TPI 270 User manual

270

Digital Clamp-on

Meter Instruction Manual

A. INTRODUCTION

1. Congratulations!!

Thank you for purchasing TPI products. The 270 is easy

to use and is built to last. It is backed by a 3 year limit-

ed warranty. Please remember to complete and return

your product warranty registration card.

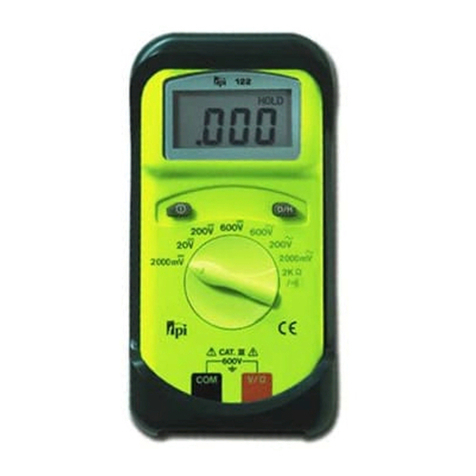

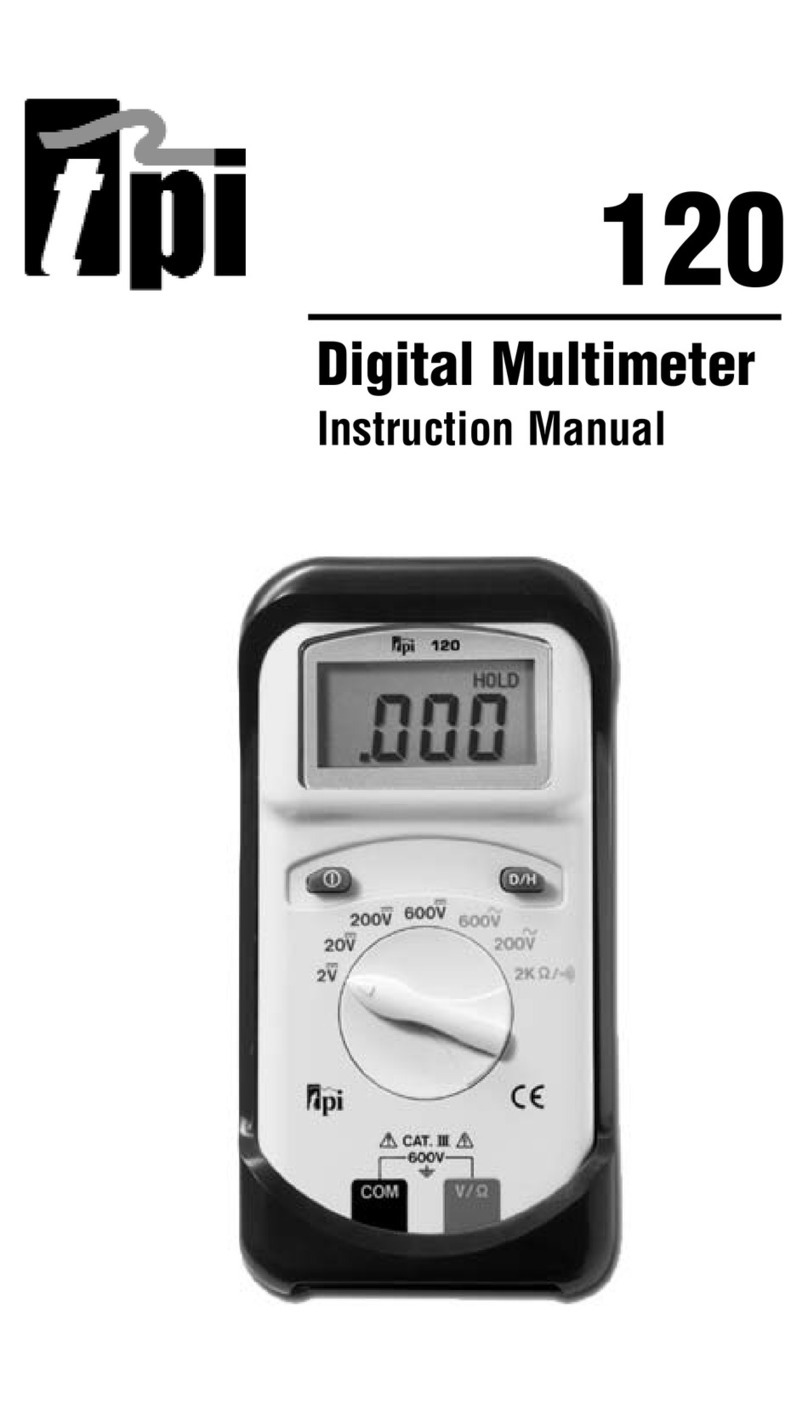

