat steps 2 to 4 to change the Hour, the Day, the Month and the Year

6. The unit will return to normal after the desired Year has been confirmed

5. SAVING DATA

It is possible to save complete combustion readings, temperature and single

pressure readings as follows:-

1. Have the 709R analyser set to the relevant screen for the readings that

you wish to save (i.e. Any of the combustion screens (see 4.1) for

combustion readings or pressure screen (see 4.3.1) for single pressure

reading)

2. Press the Store Key once

3. ‘Addr’ will be displayed and a location number (0 to

49) will be flashing on the screen.

4. Select the required address location that you wish to

save the data to by pressing the Up and

Down Arrow Keys

**Please Note:- Choosing the same Address Location on which previously

Stored Data is being held will OVERWRITE the previous readings with the New

Stored Data. This will be the case regardless of the particular readings you are

attempting to save (i.e. should you have Combustion Readings stored at Address

1 and you Save Temperature Readings to Address 1 then the Previous

Combustion Readings will be overwritten with the New Temperature Readings)

and the previously Stored Readings will not be retrievable.

5. Press the Scroll/Enter Key once and the readings will be stored to

the location that was chosen in step 3 and “End yES” with “yES”

flashing will be displayed

6. If you do not wish to save any further readings at this

moment press the Scroll/Enter Key and you will

be returned to the screen you were originally on.

7. However if you wish to continue and save another set of

readings then press the Up Arrow Key so that “no” is flashing and

press the Scroll/Enter Key.

The information that you just stored can be either be Reviewed on the screen

(see 6) or Printed to a compatible IR Printer (see 7)

6. REVIEWING DATA

1. Press the Recall Key once and the following screen will be

displayed.

‘Stor’ will be flashing on the display. If you wish to review

the Last Time Calibrated Date then press the Down

Arrow Key to have ‘CAL’ flashing rather than ‘Stor’

2. Press the Scroll/Enter Key once and if you have chosen to view

the Last Time Calibrated Date (CAL) then the Date that the Last Time the

709R was calibrated will be displayed flashing on the screen.

(Go To Step 6)

3. However if you have chosen to view Stored (Stor) Readings then ‘Addr’

will be displayed and a location number will be flashing.

Select the required address location that you wish to

review by pressing the Up and Down Arrow

Keys.

4. Press the Scroll/Enter Key once and the Time &

Date of the Saved Data from the selected address

location will be displayed flashing on the screen.

**If there is no data present at that location then ‘nULL dAtA’ will be

displayed flashing**

5. The rest of the Saved Data at this address location can be reviewed

by pressing the Up and Down Arrow Keys

6. Press the Scroll/Enter Key once and “End

YES” with “YES” flashing will be displayed. Should

you not wish to view any further stored data then press

the Scroll/Enter Key once to Exit and be

returned to the screen you were originally on.

7. However if you wish to continue and review another set of readings then

press the Up Arrow Key so that “no” is flashing.

8. Press the Scroll/Enter Key once and repeat from Step 2

7. PRINTING DATA

WARNING: - To operate correctly there must be a clear line of sight between the

Infrared Window on the instrument (see 2.3) and the Infrared Window on the IR

Printer (see Printer instructions)

1. Press the Print Key once and the following screen will be displayed.

‘rEAL’ will be flashing.

If you wish to Print Out previously Stored Data (Stor) or

Last Time Calibrated Date (CAL) then press the

Down Arrow Key to have ‘Stor’ or ‘CAL’ flashing

rather than ‘rEAL’

2. Press the Scroll/Enter Key once and if you have chosen to print out

Real Time (rEAL) readings or Last Time Calibrated Date (CAL) then the

‘Print Out’ screen (below left) will be displayed and the Real Time (rEAL)

readings or Last Time Calibrated Date (CAL) will be sent to the printer.

However if you have chosen to print the

Stored Data (Stor) then ‘Addr’ will be

displayed and a location number will be

flashing.

Select the required address location that

you wish to review the saved data from

by pressing the Up and Down

Arrow Keys

3. Press the Scroll/Enter Key . The ‘Print Out’ screen (above left) is

displayed and the selected readings will be sent to the printer.

4. Once the selected data has been sent to the IR printer

“End YES” with “YES” flashing will be displayed. Should

you not wish to print any further stored data then press the

Scroll/Enter Key once to Exit and be returned to the

screen you were originally on.

