TQC AB3120 User manual

1

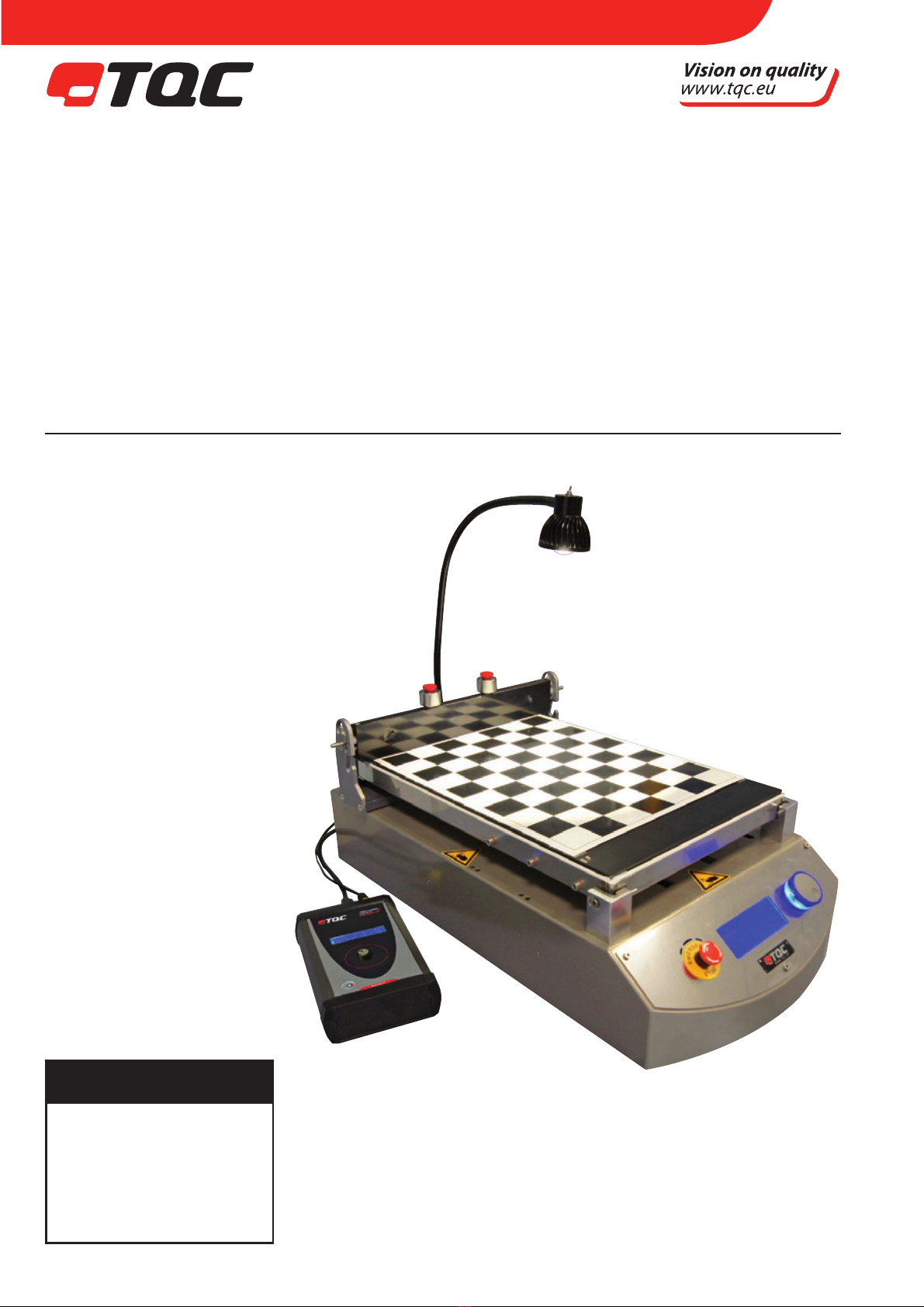

TQC AUTOMATIC FILM APPLICATOR

INCL. OPTIONAL TOOLS

AB3120, AB3220, AB3320, AB3400, AB3420, AB3425, AB3125, AB3225,

AB3325, AB3405, AB3075, AB3090

User Guide

V3.5 0417

IMPORTANT!

Before taking this

instrument in use we

strongly advise you

to read this manual

carefully.

