Trace Sun Tie ST1000 Setup guide

Installation and Operators Manual

ã

2000 Xantrex/Trace Engineering

Sun Tie Inverter

ST1000, ST1500, ST2000 and ST2500

975-0003-01-02 Rev. A 11/00

i

©2000 Xantrex/Trace Engineering

Sun Tie Inverter

ST1000, ST1500, ST2000 and ST2500

Table of Contents

Section Description Page

1.0 INTRODUCTION .....................................................................................1

Standard Features ...........................................................................1

.0 INSTALLATION .......................................................................................

Pre-Installation ................................................................................

Tools Required ..........................................................................

Hardware/Materials Required ..................................................

AC Connections ........................................................................

DC Connections ........................................................................ 3

ST1500 and ST 500 ............................................................3

ST1000 and ST 500 ............................................................4

Grounding .................................................................................5

AC Grounding .....................................................................5

DC Grounding .....................................................................5

PV Arrays ................................................................................... 5

AC Circuit Breakers ..................................................................6

Wire Routing .............................................................................6

Mounting ..........................................................................................7

Wiring ........................................................................................... 11

DC Wiring ................................................................................ 11

PV Array ................................................................................... 11

ST1500 and ST 500 DC Wiring ....................................... 11

PV Array Conduit/Wire Run ............................................. 11

ST1000 and ST 000 DC Wiring .......................................13

PV Array Conduit/Wire Run .............................................13

AC Wiring ................................................................................14

Lightning Protection ............................................................... 17

3.0 OPERATION .........................................................................................18

Start-up Procedure ........................................................................ 18

Required Equipment ............................................................... 18

AC Utility Voltage Check ........................................................ 18

Solar Array DC Voltage Check ...............................................19

Operational Test ...................................................................... 0

4.0 TROUBLESHOOTING .......................................................................... 4

5.0 SPECIFICATIONS ................................................................................. 7

6.0 SERVICE INFORMATION ..................................................................... 8

7.0 WARRANTY.......................................................................................... 9

©2000 Xantrex/Trace Engineering

ii

Disclaimer of Liability

Since the use of this manual and the conditions or methods of installation, operation, use and

maintenance of the unit are beyond the control of Xantrex/Trace, the company does not assume

responsibility and expressly disclaims liability for loss, damage, or expense arising out of or any way

connected with such installation, operation, use, or maintenance.

©2000 Xantrex/Trace Engineering iii

SAVE THESE INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

This manual contains important safety instructions that should be followed during the installation

and maintenance of this product.

To reduce the risk of electrical shock, and to ensure the safe installation and operation of this

product, the following safety symbols have been placed throughout this manual to indicate

dangerous conditions and important safety instructions.

WARNING - A dangerous voltage or condition exists in this area.

se extreme caution when performing these tasks.

AVERTISSEMENT - ne tension ou condition dangereuse existe dans cette zone.

Faire preuve dextrême prudence lors de la réalisation de ces tâches.

CAUTION - This procedure is critical to the safe installation or operation of the unit. Follow these

instructions closely.

ATTENTION - Cette procédure est essentielle à linstallation ou lutilisation

de lunité en toute sécurité. Suivre ces instructions de près.

NOTE - This statement is important. Follow instructions closely.

NOTE - Cette déclaration est importante. Suivre les instructions de près.

All electrical work must be done in accordance with local and national electrical codes.

Before installing or using this device, read all instructions and cautionary markings located in

(or on) the manual, the ST and the PV array.

Do not expose this unit to rain, snow or liquids of any type without the rain/weather shield

hood installed (optional on some models).

To reduce the chance of short-circuits when installing or working with the inverter or the PV

array, use insulated tools.

Remove all jewelry such as rings, bracelets, necklaces, etc., prior to installing this system.

This will greatly reduce the chance of accidental exposure to live circuits.

The ST unit contains more than one live circuit (PV array and AC line). Power may be present

at more than one source even when the circuit breakers are off.

This product contains no user serviceable parts. Return the unit to a Trace Authorized Service

Center for maintenance.

Wiring to the utility should only be done after receiving prior approval from the utility company

and performed only by a qualified electrician.

Completely cover the surface of all PV arrays with an opaque (dark) material BEFORE wiring

them. PV arrays produce electrical energy when exposed to light, and could create a

hazardous condition.

©2000 Xantrex/Trace Engineering

iv

NOTE: This is a one line drawing intended as a system overview only. System grounding and other

electrical details are not included.

