TQC AB5000 User manual

1

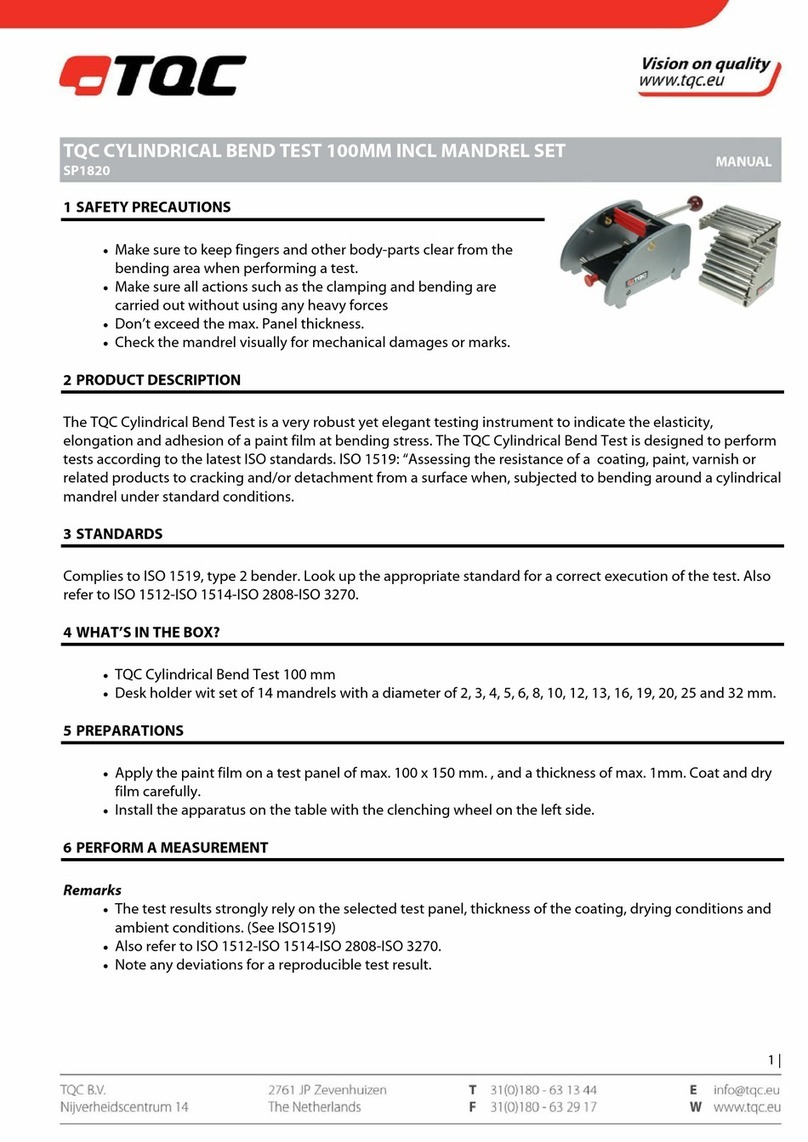

TQC SCRUB, ABRASION AND WASHABILITY TEST

AB5000

User Guide

V3.1 1216

rmware 2.0.0*

IMPORTANT!

Before taking this

instrument in use we

strongly advise you

to read this manual

carefully.

2

This product complies to

- Machinery Directive 2006/42 / EC

- Low Voltage Directive 2006/95 / EC

- EMC Directive 2004/108 / EC

This product is RoHS 2 compliant (2011/65/EU)

TQC will grant a warranty for a period of 12 months for Scrub, Abrasion and Washability Test

and 12 months for all related equipment from the date of delivery in respect of any evidence of

faulty workmanship and materials.

Should a delivered consignment prove to be contrary to contract upon inspection, the

customer shall grant TQC the opportunity hereunder of removing the fault, or else the

customer may demand replacement. Because of size and weight of the instrument TQC will

strive to give remote support.

Should the supply or delivery of any improvement or replacement not prove possible, the

customer may choose between having the purchase price reduced or in demanding the

contract of sale to be rescinded (conversion). Damage resulting from natural wear and tear,

mechanical or chemical damage, an act of God or non compliance with the operating

instructions shall be excluded from the warranty as well as mechanical interference by the

customer or by third parties with Scrub, Abrasion and Washability Test and related equipment

without TQC’s written permission. No liability will be accepted for defects, damage or injury

caused due to use not carried out in accordance with the manufacturer’s user instructions.

To claim warranty, the rejected product has to be sent to TQC together with the original

invoice, any exchange before the product has been returned to TQC is not possible. TQC

reserve the right to repair, exchange or supply an equivalent substitute. TQC is not liable for

handling or transport costs. Warranty on the purchase price is limited, all liability for

consequential damages or changes in technology is expelled.

*This manual describes the functionality on systems with rmware version 2.0.0.

The rmware version is indicated in the startup screen immediately after the system is switched on.