2

CONTENT

1 GENERAL 4

1.1 Importance of operating manual 4

1.2 User-responsibility 4

1.3 Responsibility of personnel 4

1.4 Dangers 4

1.5 Designated purpose 4

1.6 Copyright 5

1.7 Manufacturer’s/Supplier’s address 5

2 SAFETY INSTRUCTIONS 5

2.1 Meaning of Symbols 5

2.2 Availability of Safety Information 5

2.3 Training of Personnel 6

2.4 Dangers from Electrical Energy 6

2.5 Points of Special Danger - Moving Zone tool carrier 6

2.6 Points of Special Danger - Heated Film applicator 6

2.6 Care, Maintenance, Repairs 7

2.7 Modications to the Equipment 7

2.8 Cleaning of the Instrument and Disposal of Materials 7

3 TRANSPORT AND STORAGE 7

3.1 Packing 7

3.2 User: Check on Receipt 7

3.3 Reporting Transport Damage and Documentation 8

3.4 Storage and Protective Measures when not in use 8

4 INSTRUMENT DATA 8

4.1 Name / Article 8

4.2 Scope of Supply 9

4.3 Technical Data 9

4.4 Dimensions and Weight 10

4.5 Basic Unit 10

4.6 Noise Level 10

5 INSTALLATION AND ASSEMBLY 11

5.1 Installation and Operation 11

5.2 Preparation of Energy Connections 11

5.3 Vacuum 11

5.4 Mains Connection 11

EN

3

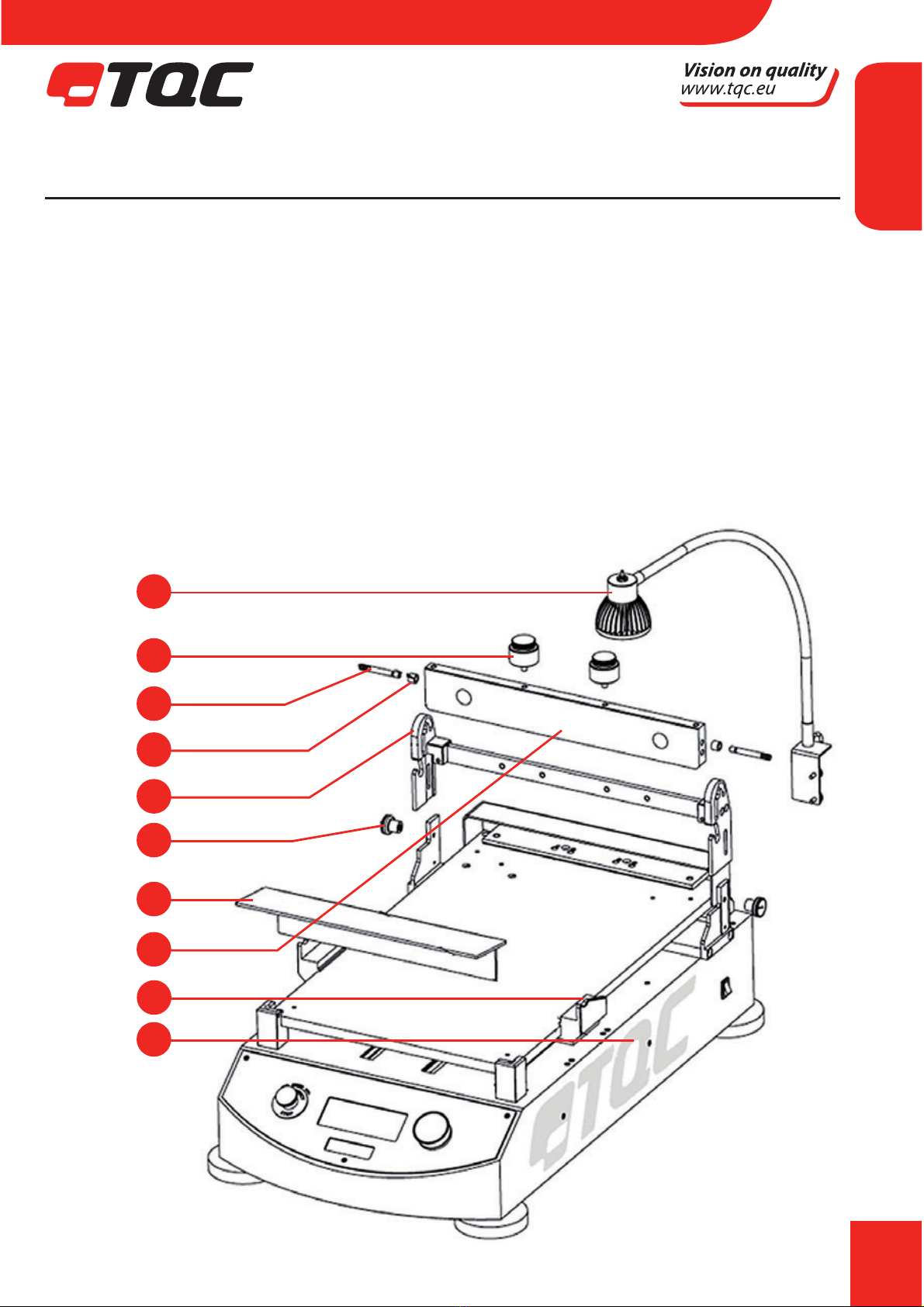

6 INSTRUMENT CONTROLS AND FUNCTIONS 12

6.1 Overview 12

7 INSTRUMENT COMPONENT ASSEMBLY 13

7.1 Overview 13

7.2 Instrument Preparations 14

7.3 Glass Bed 14

7.4 Perforated Vacuum Bed 14

7.5 Double Channel Vacuum Bed 14

7.6 Film Applicators (Tools) 15

7.7 Test Charts 15

7.8 Drying Time Recorder 16

7.9 Multi Tool Platform 16

8 MENU DISPLAY INFORMATION AND OPERATION 16

8.1 Automatic Film applicator operation 16

8.2 Drying Time recorder operation 18

8.3 Heated Film bed control 20

8.4 Warning signals 20

9 OPERATION 20

9.1 Preparatory Work 20

9.2 Film Application 20

9.3 Start the instrument 21

10 CARE AND MAINTENANCE 21

10.1 Inspection and Maintenance 21

10.2 Disposal of Materials 21

10.3 Customer Service 21

11 DISCLAIMER 22

ANNEX A | INSTALLATION OF THE VACUUM BED 23

ANNEX B | POSITIONING OF SPIRAL BAR LIFTER 24

ANNEX C | INSTALLATION OF THE LAMP 25

ANNEX D | POWER SUPPLY HEATED MODELS 26

ANNEX E1| TEST CHART PLACEMENT - NON-HEATED-MODELS 30

ANNEX E2 | TEST CHART PLACEMENT - HEATED MODELS 34

ANNEX F | GRINDOMETER TOOL FOR AFA 39

ANNEX G | TQC HARDNESS PEN HOLDER FOR AFA 48

EN

4

1 GENERAL

1.1 Importance of operating manual

This manual is written in order to become familiar with all the functions and possible applications

of the instrument. It contains important instructions about how to use the instrument safely

and economically; according to the purpose designated. Following these instructions is not only

essential to avoid risks. It also reduces repair costs and down-time and increases the products

reliability and service-life.

Anyone who works with the instrument should follow the instructions in this manual, particu-

larly the safety related instructions. Additionally local rules and regulations relating to environ-

mental safety and accident prevention should be observed.

1.2 User-responsibility

The user should

a) Only allow persons to work with the instrument who are familiar with the general instructions

on how to work safely and to prevent accidents. The use of the instrument should have been

instructed duly. The safety chapter and the warnings in this manual should have been read

and understood; acknowledged as evidenced by their signature.

b) Regularly check the safety-awareness of personnel at work.

1.3 Responsibility of personnel

Before commencing work anyone appointed to work with the instrument should pay attention

to the general regulations relating to working safety and accident prevention. The safety chapter

and the warnings in this manual should have been read and understood; acknowledged as

evidenced by their signature.

1.4 Dangers

This instrument has been designed and constructed in accordance with state-of-the-art techno-

logy and the acknowledged safety regulations. Nevertheless, working with the instrument may

cause danger to the life and health of the operator or to others, or damage to the instrument or

other property. Therefore the instrument should only be used for its designated purpose, and in

a perfect technical condition. Any defect that could have a negative eect on safety should be

repaired immediately.

1.5 Designated purpose

The TQC Film applicator is exclusively designed to apply lms of paint and coatings on test panels

and test charts and as from models launched after Apr. 2013 for testing of the drying time of

coatings on previous described substrates.

Other applications constitute improper use. TQC will not be held liable for damage resulting

from improper use.

EN

5

Danger

Warning

Designated purpose also includes properly observing all instructions in the operation manual,

and adherence to inspection and maintenance schedules.

1.6 Copyright

The copyright of this operating manual remains with TQC.

This operating manual is intended solely for the user and his personnel. Its instructions and

guidelines may not be duplicated, circulated or otherwise passed on to others, neither fully, nor

partly. Infringement of these restrictions may lead to legal action may be taken if this restrictions

are infringed upon.

1.7 Manufacturer’s/Supplier’s address

TQC The Netherlands,

Molenbaan 19 T +31(0)10-7900100,

2908 LL Capelle aan den IJssel F +31 (0)10-7900129

2 SAFETY INSTRUCTIONS

2.1 Meaning of Symbols

The following symbols for dangers are used in this instruction manual.

Symbol Explanation Warning

Possible immediate danger to If this guideline is not noted it can

the life or health of personnel lead to severe danger to health,

up to fatal injury

A dangerous situation could Non observance of this guideline

be caused can lead to injury or to

damage to equipment.

