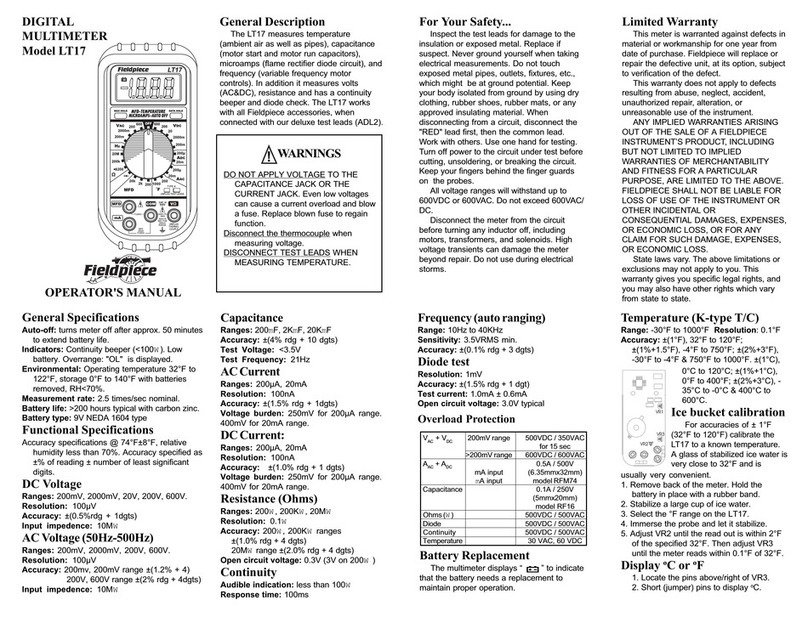

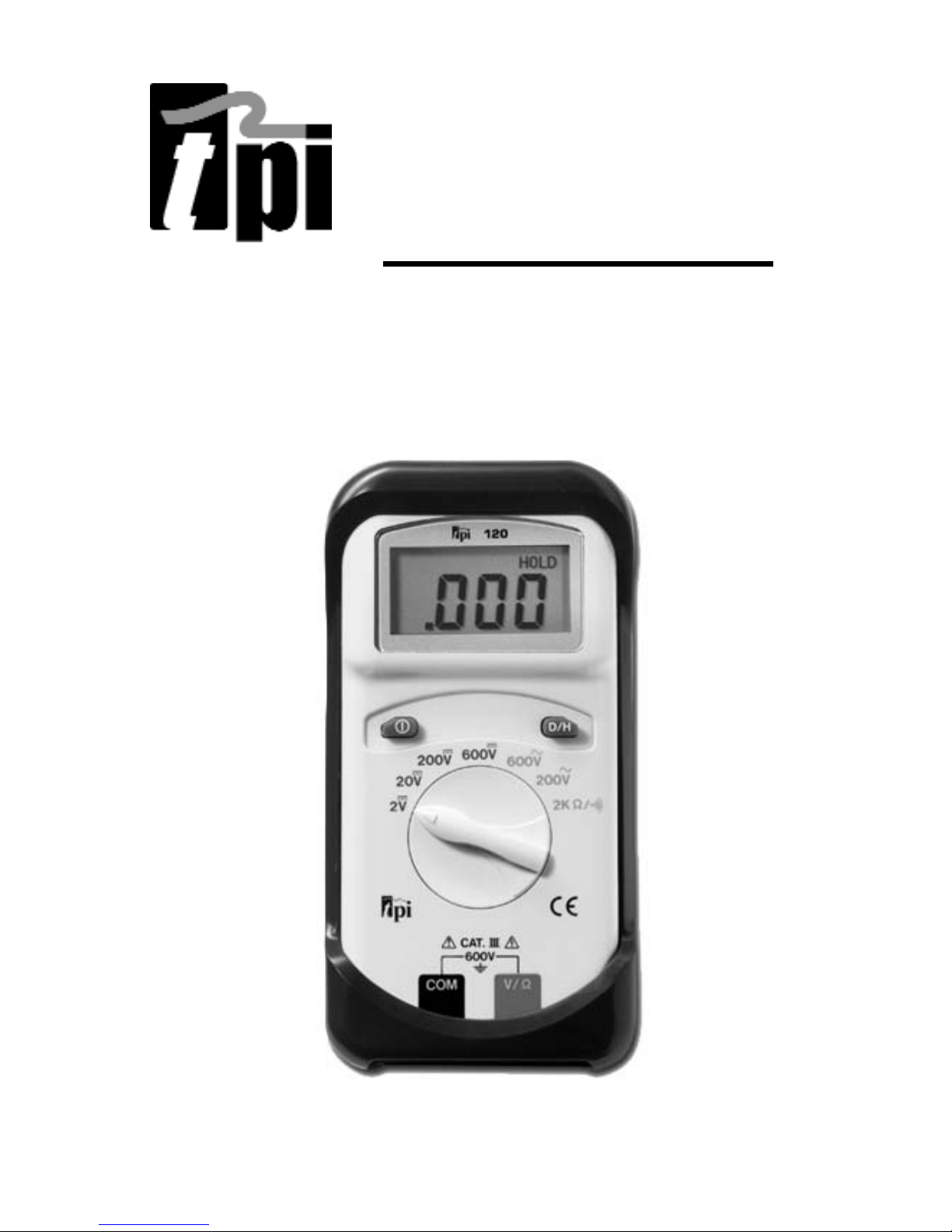

TPI 120 User manual

120

Digital Multimeter

Instruction Manual

2 3

EC DECLARATION OF CONFORMITY

This is to certify that model 120 conforms to the

protection requirements of the council directive

89/336/EEC, in the approximation of laws of the

member states relating to Electromagnetic compati-

bility and 73/23/EEC, The Low Voltage Directive by

application of the following standards:

EN 50081-1 1992 Emissions Standard

EN 50082-1 1992 Immunity Standard

EN61010-1 1993 Safety Standard

EN61010-2-031 1995 Safety Standard

To ensure conformity with these standards, this

instrument must be operated in accordance with the

instructions and specifications given in this manual.

CAUTION:

Even though this instrument complies with the immunity stan-

dards, the accuracy can be affected by strong radio

emissions not covered in the above standards. Sources such

as hand held radio transceivers, radio and TV transmitters,

vehicle radios and cellular phones generate electromagnetic

radiation that could be induced into the test leads of this

instrument. Care should be taken to avoid such situations or

alternatively, check to make sure that the instrument is not

being influenced by these emissions.

SAFETY CONSIDERATIONS

WARNING: Please follow manufacturers

test procedures whenever possible. Do not

attempt to measure unknown voltages or

components until a complete understanding

of the circuit is obtained.

GENERAL GUIDELINES

ALWAYS

• Test the 120 before using it to make sure it is operating

properly.

• Inspect test leads before using to make sure there are no

breaks or shorts.

• Double check all connections before testing.

• Have someone check on you periodically if working alone.

