TQC SP7316 User manual

1 |

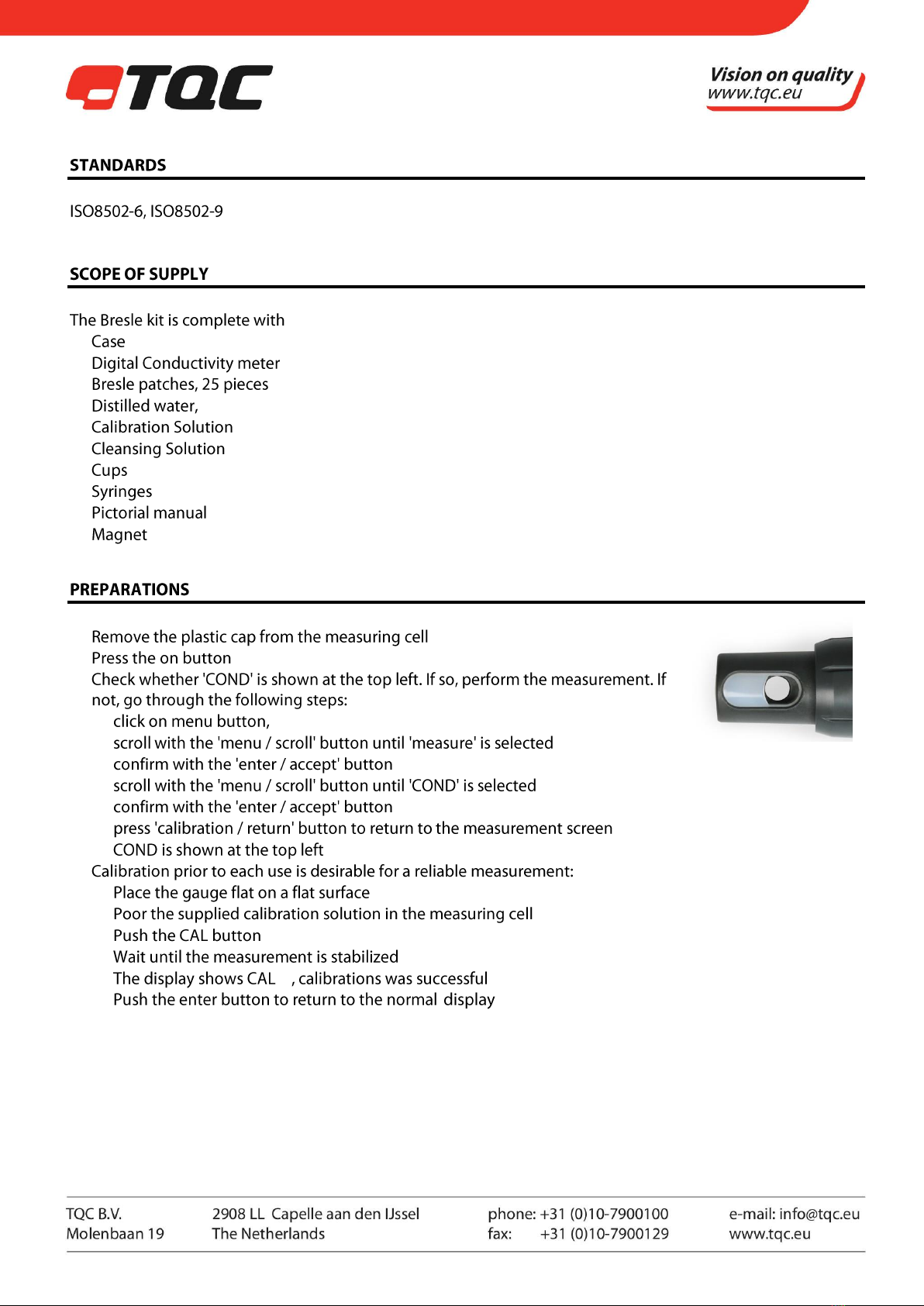

PRETREATMENT TEST KIT

SP7316

Measuring Cell

1 |

DUST TEST KIT

SP3200

DISCLAIMER

The right of technical

modifications is reserved.

The information given in this

manual is not intended to be

exhaustive and any person

using the product for any

purpose other than that

specifically recommended in

this manual without first

obtaining written

confirmation from us as to

the suitability of the product

for the intended purpose

does so at his own risk.