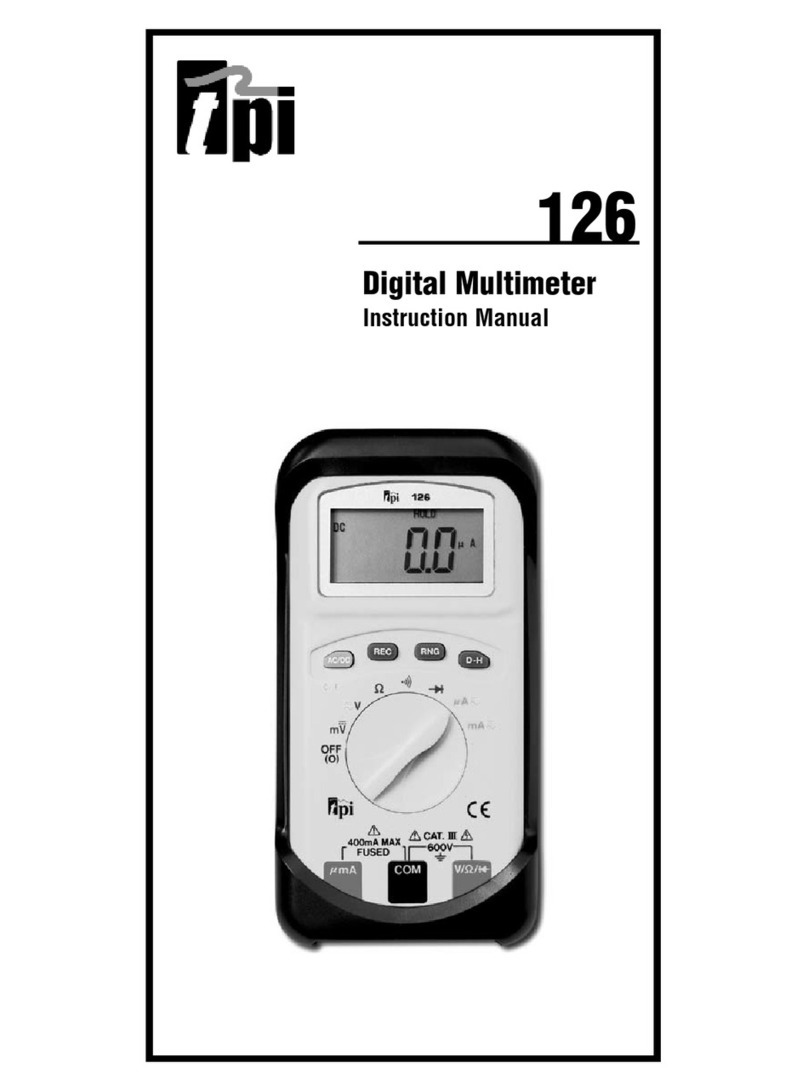

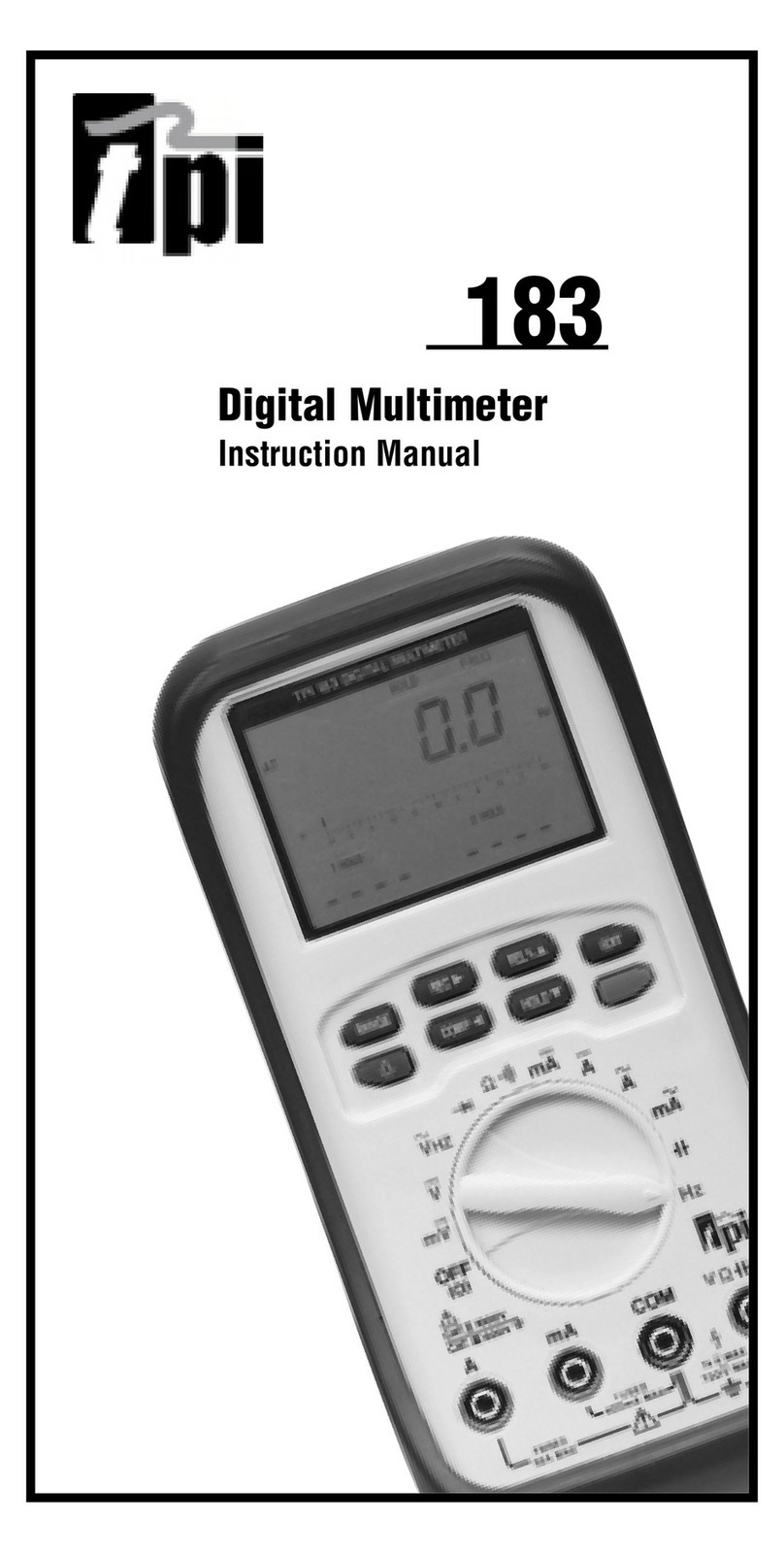

2. Product Description

The slim design 270 is a hand-held, autoranging

clamp-on DMM. Extra large numerals, min/max, capaci-

tance, DC microamps and duty cycle are just a few of the

features of the 270. An affordable choice, the 270 offers

measurements in all basic electrical functions with addi-

tional advanced features like non-contact voltage.