• Have a complete understanding of circuit being measured.

• Disconnect power to circuit, then connect test leads to the

120, then to circuit being measured.

NEVER

• Attempt to measure unknown high voltages.

• Attempt to measure current with the meter in parallel to the

circuit.

• Connect the test leads to a live circuit before setting up the

instrument.

• Touch any exposed metal part of the test lead assembly.

2 3

EC DECLARATION OF CONFORMITY

This is to certify that model 120 conforms to the

protection requirements of the council directive

89/336/EEC, in the approximation of laws of the

member states relating to Electromagnetic compati-

bility and 73/23/EEC, The Low Voltage Directive by

application of the following standards:

EN 50081-1 1992 Emissions Standard

EN 50082-1 1992 Immunity Standard

EN61010-1 1993 Safety Standard

EN61010-2-031 1995 Safety Standard

To ensure conformity with these standards, this

instrument must be operated in accordance with the

instructions and specifications given in this manual.

CAUTION:

Even though this instrument complies with the immunity stan-

dards, the accuracy can be affected by strong radio

emissions not covered in the above standards. Sources such

as hand held radio transceivers, radio and TV transmitters,

vehicle radios and cellular phones generate electromagnetic

radiation that could be induced into the test leads of this

instrument. Care should be taken to avoid such situations or

alternatively, check to make sure that the instrument is not

being influenced by these emissions.

SAFETY CONSIDERATIONS

WARNING: Please follow manufacturers

test procedures whenever possible. Do not

attempt to measure unknown voltages or

components until a complete understanding

of the circuit is obtained.