3

4

CONTENT

1 GENERAL 7

1.1 Importance of operating manual 7

1.2 User-responsibility 7

1.3 Responsibility of personnel 7

1.3.1 Dangers 7

1.4 Designated purpose 7

1.5 Copyright 8

1.6 Manufacturer’s/Supplier’s address 8

2 SAFETY INSTRUCTIONS 8

2.1 Meaning of Symbols 8

2.2 Availability of Safety Information 8

2.3 Training of Personnel 9

2.4 Dangers from Electrical Energy 9

2.5 Points of Special Danger 9

2.6 Care, Maintenance, Repairs 9

2.7 Modications to the Equipment 9

2.8 Cleaning of the Instrument and Disposal of Materials 10

3 TRANSPORT AND STORAGE 10

3.1 Packing 10

3.2 User: Check on Receipt 10

3.3 Reporting Transport Damage and Documentation 10

3.4 Storage and Protective Measures when not in use 10

4 INSTRUMENT DATA 10

4.1 Name / Article 10

4.2 Scope of Supply 11

4.3 Technical Data 11

4.4 Dimensions and Weight 11

4.5 Basic Unit 11

4.6 Accuracy 11

4.7 Noise Level 11

5 INSTALLATION AND ASSEMBLY 12

5.1 Installation and Operation 12

5.2 Preparation of Energy Connections 12

5.3 Mains Connection 12

EN

5

6 INSTRUMENT CONTROLS AND FUNCTIONS 13

6.1 General instruments settings 13

6.2 Models 13

7 MENU BASIC MODEL 14

7.1 Tqc Start Screens After Switched On 14

7.2 Main Menu 14

7.3 Run Setup 14

7.4 Run Setup – Test Edit 15

7.5 Instrument Setup 15

7.6 Run 16

8 MENU STANDARD MODEL 18

8.1 Tqc Start Screens After Switched On 18

8.2 Main Menu 18

8.3 Run Setup 18

8.4 Run Setup – Test Edit 18

8.5 Instrument Setup 19

8.6 Instrument Setup – Language 20

9 MECHANICAL 22

9.1 Test beds 22

9.2 Sample clamp frames 22

9.3 Tool holders 23

9.4 Tools 24

10 INSTRUMENT PREPARATIONS 31

10.1 Test bed 31

10.2 Test Panels 31

10.3 Test Fluid 31

10.4 Waste uid container 32

10.5 Tool carrier 32

10.6 Tools 32

11 OPERATION 32

11.1 Preparatory Work 32

11.2 Performing a Washability test 32

11.3 Start the instrument 33

EN

6

EN

12 CARE AND MAINTENANCE 33

12.1 Inspection and Maintenance 33

12.2 Disposal of Materials 33

12.3 Customer Service 33

13 DISCLAIMER 33

ANNEX A | STANDARDS CONFIGURATION TABLE 34

ANNEX B | ORDERING MATRIX 36

ANNEX C | CHEMICAL RESISTANCE OF WASHABILITY TEST COMPONENTS 37

DECLARATION OF CONFORMITY TQC BASIC SCRUB & WASHABILITY TEST 52

DECLARATION OF CONFORMITY TQC SCRUB & WASHABILITY TEST 53

7

1 GENERAL

1.1 Importance of operating manual

This manual is written in order to become familiar with all the functions and possible applicati-

ons of the instrument. It contains important instructions about how to use the instrument safely

and economically; according to the purpose designated. Following these instructions is not only

essential to avoid risks. It also reduces repair costs and down-time and increases the products

reliability and service-life.

Anyone who works with the instrument should follow the instructions in this manual, particu-

larly the safety related instructions. Additionally local rules and regulations relating to environ-

mental safety and accident prevention should be observed.

1.2 User-responsibility

The user should;

• onlyallowpersonstoworkwiththeinstrumentwhoarefamiliarwiththegeneralinstructions

on how to work safely and to prevent accidents. The use of the instrument should have been

instructed duly The safety chapter and the warnings in this manual should have been read and

understood; acknowledged as evidenced by their signature.

• regularlycheckthesafety-awarenessofpersonnelatwork.

1.3 Responsibility of personnel

Before commencing work anyone appointed to work with the instrument should pay attention

to the general regulations relating to working safety and accident prevention. The safety chapter

and the warnings in this manual should have been read and understood; acknowledged as

evidenced by their signature.

1.3.1 Dangers

This instrument has been designed and constructed in accordance with state-of-the-art techno-

logy and the acknowledged safety regulations. Nevertheless, working with the instrument may

cause danger to the life and health of the operator or to others, or damage to the instrument or

other property. Therefore the instrument should only be used for its designated purpose, and in

a perfect technical condition. Any defect that could have a negative eect on safety should be

repaired immediately.

1.4 Designated purpose

The Scrub, Abrasion and Washability Test is exclusively designed to perform washability tests of

painted and coated test panels as described within the specications.