The 270 comes complete with the following accessories:

Carrying Pouch

Test Lead Set

Temperature Probe

Instruction Manual

Battery & Fuse

TABLE OF CONTENTS

A. INTRODUCTION

1. Congratulations ..........................3

2. Product Description....................3

3. Declaration of Conformity ..........4

B. SAFETY CONSIDERATIONS ..............5

C. TECHNICAL DATA

1. Features and Benefits..................6

2. Product Applications ..................7

3. Specifications..............................8

D. MEASUREMENT TECHNIQUES

1. Controls and Functions ............12

2. Step by Step Procedures: ........14

E. OTHER FEATURES ..........................24

F. APPLICATION NOTES ......................29

G. TROUBLE SHOOTING GUIDE ..........34

H. MAINTENANCE ................................35

I. ACCESSORIES ................................36

23

A. INTRODUCTION

1. Congratulations!!

Thank you for purchasing TPI products. The 270 is easy

to use and is built to last. It is backed by a 3 year limit-

ed warranty. Please remember to complete and return

your product warranty registration card.

2. Product Description

The slim design 270 is a hand-held, autoranging

clamp-on DMM. Extra large numerals, min/max, capaci-

tance, DC microamps and duty cycle are just a few of the

features of the 270. An affordable choice, the 270 offers

measurements in all basic electrical functions with addi-

tional advanced features like non-contact voltage.

The 270 comes complete with the following accessories:

Carrying Pouch

Test Lead Set

Temperature Probe

Instruction Manual

Battery & Fuse

TABLE OF CONTENTS

A. INTRODUCTION

1. Congratulations ..........................3

2. Product Description....................3

3. Declaration of Conformity ..........4

B. SAFETY CONSIDERATIONS ..............5

C. TECHNICAL DATA

1. Features and Benefits..................6

2. Product Applications ..................7

3. Specifications..............................8

D. MEASUREMENT TECHNIQUES

1. Controls and Functions ............12

2. Step by Step Procedures: ........14

E. OTHER FEATURES ..........................24

F. APPLICATION NOTES ......................29

G. TROUBLE SHOOTING GUIDE ..........34

H. MAINTENANCE ................................35

I. ACCESSORIES ................................36

23

B. SAFETY CONSIDERATIONS

WARNING: Please follow manufacturers test

procedures whenever possible. Do not attempt to

measure unknown voltages or components until a

complete understanding of the circuit is obtained.

GENERAL GUIDELINES

ALWAYS

• Test the 270 before using it to make sure it is

operating properly.

• Inspect the test leads before using to make sure there

are no breaks or shorts.

• Double check all connections before testing.

• Have someone check on you periodically if

working alone.

• Have a complete understanding of the circuit

being measured.

• Disconnect power to circuit, then connect test leads to

the 270, then to circuit being measured.

NEVER

• Attempt to measure unknown high voltages.

• Attempt to measure DC microamps with the meter in

parallel to the circuit.

• Connect the test leads to a live circuit before

setting up the instrument.

• Touch any exposed metal part of the test lead assembly.

3. EC Declaration of Conformity

This is to certify that TPI Model 270 conforms to the

protection requirements of the council directive

89/336/EEC, in the approximation of laws of the member

states relating to Electromagnetic compatibility and

73/23/EEC. The Low Voltage Directive by application of

the following standards:

EN 50081-1 1992 Emissions Standard

EN 50082-1 1992 Immunity Standard

EN 61010-1 1993 Safety Standard

EN 61010-2-031 1995 Safety Standard

EN 61010-2-032 1995 Safety Standard

To ensure conformity with these standard, this instru-

ment must be operated in accordance with the instruc-

tions and specifications given in this manual.

CAUTION: Even though this instrument complies with

the immunity standards, it’s accuracy can be affected

by strong radio emissions not covered in the above

standards. Sources such as hand-held radio trans-

ceivers, radio and TV transmitters, vehicle radios and

cellular phones generate electromagnetic radiation

that could be induced into the test leads of this instru-

ment. Care should be taken to avoid such situations or

alternatively, check to make sure that the instrument is

not being influence by these emissions.

CAUTION: Please follow manufacturers test proce-

dures whenever possible. Do not attempt to measure

unknown voltages or components until a complete

understanding of the circuit is obtained.

4 5

B. SAFETY CONSIDERATIONS

WARNING: Please follow manufacturers test

procedures whenever possible. Do not attempt to

measure unknown voltages or components until a

complete understanding of the circuit is obtained.

GENERAL GUIDELINES

ALWAYS

• Test the 270 before using it to make sure it is

operating properly.

• Inspect the test leads before using to make sure there

are no breaks or shorts.

• Double check all connections before testing.

• Have someone check on you periodically if

working alone.

• Have a complete understanding of the circuit

being measured.

• Disconnect power to circuit, then connect test leads to

the 270, then to circuit being measured.

NEVER

• Attempt to measure unknown high voltages.

• Attempt to measure DC microamps with the meter in

parallel to the circuit.

• Connect the test leads to a live circuit before

setting up the instrument.

• Touch any exposed metal part of the test lead assembly.