GENERAL GUIDELINES

ALWAYS

• Test the 120 before using it to make sure it is operating

properly.

• Inspect test leads before using to make sure there are no

breaks or shorts.

• Double check all connections before testing.

• Have someone check on you periodically if working alone.

• Have a complete understanding of circuit being measured.

• Disconnect power to circuit, then connect test leads to the

120, then to circuit being measured.

NEVER

• Attempt to measure unknown high voltages.

• Attempt to measure current with the meter in parallel to the

circuit.

• Connect the test leads to a live circuit before setting up the

instrument.

• Touch any exposed metal part of the test lead assembly.

54

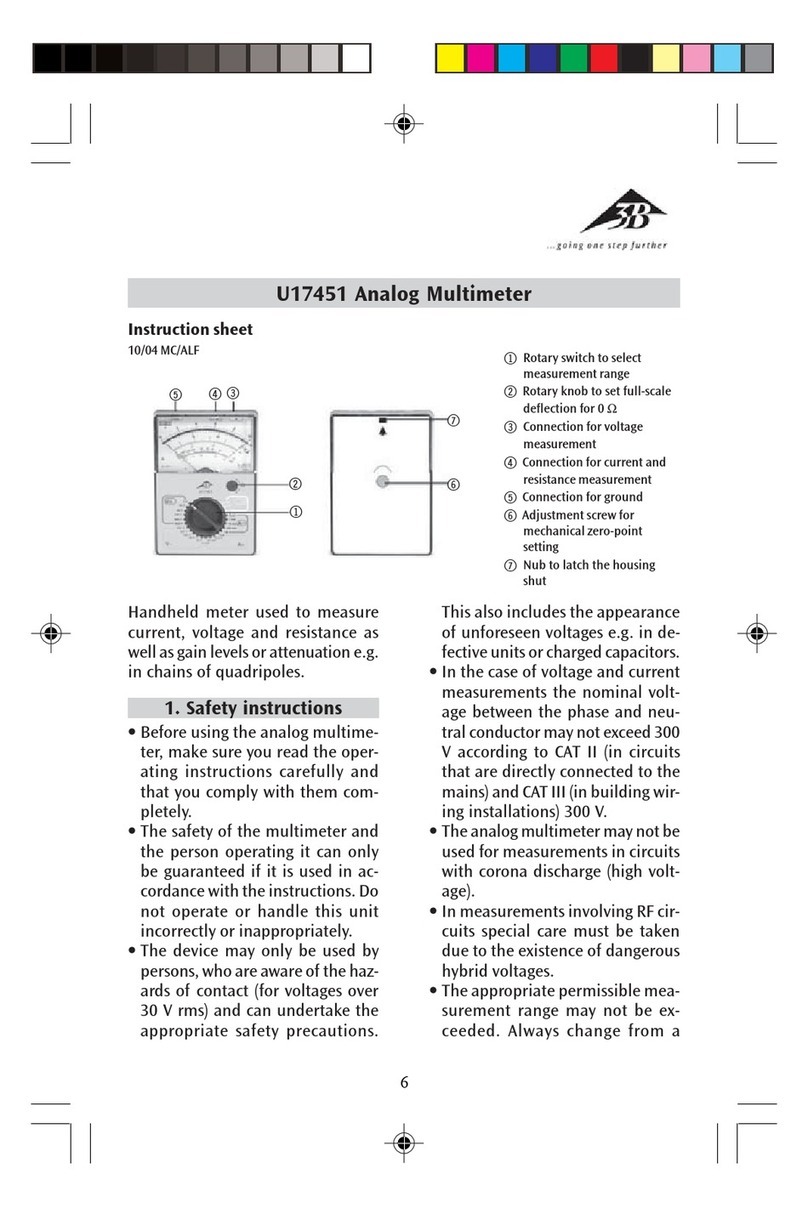

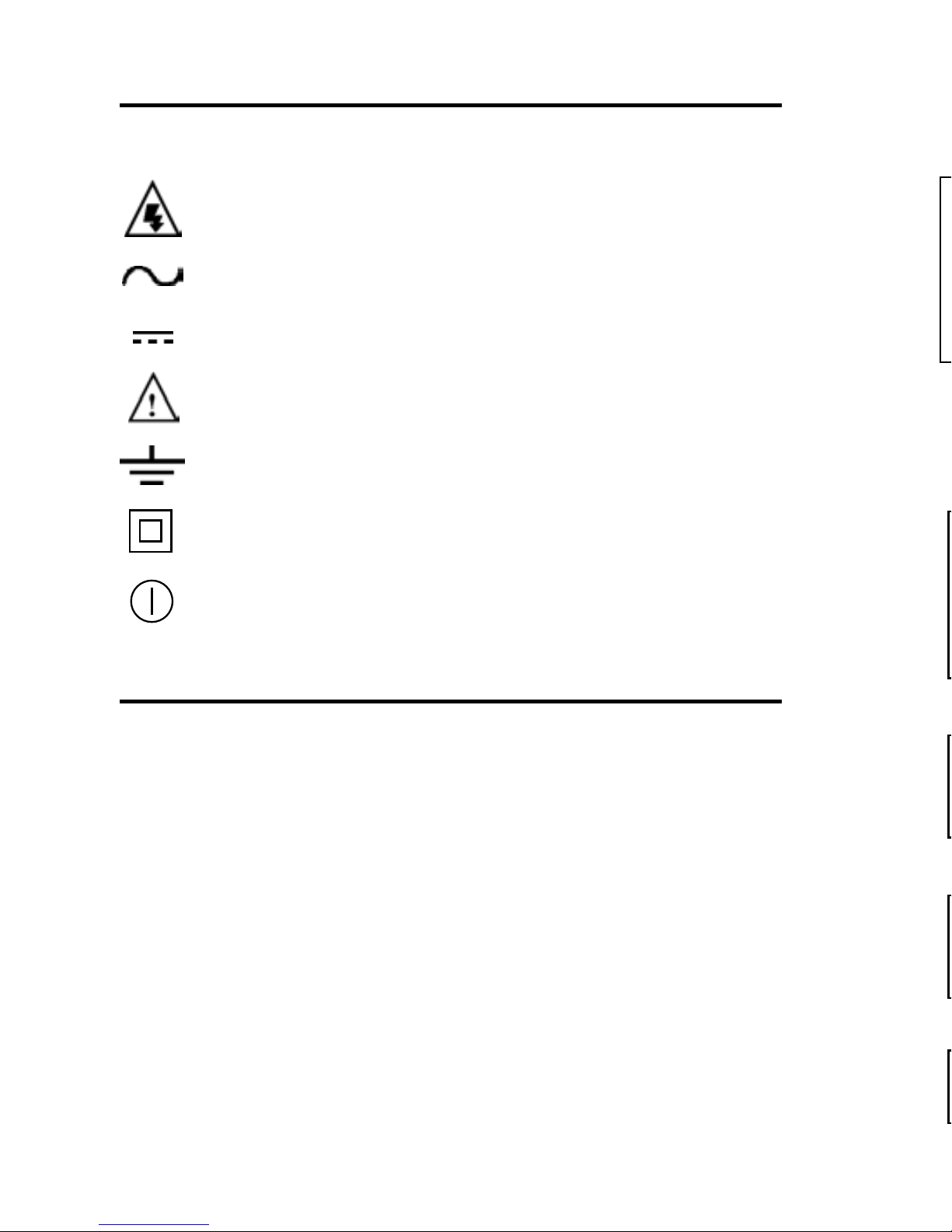

INTERNATIONAL SYMBOLS

CAUTION: RISK OF ELECTRIC SHOCK

AC (ALTERNATING CURRENT)

DC (DIRECT CURRENT)

REFER TO INSTRUCTION MANUAL

GROUND

DOUBLE INSULATION

ON/OFF, PUSH BUTTON SWITCH

Features and Benefits

Safety Meets CE and IEC 1010 requirements. UL Listed.

Large LCD Easy to read at all angles and the majority of light-

ing levels.

Data Hold Freeze readings on the display.

Rubber Boot Added protection when the instrument is dropped.

(120NB does not include boot.)

Versatile Use accessories like a carbon monoxide attachment

to expand the capabilities of the 120.