Other applications constitute improper use. TQC will not be held liable for damage resulting

from improper use. Designated purpose also includes properly observing all instructions in the

operation manual, and adherence to inspection and maintenance schedules.

EN

8

1.5 Copyright

The copyright of this operating manual remains with TQC.

This operating manual is intended solely for the user and his personnel. Its instructions and

guidelines may not be duplicated, circulated or otherwise passed on to others, neither fully, nor

partly. Infringement of these restrictions may lead to legal action may be taken if this restrictions

are infringed upon.

1.6 Manufacturer’s/Supplier’s address

TQC The Netherlands,

Molenbaan 19 T +31(0)10-7900100,

2908 LL Capelle aan den IJssel F +31 (0)10-7900129

2 SAFETY INSTRUCTIONS

2.1 Meaning of Symbols

The following symbols for dangers are used in this instruction manual.

Symbol Explanation Warning

Possible immediate danger to If this guideline is not noted it can

the life or health of personnel. lead to severe danger to health,

up to fatal injury.

A dangerous situation could Non observance of this guideline

be caused. can lead to injury or to

damage to equipment.

Special tips and particular Guidelines to make optimal use of

information. the instrument.

2.2 Availability of Safety Information

The instruction manual should be kept at the place where the instrument operates. In addition to

the information contained in the instruction manual, general and local regulations for accident

prevention and environmental protection shall be kept available and observed. Always ensure all

guidelines in respect of safety and dangers on the instrument are in readable condition. In case

of danger the instrument has to be switched o by means of the emergency- button on the front

of the instrument. Then eliminate danger.

Danger

Warning

EN

9

2.3 Training of Personnel

• Anyonewhooperatestheinstrumentshouldbetrainedproperly.

• Ithastobeclearwhohaswhichresponsibilityregardingcommissioning,set-upof

maintenance and repairs, installation, and operation.

• Anyonewhohasn’tnishedtrainingshouldbesupervisedbyanexperiencedpersonwhile

working with the instrument.

2.4 Dangers from Electrical Energy

• Workontheelectricalsupplymayonlybedonebyaqualiedelectrician.

• Theelectricalequipmentoftheinstrumentmustbecheckedregularly.Looseconnectionsand

cable damaged by heat must be corrected immediately.

• Alwaysmakesuretheinstrument’spoweristurnedowhileadjustinganyelectric

component.

2.5 Points of Special Danger

There are two special point of danger in the moving zone of the tool carriers:

Always have the tool carrier locked into place prior to testing.

Keep your hands away from the working area after the instrument has started!

2.6 Care, Maintenance, Repairs

• Alwaysmakesuretheinstrumentisconnectedtoanearthedsocket.

• Maintenanceandinspectionshouldbecarriedoutatthecorrectintervals

• Operatingpersonnelshouldbeinformedbeforestartingwithmaintenanceorrepairwork

• Alwaysmakesuretheinstrumentspoweristurnedoandtheinstrumentisnotconnectedto

a socket while adjusting any electrical component whenever maintenance, inspection or

repair work is done.

• Donotopentheinstrument.Incaseofmalfunctionalwaysconsultthemanufacturer.

2.7 Modications to the Equipment

• Anymodicationsoradditionsoralterationstotheinstrumentmaysolelybemadewith

permission from the manufacturer.

• AllmeasuresinvolvingmodicationsrequirewrittenconrmationofapprovalfromTQC

• Instrumentswhicharenotinfault-freeconditionmustimmediatelybeswitchedo

• Onlyusereplacementpartsfromtheoriginalsupplier.Partsusedfromothersourcesaren’t

guaranteed to take the loading and meet the safety requirements.

Danger

EN

10

2.8 Cleaning of the instrument and disposal of materials

• Wheninuseitisnotalwayspossibletoavoidsomespillofpaintontheworksurface.

• Trytokeeptheinstrumentascleanaspossibletopreventdistortionsoffunctions.

• Tocleantheinstrumentproperlyuseasuitablesolventtodisposeremainsofpaintorink.

• Wearglovesduringcleaning;Don’tspillanoverdoseofsolventduringcleaning.

• Cleaningmaterialsmustalwaysbeusedanddisposedofcorrectly.

3 TRANSPORT AND STORAGE

3.1 Packing

Please take note of pictorial symbols on the packing.

3.2 User: Check on Receipt

Check packing for damage

After unpacking check complete supply.

3.3 Reporting Transport Damage and Documentation

Any damage to the package or instrument should be documented as accurately as possible (pos-

sibly photographed) and reported to the relevant insurers or, in the case of sales “delivered to

customers works”, to the supplier. Always have damages to the package reported on the receipt

note and registered to the deliverer.

3.4 Storage and Protective Measures when not in use

• Theinstrumentmustbestoredinadryplaceatatemperaturebetween10-40°C.

• Thestorageperiodshouldnotbelongerthan3months.

• Storeinstrumentintheoriginalpackingifpossible.