3. EC Declaration of Conformity

This is to certify that TPI Model 270 conforms to the

protection requirements of the council directive

89/336/EEC, in the approximation of laws of the member

states relating to Electromagnetic compatibility and

73/23/EEC. The Low Voltage Directive by application of

the following standards:

EN 50081-1 1992 Emissions Standard

EN 50082-1 1992 Immunity Standard

EN 61010-1 1993 Safety Standard

EN 61010-2-031 1995 Safety Standard

EN 61010-2-032 1995 Safety Standard

To ensure conformity with these standard, this instru-

ment must be operated in accordance with the instruc-

tions and specifications given in this manual.

CAUTION: Even though this instrument complies with

the immunity standards, it’s accuracy can be affected

by strong radio emissions not covered in the above

standards. Sources such as hand-held radio trans-

ceivers, radio and TV transmitters, vehicle radios and

cellular phones generate electromagnetic radiation

that could be induced into the test leads of this instru-

ment. Care should be taken to avoid such situations or

alternatively, check to make sure that the instrument is

not being influence by these emissions.

CAUTION: Please follow manufacturers test proce-

dures whenever possible. Do not attempt to measure

unknown voltages or components until a complete

understanding of the circuit is obtained.

4 5

INTERNATIONAL SYMBOLS

CAUTION: RISK OF ELECTRIC SHOCK

AC (Alternation Current)

DC (Direct Current)

REFER TO INSTRUCTION MANUAL

GROUND

DOUBLE INSULATION

EITHER DC OR AC

C. TECHNICAL DATA

1. Features and Benefits

Agency Meets CE and IEC 1010.

Analog Bar Displays rapidly changing input

Graph signals.

NCV Non-contact voltage detection. Detect

the presence of voltage without con-

tacting the circuit.

P-H Captures min / max peak.

MAX/MIN Records Min/Max readings for all

functions and ranges.

REL Measurements made are displayed

relative to a stored value.

Auto Off Automatically powers off after 30

minutes of inactivity.

2. Product Applications

Perform the following tests and/or measurements with

the 270 and the appropriate function:

HVAC/R

DCmV • Thermocouples in furnaces.

ACA • Heat anticipator current in thermostats.

ACV • Line voltage.

ACV or DCV • Control circuit voltage.

DCmA• Flame safegaurd control current.

OHMS • Compressor winding resistance.

OHMS • Continuity of wiring.

CAP • Motor start and run capacitors.

ACA • Motor and compressor start up current.

Hz • Frequency on controls and line voltage.

TEMP • Air duct temperatures.

ALL • Bar graph to indicate rapid fluctuations.

ELECTRICAL

ACV • Measure line voltage.

ACA • Measure line current.

OHMS • Continuity of circuit breakers.

DCV • Voltage of direct drive DC motors.

ACA • Start up current of motors, relays,

contactors and transformers.

ELECTRONIC

ACV • Measure power supply voltage.

ACA • Measure power supply current.

OHMS • Continuity of circuit breakers and fuses.

6 7

INTERNATIONAL SYMBOLS

CAUTION: RISK OF ELECTRIC SHOCK

AC (Alternation Current)

DC (Direct Current)

REFER TO INSTRUCTION MANUAL

GROUND

DOUBLE INSULATION

EITHER DC OR AC

C. TECHNICAL DATA

1. Features and Benefits

Agency Meets CE and IEC 1010.

Analog Bar Displays rapidly changing input

Graph signals.

NCV Non-contact voltage detection. Detect

the presence of voltage without con-

tacting the circuit.

P-H Captures min / max peak.

MAX/MIN Records Min/Max readings for all

functions and ranges.

REL Measurements made are displayed

relative to a stored value.

Auto Off Automatically powers off after 30

minutes of inactivity.

2. Product Applications

Perform the following tests and/or measurements with

the 270 and the appropriate function:

HVAC/R

DCmV • Thermocouples in furnaces.

ACA • Heat anticipator current in thermostats.

ACV • Line voltage.

ACV or DCV • Control circuit voltage.

DCmA• Flame safegaurd control current.

OHMS • Compressor winding resistance.

OHMS • Continuity of wiring.

CAP • Motor start and run capacitors.

ACA • Motor and compressor start up current.

Hz • Frequency on controls and line voltage.

TEMP • Air duct temperatures.

ALL • Bar graph to indicate rapid fluctuations.

ELECTRICAL

ACV • Measure line voltage.

ACA • Measure line current.

OHMS • Continuity of circuit breakers.

DCV • Voltage of direct drive DC motors.

ACA • Start up current of motors, relays,

contactors and transformers.

ELECTRONIC

ACV • Measure power supply voltage.

ACA • Measure power supply current.

OHMS • Continuity of circuit breakers and fuses.

6 7

9

3. Specifications

IEC 1010 Over Voltage:

CAT II - 1000V

CAT III - 600V

Pollution Degree 2

Temperature for gauranteed accuracy: 23ºC +5ºC

DC VOLTS

Range Res. Accuracy

400mV 0.1mV Impedance:

4V 0.001V +/-(0.5% of reading + 2 digits) 10MW

40V 0.01V Overload Protection:

400V 0.1V 600VDC or AC RMS

600V 1V

(45Hz to 100Hz Frequency Response 400mV Range)

AC VOLTS (45Hz to 450Hz Frequency Response All Other Ranges)

Range Res. Accuracy

400mV 0.1mV +/-(1.2% of reading + 5 digits) Impedance:

4V 0.001V +/-(1.2% of reading + 3 digits) 10MW

40V 0.01V Overload Protection:

400V 0.1V +/-(1.5% of reading + 3 digits) 600VDC or AC RMS

600V 1V

8

DC Microamps

Range Res. Accuracy

40uA 0.01mA+/-(0.8% of reading + 2 digits) Overload Protection:

400uA 0.1mA0.5A / 600V Fusee

*DC microamps are measured with the test leads in series with

the circuit under test.