NOTE Special tips and particular Guidelines to make optimal use of

information the instrument.

2.2 Availability of Safety Information

The instruction manual should be kept at the place where the instrument is operated.

In addition to the information contained in the instruction manual, general and local regulations

for accident prevention and environmental protection shall be kept available and observed.

EN

6

Always ensure all guidelines in respect of safety and dangers on the instrument are in readable

condition.

In case of danger the instrument has to be switched o by means of the emergency-button on

the front of the instrument. Then eliminate danger.

2.3 Training of Personnel

t "OZPOFXIPPQFSBUFTUIFJOTUSVNFOUTIPVMECFUSBJOFEQSPQFSMZ

t *UIBTUPCFDMFBSXIPIBTXIJDISFTQPOTJCJMJUZSFHBSEJOHDPNNJTTJPOJOHTFUVQPG

maintenance and repairs, installation, and operation.

t "OZPOFXIPIBTOUöOJTIFEUSBJOJOHTIPVMECFTVQFSWJTFECZBOFYQFSJFODFEQFSTPOXIJMF

working with the instrument.

2.4 Dangers from Electrical Energy

t 8PSLPOUIFFMFDUSJDBMTVQQMZNBZPOMZCFEPOFCZBRVBMJöFEFMFDUSJDJBO

t 5IFFMFDUSJDBMFRVJQNFOUPGUIFJOTUSVNFOUNVTUCFDIFDLFESFHVMBSMZ-PPTFDPOOFDUJPOTBOE

cable damaged by heat must be corrected immediately.

t "MXBZTNBLFTVSFUIFJOTUSVNFOUTQPXFSJTUVSOFEPòXIJMFBEKVTUJOHBOZFMFDUSJDBM

component.

2.5 Points of Special Danger - Moving Zone tool carrier

There is one special point of danger in the moving zone of the tool carriers:

Do not move the Applicators Tool Carrier Bar on the instrument manually!

Keep your hands away from the work area and tool carrier bar after the

instrument has started!

2.6 Points of special danger - Heated Film applicators

The TQC AB3400 and AB3405 are both heated lm applicators and are able to reach temperatu-

res above 60 °C.

Contacting the heated lm applicator may cause injuries. Handle the hot surface

with care.

Don’t leave the heated vacuum bed unattended for extended periods.

Danger

Danger

Warning

EN

7

2.7 Care, Maintenance, Repairs

t "MXBZTNBLFTVSFUIFJOTUSVNFOUJTDPOOFDUFEUPBOFBSUIFETPDLFU

t .BJOUFOBODFBOEJOTQFDUJPOTIPVMECFDBSSJFEPVUBUUIFDPSSFDUJOUFSWBMT

t 0QFSBUJOHQFSTPOOFMTIPVMECFJOGPSNFECFGPSFTUBSUJOHXJUINBJOUFOBODFPSSFQBJSXPSL

t "MXBZTNBLFTVSFUIFJOTUSVNFOUTQPXFSJTUVSOFEPòBOEUIFJOTUSVNFOUJTOPUDPOOFDUFEUP

a socket while adjusting any electrical component whenever maintenance, inspection or repair

work is done.

t %POPUPQFOUIFJOTUSVNFOU*ODBTFPGNBMGVODUJPOBMXBZTDPOTVMUUIFNBOVGBDUVSFS

t /FWFSUPVDIFMFDUSPOJDTPSDJSDVJUCPBSETXIFOOPU&4%TFDVSFE

2.8 Modications to the Equipment

t "OZNPEJöDBUJPOTPSBEEJUJPOTPSBMUFSBUJPOTUPUIFJOTUSVNFOUNBZTPMFMZCFNBEFXJUI

permission from the manufacturer.

t "MMNFBTVSFTJOWPMWJOHNPEJöDBUJPOTSFRVJSFXSJUUFODPOöSNBUJPOPGBQQSPWBMGSPN52$

t *OTUSVNFOUTXIJDIBSFOPUJOGBVMUGSFFDPOEJUJPONVTUJNNFEJBUFMZCFTXJUDIFEPò

t 0OMZVTFSFQMBDFNFOUQBSUTGSPNUIFPSJHJOBMTVQQMJFS1BSUTVTFEGSPNPUIFSTPVSDFTBSFOU

guaranteed to take the loading and meet the safety requirements.

2.9 Cleaning of the Instrument and Disposal of Materials

t 8IFOJOVTFJUJTOPUBMXBZTQPTTJCMFUPBWPJETPNFTQJMMPGQBJOUPOUIFXPSLTVSGBDF

t 5SZUPLFFQUIFJOTUSVNFOUBTDMFBOBTQPTTJCMFUPQSFWFOUEJTUPSUJPOTPGGVODUJPOT

t 5PDMFBOUIFJOTUSVNFOUQSPQFSMZVTFBTVJUBCMFTPMWFOUUPEJTQPTFSFNBJOTPGQBJOUPSJOL

t 8FBSHMPWFTEVSJOHDMFBOJOH%POUTQJMMBOPWFSEPTFPGTPMWFOUEVSJOHDMFBOJOH

t $MFBOJOHNBUFSJBMTNVTUBMXBZTCFVTFEBOEEJTQPTFEPGDPSSFDUMZ

3 TRANSPORT AND STORAGE

3.1 Packing

Please take note of pictorial symbols on the packing.

3.2 User: Check on Receipt

Check packing for damage

After unpacking check complete supply.

EN

8

3.3 Reporting Transport Damage and Documentation

Any damage should be documented as accurately as possible (possibly photographed) and

reported to the relevant insurers or, in the case of sales “delivered to customers works”, to the

supplier.

3.4 Storage and Protective Measures when not in use

The instrument must be stored in a dry (± 40%rH) place at a temperature between 10 - 40°C.

The storage period should not be longer than 3 months.

Store instrument in the original packing if possible.