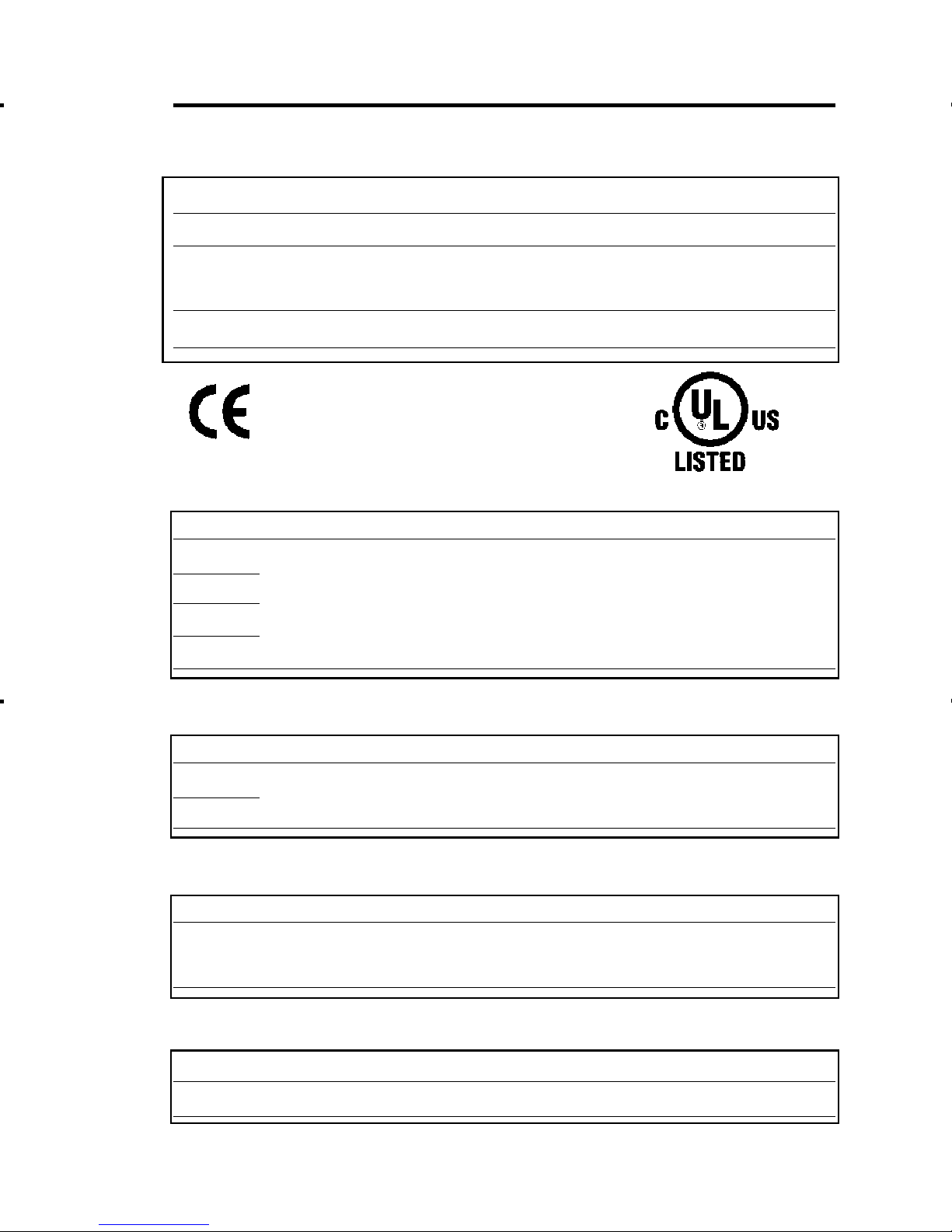

SPECIFICATIONS

a. General Specifications

Power Supply 9 Volt Battery

Battery Life 560 hrs. Alkaline

Size (H x L x W) 33mm x 86mm x 187mm

(1.3” x 3.4” x 7.4”)

Weight 340g (12 oz)

IEC 1010 Over Voltage:

CAT II - 1000V, CAT III - 600V

Pollution Degree 2

b. DCV

Range Resolution Accuracy Impedance

2V 0.001V ±0.5% of reading, 10MΩ

20V 0.01V ±2 digits

200V 0.1V

600V 0.1V

c. ACV (45Hz to 450Hz)

Range Resolution Accuracy Impedance

200V 0.1V ±1.2% of reading, 10MΩ

600V 1V ±3 digits

d. OHM (Resistance,ΩΩ)

Range Resolution Accuracy Overload Protection

2kΩ0.001kΩ±0. 5% of rdg, 600V DC or AC Peak

±1 digit

e. Continuity Buzzer

Test Voltage Threshold Overload Protection

2.5V <100Ω600 V DC or Peak AC

*Warning: Test Leads: Use only correct type and overvoltage category rating.