OHM (Resistance, W)

Range Res. Accuracy

400W0.1W±(1% of reading +5 digits)

4kW0.001kW±(1% of reading +2 digits) Overload Protection:

40kW0.01kW250VDC or AC RMS

400kW0.1kW

4MW0.001MW±(3% of reading +5 digits)

40MW0.01MW ±(3% of reading +10 digits)

Frequency (Hz)

Range Res. Accuracy

4.000kHz 0.001kHz ±(1% of reading +2 digits)

40.00kHz 0.01kHz

400.0kHz 0.1kHz Overload Protection:

4.000MHz 0.001MHz 250VDC or AC RMS

40.00MHz 0.01MHz

400.0MHz 0.1MHz

UL 3111 Pending

(45Hz to 100Hz Frequency Response 200A to 400A)

AC AMPS (45Hz to 450Hz Frequency Response Below 200A)

Range Res. Accuracy

40A 0.01A +/-(3.0% of reading + 5 digits)

400A 0.1A e

Warning: Use only correct type and overvoltage

category rated test leads. Remove the

temperature probe when using the test

leads or amp clamp.

9

3. Specifications

IEC 1010 Over Voltage:

CAT II - 1000V

CAT III - 600V

Pollution Degree 2

Temperature for gauranteed accuracy: 23ºC +5ºC

DC VOLTS

Range Res. Accuracy

400mV 0.1mV Impedance:

4V 0.001V +/-(0.5% of reading + 2 digits) 10MW

40V 0.01V Overload Protection:

400V 0.1V 600VDC or AC RMS

600V 1V

(45Hz to 100Hz Frequency Response 400mV Range)

AC VOLTS (45Hz to 450Hz Frequency Response All Other Ranges)

Range Res. Accuracy

400mV 0.1mV +/-(1.2% of reading + 5 digits) Impedance:

4V 0.001V +/-(1.2% of reading + 3 digits) 10MW

40V 0.01V Overload Protection:

400V 0.1V +/-(1.5% of reading + 3 digits) 600VDC or AC RMS

600V 1V

8

DC Microamps

Range Res. Accuracy

40uA 0.01mA+/-(0.8% of reading + 2 digits) Overload Protection:

400uA 0.1mA0.5A / 600V Fusee

*DC microamps are measured with the test leads in series with

the circuit under test.

OHM (Resistance, W)

Range Res. Accuracy

400W0.1W±(1% of reading +5 digits)

4kW0.001kW±(1% of reading +2 digits) Overload Protection:

40kW0.01kW250VDC or AC RMS

400kW0.1kW

4MW0.001MW±(3% of reading +5 digits)

40MW0.01MW ±(3% of reading +10 digits)

Frequency (Hz)

Range Res. Accuracy

4.000kHz 0.001kHz ±(1% of reading +2 digits)

40.00kHz 0.01kHz

400.0kHz 0.1kHz Overload Protection:

4.000MHz 0.001MHz 250VDC or AC RMS

40.00MHz 0.01MHz

400.0MHz 0.1MHz

UL 3111 Pending

(45Hz to 100Hz Frequency Response 200A to 400A)

AC AMPS (45Hz to 450Hz Frequency Response Below 200A)

Range Res. Accuracy

40A 0.01A +/-(3.0% of reading + 5 digits)

400A 0.1A e

Warning: Use only correct type and overvoltage

category rated test leads. Remove the

temperature probe when using the test

leads or amp clamp.

Diode Test

Test Current Over Load Protection

1.5mA MAX 250 V DC or AC RMS

Continuity Buzzer

Test Voltage Threshold Over Load Protection

3V <35W250 V DC or AC RMS

Non-Contact Voltage (NCV)

Detection Range: 24VAC and above

Temperature (K-Type thermocouple)

Range Res. Accuracy

-40ºF to 399.9ºF 0.1ºF +(1ºF) 32.0ºF to 120.0ºF

+(1%+1.5ºF) -4.0ºF to 31.9ºF

+(1%+1.5ºF) -120.1ºF to 399.9ºF

+(2%+4ºF) -40.0ºF to -3.9ºF

-40ºF to 1000ºF 1ºF +(2ºF) 32.0ºF to 120ºF

+(1%+2ºF) -3ºF to 749ºF

+(2%+1.5ºF) 750ºF to 1000ºF

+(2%+4ºF) -40ºF to -4ºF

Overload Protection: 60VDC or 30VAC RMS

**Celsius version of the 270 is available

11

10

Capacitance

Range Res. Accuracy

4nF 0.001nF ±(1% of reading +2 digits)

40nF 0.01nF

400nF 0.1nF Overload Protection:

4mF 0.001mF500VDC or AC RMS

40mF 0.01mF

400mF 0.1uF

4mF 0.001mF

40mF 0.01mF ±(3% of reading +5 digits)

nF= nanofarad, mF= microfarad, mF= millifarad

General

Max Voltage between any 600V

input and ground

Fuse Protection (mmA range) 0.5A/600V

Display Type 4000 Count 41 seg. bargraph

Operating Temperature 32ºF to 104ºF (0ºC to 40ºC)

Storage Temperature 14ºF to 122ºF (-10ºC to 50ºC)

Relative Humidity 80% non-condensing

Power Supply 9V (MN1604)

Battery Life 80 hrs. typical

Size (H x L x W) 32.5mm x 255mm x 65mm

(1.3in x 10in x 2.5in)

Weight 363g (0.8lbs)

Warning: Use only correct type and overvoltage

category rated test leads. Remove the

temperature probe when using the test

leads or amp clamp.

Warning: Use only correct type and overvoltage

category rated test leads. Remove the

temperature probe when using the test

leads or amp clamp.