4 INSTRUMENT DATA

4.1 Name / Article

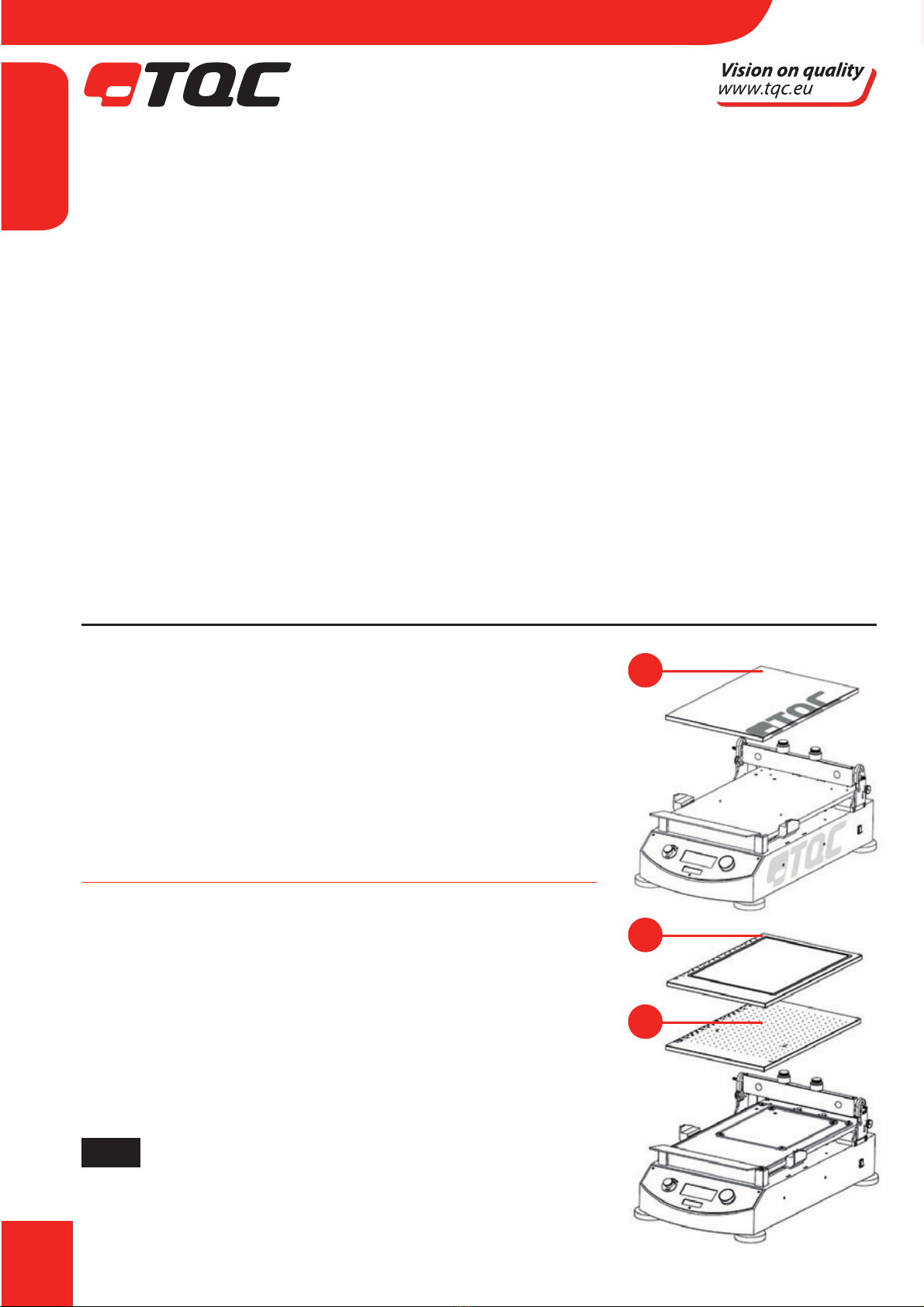

AB3120 TQC motorised automatic lm applicator 230V with

glass bed (A) and combined attachment assembly for

standard block applicators and wire bar coaters.

AB3125 TQC motorised automatic lm applicator 110V with

glass bed (A) and combined attachment assembly for

standard block applicators and wire bar coaters.

AB3220 TQC motorised automatic lm applicator 230V with

perforated vacuum bed (B), built-in vacuum pump

and combined attachment assembly for standard

block applicators and wire bar coaters.

AB3225 TQC motorised automatic lm applicator 110V with

perforated vacuum bed (B), built-in vacuum pump

and combined attachment assembly for standard

block applicators and wire bar coaters.

NOTE TQC Automated Film Applicators equipped with a

perforated vacuum bed can be retrotted with an

optional double channeled vacuum bed and vice

versa.

A

C

B

EN

9

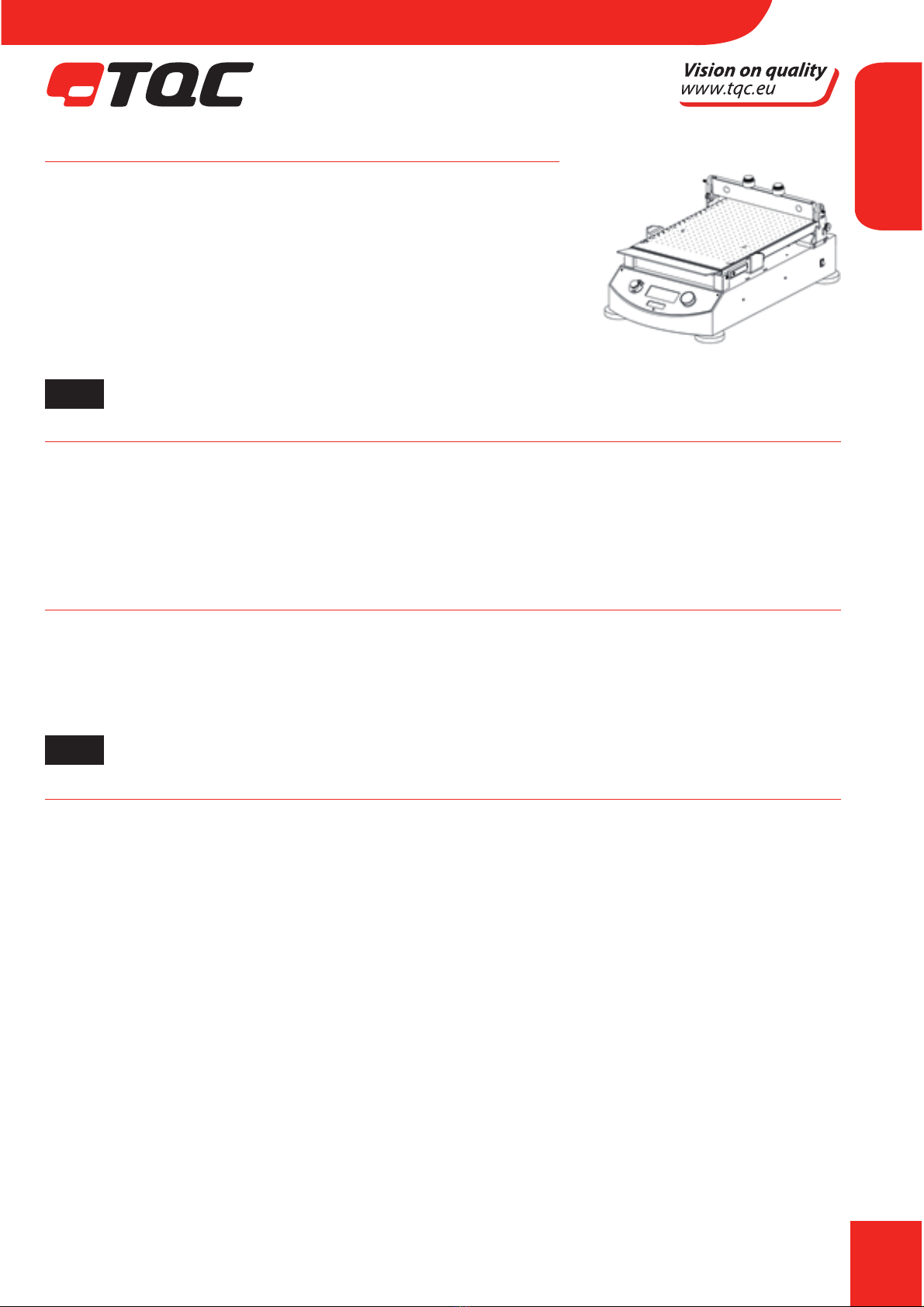

AB3320 TQC motorised automatic lm applicator 230V with

double channelled vacuum bed (C), built-in vacuum

pump and combined attachment assembly for

standard block applicators and wire bar coaters.