4 INSTRUMENT DATA

4.1 Name / Article

TQC Scrub, Abrasion and Washability Test – Microprocessor controlled scrub, abrasion and

washability test.

EN

11

4.2 Scope of Supply

• TQCScrub,AbrasionandWashabilityTest

• Powercord

• FlexibleLEDlight

• Tubing(onlyAB5000,AB5005)

• Fluidcontainers(onlyAB5000,AB5005)

• Optionalaccessories

4.3 Technical Data

Stroke speed : 1 – 60 cycles per minute

Stroke length : 20 - 300 mm

Max panel width : max 70 mm

Max panel length : max 350 mm

Max panel height : max. 35 mm

Pump speed : 0,0 - 3,0 ml (only AB5000, AB5005)

4.4 Dimensions and Weight

Depth : 650 mm *

Width : 350 mm *

Height : 350 mm *

Net weight : approx. 35 kg

* without uid containers

4.5 Basic Unit

Power supply : 115 – 230 V, 50 - 60 Hz

Power consumption : max. 80 Watt

Display : Blue illuminated, graphic 100 x 35 mm, 193x64 pixels

Safety : Emergency button, integrated acoustic alarm

Function : Jog shuttle knob by rotation / pushing

4.6 Accuracy

Tool carrier speed accuracy : +/- 1% of set speed

Stroke length accuracy : +/- 0.01 mm (with empty carrier)

4.7 Noise Level

The continuous noise level from the instrument does not exceed 70 dB.

EN

12

5 INSTALLATION AND ASSEMBLY

5.1 Installation and Operation

The instrument has to be installed in a suitable place, preferably on a sturdy table or work area,

with normal ambient temperature. Special xings are not required.

Carefully unpack the apparatus and the accessories and check complete supply. Place, if neces-

sary, a spirit level on the work surface and adjust the height of the feet.

5.2 Preparation of Energy Connections

The instrument is equipped with a safety tested mains supply cable and may only be connected

to plug sockets with earth connection complying with the safety regulations.

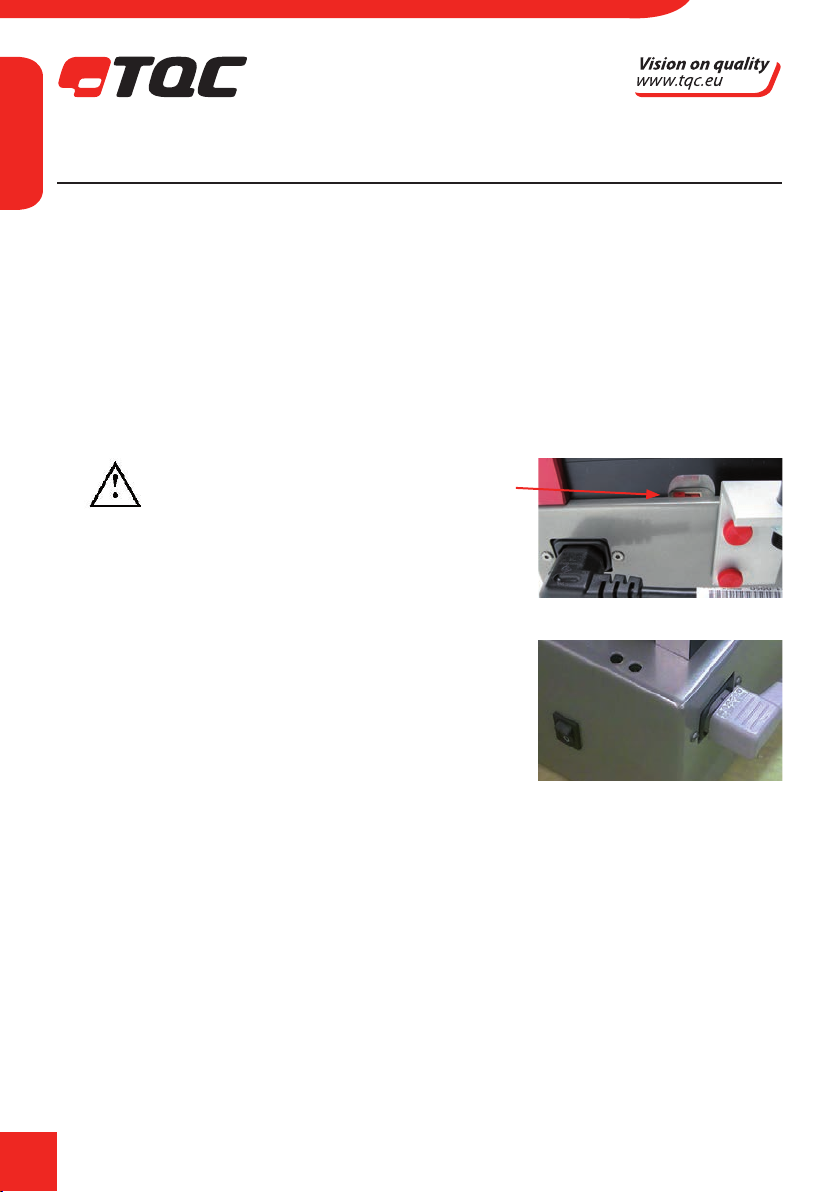

5.3 Mains Connection

The mains connection is located at the rear of the instrument.