DC Input Voltage AC Output

Voltage

Main Utility

Service Panel

AC Utility

Meter

Solar Power

AC to Grid

Solar PV Array

975-F00-008SA

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

Sun Tie

Sun Tie Unit

1

1.0 INTR DUCTI N

©2000 Xantrex/Trace Engineering

The Trace Sun Tie (ST) solar power conversion center is designed to convert a home or

business into a green power generating station. The ST unit converts solar electric (PV) power into

utility grade electricity which can be used by the home, or sold to the power company. Installing an

ST unit is as simple as mounting it to the wall and connecting a DC source (PV array), and the AC

output to the utility.

Standard Features

All-in-one Design

All necessary DC input and AC output connections, disconnects and circuit breakers are housed

within the STs easily installed, compact enclosure. A built-in LCD panel provides easy-to-read

system status and daily cumulative energy production information.

Uses Most Types of PV Technology

The ST is designed to take advantage of most types of solar electric technologies. The inverter

allows up to 120 VDC open circuit PV modules to be used so both crystalline and thin film PV

modules can be used.

Maximum Power Point Tracking

The inverter performs a power sweep every minute adjusting array voltage and current,

maximizing PV power generation. Maximum Power Point Tracking (MPPT) ensures the system

produces as much AC power as possible under any light condition.

High Efficiency and Long Life

The high frequency, solid-state design of the ST inverter is extremely efficient. When array

output is over 500 watts, the inversion process is over 90% efficient (with a peak efficiency of 94%).

The ST inverter has a design life of over twenty years.

Expandable

ST inverters may be connected in a parallel configuration for increasing net metering capacity.

The modular expandability of the ST Series allows for system growth.

UL Listed

The ST has complete on-board islanding protection and meets safety operating standards and

code requirements world wide. In North America, it is L listed ( L 1741-First Edition) and c L listed

to CSA C22.2 No. 107.1-95. NEC 690 building code requirements for PV may be met with the

optional ground fault protection (PVGFP).

Options

These features are included on some models:

PV array combiner board with six 20 amp max. protected inputs

PV array Ground Fault Protection PVGFP

2.0 INSTALLATI N

©2000 Xantrex/Trace Engineering

Pre-Installation

Before installing the Trace ST unit, read all instructions and cautionary markings located in

this manual, on the PV array and on the main service panel.

NOTE: The Trace ST weighs approximately 35 pounds (depending upon configuration and model).

Always use proper lifting techniques during installation to prevent personal injury.

Mounting:

The Trace ST unit can be mounted outdoors with the optional Rain Shield (STRS).

Tools required:

Phillips screw drivers level

slotted screw drivers wire strippers

open-end wrenches torque wrench

socket wrench and fittings electrical tape

multimeter (true rms) pencil

frequency counter (optional) utility knife

Hardware/Materials required:

wood screws and washers (supplied)

conduit and appropriate fittings

anchors for screws (material dependent)

AC Connections:

The inverters AC output breakers accept wire sizes from #614 AWG. Refer to the table

below for minimum recommended wire size.

Inverter

Model

AC Amps

Output per

leg

NEC Amp

(Amps *125%)

Minimum Wire Size for Specified Distance

0–50 Ft

One Way 50–100 Ft

One Way 100–200 Ft

One Way

ST1000 4.2 5.2 14 AWG 14 AWG 12 AWG

ST1500 6.3 7.8 14 AWG 12 AWG 10 AWG

ST2000 8.3 10.4 14 AWG 12 AWG 10 AWG

ST2500 10.4 13 14 AWG 12 AWG 8 AWG

975-000-001

Table 1

Recommended Minimum AC Wire Sizes

NOTE: These are the minimum recommended wire sizes in conduit. Installing a large number of

wires in conduit or enclosed locations may require larger wire sizes. Consult your local/national

electrical code for more information.

3

2.0 INSTALLATI N

©2000 Xantrex/Trace Engineering

Pre-Installation (continued)

DC Connections:

ST1500 and ST 500

DC connections are made on the combiner board for models ST1500 and ST2500. The

combiner board accepts wire sizes from #614 AWG. Refer to the table below for minimum

recommended wire sizes.