Diode Test

Test Current Over Load Protection

1.5mA MAX 250 V DC or AC RMS

Continuity Buzzer

Test Voltage Threshold Over Load Protection

3V <35W250 V DC or AC RMS

Non-Contact Voltage (NCV)

Detection Range: 24VAC and above

Temperature (K-Type thermocouple)

Range Res. Accuracy

-40ºF to 399.9ºF 0.1ºF +(1ºF) 32.0ºF to 120.0ºF

+(1%+1.5ºF) -4.0ºF to 31.9ºF

+(1%+1.5ºF) -120.1ºF to 399.9ºF

+(2%+4ºF) -40.0ºF to -3.9ºF

-40ºF to 1000ºF 1ºF +(2ºF) 32.0ºF to 120ºF

+(1%+2ºF) -3ºF to 749ºF

+(2%+1.5ºF) 750ºF to 1000ºF

+(2%+4ºF) -40ºF to -4ºF

Overload Protection: 60VDC or 30VAC RMS

**Celsius version of the 270 is available

11

10

Capacitance

Range Res. Accuracy

4nF 0.001nF ±(1% of reading +2 digits)

40nF 0.01nF

400nF 0.1nF Overload Protection:

4mF 0.001mF500VDC or AC RMS

40mF 0.01mF

400mF 0.1uF

4mF 0.001mF

40mF 0.01mF ±(3% of reading +5 digits)

nF= nanofarad, mF= microfarad, mF= millifarad

General

Max Voltage between any 600V

input and ground

Fuse Protection (mmA range) 0.5A/600V

Display Type 4000 Count 41 seg. bargraph

Operating Temperature 32ºF to 104ºF (0ºC to 40ºC)

Storage Temperature 14ºF to 122ºF (-10ºC to 50ºC)

Relative Humidity 80% non-condensing

Power Supply 9V (MN1604)

Battery Life 80 hrs. typical

Size (H x L x W) 32.5mm x 255mm x 65mm

(1.3in x 10in x 2.5in)

Weight 363g (0.8lbs)

Warning: Use only correct type and overvoltage

category rated test leads. Remove the

temperature probe when using the test

leads or amp clamp.

Warning: Use only correct type and overvoltage

category rated test leads. Remove the

temperature probe when using the test

leads or amp clamp.

13

12

1. Controls and Functions: (cont.)

Rotary Switch

OFF Turns the 270 completely off.

VUsed to measure DC volts.

VUsed to measure AC volts.

WUsed to measure resistance.

Used to measure continuity.

Selects diode test function.

Selects capacitance test function.

Hz Selects frequency test function.

mASelects DC microamp function.

Used to measure AC amperage.

TEMP Selects the temperature function.

Input Jacks

COM Black test lead connection for all

tests except temperature, non-con-

tact voltage and AC Amps.

V/W/mARed test lead connection for all

tests except temperature, non-con-

tact voltage and AC Amps.

D. MEASUREMENT TECHNIQUES

1. Controls and Functions:

Push Buttons

REL Activates Relative mode. Press

and hold for 2 seconds to deacti-

vate.

D-H Holds the reading on the display

until the button is pushed a

second time.

R-H Activates manual ranging. Press

and hold for 2 seconds to return

to auto ranging.

MAX MIN Activates record mode. Press to

cycle between maximum and min-

imum recorded reading. Press and

hold for 2 seconds to return to

normal mode.

P-H Activates peak hold mode. Used to

capture in-rush current.

NCV Activates the non-contact voltage

detection feature. Press and hold

while holding the jaw close to

electrical wires.

13

12

1. Controls and Functions: (cont.)

Rotary Switch

OFF Turns the 270 completely off.

VUsed to measure DC volts.

VUsed to measure AC volts.

WUsed to measure resistance.

Used to measure continuity.

Selects diode test function.

Selects capacitance test function.

Hz Selects frequency test function.

mASelects DC microamp function.

Used to measure AC amperage.

TEMP Selects the temperature function.

Input Jacks

COM Black test lead connection for all

tests except temperature, non-con-

tact voltage and AC Amps.

V/W/mARed test lead connection for all

tests except temperature, non-con-

tact voltage and AC Amps.

D. MEASUREMENT TECHNIQUES

1. Controls and Functions:

Push Buttons

REL Activates Relative mode. Press

and hold for 2 seconds to deacti-

vate.

D-H Holds the reading on the display

until the button is pushed a

second time.

R-H Activates manual ranging. Press

and hold for 2 seconds to return

to auto ranging.

MAX MIN Activates record mode. Press to

cycle between maximum and min-

imum recorded reading. Press and

hold for 2 seconds to return to

normal mode.

P-H Activates peak hold mode. Used to

capture in-rush current.

NCV Activates the non-contact voltage

detection feature. Press and hold

while holding the jaw close to

electrical wires.

Measuring AC Voltage

WARNING!

Do not attempt to make a voltage measurement of more than

600V or of a voltage level that is unknown. Make sure the tem-

perature probe is NOT plugged in during this test.

Instrument set-up:

FUNC. BLACK RED MIN MAX

TEST LEAD TEST LEAD READING READING

COM V/W0.1mV 600V

Measurement Procedure:

1. Disconnect power to circuit to be measured.

2. Plug black test lead into the COM input jack.

3 Plug red test lead into the V/Winput jack.

4. Set rotary switch to the V range.

5. Connect test leads to circuit to be measured.

6. Reconnect power to circuit to be measured.

7. Read the voltage on the 270.

Optional Modes

(See Other Features Section)

•D-H: Freezes the reading on the LCD.

•MAX/MIN: Records minimum and maximum measurements.

•P-H: Displays peak voltage.

2. Step by Step Procedures:

Measuring DC Voltage

WARNING!