Whilst we endeavour to

ensure that all advice we

give about the product

(whether in this manual or

otherwise) is correct we

have no control over either

the quality or condition of

the product or the many

factors affecting the use and

application of the product.

Therefore, unless we

specifically agree in writing

to do so, we do not accept

any liability whatsoever or

howsoever arising for the

performance of the product

or for any loss or damage

(other than death or

personal injury resulting

from our negligence) arising

out of the use of the

product. The information

contained in this manual is

liable to modification from

time to time in the light of

experience and our policy of

continuous product

development.

1 |

SPRING LOADED ROLLER FOR DUST TEST TAPE

SP3600

1SAFETY PRECAUTIONS

•Always keep the instrument in its case when not in use.

•Though robust in design, this instrument is precision-machined. Never drop it

or knock it over

•Clean the instrument with a damp soft cloth. Never use abrasives or solvents.

2PRODUCT DESCRIPTION

The Spring Loaded Roller is used to perform objective dust tape tests, as mentioned in ISO 8502-3, and

eliminates the human factor. The Spring loaded roller is so designed that it is capable of applying a load of 44,13

N. Iso 8502-3 quantifies the quantity and size of dust particles on surfaces prepared for painting. This test has to

be performed just before the paint is applied. The test itself is not included in the delivery

3STANDARDS

ISO 8502-3, IMO-PSPC MSC.215(82) and MSC.244(83)

4WHAT’S IN THE BOX?