5. However if you wish to continue and review another set of readings then

press the Up Arrow Key so that “no” is flashing.

6. Press the Scroll/Enter Key once and repeat.

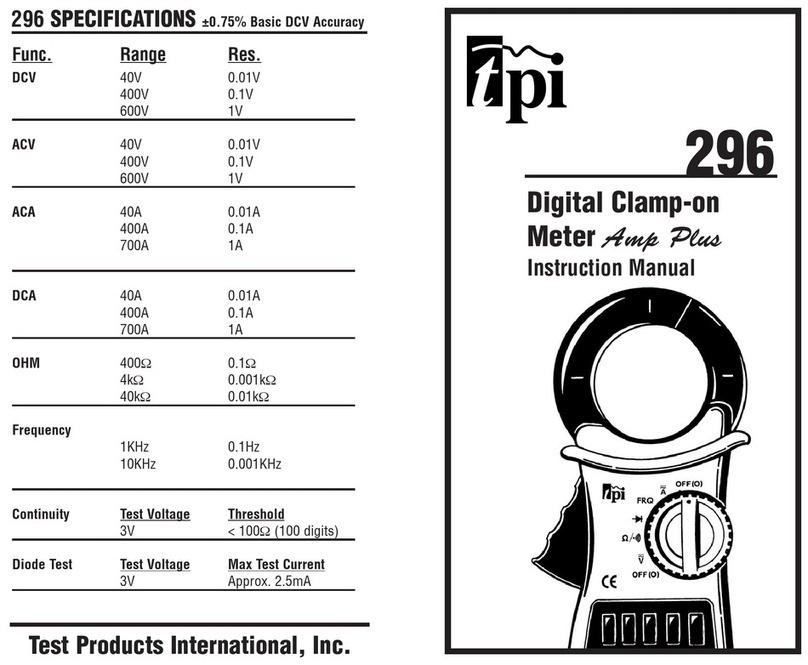

Other manuals for 709R

1

This manual suits for next models

1

Table of contents

Other TPI Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Balcrank

Balcrank 3331-018 Operation, installation, maintenance and repair guide

Aethlabs

Aethlabs microAeth AE51 quick start guide

CiDRA

CiDRA CYCLONEtrac PST installation manual

Delmhorst Instrument Co