AB3325 TQC motorised automatic lm applicator 110V with

double channelled vacuum bed (C), built-in vacuum

pump and combined attachment assembly for

standard block applicators and wire bar coaters.

NOTE TQC Automated Film Applicators equipped with a double channelled vacuum bed can

be retrotted with an optional perforated vacuum bed and vice versa.

AB3400 TQC motorised automatic lm applicator 230V with heated perforated vacuum bed,

built-in vacuum pump and combined attachment assembly for standard

block applicators and wire bar coaters.

AB3405 TQC motorised automatic lm applicator 110V with heated perforated vacuum bed,

built-in vacuum pump and combined attachment assembly for standard

block applicators and wire bar coaters. Includes 110 VAC to 230 VAC converter

AB3420 TQC motorized automatic lm applicator 230 VAC

(exclusive application bed) inclusive vacuum pump + automatic clamp unit.

AB3425 TQC motorized automatic lm applicator 110 VAC

(exclusive application bed) inclusive vacuum pump + automatic clamp unit.

NOTE Include one or more application beds form the Accessories (Optional) section

below to complete the TQC motorized automatic lm applicator.

Accessories (Optional)

AB3500 TQC Drying time recorder tool

(Only suitable for models with rmware version 2.01 or above)

AB3000 Rubber mat for TQC Automated Film Applicator.

AB3100 Replacement Glass Bed for TQC Automated Film Applicator

AB3200 Replacement perforated vacuum bed for TQC Automatic Film Applicator

(Not for heated model).

AB3300 Replacement double channelled vacuum bed for TQC Automated Film Applicator.

VF0135 Spiral bar adapters / lengthening rods

AB3416 110 VAC to 230 VAC converter

AB3075 Grindometer tool for AFA

4.2 Scope of Supply

The scope of supply varies due to the specic applications previously mentioned in the purchase

order. (I.e. Glass Bed Perforated Vacuum Bed, Double Channel Vacuum Bed and accessories.)

EN

10

4.3 Technical Data

Automatic Film Applicator

Traverse Speed : 2 – 500 mm/s

Traverse Speed accuracy : +/- 1% of set speed

Stroke length : 50 – 359 mm

Stroke length accuracy : +/- 2 mm

Max test chart size : DIN A3

Max test substrate thickness : 35mm including applied coating

Max. test panel size (only glass bed models) : 460 x 300 x 9 mm ( LxWxH)

Max. Width alternative lm applicators : max. 300 mm

Max. Height alternative lm applicators : max. 80 mm

Wire bar length : max. 325 mm spiral area in 364 mm length at

xation points

Wire bar diameter : max. Ø10 mm at the xation points

Max vacuum : -178 mbar

Drying Time Recorder

Drying time range : 1 min. – 2880 min (48 hours)

Time accuracy : ≤ 1% of set time

Maximum test length : 350mm

Maximum number of tracks : 8

Force per needle : 3,5g / 0,03N

Weight separate weights : 5g / piece

Ø needle : 2 mm

Material : aluminium, stainless steel

Dimensions : 50x60x 315 mm / 1.97x2.36x315x12.4 inch

Weight : 280g

Heated perforated vacuum bed

Minimum temperature : Ambient + 5ºC

Maximum temperature : Ambient + 100ºC (Absolute max 140ºC)

Resolution of set temperature : 1ºC

Resolution of readout temperature : 0.1ºC

Temperature controller : Separate

Power consumption heating : 450 Watt

Power Supply : 230V, 50Hz

4.4 Dimensions and Weight

D x W X H : 650 x 350 x 240 mm

Net weight : 31 kg – 36 kg dependent on model

EN

11

Danger

4.5 Basic Unit

Power Supply : 115 – 230 V, 50 - 60 Hz

Power consumption : max. 80 Watt

Display : Blue Illuminated, graphic 100 x 35 mm, 193x64 pixels

Safety : Emergency Button and intelligent proximity

switches, integrated Acoustic Alarm

Function : Jog Shuttle knob by Rotation / Pushing

Drawn down Speeds : 12 steps selectable from 2 - 500 mm/s. and free selectable (custom)

Drawn down Lengths : A5 / A4 / A3 and free selectable (custom with variable starting/

stopping point), except for the heated vacuum bed which only

operates with A3. If smaller test charts are used a A3 sized paper

frame

has to be created to protect the holes from paint walk.

4.6 Noise Level

The continuous noise level from the instrument does not exceed 70 dB.

5 INSTALLATION AND ASSEMBLY

5.1 Installation and Operation

The instrument has to be installed in a suitable place, preferably on a sturdy table or work area,

with normal ambient temperature. Special xings are not required.

Carefully unpack the apparatus and the accessories and check complete supply.

Place, if necessary, a spirit level on the work surface and adjust the height of the feet.