DC Amps NEC Amp

(Amps x 156%)

Minimum Wire Size for Specified Distance

0–25 Ft

One Way 25–50 Ft

One Way 50–100 Ft

One Way

1.0 1.6 14 AWG 14 AWG 14 AWG

3.0 4.7 14 AWG 12 AWG 10 AWG

5.0 7.8 12 AWG 10 AWG 6 AWG

7.0 10.9 12 AWG 8 AWG 6 AWG

9.0 14.0 10 AWG 8 AWG Not Recommended

11.0 17.2 10 AWG 6 AWG Not Recommended

975-000-002

Table 2

Recommended Minimum DC Wire Sizes

NOTE: These are the minimum recommended wire sizes. Installing a large number of wires in

conduit or enclosed locations may require larger wire sizes. Consult your local/national electrical

code for more information.

NOTE: The National Electrical Code (NEC) places restrictions on minimum DC wire bending radius.

A #6 AWG wire is the largest that may be used on the ST1500 and ST2500 inverters.

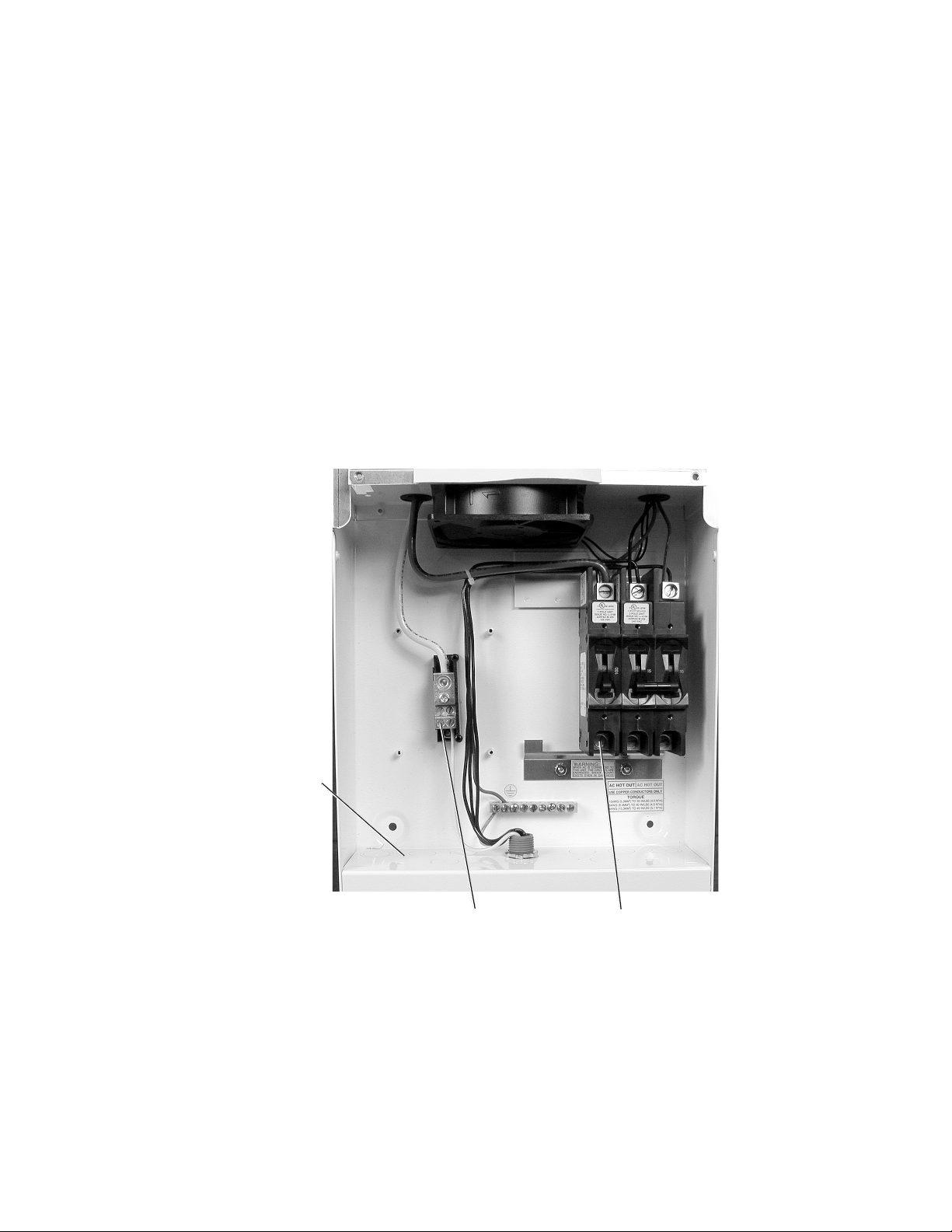

Figure 1

Combiner Board Indicating DC P Array Wire Connection Points

PV array iring

(note polarity)

DC conduit iring

(from solar arrays)

4

2.0 INSTALLATI N

©2000 Xantrex/Trace Engineering

Pre-Installation (continued)

DC Connections:

ST1000 and ST 000

DC connections are made at the 100 amp DC circuit breaker and the DC negative terminal

block for models ST1000 and ST2000. Refer to the table below for minimum recommended wire

sizes.