Plug in the female plug in the socket on the rear of the housing.

The ON/OFF Switch is located at the right hand site near the

end of the instrument.

Warning

Before connecting the instrument, check

whether the supply voltage specied in the

indication window corresponds to the local

supply voltage. If it does not, the instrument

shall not be connected under any circums-

tances. This switch is located at the rear of

the instrument.

EN

13

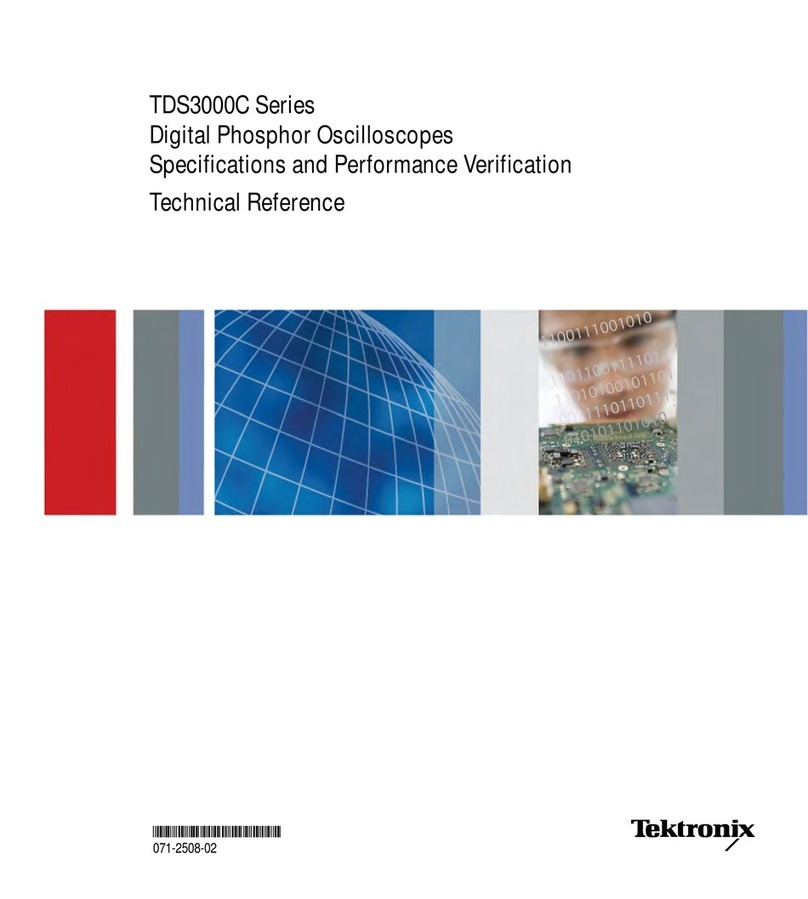

1

2

3

5

10

7

8

6

9

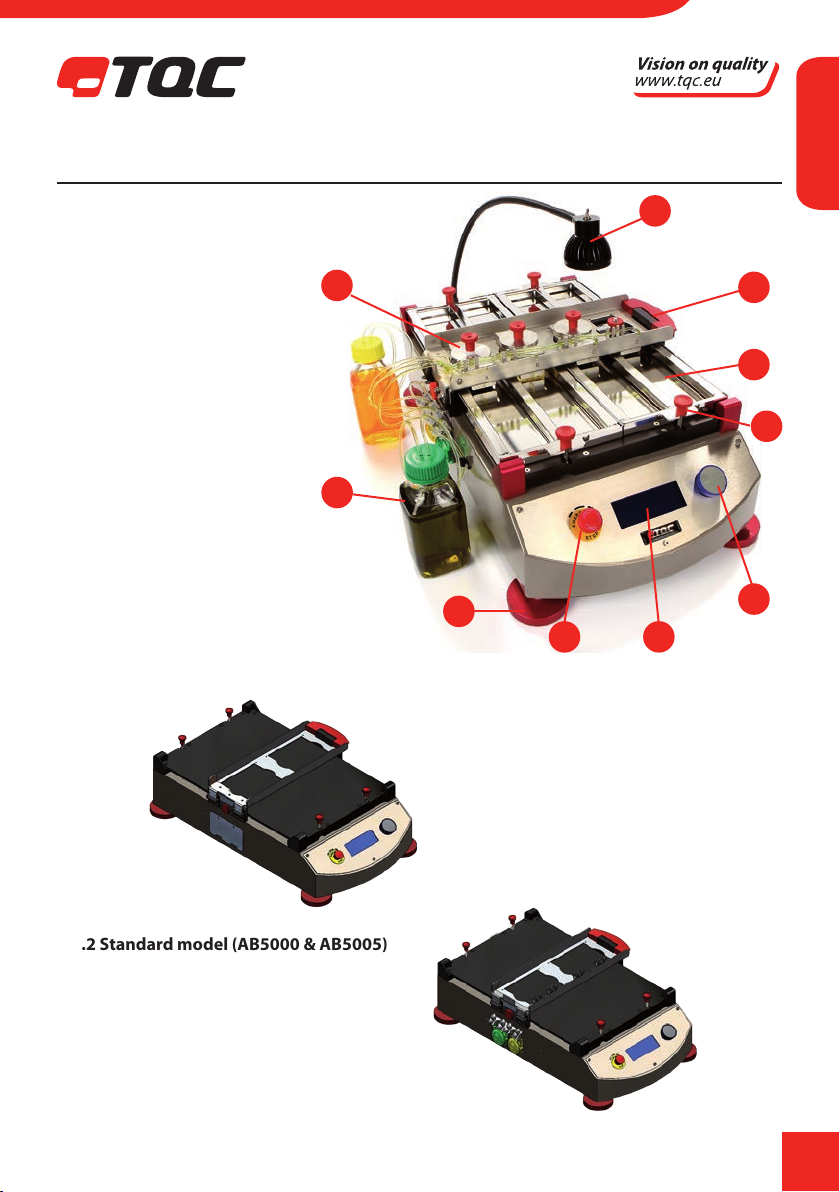

6 INSTRUMENT CONTROLS AND FUNCTIONS