TQC Spring Loaded Roller

Plastic carrying case

Calibration certificate

5PERFORM A MEASUREMENT

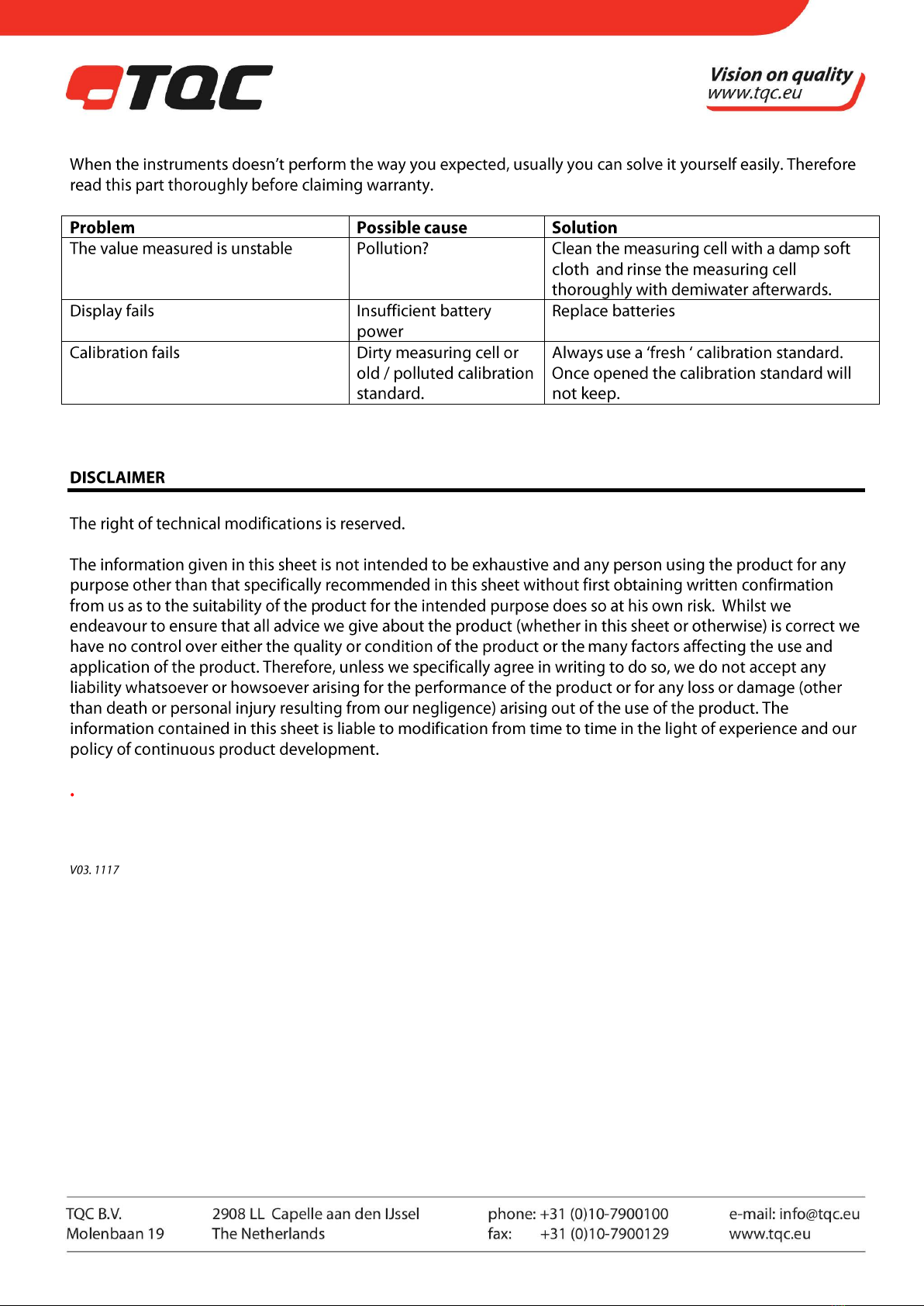

•Cut a piece of 20 cm from the special specified dust tape(SP3209) supplied with the Dust Test Kit SP3200 or

the PreTreatment Kit SP7315/7316.

•Apply the tape at an appropriate location and rub 3 times by thumb with a hand force of approx. 4-5 kg.

•Take the Spring Loaded Roller and place it axial over the applied tape before.

•Press and hold down the roller till all wheels are in contact with the surface to assure the specified force of

44,13 N is applied.

•Move the spring roller, while holding it down, 3 times for and backwards over the tape.

•Peel the tape off by taking it on one of the corners and apply it on a Sample Transfer Sheet (SP3221) to

examine and rate.

2 |

6MAINTENANCE

•Though robust in design, this instrument is precision-machined. Never drop it or knock it over

•Always clean the instrument after use.

•Clean the instrument using a soft dry cloth. Never clean the instrument by any mechanical means such as a

wire brush or abrasive paper. This may cause, just like the use of aggressive cleaning agents, permanent

damage.

•Always keep the instrument in its case when not in use.

7DISCLAIMER

The right of technical modifications is reserved.