DC Amps

(from PV array) NEC Amp

(Amps x 156%)

Minimum Wire Size for Specified Distance

0–25 Ft

One Way 25–50 Ft One Way 50–100 Ft

One Way

10 15.6 10 AWG 6 AWG 4 AWG

15 23.4 8 AWG 4 AWG *2 AWG

20 31.2 6 AWG 4 AWG *1 AWG

30 46.8 4 AWG *2 AWG Not Recommended

40 62.4 4 AWG *1 AWG Not Recommended

60 93.6 *2 AWG Not Recommended Not Recommended

975-000-004

Table 3

Recommended Minimum DC Wire Sizes

*NOTE: The National Electrical Code (NEC) places restrictions on minimum DC wire bending radius.

If the enclosures side is used for routing the wires to the DC terminals, then the wires must be bent

to make the appropriate connections. A #3 AWG wire is the largest that may be used on the ST1000

and ST2000 inverters if the side panel is used. Side knockouts are NOT provided on the unit.

Figure 2

DC P Array Wire Connection Points

(with no combiner board)

PV array Negative iring

PV array Positive iring

5

2.0 INSTALLATI N

©2000 Xantrex/Trace Engineering

Pre-Installation (continued)

Grounding:

AC Grounding

The Trace ST unit should be connected to a grounded, permanent wiring system.

DC Grounding

The negative PV conductor should be bonded to the grounding system at only one point in the

system. The size for the conductor is usually based on the size of the largest conductor in the DC

system. Negative/ground bonding is accomplished by factory wired PVGFP breakers (when this

option is installed) or a factory installed grounding block (when PVGFP is not installed).

PV Arrays:

The ST unit is optimized to work with 4-each, 12 volt nominal crystalline PV modules in series

(48 VDC nominal), or various combinations of amorphous, thin film PV modules. Ensure the PV

array used in the system operates within the MPPT operational window.

The solar array connected to the ST Series inverter should have a minimum of 50 volts DC

open-circuit in full sunlight conditions. Crystalline solar arrays configured for 48 volts DC nominal will

have a open-circuit voltage in the area of 84 volts DC in full sunlight. The maximum peak power

tracking (MPPT) software controls the output of the solar modules, under loaded conditions, in the

42-85 volts DC range (full inverter output power occurs between 5285 VDC). Other array voltage

will either not operate the inverter or will not allow maximum harvest of the suns energy.

WARNING: WHENEVER A PV ARRAY IS EXPOSED TO SUNLIGHT, A SHOCK HAZARD EXISTS

AT THE OUTPUT CABLES OR EXPOSED TERMINALS. TO REDUCE THE RISK OF SHOCK

DURING INSTALLATION, COVER THE ARRAY WITH AN OPAQUE (DARK) MATERIAL BEFORE

MAKING ANY CONNECTIONS.

Figure 3

Ground Bar Location

Ground Bar Location

(connect to solid earth ground)

ST1000 and ST2000 Models ST1500 and ST2500 Models

6

2.0 INSTALLATI N

©2000 Xantrex/Trace Engineering

AC Circuit Breakers:

The main service panel must dedicate a 15 amp minimum, double pole breaker (120/240 volts

AC) to operate the ST unit.

Wire Routing:

Determine all wire routes both to and from the Sun Tie. Possible routing considerations include:

AC input wiring from the main service panel to the ST

DC input wiring from the PV array to the ST

DC ground from the PV array to an external ground rod

All wiring and installation methods should conform to applicable electrical and building codes.

Pre-plan the wire and conduit runs. The DC terminal blocks accept up to a #6 AWG wire

(ST1500 and ST2500) and #2 AWG* wire (ST1000 and ST2000); the AC circuit disconnects

accept cable sizes up to #6 AWG.

For maximum safety, run AC and DC wires/cables in (separate) conduits.

*NOTE: #2 AWG wire can only be used if the bottom knockouts are used. If punching side walls for

wire routing, the largest wire for acceptable wire bend radius is #3 AWG maximum.

WARNING: CHECK FOR EXISTING ELECTRICAL OR PLUMBING PRIOR TO DRILLING HOLES

IN THE WALLS!