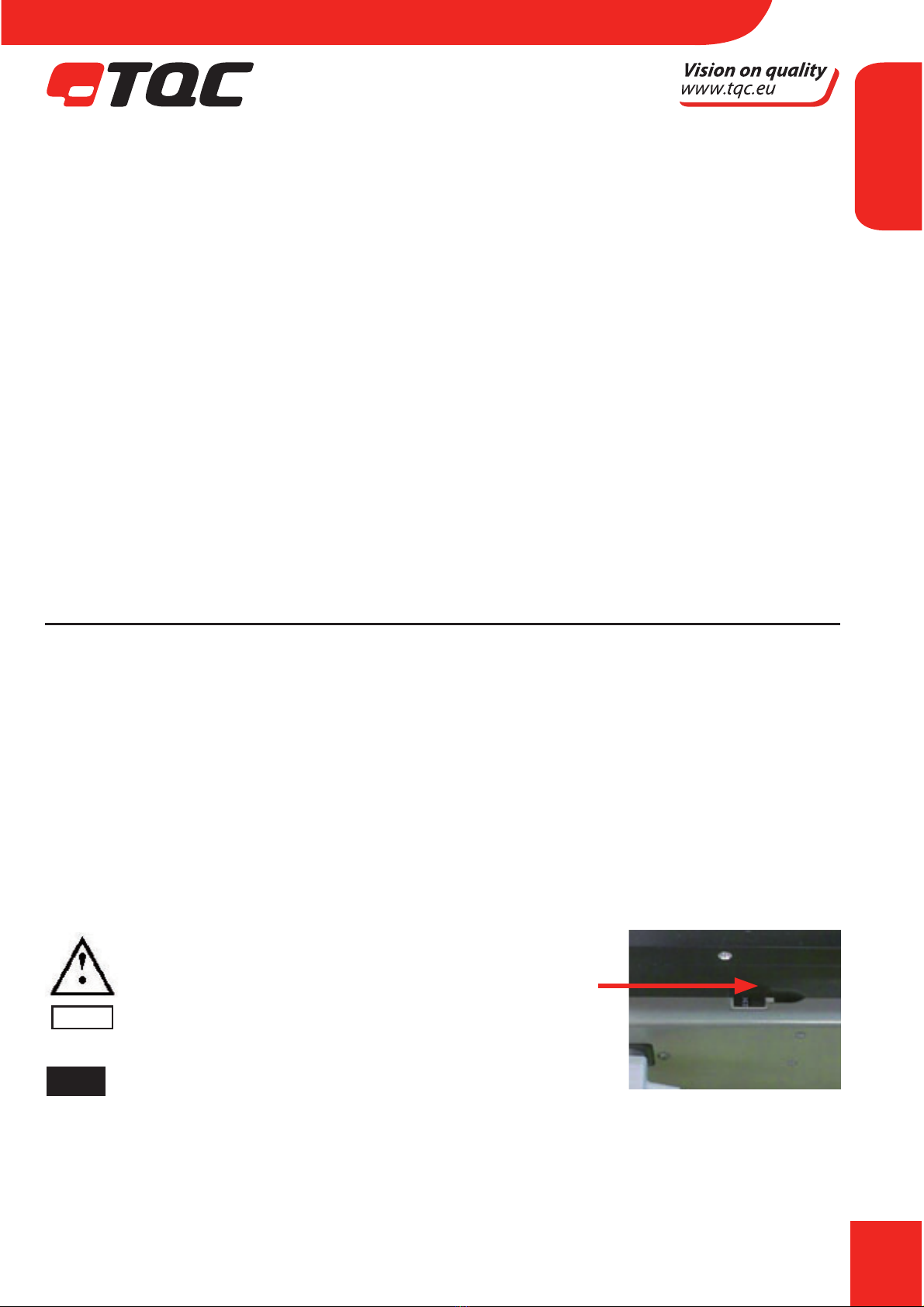

5.2 Preparation of Energy Connections

The instrument is equipped with a safety tested mains supply cable and may only be connected

to plug sockets with earth connection complying with the safety regulations.

Before connecting the instrument, check whether

the supply voltage specied on the indication label

corresponds to the local supply voltage. If it does not,

the instrument must not be connected under any

circumstances. Contact your local supplier or TQC for

full specications on how to set the correct voltage.

NOTE Voltage selector might be hidden, depending on model.

5.3 Vacuum Connection

Only applicable for selected applicator series. The applicator has a built in vacuum pump to

provide the vacuum bed enough under pressure to hold test charts of either A4 or A3 size. When

the size diers from the stated A4 or A3, cover up all remaining holes to the nearest larger size in

EN

12

order to create adequate vacuum. The level of vacuum created may

dependon operation and age of the machine as well as test substrate used.

5.4 Mains Connection

The mains connection is located at the rear of the instrument. Plug in the female plug in the

socket on the rear of the housing. The ON/OFF Switch is located at the right hand site near the

end of the instrument.

NOTE When installing AB3400 and AB3405, please see Annex D for installation

6 INSTRUMENT CONTROLS AND FUNCTIONS

6.1 Overview

1. Display with process information

2. Jog Shuttle

3. Emergency button

4. Acoustic alarm / Buzzer

5. Levelling supports

6. Glass bed or vacuum bed

7. Automated clamping device for test charts

8. Mains connection

9. Spiral applicator weight

10. Spiral bar release device

11. Hand protection device

12. Adjustable tool holder

13. Main Switch

3 4 1 52

9

7

12

8

13

6

10

11

EN

13

7 INSTRUMENT COMPONENT ASSEMBLY

7.1 Overview

1. Housing

2. Splash shield

3. Tool Carrier

4. Hight Adjustment xation

5. Spiral bar weight

6. Spiral bar weight guide pins

7. Spiral bar weight guide rings

8. Spiral bar weight extra weights

9. Lamp assembly

10. Lifter

9

8

6

7

3

4

2

1

5

10

EN

14

7.2 Instrument Preparations

Position glass bed or vacuum bed between the designated red supporting studs at the 4 corners

on the unit. The heated vacuum bed model comes with a pre assembled vacuum bed. For the

other vacuum models follow the vacuum seal installation instructions in Annex A.

7.3 Glass Bed

This bed 470 x 300 x 12 mm can either be used directly as an application carrier or (for example)

smaller cards or foils.

Charts or foils are automatically clamped in a special device at the end of the unit as soon a test is

performed. For cleaning purposes the glass bed can be removed.

7.4 Perforated Vacuum Bed

In order to create an adequate vacuum the instructions for setting up the vacuum seal O-rings

as in Annex A need to followed. The Perforated Vacuum Bed is automatically connected to the

vacuum pump as soon as placed between the red supporting studs on the O-rings.

The Perforated Vacuum Bed serves to hold thick foils, charts and other papers for coating.

The area size under vacuum depends on the selection made in the menu of the instrument

and on the model. (See 8.1 – RUN SETUP-LENGTH) See ANNEX E1 / E2 for more information on

Test Chart Placement.

7.5 Double Channel Vacuum Bed

In order to create an adequate vacuum the instructions for setting up the vacuum seal O-rings

as in Annex A need to be followed . Double Channel Vacuum Beds are used for testing on foils.

When otherwise the foil will not remain smooth on a normal vacuum bed. The Double Channel

Vacuum Bed only has vacuum in two concentrically rings on the outside of the bed. This requires

the foils to be about A3 size for the Double Channel Vacuum Bed to be able to hold them.

To prevent pollution of some holes outside the dimensions of charts we advise to cover the

surrounded area with paper or tape.