54

INTERNATIONAL SYMBOLS

CAUTION: RISK OF ELECTRIC SHOCK

AC (ALTERNATING CURRENT)

DC (DIRECT CURRENT)

REFER TO INSTRUCTION MANUAL

GROUND

DOUBLE INSULATION

ON/OFF, PUSH BUTTON SWITCH

Features and Benefits

Safety Meets CE and IEC 1010 requirements. UL Listed.

Large LCD Easy to read at all angles and the majority of light-

ing levels.

Data Hold Freeze readings on the display.

Rubber Boot Added protection when the instrument is dropped.

(120NB does not include boot.)

Versatile Use accessories like a carbon monoxide attachment

to expand the capabilities of the 120.

SPECIFICATIONS

a. General Specifications

Power Supply 9 Volt Battery

Battery Life 560 hrs. Alkaline

Size (H x L x W) 33mm x 86mm x 187mm

(1.3” x 3.4” x 7.4”)

Weight 340g (12 oz)

IEC 1010 Over Voltage:

CAT II - 1000V, CAT III - 600V

Pollution Degree 2

b. DCV

Range Resolution Accuracy Impedance

2V 0.001V ±0.5% of reading, 10MΩ

20V 0.01V ±2 digits

200V 0.1V

600V 0.1V

c. ACV (45Hz to 450Hz)

Range Resolution Accuracy Impedance

200V 0.1V ±1.2% of reading, 10MΩ

600V 1V ±3 digits

d. OHM (Resistance,ΩΩ)

Range Resolution Accuracy Overload Protection

2kΩ0.001kΩ±0. 5% of rdg, 600V DC or AC Peak

±1 digit

e. Continuity Buzzer

Test Voltage Threshold Overload Protection

2.5V <100Ω600 V DC or Peak AC

*Warning: Test Leads: Use only correct type and overvoltage category rating.

76

MEASUREMENT TECHNIQUES

1. Controls and Functions:

Push Buttons

Turns the 120 on and off.

D/H Activates the Data Hold function.

Rotary Switch

VUsed for measurement of DC Volts.

Select best range for the voltage to

be measured.

VUsed for measurement of AC Volts.

Select best range for the voltage to

be measured.

ΩΩUsed for measurement of

Resistance and Continuity.

Input Jacks

COM Black test lead connection for all

functions.

V/ΩΩRed test lead connection for OHM,

Continuity Buzzer, DCV and ACV

functions.

STEP BY STEP PROCEDURES

a.Measuring DC Volts

WARNING!

Do not attempt to make a voltage measure-

ment of more than 600V or of a voltage level that

is unknown.

Instrument set-up:

FUNC BLACK RED MIN MAX

TEST LEAD TEST LEAD READING READING

DCV COM VΩ0.001V 600V

Measurement Procedure:

1. Disconnect power to circuit to be meas-

ured.

2. Plug the black test lead into the COM input

jack.

3 Plug red test lead into V/Ωinput jack.

4. Set rotary switch on 120 to desired range

in DCV function depending on the voltage

to be measured.

5. Connect the test leads to the circuit to be

measured.

6. Reconnect power to the circuit to be meas-

ured.

7. Read the voltage on the 120.

76

MEASUREMENT TECHNIQUES

1. Controls and Functions:

Push Buttons

Turns the 120 on and off.

D/H Activates the Data Hold function.

Rotary Switch

VUsed for measurement of DC Volts.

Select best range for the voltage to

be measured.

VUsed for measurement of AC Volts.

Select best range for the voltage to

be measured.

ΩΩUsed for measurement of

Resistance and Continuity.

Input Jacks

COM Black test lead connection for all

functions.

V/ΩΩRed test lead connection for OHM,

Continuity Buzzer, DCV and ACV

functions.

