2|

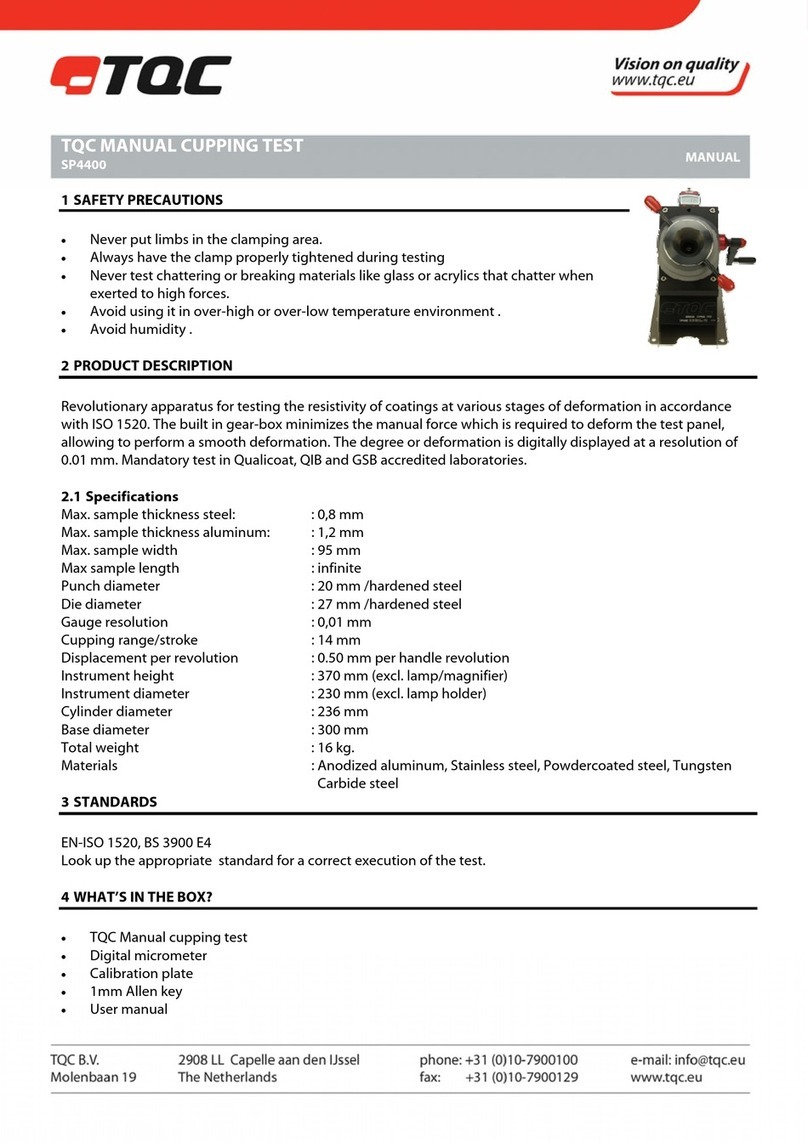

1. Sufficiently open the apparatus

to insert the mandrel with the

correct dia. turning the handle

of the pressure rollers anti

clockwise.

3. Pull the handle, and with a

smooth movement, taking

1 - 2 seconds, make an even

180° bend.

2. Place and secure a test-panel in

the apparatus, positioned

against the mandrel. Fix it

upright into the clamp. The

coated side of the panel should

face outwards once the bend

has been made.

4. Release the test-panel from

the test-apparatus and

examine results immediately.

7MAINTENANCE

•Though robust in design, this instrument is precision-machined. Never drop it or knock it over

•Always clean the instrument after use.

•Clean the instrument using a soft dry cloth. Never clean the instrument by any mechanical means such

as a wire brush or abrasive paper. This may cause, just like the use of aggressive cleaning agents,

permanent damage.

•Do not use compressed air to clean the instrument.

8DISCLAIMER

The right of technical modifications is reserved.

The information given in this manual is not intended to be exhaustive and any person using the product for any

purpose other than that specifically recommended in this manual without first obtaining written confirmation

from us as to the suitability of the product for the intended purpose does so at his own risk. Whilst we

endeavour to ensure that all advice we give about the product (whether in this manual or otherwise) is correct

we have no control over either the quality or condition of the product or the many factors affecting the use and

application of the product. Therefore, unless we specifically agree in writing to do so, we do not accept any

liability whatsoever or howsoever arising for the performance of the product or for any loss or damage (other

than death or personal injury resulting from our negligence) arising out of the use of the product. The

information contained in this manual is liable to modification from time to time in the light of experience and

our policy of continuous product development.