7

2.0 INSTALLATI N

©2000 Xantrex/Trace Engineering

Mounting:

The ST unit must be mounted to a flat, vertical surface such as wallboard or wood siding.

Installation onto wallboard or concrete requires the use of anchors to properly hold the screws.

Outdoor installation requires the use of the optional rain shield (STRS) to prevent water from enter-

ing the unit.

WARNING: DO NOT INSTALL THE SUN TIE UNIT OUTDOORS WITHOUT THE RAIN SHIELD

HOOD. WATER ENTERING THE UNIT COULD CAUSE A DANGEROUS CONDITION AND

CAUSE THE UNIT TO FAIL. FAILURE DUE TO IMPROPER INSTALLATION WILL VOID THE

WARRANTY.

Procedure

WARNING: BEFORE DRILLING HOLES TO MOUNT THE SUN TIE, ENSURE THERE ARE NO

ELECTRICAL WIRES OR PLUMBING IN THIS AREA. SINCE THIS UNIT IS INSTALLED CLOSE

TO THE UTILITY ENTRANCE OR METER, THERE MAY BE A HIGH CONCENTRATION OF

ELECTRICAL WIRES IN THE AREA.

1. Locate the area where the ST is to be installed. It should be as close to the utility service panel as

possible. The bottom of the unit must be at least 36 inches from the floor or ground when

mounted.