6.1 General instruments settings

1. Display with process information

2. Jog Shuttle

3. Emergency button

4. Acoustic alarm / Buzzer

5. Levelling supports

6. Traverse / tool carrier

7. Drippers

8. Lamp

9. Panel Clamp on test bed

10. Fluid bottles

11. Fixture screws

6.2 Models

6.2.1 Basic model (AB5210 & AB5215)

6.2.2 Standard model (AB5000 & AB5005)

11

EN

14

7 MENU BASIC MODEL

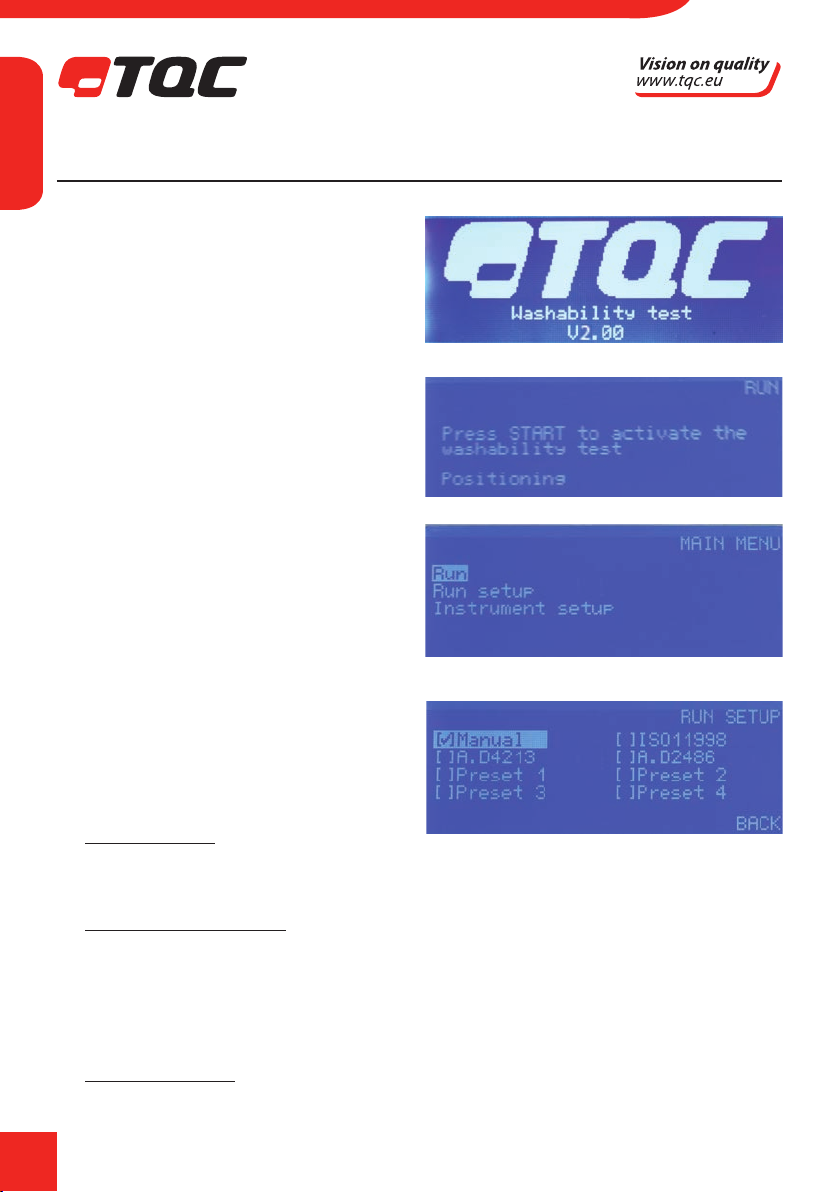

7.1 TQC Start screens after switched on

Switch on instrument by mains switch at the

right side on the housing. This is the rst screen

shown after switching on the instrument.