NOTE For assembly please also watch included DVD

EN

15

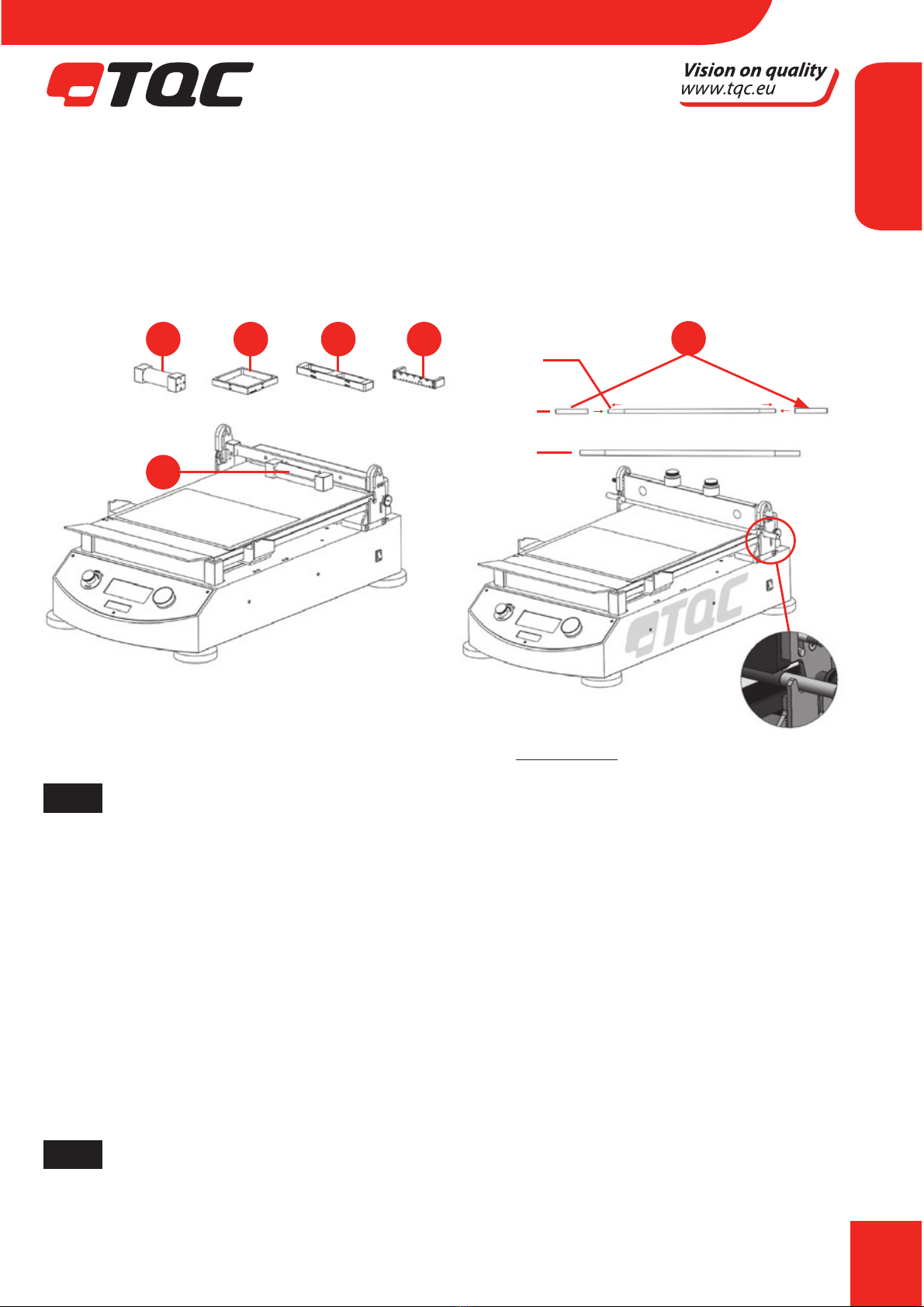

7.6 Film Applicators (Tools)

Spiral Bar applicators, Bird applicators, Baker applicators, Quadruplex applicators, SAG Quadru-

plex applicators Adjustable Micrometer applicators, SAG and levelling applicators. Place the

applicators as shown in below pictures;

For details on lm applicators datasheets are available on www.tqc.eu

NOTE The length of TQC Spiral bar coaters has changed during the years. The older shorter

version can be used on the TQC Automatic Film Applicator by the use of optional

available lengthening rods.

7.7 Test Charts

We supply a range of test charts (TQC, Leneta® or equivalent) like:

Opacity (hiding power) charts, Opacity Display charts, Sag and levelling charts, Brush out charts,

Plain White charts or others. CERTIFIED TQC TEST CHARTS!!!

For more details go to:

http://www.tqc.eu/en/products/productlistarticles/214/1/false/Test-charts

NOTE For details on Test Chart placement, please see Annex E

2 3 4 5

1

A

Total length 334 mm

Total length 440 mm

Detail A scale 2:3

Ø 8 mm

Ø 10 mm

Ø 10 mm

EN

16

7.8 Drying Time Recorder

The TQC Automated Film Applicator can be used as a Drying Time Recorder. In order to use the

TQC Automatic Film Applicator as a Drying Time Recorder following steps need to be followed:

t 3FNPWFUIF4QJSBMCBSXFJHIUGSPNESBXJOHDIBQUFSCZQVMMJOHPVUUIF4QJSBMCBSXFJHIU

guide pins(6).

t 5BLFDBSFUIBUCPUI4QJSBMCBSXFJHIUHVJEFQJOTBOE4QJSBMCBSXFJHIUHVJEFSJOHTBSF

stored in a safe place. In order to not to lose them.

t 1MBDFUIFPQUJPOBMBWBJMBCMF%SZJOH5JNF3FDPSEFS5PPMPOUIFCBSPGUIF52$"VUPNBUJD'JMN

Applicator as illustrated in below image:

8 MENU DISPLAY INFORMATION AND OPERATION

8.1 Automatic Film applicator operation

TQC Start screen after switched on.

Switch on instrument by mains switch at the right side on

the housing. This is the rst screen shown after switching

on the instrument.

NOTE The version number displayed is the rmware version number.

RUN - Automatically the rst selection screen or the

MAIN MENU appears

Press the Jog shuttle knob to start the sequence.

The applicator carrier bar is moved and set in position.

3A A

Detail Ascale 1:1

3B

B

Detail Bscale 1:1

Click

Automatic Film Applicator

V2.01

RUN

Press START to activate the

automatic lm applicator.

START

EN

17

RUN - Positioning Chart

The current draw down speed as well as the length is

shown in the top of the display. Press the Jog shuttle knob

to conrm or turn it to go back in the menu and make

changes. Place the draw down chart on the glass bed or

glass bed or vacuum bed. Choose the appropriate

applicator to full the test.

RUN – Applicator and Paint applying

Apply just enough paint to full the test on the test chart

chosen. Press the Jog shuttle knob to start the run or turn

it to go back in the menu and make changes. Display

shows“Running”. Keep your hands away from moving

parts.

MAIN MENU – Run, Run setup, Instrument setup

In the main menu you can change parameters according to

your needs. Rotate the Jog shuttle knob to select and press

to

choose. Follow the questions as they come.

RUN SETUP - Set Speed

Push the Jog shuttle knob to set the draw down speed.

RUN SET-SPEED

There are 12 preset speeds to choose from, 2 – 500 mm/s.

Custom is a free selectable speed in 1mm/s intervals.

After made changes rotate to BACK and press the Jog

shuttle knob.

RUN SETUP – Set Length

Push the Jog shuttle knob to set the traverse length.

RUN SETUP-LENGTH

There are 3 preset chart sizes selectable, A5 - A4 - A3

followed by an auto return of the tool carrier bar. Selecting

“Custom” oers you to set a Start and End point on the

platform. The traverse length is automatically set in

RUN

Place applicator and apply

print.

Stay clear from moving parts !

RUN BACK

50 mm/s A4

RUN

Place applicator and apply

print.

Stay clear from moving parts !