Do not attempt to make a voltage measurement of more

than 600V or of a voltage level that is unknown. Make sure

the temperature probe is NOT plugged in during this test.

Instrument set-up:

FUNC. BLACK RED MIN MAXI

TEST LEAD TEST LEAD READING READING

COM V/W0.1mV 600V

Measurement Procedure:

1. Disconnect power to circuit to be measured.

2. Plug black test lead into the COM input jack.

3 Plug red test lead into the V/Winput jack.

4. Set rotary switch to the V range.

5. Connect test leads to circuit to be measured.

6. Reconnect power to circuit to be measured.

7. Read the voltage on the 270.

Optional Modes

(See Other Features Section)

•D-H: Freezes the reading on the LCD.

•MAX/MIN: Records minimum a.

•P-H: Displays peak voltage.

15

14

Measuring AC Voltage

WARNING!

Do not attempt to make a voltage measurement of more than

600V or of a voltage level that is unknown. Make sure the tem-

perature probe is NOT plugged in during this test.

Instrument set-up:

FUNC. BLACK RED MIN MAX

TEST LEAD TEST LEAD READING READING

COM V/W0.1mV 600V

Measurement Procedure:

1. Disconnect power to circuit to be measured.

2. Plug black test lead into the COM input jack.

3 Plug red test lead into the V/Winput jack.

4. Set rotary switch to the V range.

5. Connect test leads to circuit to be measured.

6. Reconnect power to circuit to be measured.

7. Read the voltage on the 270.

Optional Modes

(See Other Features Section)

•D-H: Freezes the reading on the LCD.

•MAX/MIN: Records minimum and maximum measurements.

•P-H: Displays peak voltage.

2. Step by Step Procedures:

Measuring DC Voltage

WARNING!

Do not attempt to make a voltage measurement of more

than 600V or of a voltage level that is unknown. Make sure

the temperature probe is NOT plugged in during this test.

Instrument set-up:

FUNC. BLACK RED MIN MAXI

TEST LEAD TEST LEAD READING READING

COM V/W0.1mV 600V

Measurement Procedure:

1. Disconnect power to circuit to be measured.

2. Plug black test lead into the COM input jack.

3 Plug red test lead into the V/Winput jack.

4. Set rotary switch to the V range.

5. Connect test leads to circuit to be measured.

6. Reconnect power to circuit to be measured.

7. Read the voltage on the 270.

Optional Modes

(See Other Features Section)

•D-H: Freezes the reading on the LCD.

•MAX/MIN: Records minimum a.

•P-H: Displays peak voltage.

15

14

Measuring AC Amperage

CAUTION!

Do not attempt to make a current measurement with the

test leads. The 270 measures the current by clamping the

jaw around one conductor (wire). Clamping around more

than one wire will result in erroneous readings. Make sure

the temperature probe is NOT plugged in during this test.

Instrument set-up:

FUNC. BLACK RED MIN MAX

TEST LEAD TEST LEAD READING READING

NOT USED NOT USED 0.01A 400A

Measurement Procedure:

1. Disconnect power to circuit to be measured.

2. Set rotary switch to function.

3. Clamp the jaws around one conductor of the circuit to

be measured. For best results, center the wire in the

jaw.

4. Reconnect power to circuit to be measured.

5. Read the current on the 270.

Optional Modes

(See Other Features Section)

•D-H: Freezes the reading on the LCD.

•MAX/MIN: Records minimum and maximum measure-

ments

•P-H: Displays peak amperage.

17

16

Measuring Resistance

WARNING!

Do not attempt to make resistance measurements with circuit

energized. For best results, remove the resistor completely from

circuit before attempting to measure it. Make sure the tempera-

ture probe is NOT plugged in during this test.

NOTE:

To make accurate low ohm measurements, short the ends of the

test leads together and press the REL button to store the reading.

This will deduct the stored value from subsequent measurements

eliminating the test lead resistance from the reading.

Instrument set-up:

FUNC. BLACK RED MIN MAX

TEST LEAD TEST LEAD READING READING

WCOM V/W0.1W40.00MW

Measurement Procedure:

1. Disconnect power to circuit to be measured.

2. Plug black test lead into the COM input jack.

3. Plug red test lead into V/Winput jack.

4. Set the rotary switch to the Wfunction.

5. Connect test leads to circuit to be measured.

6. Read the resistance value on the 270.

Optional Modes

(See Other Features Section)

•D-H: Freezes the reading on the LCD.

Measuring AC Amperage

CAUTION!

Do not attempt to make a current measurement with the

test leads. The 270 measures the current by clamping the

jaw around one conductor (wire). Clamping around more

than one wire will result in erroneous readings. Make sure

the temperature probe is NOT plugged in during this test.

Instrument set-up:

FUNC. BLACK RED MIN MAX

TEST LEAD TEST LEAD READING READING

NOT USED NOT USED 0.01A 400A

Measurement Procedure:

1. Disconnect power to circuit to be measured.

2. Set rotary switch to function.

3. Clamp the jaws around one conductor of the circuit to

be measured. For best results, center the wire in the

jaw.

4. Reconnect power to circuit to be measured.

5. Read the current on the 270.

Optional Modes

(See Other Features Section)

•D-H: Freezes the reading on the LCD.

•MAX/MIN: Records minimum and maximum measure-

ments

•P-H: Displays peak amperage.

17

16

Measuring Resistance

WARNING!

Do not attempt to make resistance measurements with circuit

energized. For best results, remove the resistor completely from

circuit before attempting to measure it. Make sure the tempera-

ture probe is NOT plugged in during this test.

NOTE:

To make accurate low ohm measurements, short the ends of the

test leads together and press the REL button to store the reading.