Every time the TQC Basic Washability Test is

turned on. The indenter needs to nd its

reference positions. Press the jog shuttle to

activate the reference procedure.

7.2 MAIN MENU

The TQC Basic Washability Test has an advanced

menu structure. The Main Menu allows the user

to access all the features, available. To select a

function turn the Jog shuttle till the white

selector is on the item and push the Jog shuttle.

7.3 RUN SETUP

The TQC Basic Washability Test is able to operate

in eight programs. The programs are dened in

three groups. *

1. Manual program: This program allows for

free editing of all the parameters except

name.

2. Standard dened programs: TQC prepro-

grammed 3 standards into the Basic

washability test. ISO 11998, ASTM D4213

and ASTM D2486 are the selected standards,

when selected all the normative parameters

can not be edited.

3. User dened presets: These 4 presets can be

programmed by the user. All parameters

and name can be edited and stored.

*Preset test: maximum count is 99999 cycles

It is not possible to set any value larger than

99999.

Manual / user dened test: stops counting on

the display at 999999. It will show up to 999999

on the display but will not stop and count until

the machine is broken, overow at 4294967296

cycles.

EN

15

7.4 RUN SETUP – Test Edit

After selecting a test by and pressing the jog

shuttle for a second time the Test-Edit menu

appears. The elds in this menu that can be

edited depending on the selected program type.

Within this menu speeds and stroke length can

be edited. The alarm settings are divided in 2 categories. The rst number is for an intermediate

alarm. In this example every 100 cycles the TQC Basic Washability tester gives an alarm. This alarm

will not stop the test but just mark regular intervals as reminders for analysts to check if any wear

occurred. The number 200 in this example marks the end of the test and will sound a long alarm.

After the values have been set, choosing the back button will automatically store the settings.

7.5 INSTRUMENT SETUP

The instrument setup menu gives the user access

to more advanced settings allowing him or her to

ne tune the instrument to their specications.

7.5.1 INSTRUMENT SETUP – LANGUAGE

The TQC Basic Washability Test is equipped with

a multi.language menu. In this part of the menu

you can select the desired language. by setting

the tick mark in front it.

7.5.2 INTRUMENT SETUP – UNITS

The units used in the display can be set to one of

the three available units. The selected unit will be

displayed in all other menus.

7.5.3 INSTRUMENT SETUP – ACOUSTICS

The audible alarm levels can be set in this menu.

The three available options are no sound, low

volume or high volume. When Signals o is

selected the audible alarm for depth indication

will also not be heard.

EN

16

7.5.4 INSTRUMENT SETUP – ALARMS

During a run with set alarm intervals as in

RUN SETUP -Test Edit. The alarm is sounded

during the test to remind the operator to check

the status.

This alarm can either be a single alarm or be repeated every minute. When the repeated alarm

option is selected the alarm can be acknowledged during the run. The alarm will then remain

silent till the next time the set interval is reached. Otherwise it will sound every minute. When

“pause at“ALARM EACH”is selected the TQC Wash, scrub and abrasion tester pauzes at each

alarm, and continues after conformation on the alarm.

NOTE: The pause at alarm each function is only available on rmware versions 2 or higher.

7.6 RUN

• Connecttheinstrumenttothemainsattherearsideofthehousing.

• Insertthecorrecttoolsinthetoolcarrierandmakesuretheyaresettothecorrectweight.

• Setthestrokelengthtothecorrectlength.

For performing a Basic Washability test a suitable panel is required. Please see the specications

and required standards for further specications.

7.6.1 RUN (1)

After selecting RUN in the main menu the TQC

Basic Washability Tester will show the main

setting of the selected program. In this case the

cycles per minute and stroke length. A warning

is shown to check if the tool carrier and sample

holders are locked into place. When the check has been done select conrm to continue.

7.6.2 RUN (2)

After conrmation the last safety warning appears. If all safety precautions have been taken

please select conrm to start the test. The half stroke made prior to the beginning of the test is an

addition to the rmware as of version 2.0. In earlier version the 2 screens displayed, are combined

in one.

7.6.3 RUN (3)

During the test the following screen appears.

The screen again shows the setting that are in

use above the line. In the middle it shows the

number of counts that have been made and the

time. When running manual mode the elapsed

time is shown. In the other presets the remaining

time will be shown.