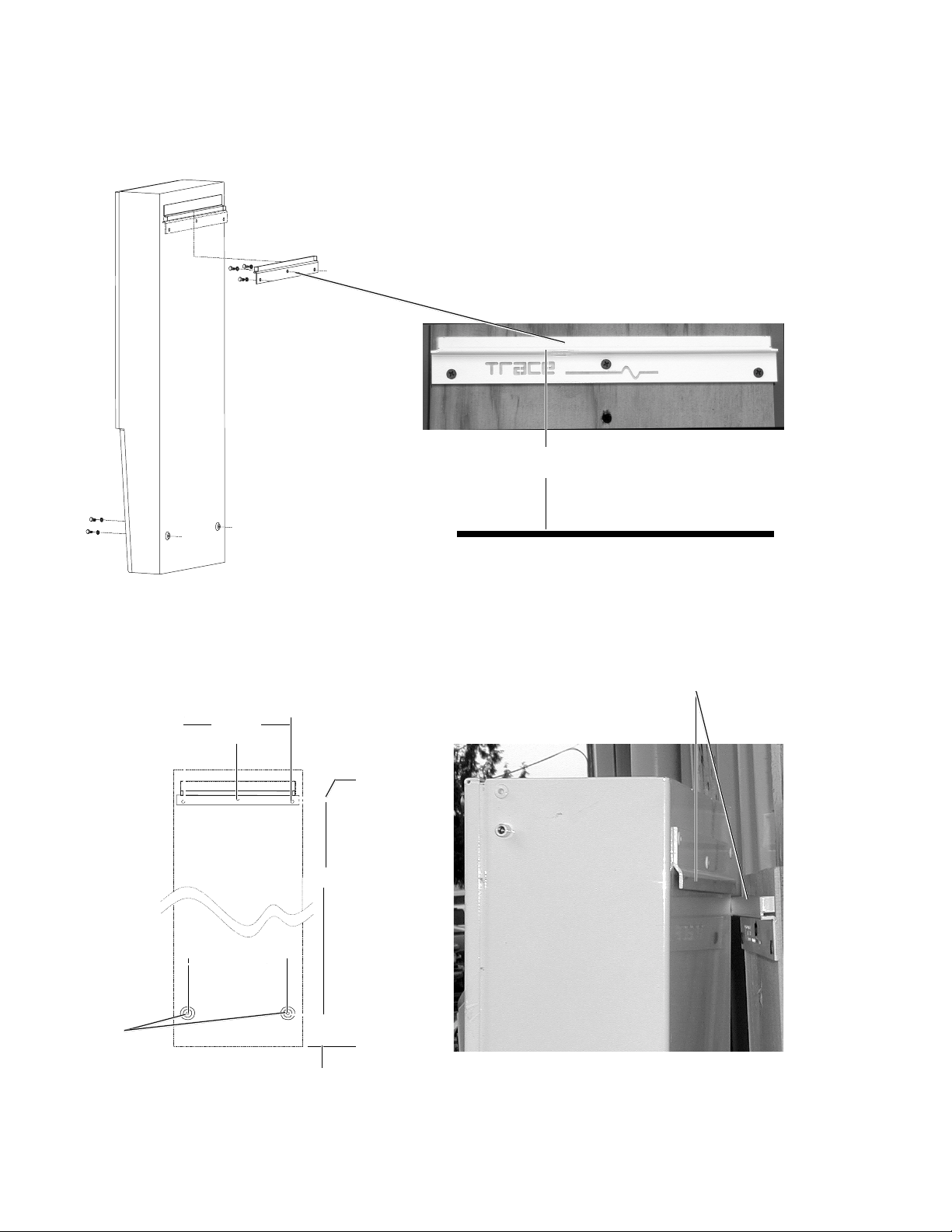

. sing a level, place the mounting bracket up to the wall (in a horizontal position) and mark the

area for the three screws (Figure 4A). To achieve the 36 inch height from the bottom of the ST

unit to the ground, mount the bracket 70 inches from the ground.

3. If required, remove the bracket and drill the holes using a #10 (0.193 inch diameter) drill bit. Drill

appropriately sized holes for anchors when installing on non-wood surfaces.

4. Mount the bracket to the wall using the screws and washers provided. If mounting to other than a

wood wall or surface, use appropriate screws and anchors if required.

5. Place the Sun Ties rear lip, located on the back top of the enclosure, over the bracket and

ensure it is seated properly (Figure 4B).

6. Remove the lower external cover to access the internal circuit breaker panel by removing the

screw on each side of the cover (Figure 5).

7. Remove the internal breaker panel by removing the screws in the breakers and two screws from

the underside of the unit, then lifting until the lower locking tabs are free, then gently pull the inner

cover outward (Figure 6). Save the screws for reinstallation.

8. After the unit is correctly seated on the upper bracket, locate the two screw holes in the bottom

(back) area of the enclosure and mark these locations on the wall (Figures 4B and 7A). Remove

the ST (if required).

9. Drill two pilot holes (as above, if required).

10. Reinstall the ST, to the bracket and secure the bottom of the unit with the wood screws and

washers provided (or appropriate screws and anchors for non-wood surfaces) and tighten

(Figures 4B and 7A).

NOTE: Mounting hardware for surfaces other than wood is not supplied.

8

2.0 INSTALLATI N

©2000 Xantrex/Trace Engineering

Figure 4A

Bracket Mounting

Mounting: (continued)

Figure 4B

Enclosure Mounting

4068-E00-002

Scre

holes

Enclosure

mounted on all

bracket

3.20"

26 - 21/32"

19/64"

8 - 55/64"

4 - 13/16"

9 - 41/64"

Slide ST enclosure lip onto bracket

4068-E00-001

Sun Tie back vie

Wall Bracket, scre s

and ashers

(supplied)

Mount 70 inches from ground

9

2.0 INSTALLATI N

©2000 Xantrex/Trace Engineering

Figure 5

Outer Cover Components

Figure 6

Inner Breaker Cover

Remove breaker scre s

Lift up and pull for ard to

remove

Remove scre s

from tabs

Locking tabs

Upper cover

External breaker cover

(remove during installation)

Remove scre s

(one on each side)