The information given in this manual is not intended to be exhaustive and any person using the product for any

purpose other than that specifically recommended in this manual without first obtaining written confirmation

from us as to the suitability of the product for the intended purpose does so at his own risk. Whilst we

endeavour to ensure that all advice we give about the product (whether in this manual or otherwise) is correct

we have no control over either the quality or condition of the product or the many factors affecting the use and

application of the product. Therefore, unless we specifically agree in writing to do so, we do not accept any

liability whatsoever or howsoever arising for the performance of the product or for any loss or damage (other

than death or personal injury resulting from our negligence) arising out of the use of the product. The

information contained in this manual is liable to modification from time to time in the light of experience and

our policy of continuous product development.

1|

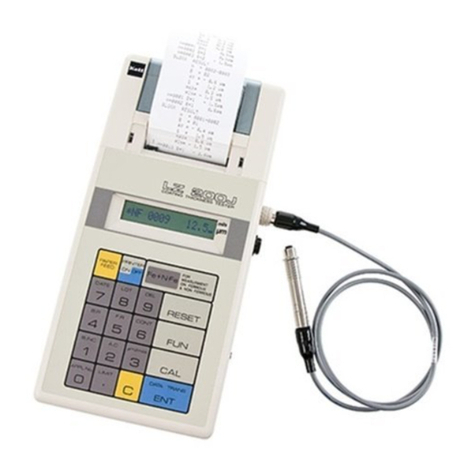

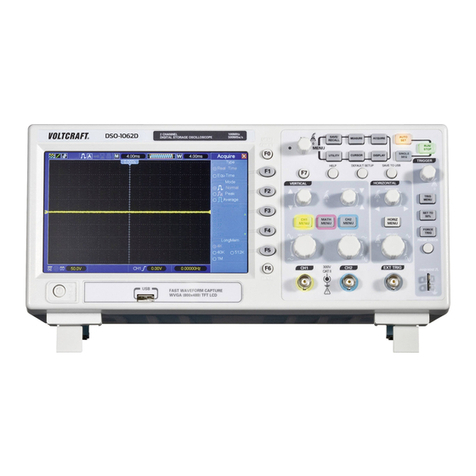

TQC SURFACE PROFILE AND COATING THICKNESS GAUGE

SP1560

1PRODUCT DESCRIPTION

The TQC Surface Profile & Coating Thickness gauge is a combination gauge. that can be

equipped with two different tips, one for surface roughness and another for coating

thickness.

