MODEL WPMZ-3-□□□-□□-□□□ 1/12

IM-0881-04

Thank you for purchasing the WPMZ graphical digital panel meter.

This manual is a quick instruction manual only for preparation,

connection and basic condition settings of the WPMZ. For the all

functions of the WPMZ, please refer to a detailed instruction

manual which can be downloaded from our homepage.

For models with RS communication functions, please refer to

"Modbus communication manual" or "RS-232C communication

manual" which also can be downloaded from our homepage.

(https://www.watanabe-electric.co.jp/en/)

Checks before suppling power, preparations, wiring

1. CHECKING THE PRODUCT

1-1. MODEL CODES

Please check that the product has been delivered matches the

model code ordered in reference to “19. SPECIFICATIONS”.

2. PRECAUTIONS FOR USE

2-1. ENVIRONMENTS AND CONDITIONS OF USE

Please do not use the product under the following circumstances.

It might cause malfunctions and shortening the life of the

product.

1)Ambient temperature of out of -5 to 50°C

2)Ambient humidity of out of 35 to 85%, or freezing

condensing

3)Excessive dust or metal particles

(Storing in a dust-proof chassis and a countermeasure

against heat dissipation are required.)

4)Environment of corrosive gas, salty air or oily smoke

5)Environment of much vibration or impact

6)Environment of rain or water drops (except the front

panel)

7)Environment of strong electromagnetic field or much

exogenous noises.

2-2. INSTALLATION AND CONNECTION

1)Please read this manual before the installation and the

connection of wires. And they should be performed by a

person having a specialized technique. In addition, the

insulation class of the WPMZ is as shown by the figure

below. Please confirm that the insulation class satisfies a

use condition prior to the installation.

Reinforced Insulation Basic Insulation

Operational Insulation

Comparative outputs, External

control inputs, Analog output, BCD

output,RS-232C

Comparative outputs, External

control inputs, Analog output, BCD

output,RS-232C

2)Do not wire the power supply line, input signal lines and

output signal lines near noise sources or relay drive lines.

3)Bundling or containing in a same duct with lines including

noises might cause malfunctions.

4)The WPMZ becomes available functionally right after

power activation, but requires 30 minutes' warming to

satisfy all performance requirements.

Note: The inputs “A channel” and “B channel”may be

abbreviated to “Ach”and “Bch”in this manual.

2-3. CHECKING BEFORE USE

Install the WPMZ under the environments and conditions of use

which meet requirements.

If you find any damage to the product or any problem, please

contact to your dealer or our company directly.

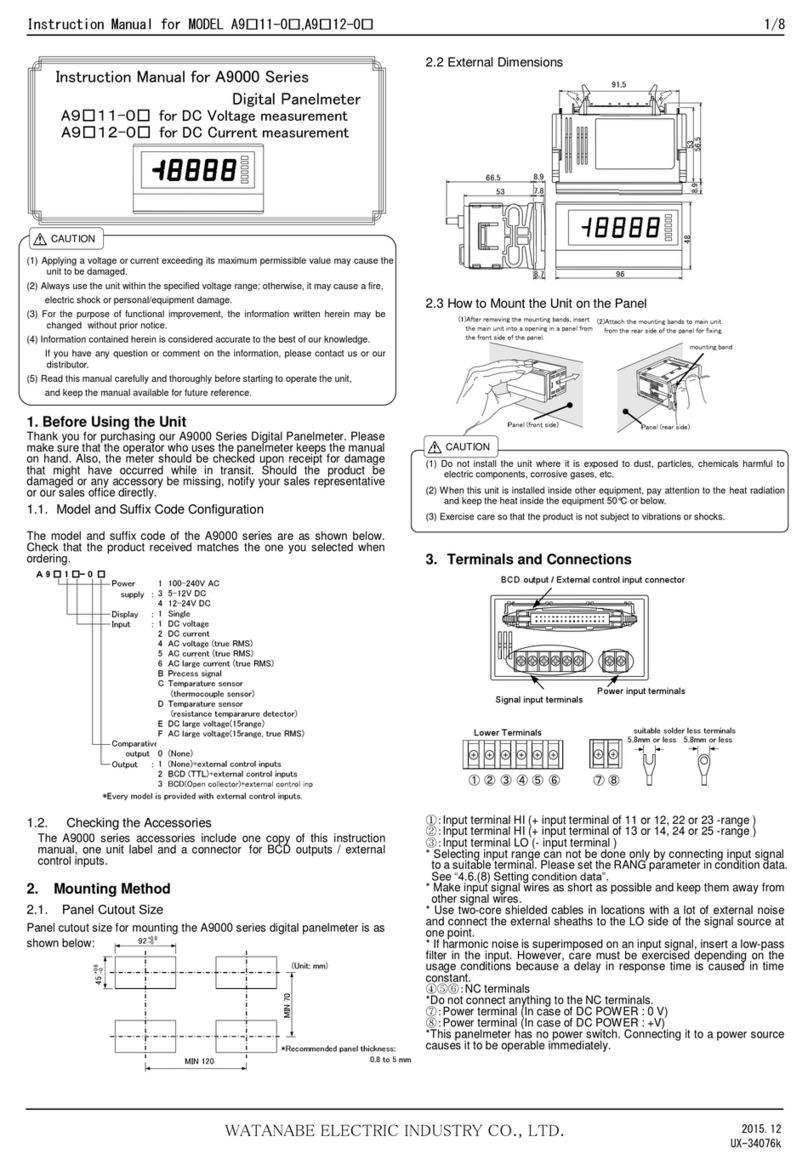

3. HOW TO INSTALL (PANEL CUT DIMENTIONS)

To install the WPMZ, panel cut dimensions are as shown by the

figure below.

4. CONNECTING TERMINALS

4-1. BACK VIEW

4-2. WIRING TO SCREWLESS TERMINALS

Pushing the wire release button with a flat-blade screwdriver,

insert the wire to the wire insert hole deeply and then release

the button.

(Suitable tool for pushing buttons :flat-blade screwdriver blade

width 2.5mm)

4-3. CONNECTION FOR LOWER ROW TERMINALS

(COMPARETIVE OUTPUT/EXTERNAL CONTROL

INPUT, POWER)

4-3-1. Comparative Output / External Control Input

-Open-collector output products

AL1 open-collector output (collector)

AL2 open-collector output (collector)

AL3 open-collector output (collector)

AL4 open-collector output (collector)

Common terminal for PNP output (emitter)

(NPN output : no connection)

Common terminal for NPN output (emitter)

(PNP output : GND for PNP)

Common terminal for external control inputs

External control input No.1

External control input No.2

External control input No.3

External control input No.4

External control input No.5

Graphical Digital Panel Meter

WPMZ-3-□□□-□□-□□□

Quick instruction manual

120mm min.

70mm min.

+0.6

-0

45

92 -0

+0.8

Ach inputs Bch inputs

Power

Comparetive output/External control input

outputs

UPPER ROW TERMINALS

MIDDLE ROW

TERMINALS

LOWER ROW TERMINALS

Wire insert hole

Wire release button

AL2 (c)

5

COM

AL1 (c)

AL4 (c)

AL3 (c)

COM

AL +COM(e)

AL -COM(e)

1 2 3 4 5 6 7 8 9

10 11 12 13

4

32

1

EXT CONTROL

PNP

NPN

Suitable wire:AWG24 to 16

*⑥、⑦、⑧:connected internally