Delmhorst Instrument Co KS-D1 operating instructions

Inficon

Inficon Cube CDGsci operating manual

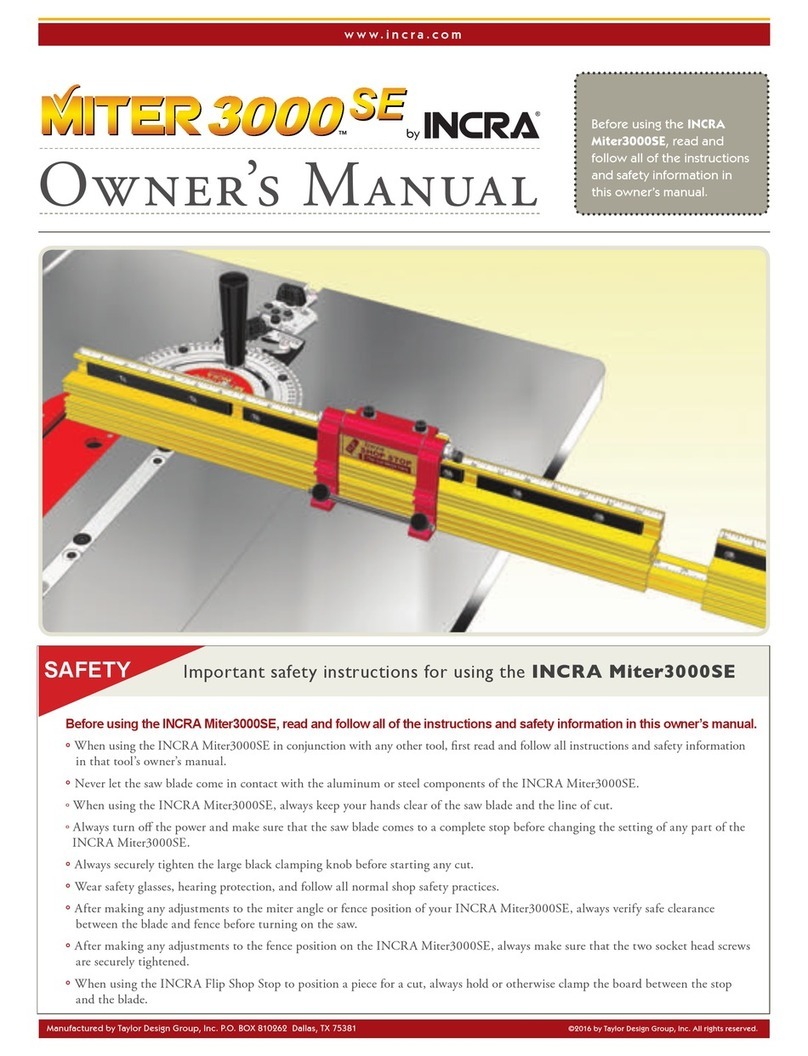

Incra

Incra Miter 3000 SE owner's manual

GEX Corporation

GEX Corporation Thermo Scientific GENESYS 30 Product Specifications and Usage Information

WESTECH

WESTECH EPIPC-COM Series instruction manual

THORLABS

THORLABS NPL Series user guide

Miyachi

Miyachi MG3D operating instructions

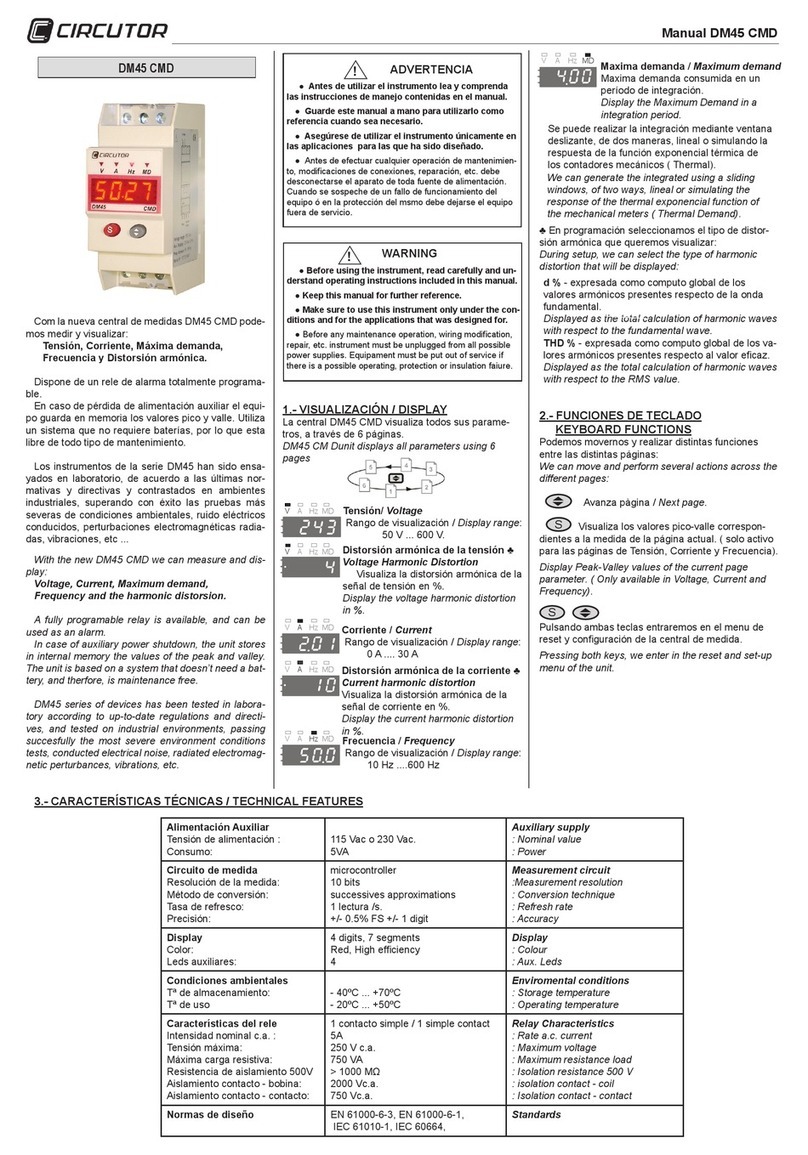

Circutor

Circutor DM45 CMD manual

RND lab

RND lab RND 365-00008 user manual