RUN BACK

50 mm/s A4

MAIN MENU

Run

Run setup

Instrument setup

Drying time recorder

RUN SETUP

Set speed

Set length

Set drying time recorder BACK

RUN SETUP-SPEED

Speed in mm/sec

BACK

[] 2 [ ] 5 [ ] 10

[] 20 [ ] 30 [√] 50

[] 70 [ ] 80 [ ] 100

[] 200 [ ] 300 [ ] 500

[] Custom [ 500 ]

RUN SETUP

Set speed

Set length

BACK

RUN SETUP-LENGTH

BACK

[] DIN A5

[√] DIN A4 [] DIN A3

[] Custom Start point [ 04.9]cm

End point [ 29.2]cm

Length 24.3 cm

[√] Auto return option

EN

18

accordance with the start/end points in millimetres.

After made changes rotate to BACK and press the Jog shuttle

knob VACUUM will only switch dependent on the length

of the test chart to A4 or A3, except for the heated vacuum

bed which only operates with A3. If smaller test charts are

used you have to create a A3 sized paper frame to protect

the holes from paint walk.

NOTE When using the custom length settings the spiral bar release studs can not be used

and need to be set to the end of the application bed, as close as possible to the display.

MAIN-MENU – Instrument setup

In the main menu rotate the jog shuttle knob to

Instrument setup and press on it.

INSTRUMENT SETUP

Select Language to set the desired language.

Select Units to set: Speed in mm/s, cm/s or inch/s and

Length in mm, cm or inches. Select Acoustic signals:

Signals o, Low volume or High Volume.

8.2 Drying Time recorder operation

The TQC drying time recorder is partially preset by the settings of the Automatic Film application.

In order to set up a new drying time test follow the steps below:

MAIN MENU – RUN SETUP

In the run setup menu the general setting of the Film

applicator and separate of the drying time recorder settings

can be entered. Select the “Set drying time recorder” menu

to get into the set-up menu for the drying time recorder.

RUN SETUP-DRYING TIME RECORDER

Within the Drying time recorder setup options as track time

total run time for drying time, alarm interval and vacuum

control can be set. Track time can be set from 1 minute to

48 hours. The speed will be depended on track time and set

track length. A shorter track length will mean a lower speed.

When performing drying time tests for extended test times

turn o the vacuum pump to prevent extensive wear on the

internal vacuum pump. Return to run setup menu by selecting

NOTE The vacuum control is only available for models equipped with vacuum.

MAIN MENU

Run

Run setup

Instrument setup

Drying time recorder

INSTRUMENT SETUP

Language

Units

Acoustics

BACK

RUN SETUP

Set speed

Set length

Set drying time recorder BACK

RUN SETUP-DRYING TIME RECORDER

BACK

Track time [01] hour [01] min

Alarm at [24] hour

Vacuum OFF [ √ ] hour

EN

19

RUN SETUP LENGTH

The length of a drying time test can be set here. The

operation is the same as that for setting the length for an

application.

MAIN MENU

To perform a new drying time test select “Drying time

recorder” in the main menu. This will start a drying time

run with the setting of the previous menus.

DTR-RUN (1)

The drying time recorder will now be initiated. Follow the

instruction on the screen, and position a test chart or a test

substrate. When placed, select conrm to continue.

DTR-RUN (2)

The chart / test substrate is now xed and the drying time

recorder tool can now be placed. Click the tool in place as

shown in below illustrations. When ready select run to

continue.

DTR-RUN (3)

The drying time recorder is now running. The display

shows the set time in the top left corner and the Running

time in the centre of the screen. To end the run select stop.

IT can appear that the drying time recorder is not reacting

to your command. The internal processor causes this. The

processor is at that time busy performing other tasks, and

will execute your command as soon as the performed task

is completed.

DTR-RUN (4)

When the RUN is ended the tool holder can be moved to

the points of interest on the test track by rotating the jog

shuttle. The display will show the elapsed time of when

the tool holder rst passed that point. Select back to

conrm.

DTR-RUN (5)

At this step the vacuum or clamp will be released and the

chart / substrate can be removed from the test bed.

RUN SETUP-LENGTH

BACK

[] DIN A5

[] DIN A4 [√]DIN A3

[] Custom Start point [ 44 ] mm

End point [ 350] mm

Length 306 mm

[√] Auto return option

MAIN MENU

Run

Run setup

Instrument setup

Drying time recorder

DTR-RUN

Position chart

(chart will be xed)

CONFIRM BACK

01: 01 A3

DTR-RUN

Place pins

Stay clear from moving parts !

RUN BACK

01: 01 A3

DTR-RUN

Run ended.

Rotate knob to locate position

Press knob to exit.

Time position: 00:00:27 H:M:S

01: 01 A3

BACK

DTR-RUN

Run completed, remove card

when repositioned

Repositioning . . .

01: 01 A3

DTR-RUN

Running . . .

Runing time: 00 : 00 H:M

STOP

01: 01 A3

EN

20

8.3 Heated Film bed control

The TQC Heated lm bed controller is operated by two buttons.

The power switch on the top and the temperature set knob on

the front. To set the temperature rst turn the machine on and

then set the temperature. The test bed will warm up to the set

temperature.

8.4 Warning signals

Due to circumstances the display can show:

“Release the Emergency Stop” Caused by manually pressing of

the Red emergency button. Check the fault or wrong handling,

and, after assuring that there is no danger, release the

emergency stop

“Lifter is in wrong position” Caused by wrong movement or positioning

after spiral bar lifting situations. The lifter is in position when you feel a click.

See Annex B on lifter positioning

“Emergency Stop” Remove applicator and turn machine o. For

safety reasons 3 sets of detection sensors at each site on the

housing register the proximity of ngers and shuts down any activity of

the instrument.

9 OPERATION

9.1 Preparatory Work

t $POOFDUUIFJOTUSVNFOUUPUIFNBJOTBUUIFSFBSTJEFPGUIFIPVTJOH

t 8IFOVTJOHUIFHMBTTCFEQPTJUJPOUIFUFTUDIBSUPSGPJMUPUBMMZUPUIFSFBSBOEBVUPNBUJD

clamping device.

t 8IFOVTJOHUIFWBDVVNCFEQPTJUJPOUIFUFTUDIBSUUPUBMMZUPUIFSFBSBOEMFUUIF

chart or foil suck in for some seconds.

t *OTUBMMBOEöYUIFUPPMDBSSJFSBOEUIFBQQSPQSJBUFöMNBQQMJDBUPS

9.2 Film Application

For lm application a suitable at and even base, the glass bed or vacuum bed, as well as a

suitable to use type applicator is necessary.

EN

Other manuals for AB3120

1

This manual suits for next models

11

Table of contents

Other TQC Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

HIK VISION

HIK VISION DS-K3Y501SX Series quick start guide

Little Giant

Little Giant OS3 Series owner's manual

Flex-A-Seal

Flex-A-Seal 73 Installation, operation, maintenance guide

Ebmpapst

Ebmpapst D2E146-AP47-22 operating instructions

woodmizer

woodmizer 4015X5 Safety & operation manual

EL-CELL

EL-CELL PAT-Channel-1 user manual