1.1 Technical Specifications

Range : 0~3,4 mm / 0~0.13 inch

Resolution : 1µm / 0.04 mil

Accuracy : ± 5µm / 0.2 mil

Thread : M2.5 x 0,45

Stem Diameter : 8 mm / 0.3 inch

Battery : Type LR44 1.5 V

1.2 Details

Tips: : Sharp needle tip for Surface Roughness gauge (standard on the gauge)

: Round tip for Coating Thickness Gauge

2STANDARDS

ISO 2808-4B, ASTM D 4417-B, JIS K 5600-1-7, BS 3900-C5

Look up the appropriate standard for a correct execution of the test

3WHAT’S IN THE BOX?

The instrument comes with two tips and a glass calibration plate, all in a leather pouch.

4SPARES / ACCESSORIES

SP1619 Replacement tip for coating thickness

SP1616 Replacement tip for roughness

SP1618 Spare leather pouch for SP1560

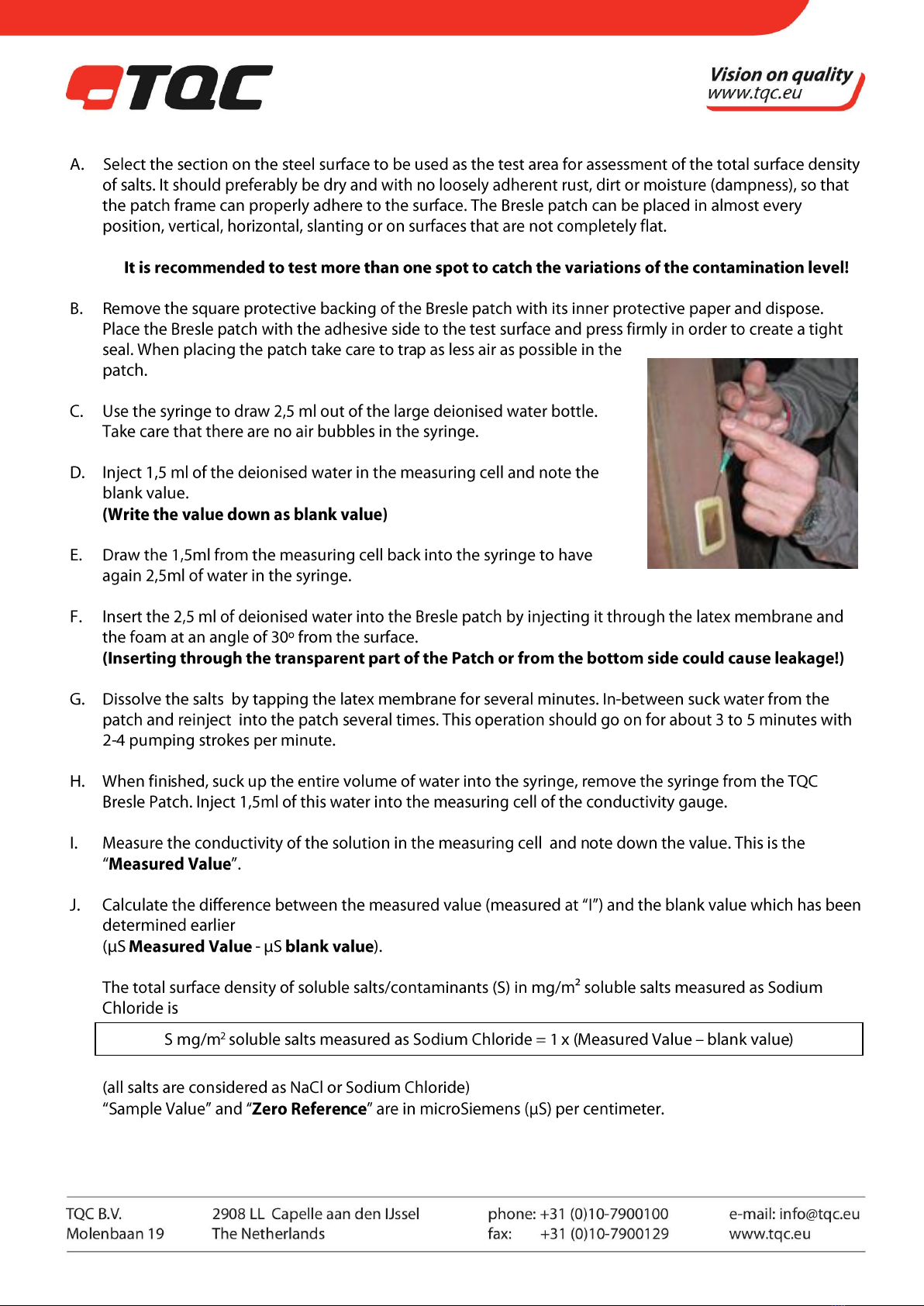

5PERFORM A MEASUREMENT

5.1 Measuring Roughness

1. Press the On/Off button to switch the gauge on.

2. Check if the right tip is chosen. (the sharp needle tip is suitable for measuring roughness)

3. Choose parameter by pressing the IN/MM button.

4. Place the needle of the gauge on the flat glass specimen (zero plate) and press the gauge with the

holder down until the base of the holder stands firmly on the zero plate.

5. Press the ZERO button to make the instrument read zero.

2

|

6. Place the needle gentle on the blasted surface and press the base of the gauge-holder firmly against the

steel. Do not drag the instrument.

7. Read the peak-valley value.

8. Make 10 measurements on each desired location and determine the mean as being the profile of the

surface.

5.2 Measuring Thickness

1. Press the On/Off button to switch the gauge on.

2. Check if the right tip is chosen. (the round tip is suitable for measuring thickness)

3. Choose parameter by pressing the IN/MM button.

4. Place the needle of the gauge on the flat glass specimen (zero plate) and press the gauge with the

holder down until the base of the holder stands firmly on the zero plate.

5. Press the ZERO button to make the instrument read zero.

6. Gently remove a piece of paint with a diameter of 8mm. from the surface. Try to remove the paint

without damaging the underground material.

