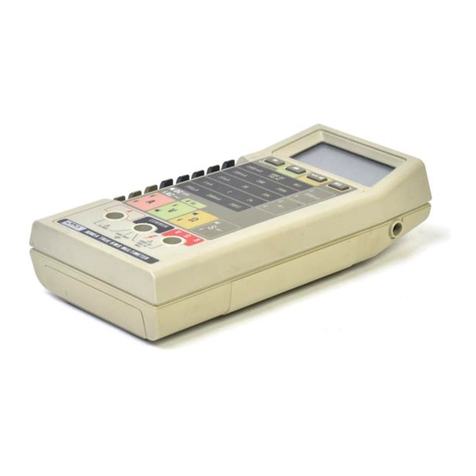

Digital Multimeters

General Specifications

5

General Specifications

Maximum voltage between any

terminal and earth ground ........................................... 1000 V rms

WFuse for mA inputs .................................................. 440 mA, 1000 V FAST Fuse

WFuse for A inputs ..................................................... 11 A, 1000 V FAST Fuse

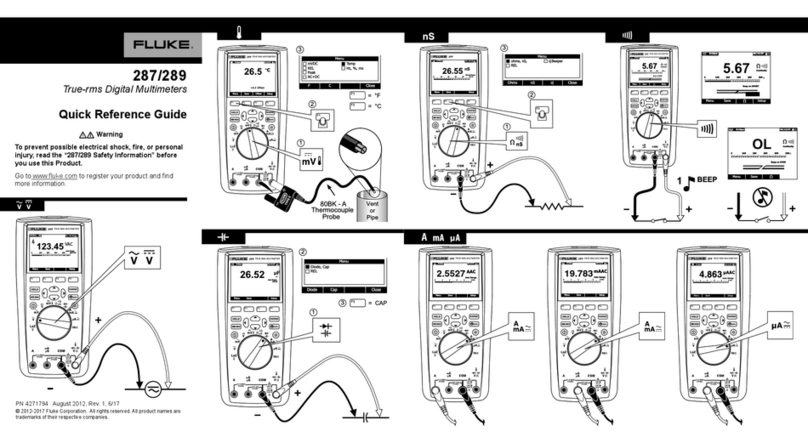

Display

Digital.......................................................................... 6000 counts, updates 4/sec (Model 28 II also has 19,999 counts

in high-resolution mode).

Bargraph..................................................................... 33 segments; updates 40/sec

Altitude

Operating.................................................................... 2,000 meters

Storage ....................................................................... 10,000 meters

Temperature

Operating.................................................................... -15 °C to +55 °C, to -40 °C for 20 minutes when taken from 20 °C

Storage ....................................................................... -55 °C to +85 °C (without battery)

-55 °C to +60 °C (with battery)

Temperature coefficient

28 II............................................................................. 0.05 X (specified accuracy) / °C (< 18 °C or > 28 °C)

27 II............................................................................. 0.1 X (specified accuracy) / °C (< 18 °C or > 28 °C)

Electromagnetic Compatibility (EN 61326-1:1997) .... In an RF field of 3 V/M, accuracy = specified accuracy +20

counts, except 600 μA dc range total accuracy = specified

accuracy +60 counts. Temperature not specified

Relative Humidity.......................................................... 0 % to 95 % (0 °C to 35 °C)

0 % to 70 % (35 °C to 55 °C)

Battery Type .................................................................. 3 AA Alkaline batteries, NEDA 15A IEC LR6

Battery Life .................................................................... 800 hrs typical without backlight (Alkaline)

Vibration ........................................................................ Per MIL-PRF-28800 for a Class 2 instrument

Shock ............................................................................. 1 Meter drop per IEC 61010 (3 Meter drop with holster)

Size (H x W x L) ............................................................. 1.80 in x 3.95 in x 8.40 in (4.57 cm x 10.0 cm x 21.33 cm)

Size with Holster ........................................................... 2.50 in x 3.95 in x 7.80 in (6.35 cm x 10.0 cm x 19.81 cm)

Weight ............................................................................ 1.14 lb (517.1 g)

Weight with Holster and Flex-Stand............................ 1.54 lb (698.5 g)

Safety Compliance........................................................ Complies with ANSI/ISA S82.01-2004, CAN/CSA C22.2 61010-1-

04 to 600 V Measurement Category IV. Licensed by TÜV to

EN61010-1

Certifications ................................................................. CSA, TÜV, P, ;(N10140), GOST

IP Rating ........................................................................ 67 (Protected against dust and the effect of immersion between

15 cm and 1 m for 30 min)

Detailed Specifications

For all detailed specifications:

Accuracy is specified for 2 years after calibration, at operating temperatures of 18 °C to 28 °C, with relative humidity at 0

% to 95 %. Accuracy specifications take the form of ±([% of Reading] + [Number of least-significant digits]). For Model

28 II in the 4 ½-digit mode, multiply the number of least-significant digits (counts) by 10.

27 II AC Voltage

Accuracy [2]

Range Resolution

40 Hz – 2 kHz 2 kHz – 10 kHz 10 kHz – 30 kHz

600.0 mV 0.1 mV

6.000 V 0.001 V

60.00 V 0.01 V

±(4 % + 10)

600.0 V 0.1 V

±(0.5 % + 3) ±(2 % + 3)

±(4 % + 10) [1]

1000 V 1 V ±(1.0 % + 3) ±(3 % + 3) Unspecified

[1] Specified to a maximum of 300 V ac

[2] Below 5 % of range, temperature coefficient is 0.15 X (specified accuracy)/ °C (>40 °C).