STEP BY STEP PROCEDURES

a.Measuring DC Volts

WARNING!

Do not attempt to make a voltage measure-

ment of more than 600V or of a voltage level that

is unknown.

Instrument set-up:

FUNC BLACK RED MIN MAX

TEST LEAD TEST LEAD READING READING

DCV COM VΩ0.001V 600V

Measurement Procedure:

1. Disconnect power to circuit to be meas-

ured.

2. Plug the black test lead into the COM input

jack.

3 Plug red test lead into V/Ωinput jack.

4. Set rotary switch on 120 to desired range

in DCV function depending on the voltage

to be measured.

5. Connect the test leads to the circuit to be

measured.

6. Reconnect power to the circuit to be meas-

ured.

7. Read the voltage on the 120.

98

STEP BY STEP PROCEDURES

b.Measuring AC Volts

WARNING!

Do not attempt to make a voltage measure-

ment of more than 600V or of a voltage level that

is unknown.

Instrument set-up:

FUNC BLACK RED MIN MAX

TEST LEAD TEST LEAD READING READING

ACV COM VΩ0.001V 600V

Measurement Procedure:

1. Disconnect power to circuit to be meas-

ured.

2. Plug the black test lead into the COM input

jack.

3 Plug red test lead into V/ΩΩinput jack.

4. Set rotary switch on 120 to desired range

in ACV function depending on the voltage

to be measured.

5. Connect the test leads to the circuit to be

measured.

6. Reconnect power to the circuit to be

measured.

7. Read the voltage on the 120.

c. Measuring Resistance

WARNING!

Do not attempt to make resistance measurements

with circuit energized. For best results, remove

resistor completely from circuit before attempting

to measure.

NOTE:

To make accurate low ohm measurements, short ends of test

leads together and record resistance reading. Deduct this

value from actual readings.

Instrument set-up:

FUNC BLACK RED MIN MAX

TEST LEAD TEST LEAD READING READING

OHM COM VΩ1Ω2.000kΩ

Measurement Procedure:

1. Disconnect power to the circuit to be meas-

ured.

2. Plug the black test lead into the COM input

jack.

3. Plug the red test lead into the V/ΩΩinput jack.

4. Set rotary switch on the 120 to 2kΩΩfunction

depending on the voltage to be measured.

5. Connect the test leads to the circuit to be

measured.

6. Read the resistance value on the 120.

STEP BY STEP PROCEDURES

98

STEP BY STEP PROCEDURES

b.Measuring AC Volts

WARNING!

Do not attempt to make a voltage measure-

ment of more than 600V or of a voltage level that

is unknown.

Instrument set-up:

FUNC BLACK RED MIN MAX

TEST LEAD TEST LEAD READING READING

ACV COM VΩ0.001V 600V

Measurement Procedure:

1. Disconnect power to circuit to be meas-

ured.

2. Plug the black test lead into the COM input

jack.

3 Plug red test lead into V/ΩΩinput jack.

4. Set rotary switch on 120 to desired range

in ACV function depending on the voltage

to be measured.

5. Connect the test leads to the circuit to be

measured.

6. Reconnect power to the circuit to be

measured.

7. Read the voltage on the 120.

c. Measuring Resistance

WARNING!

Do not attempt to make resistance measurements

with circuit energized. For best results, remove

resistor completely from circuit before attempting

to measure.

NOTE:

To make accurate low ohm measurements, short ends of test

leads together and record resistance reading. Deduct this

value from actual readings.

Instrument set-up:

FUNC BLACK RED MIN MAX

TEST LEAD TEST LEAD READING READING

OHM COM VΩ1Ω2.000kΩ

Measurement Procedure:

1. Disconnect power to the circuit to be meas-

ured.

2. Plug the black test lead into the COM input

jack.

3. Plug the red test lead into the V/ΩΩinput jack.

4. Set rotary switch on the 120 to 2kΩΩfunction

depending on the voltage to be measured.

5. Connect the test leads to the circuit to be

measured.

6. Read the resistance value on the 120.

STEP BY STEP PROCEDURES

1110

d. Continuity Buzzer

WARNING!

Do not attempt to make continuity measurements

with circuit energized.