10

2.0 INSTALLATI N

©2000 Xantrex/Trace Engineering

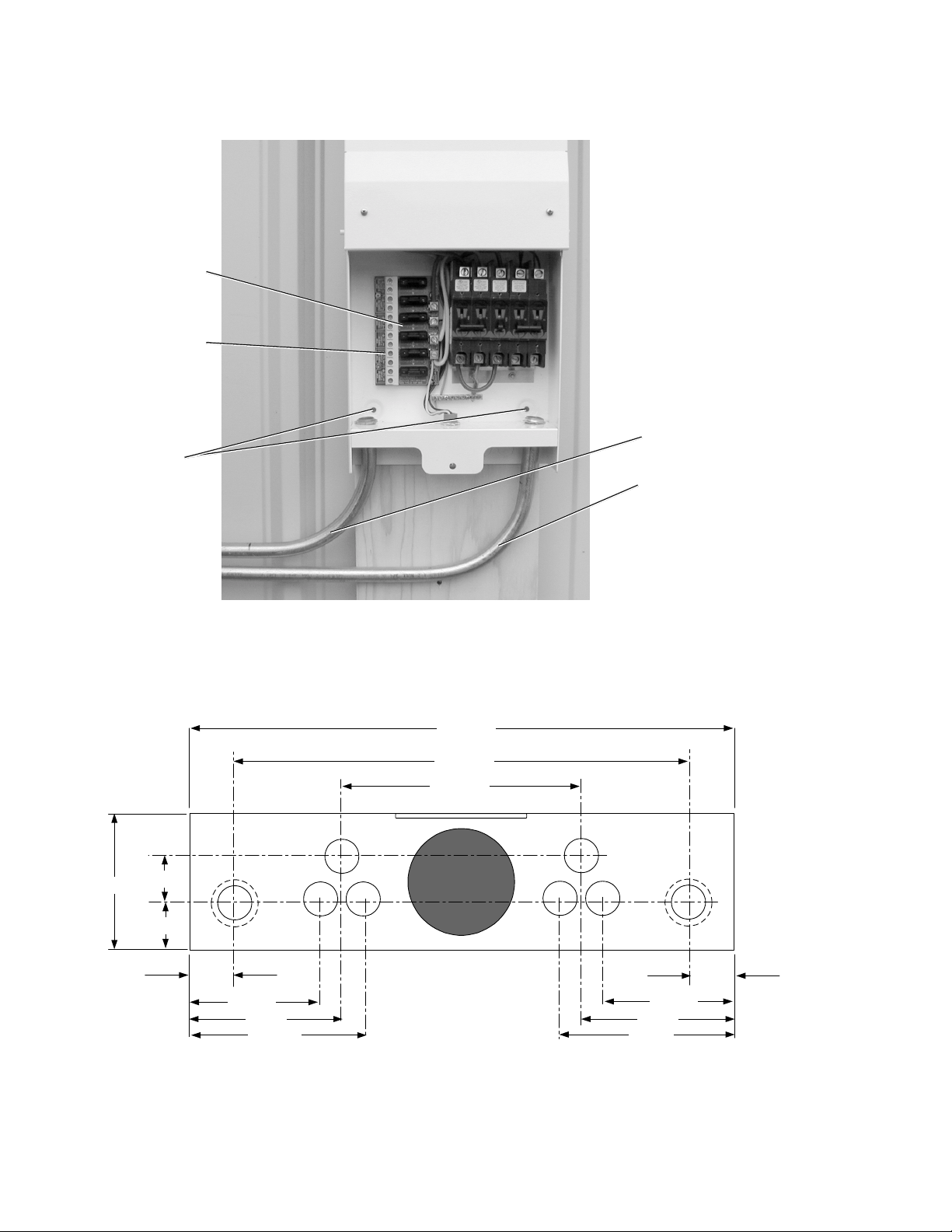

Figure 7A

Mounting Holes and AC DC Conduit in Customer Access Area

Internal mounting

holes

DC Conduit

AC Conduit

PV Combiner Board

(included on some

models)

NOTE: The internal

Combiner Board is not

available on all models.

Lightning Arrestor

5-1/64"

9-15/32"

11-13/64"

61/64"

61/64"

2-13/32"

2-13/32"

3-5/32"3-5/32" 3-23/32"

3-23/32"

27/32"

2-1/16"

3-11/32"