7. Place the needle on the removed paint. Make sure the aluminium footing stands on the painted area.

8. The Coating thickness appears on the display.

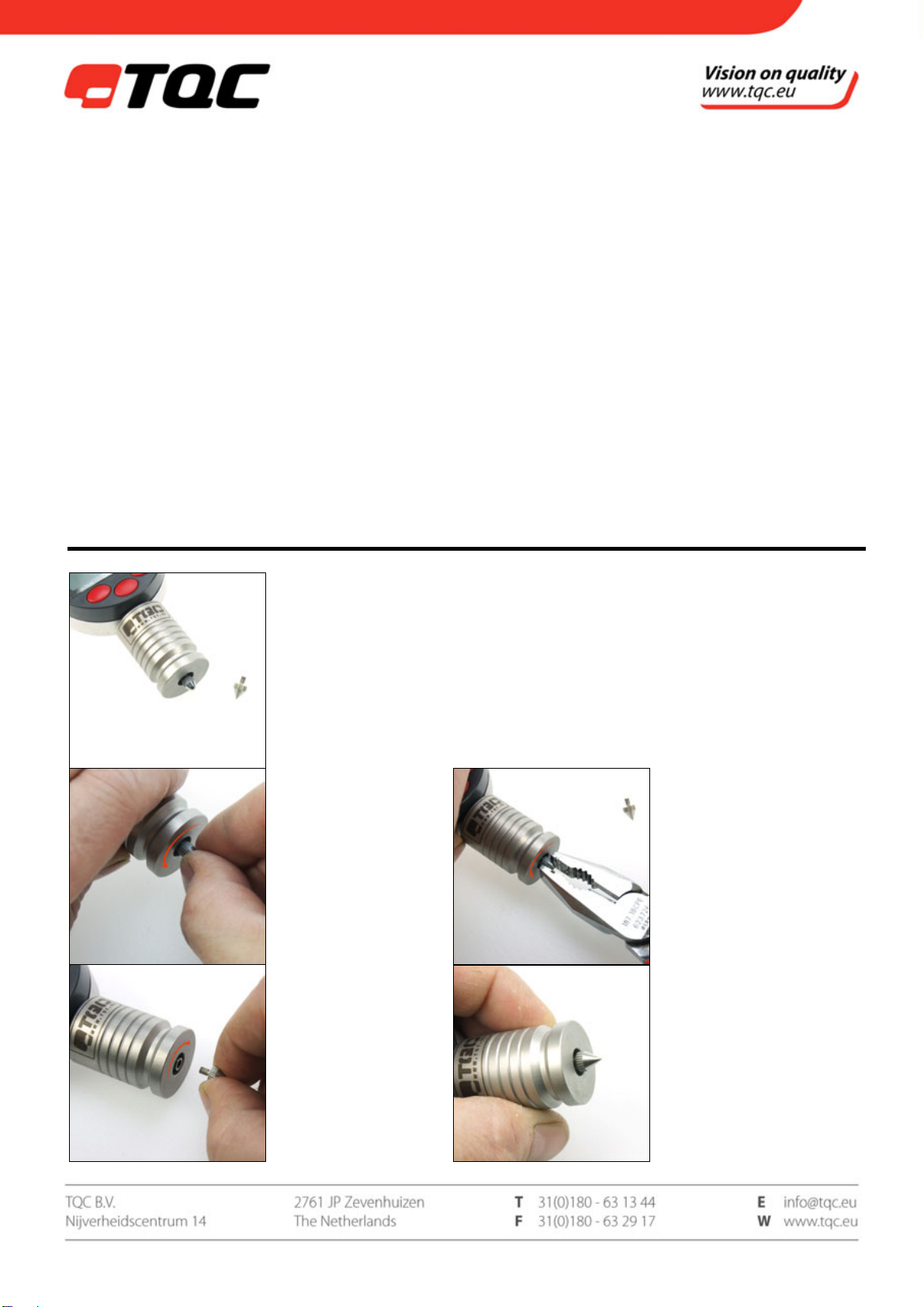

6CHANGING TIPS

Step 1

Two tips are supplied.

The sharp needle tip is

suitable for measuring

roughness, the round

one for thickness.

Step 2

Take the tip between

two fingers and turn

anti-clockwise until it is

loose. If the tip stays

stuck, go to step 2a.

Step 2a

Only when loosening the tip

anti-clockwise by hand fails,

a pair of tongs may be used

GENTLY. Make sure the tip

remains undamaged.

Step 3

Turn the new tip

clockwise until it’s

stuck.

Step 4

The tips have been changed.

Don’t forget to store the tip

that’s not in use.

3

|

7BATTERY REPLACEMENT

If the display blinks it’s necessary to replace the battery. The battery compartment lid is the grey cap on top of

the gauge. Remove it by lifting it with a small screw driver.

Replace the LR44 battery with its positive side facing upwards.

8CALIBRATIONS

We recommend annual calibration. You can send the instrument to the TQC Service department, together with

a completed RMA form. This form is available on www.tqc.eu under the Service-menu ; Repairs / Calibrations

9MAINTENANCE

•Though robust in design, this instrument is precision-machined. Never drop it or knock it over

•Always clean the instrument after use.

•Clean the instrument using a soft dry cloth. Never clean the instrument by any mechanical means such as a

wire brush or abrasive paper. This may cause, just like the use of aggressive cleaning agents, permanent

damage.

•Do not use compressed air to clean the instrument.

•Always keep the instrument in its case when not in use.

10 DISCLAIMER

The right of technical modifications is reserved.

The information given in this manual is not intended to be exhaustive and any person using the product for any

purpose other than that specifically recommended in this manual without first obtaining written confirmation

from us as to the suitability of the product for the intended purpose does so at his own risk. Whilst we

endeavour to ensure that all advice we give about the product (whether in this manual or otherwise) is correct

we have no control over either the quality or condition of the product or the many factors affecting the use and

application of the product. Therefore, unless we specifically agree in writing to do so, we do not accept any

liability whatsoever or howsoever arising for the performance of the product or for any loss or damage (other

than death or personal injury resulting from our negligence) arising out of the use of the product. The

information contained in this manual is liable to modification from time to time in the light of experience and

our policy of continuous product development.

1 |

STEEL SURFACE ROUGHNESS COMPARATOR

LD2040, LD2050

1PRODUCT DESCRIPTION

Comparison standard according to ISO 8503 part 1 made of quality steel. Indicates the

surface condition of blasted steel according to ISO 8503 in grades of fine, medium,

and coarse.

1.1 Specifications

LD2040 - Surface Roughness Comparator for Grit Blasting

LD2050 - Surface Roughness Comparator for Shot Blasting

Material : High purity nickel

Width : 85mm

Height : 85mm

The comparator has been reproduced from a specially prepared and numbered master block

2STANDARDS

ASTM D 4417 Method A, ISO 8503-1

3WHAT’S IN THE BOX?