This will deduct the stored value from subsequent measurements

eliminating the test lead resistance from the reading.

Instrument set-up:

FUNC. BLACK RED MIN MAX

TEST LEAD TEST LEAD READING READING

WCOM V/W0.1W40.00MW

Measurement Procedure:

1. Disconnect power to circuit to be measured.

2. Plug black test lead into the COM input jack.

3. Plug red test lead into V/Winput jack.

4. Set the rotary switch to the Wfunction.

5. Connect test leads to circuit to be measured.

6. Read the resistance value on the 270.

Optional Modes

(See Other Features Section)

•D-H: Freezes the reading on the LCD.

Measuring Diodes

WARNING!

Do not attempt to make diode measurements with the circuit

energized. For accurate tests, remove the diode completely

from the circuit prior to measuring it. Make sure the tempera-

ture probe is NOT plugged in during this test.

Instrument set-up:

FUNC. BLACK RED

TEST LEAD TEST LEAD

COM V/W/mA

Measurement Procedure:

1. Disconnect power to circuit to be measured.

2. Plug black test lead into the COM input jack.

3. Plug red test lead into V/Winput jack.

4. Set the rotary switch to the

5. Connect the black test lead to the banded end of the diode

(cathode) and the red test lead to the non-banded end of

the diode (anode).

6. For a good diode, the reading on the display should be

between 0.5V and 0.8V. The reading will be lower for a

germanium diode.

7. Reverse the leads on the diode.

8. For a good diode, the reading on the display should be OL

(overload).

Optional Modes

(See Other Features Section)

•D-H: Freezes the reading on the LCD.

19

18

position.

Measuring Continuity

WARNING!

Do not attempt to make continuity measurements with circuit

energized. Make sure the temperature probe is NOT plugged

in during this test.

Instrument set-up:

FUNC. BLACK RED

TEST LEAD TEST LEAD

COM V/W

Measurement Procedure:

1. Disconnect power to circuit to be measured.

2. Plug black test lead into the COM input jack.

3. Plug red test lead into V/Winput jack.

4. Set the rotary switch to the position.

5. Connect test leads to circuit to be measured.

6. The 270 will beep and the LED will illuminate at

resistances of 35Wor lower.

Optional Modes

(See Other Features Section)

•D-H: Freezes the reading on the LCD.

Measuring Diodes

WARNING!

Do not attempt to make diode measurements with the circuit

energized. For accurate tests, remove the diode completely

from the circuit prior to measuring it. Make sure the tempera-

ture probe is NOT plugged in during this test.

Instrument set-up:

FUNC. BLACK RED

TEST LEAD TEST LEAD

COM V/W/mA

Measurement Procedure:

1. Disconnect power to circuit to be measured.

2. Plug black test lead into the COM input jack.

3. Plug red test lead into V/Winput jack.

4. Set the rotary switch to the

5. Connect the black test lead to the banded end of the diode

(cathode) and the red test lead to the non-banded end of

the diode (anode).

6. For a good diode, the reading on the display should be

between 0.5V and 0.8V. The reading will be lower for a

germanium diode.

7. Reverse the leads on the diode.

8. For a good diode, the reading on the display should be OL

(overload).

Optional Modes

(See Other Features Section)

•D-H: Freezes the reading on the LCD.

19

18

position.

Measuring Continuity

WARNING!

Do not attempt to make continuity measurements with circuit

energized. Make sure the temperature probe is NOT plugged

in during this test.

Instrument set-up:

FUNC. BLACK RED

TEST LEAD TEST LEAD

COM V/W

Measurement Procedure:

1. Disconnect power to circuit to be measured.

2. Plug black test lead into the COM input jack.

3. Plug red test lead into V/Winput jack.

4. Set the rotary switch to the position.

5. Connect test leads to circuit to be measured.

6. The 270 will beep and the LED will illuminate at

resistances of 35Wor lower.

Optional Modes

(See Other Features Section)

•D-H: Freezes the reading on the LCD.

Measuring Capacitance

WARNING!

All capacitance measurements are to be made on de-energized

circuits with all capacitors discharged only. Failure to de-energize

and discharge capacitors prior to measuring them could result in

instrument damage and/or personal injury. Make sure the temper-

ature probe is NOT plugged in during this test.

Instrument set-up:

FUNC. BLACK RED

TEST LEAD TEST LEAD

COM V/W/mA

Measurement Procedure:

1. Disconnect power to circuit to be measured.

2. Plug black test lead into the COM input jack.

3. Plug red test lead into V/Winput jack.

4. Set the rotary switch to the

5. Remove the capacitor from the circuit and discharge it.

6. Connect test leads to the capacitor to be measured.

Observe polarity on polarity sensitive capacitors.

7. Read the capacitor value on the LCD.

Optional Modes

(See Other Features Section)

•D-H: Freezes the reading on the LCD.

21

20

Measuring Frequency

WARNING!

Never attempt a frequency measurement with a voltage source

greater than 500V. Determine the voltage of any unknown fre-

quency source before connecting the instrument in frequency

mode. Make sure the temperature probe is NOT plugged in

during this test.

Instrument set-up:

FUNC. BLACK RED

TEST LEAD TEST LEAD

Hz COM V/W/mA

Measurement Procedure:

1. Disconnect power to the circuit to be measured.

2. Plug black test lead into the COM input jack.

3. Plug red test lead into V/Winput jack.

4. Set the rotary switch to the Hz position.

5. Reconnect power to the circuit to be measured.

6. Read the frequency on the LCD.

Optional Modes

(See Other Features Section)

•D-H: Freezes the reading on the LCD.

•MAX/MIN: Records minimum and maximum measure-

ments

position.

Table of contents

Other TPI Multimeter manuals