EN

17

The view tags option brings you to the 4 screens

where per track the selected markers are display-

ed. Selecting the letter of the track will show the

5 markers per track. Selecting back will bring you

again back to the former screen.

After the RUN has been ended and the traverse

has come to a halt. The screen shows three

options. View tags to view the set markers during

the run and resume to continue the test. The back

option gets you back to the main menu. When

resume is selected the timer will not countdown

any more but will mark the elapsed time after the

test has been continued.

The view tags option brings you to the 4 screens

where per track the selected markers are display-

ed. Selecting the letter of the track will show the

5 markers per track. Selecting back will bring you

back to the former screen.

EN

18

8 MENU STANDARD MODEL

8.1 TQC Start screens after switched on

Switch on instrument by mains switch at the right

side on the housing. This is the rst screen shown

after switching on the instrument.

Every time the TQC Washability Test is turned on, it

needs to nd its reference positions. Press the jog shuttle to activate the reference procedure.

8.2 MAIN MENU

The TQC Washability Test has an advanced menu

structure. The Main Menu allows the user to access

all the features available. To select a function turn

the Jog shuttle until the white selector is on the

item. Push the Jog shuttle to conrm.

8.3 RUN SETUP

The TQC Washability Test is able to operate in

eight programs. The programs are dened in three

groups.*

1. Manual program: This program allows for free

editing of all the parameters except name.

2. Standard dened programs: TQC prepro-

grammed 3 standards into the Washability

test : ISO 11998, ASTM D4213 and

ASTM D2486. When a standard is selected all

the normative parameters can not be edited.

3. User dened presets: These 4 presets can be

programmed by the user. All parameters and

name can be edited and stored.

8.4 RUN SETUP – Test Edit

After selecting a test, pressing the jog shuttle for

a second time activates the Test-Edit menu. The

editable elds in this menu depend on the

selected program type. Within this menu speeds,

stroke length and pump speeds can be edited.

*Preset test: maximum count is 99999 cycles

It is not possible to set any value larger than

99999.

Manual / user dened test: stops counting on

the display at 999999. It will show up to 999999

on the display but will not stop and count until

the machine is broken, overow at 4294967296

cycles.

EN

19

The alarm setting is divided in 2 categories.

The rst number corresponds to the intermediate alarm. In this example every 100 cycles the

TQC Washability tester gives an alarm. This alarm will not stop the test but just mark regular inter-

vals as reminders for analysts to check if any wear occurred. The number 10000 in this example

marks the end of the test and a long alarm will sound. After the values have been set, using the

back button will automatically store the settings.

8.5 INSTRUMENT SETUP

The instrument setup menu gives the user access

to more advanced settings allowing him or her to

ne-tune the instrument to their specications.

8.5.1 INSTRUMENT SETUP – LANGUAGE

The TQC Washability Test is equipped with a multi.

language menu. In this part of the menu you can

select the desired language. Set the tick mark in

front of the desired language.

8.5.2 INTRUMENT SETUP – UNITS

The units used in the display can be set to one of

the three available units. The selected unit will be

displayed in all other menus. The unit GPH stands

for Gallons per Hour.

8.5.3 INSTRUMENT SETUP – ACOUSTICS

The audible alarm levels can be set in this menu.

The three available options are no sound, low

volume or high volume. When Signals o is

selected the audible alarm for depth indication

will also not be heard.

EN

20

8.5.4 INSTRUMENT SETUP – ALARMS

During a run with set alarm intervals as in RUN

SETUP -Test Edit. The alarm is sounded

during the test to remind the operator to check

the status.

This alarm can either be a single alarm or be repea-

ted every minute. When the repeated alarm

option is selected the alarm can be acknowledged during the run. The alarm will then remain

silent till the next time the set interval is reached. Otherwise it will sound every minute.

When“pause at“ALARM EACH” is selected the TQC Wash, scrub and abrasion tester pauzes at

each alarm, and continues after conformation on the alarm.

NOTE: The pause at alarm each function is only available on rmware versions 2 or higher.

8.5.5 INSTRUMENT SETUP – FLUSH SYSTEM

The TQC Washability Test has two pumps that can

be ushed in order to clean them or to prepare

for a test. When pressing the jog shuttle shortly

the pump will remain on until pressed again.

When holding the button down, the pump will

stop when the button is released.

8.6 RUN

8.6.1 RUN (1)

After selecting RUN in the main menu the TQC

Washability Tester will show the main setting of

the selected program. In this case

the cycles per minute, stroke length, and both

pump speeds. A warning is shown to check if

the tool carrier and sample holders are locked

into place. When the check has been done select

conrm to continue.

8.6.2 RUN (2)

After the rst screen has been conrmed, a check

should be performed that the test uid is at the

tips of the tubing. If the uid is present

this can be conrmed. Selecting ush will bring

the user to the screen as described in 8.5.5

Selecting back after ushing will take the user

back to the Run (2) screen.

EN

This manual suits for next models

3

Table of contents

Other TQC Test Equipment manuals