The Surface Roughness Comparator comes in a sturdy leather wallet.

4PERFORM A MEASUREMENT

By placing the appropriate comparator (G for Grit, S for Shot) against a blast cleaned surface, the finish achieved

can be compared against the four sections of the comparator. It is then a simple matter to identify (by sight and

touch) the standard surface:

Fine grade equal to or above segment 1 but below segment 2

Medium grade equal to or above segment 2 but below segment 3

Coarse grade equal to or above segment 3 but below segment 4

5MAINTENANCE

Always keep the instrument in its case when not in use.

6DISCLAIMER

The right of technical modifications is reserved.

The information given in this manual is not intended to be exhaustive and any person using the product for any

purpose other than that specifically recommended in this manual without first obtaining written confirmation

from us as to the suitability of the product for the intended purpose does so at his own risk. Whilst we

endeavour to ensure that all advice we give about the product (whether in this manual or otherwise) is correct

2 |

we have no control over either the quality or condition of the product or the many factors affecting the use and

application of the product. Therefore, unless we specifically agree in writing to do so, we do not accept any

liability whatsoever or howsoever arising for the performance of the product or for any loss or damage (other

than death or personal injury resulting from our negligence) arising out of the use of the product. The

information contained in this manual is liable to modification from time to time in the light of experience and

our policy of continuous product development.

1 |

UV POCKET FLASHLIGHT

LD7290

1SAFETY PRECAUTIONS

WARNING: The light from this flashlight is very powerful and should not be

shone directly into anyone's eyes, as this may cause short term blindness. If the

beam does shine in your eyes, close them and look away immediately.

2PRODUCT DESCRIPTION

Small, light weight, UV pocket flashlight powered by an ultra-high output 390-

410nm UV LED. This TQC UV pocket flashlight is used to detect contaminations that react under UV-

illumination and cannot be seen with naked eye such as some organic fats, alkaline contaminants etc. Ideal to

inspect the cleanliness of steel prior to painting.

2.1 Specifications

Light Source : LED

Chip : 1x Edixeon UV LED

Batteries : 3xAAA alkaline batteries

Net. weight : 76 grams excl. batteries

Wavelength : 395-410 NM

Beam distance : 50 meters

Burning time : 170 hours

IP No. : IP67

Contacts : Hard gold-plated contacts

Size : 32 x 126mm

3WHAT’S IN THE BOX?

UV pocket flashlight

3 x AAA alkaline battery

Wrist strap

Pouch

4PERFORM A MEASUREMENT

4.1 installing the batteries

Hold the aluminium casing firmly in one hand and

turn the end cap in a counter clockwise direction

until fully unscrewed (see figure) Pull the end cap

away from the casing and this will reveal the battery

cartridge. Place each battery in turn within the

cartridge ensuring that the polarity marks (+ and -)

on the battery match that of the cartridge. With all

LD7290

2 |

batteries installed replace the cartridge in to the casing and turn the end cap in a clockwise direction until fully

tightened. The flashlight is now ready to use.

IMPORTANT: please make sure the batteries are installed correctly otherwise battery damage may occur,

possibly resulting in a explosion. Never try to recharge batteries or use new and used batteries together. Always

change all the batteries at the same time and only use high quality ones. Be careful not to touch the gold

contacts at the end of the battery cartridge or rest them against anything conductive as this could cause short

circuit. If you do not intend to use the flashlight for a long period of time, remove the batteries to prevent them

leaking and damaging the flashlight.

4.2 operating the flashlight

To switch on the flashlight simply press the end cap switch until it engages, then release. To switch the

flashlight off, press the end cap switch once again until it disengages, then release.

5DISCLAIMER

The right of technical modifications is reserved.

The information given in this manual is not intended to be exhaustive and any person using the product for any

purpose other than that specifically recommended in this manual without first obtaining written confirmation

from us as to the suitability of the product for the intended purpose does so at his own risk. Whilst we

endeavour to ensure that all advice we give about the product (whether in this manual or otherwise) is correct

we have no control over either the quality or condition of the product or the many factors affecting the use and

application of the product. Therefore, unless we specifically agree in writing to do so, we do not accept any

liability whatsoever or howsoever arising for the performance of the product or for any loss or damage (other

than death or personal injury resulting from our negligence) arising out of the use of the product. The

information contained in this manual is liable to modification from time to time in the light of experience and

our policy of continuous product development.

Table of contents

Other TQC Test Equipment manuals