Instrument set-up:

FUNCTION BLACK TEST LEAD RED TEST

LEAD

OHM( ) COM VΩ

Measurement Procedure:

1. Disconnect power to the circuit to be measured.

2. Plug the black test lead into the COM input jack.

3. Plug the red test lead into the V/Ωinput jack.

4. Set the rotary switch on the 120 to the

position.

5. Connect the test leads to the circuit to be meas-

ured.

6. Listen for the buzzer to confirm continuity.

e. Data Hold

Press the DATA-H button at any time on any func-

tion or range to freeze the reading on the LCD dis-

play. This function is very useful when measuring

in locations where the display is difficult to read.

STEP BY STEP PROCEDURES: 10 Standard Accessories Part No.

9V Battery A009

Test Lead Set A040

Rubber Boot (120 only) A121

Optional Accessories Part No.

Deluxe Test Lead Set SDK1C

Microamp Adapter A112

Temperature Adapter A301

Carbon Monoxide Accessories A701/A702/A711

Boot Hook A120

Soft Carrying Case A255

Carrying Case for multiple instruments A901

*These accessories have not been evaluated by UL and are

not considered as part of the UL Listing of this product.

MAINTENANCE

1. Battery Replacement: The 120 will display BAT when the

internal 9 Volt battery needs replacement. The battery is

replaced as follows:

a. Disconnect and remove all test leads from live circuits

and from 120.

b. Remove the 120 from its protective boot.

c. Remove the four screws from back of 120 housing.

d. Carefully pull apart front and rear instrument housing.

e. Remove old battery and replace it with new battery.

f. Reassemble instrument in reverse order from above.

2. Cleaning your 120

Use a mild detergent and slightly damp cloth to clean the

surfaces of 120.

1110

d. Continuity Buzzer

WARNING!

Do not attempt to make continuity measurements

with circuit energized.

Instrument set-up:

FUNCTION BLACK TEST LEAD RED TEST

LEAD

OHM( ) COM VΩ

Measurement Procedure:

1. Disconnect power to the circuit to be measured.

2. Plug the black test lead into the COM input jack.

3. Plug the red test lead into the V/Ωinput jack.

4. Set the rotary switch on the 120 to the

position.

5. Connect the test leads to the circuit to be meas-

ured.

6. Listen for the buzzer to confirm continuity.

e. Data Hold

Press the DATA-H button at any time on any func-

tion or range to freeze the reading on the LCD dis-

play. This function is very useful when measuring

in locations where the display is difficult to read.

STEP BY STEP PROCEDURES: 10 Standard Accessories Part No.

9V Battery A009

Test Lead Set A040

Rubber Boot (120 only) A121

Optional Accessories Part No.

Deluxe Test Lead Set SDK1C

Microamp Adapter A112

Temperature Adapter A301

Carbon Monoxide Accessories A701/A702/A711

Boot Hook A120

Soft Carrying Case A255

Carrying Case for multiple instruments A901

*These accessories have not been evaluated by UL and are

not considered as part of the UL Listing of this product.

MAINTENANCE

1. Battery Replacement: The 120 will display BAT when the

internal 9 Volt battery needs replacement. The battery is

replaced as follows:

a. Disconnect and remove all test leads from live circuits

and from 120.

b. Remove the 120 from its protective boot.

c. Remove the four screws from back of 120 housing.

d. Carefully pull apart front and rear instrument housing.

e. Remove old battery and replace it with new battery.

f. Reassemble instrument in reverse order from above.

2. Cleaning your 120

Use a mild detergent and slightly damp cloth to clean the

surfaces of 120.

Copyright © 2002, Test Products International, Inc

The Value LeaderTM

www.tpi-thevalueleader.com

Test Products International, Inc.

9615 SW Allen Blvd

Beaverton, OR 97005-4814 USA

Ph: 503-520-9197 Fax: 503-520-1225

Test Product International Ltd.

342 Bronte Street South, Unit 9

Milton, Ontario L9T 5B7

Ph: 905-693-8558 Fax: 905-693-0888

Test Products International UK Ltd.

Longley House, East Park

Crawley, West Sussex RH10 6AP

Ph: +44 (0) 1293 561212 Fax: +44 (0) 1293 813465

120 Instruction Manual

Table of contents

Other TPI Multimeter manuals