975-0003-D-001

Figure 7B

Conduit Hole Locations

11

2.0 INSTALLATI N

©2000 Xantrex/Trace Engineering

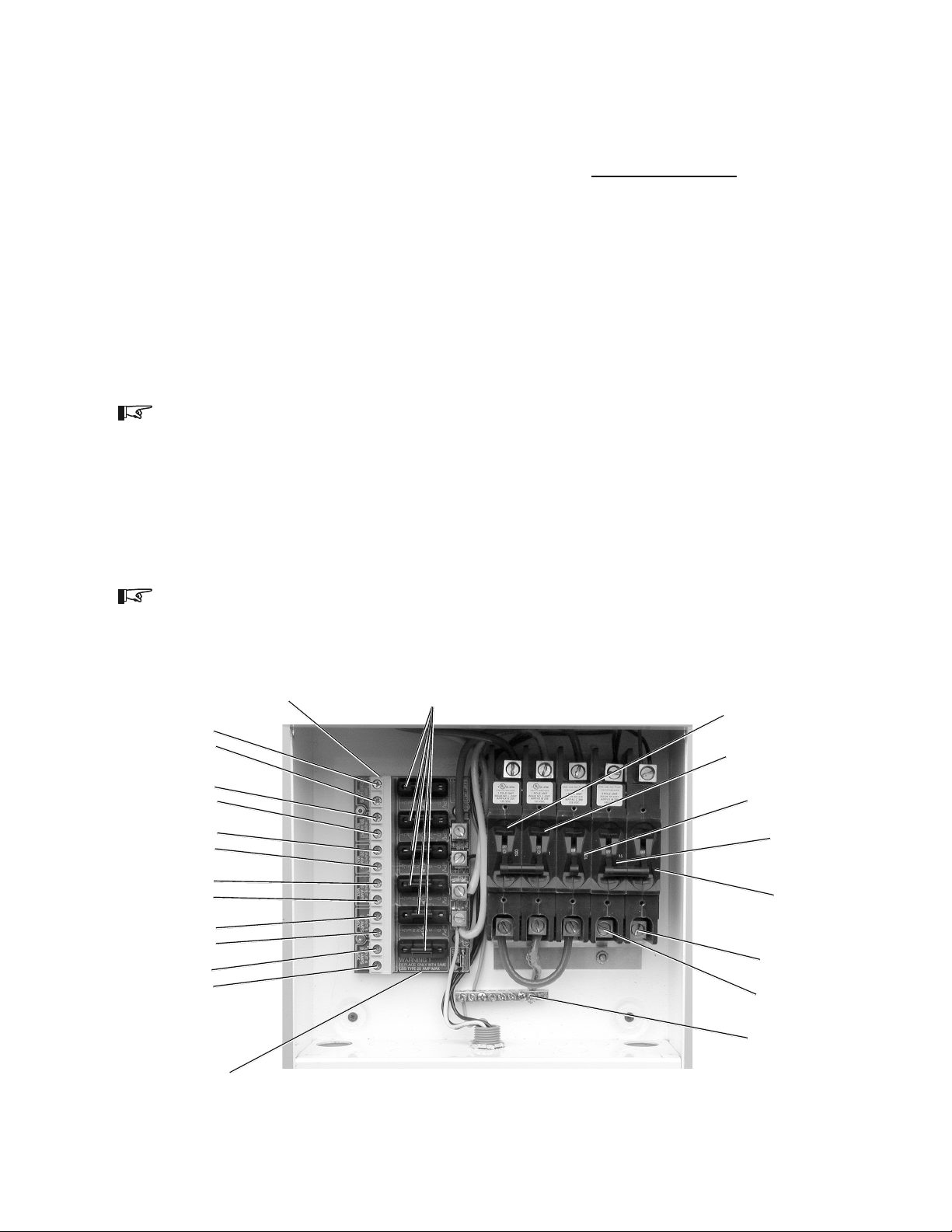

Figure 8

ST1500 and ST 500 Electrical Component Location

Wiring:

DC Wiring

The combiner board (included on some models) in the ST accepts up to six individual PV array

circuits (positive and negative wires). Each circuit on the combiner board contains a fuse to protect

against over-current. Always replace this fuse with one of the same type and rating (GBB, 20 amp

maximum, ceramic type, 0.25" x 1.25").

The combiner board PV array input connection block is located in the lower section of the ST

unit.

ST1500 and ST 500 DC Wiring (Refer to Figures 8 and 9)

PV Array Conduit/Wire Run

1. Install the DC conduit from the PV arrays to the bottom of the ST unit, via one of the knockout

holes (Figures 7A and 7B).

. Route the wires from the PV array(s) through conduit and into the lower section of the ST

enclosure (Figure 9).

NOTE: If more than one PV array is used, label the wire pairs (positive and negative) appropriately

(i.e., PV 1, PV 2, etc.).

3. Connect the positive (+) wire from the #1 array to the terminal strip labeled PV INP T 1

POSITIVE terminal. Check that the wire is in the proper location and tighten the screw.

4. Connect the negative () wires from the PV array to the PV INP T 1 NEGATIVE terminal.

Check that the wire is in the proper location and tighten the screw.

5. Repeat this procedure for each PV array circuit, connecting the #2 PV Positive wire to the

terminal labeled PV INP T 2 POSITIVE, etc.

NOTE: The solar arrays do not have to connect in the order marked on the board (this is just for

reference). All solar array positives on the combiner board are joined together AFTER the fuse.

L1 breaker

AC connection

L2 breaker

AC connection

Solar array

100 amp DC breaker

PVGFP (ganged)

1 amp DC breaker

PVGFP (ganged)

100 amp DC breaker

Solar DC terminal block

Solar input 4

+

-

Solar input 3

+

-

Solar input 2

+

-

Solar input 1

+

-

Solar input 5

+

-

Solar input 6

+

-

Solar DC Fuses

Grounding

block

L1

15 amp AC breaker

(ganged)

L2

15 amp AC breaker

(ganged)

Combiner board

1

2.0 INSTALLATI N

©2000 Xantrex/Trace Engineering

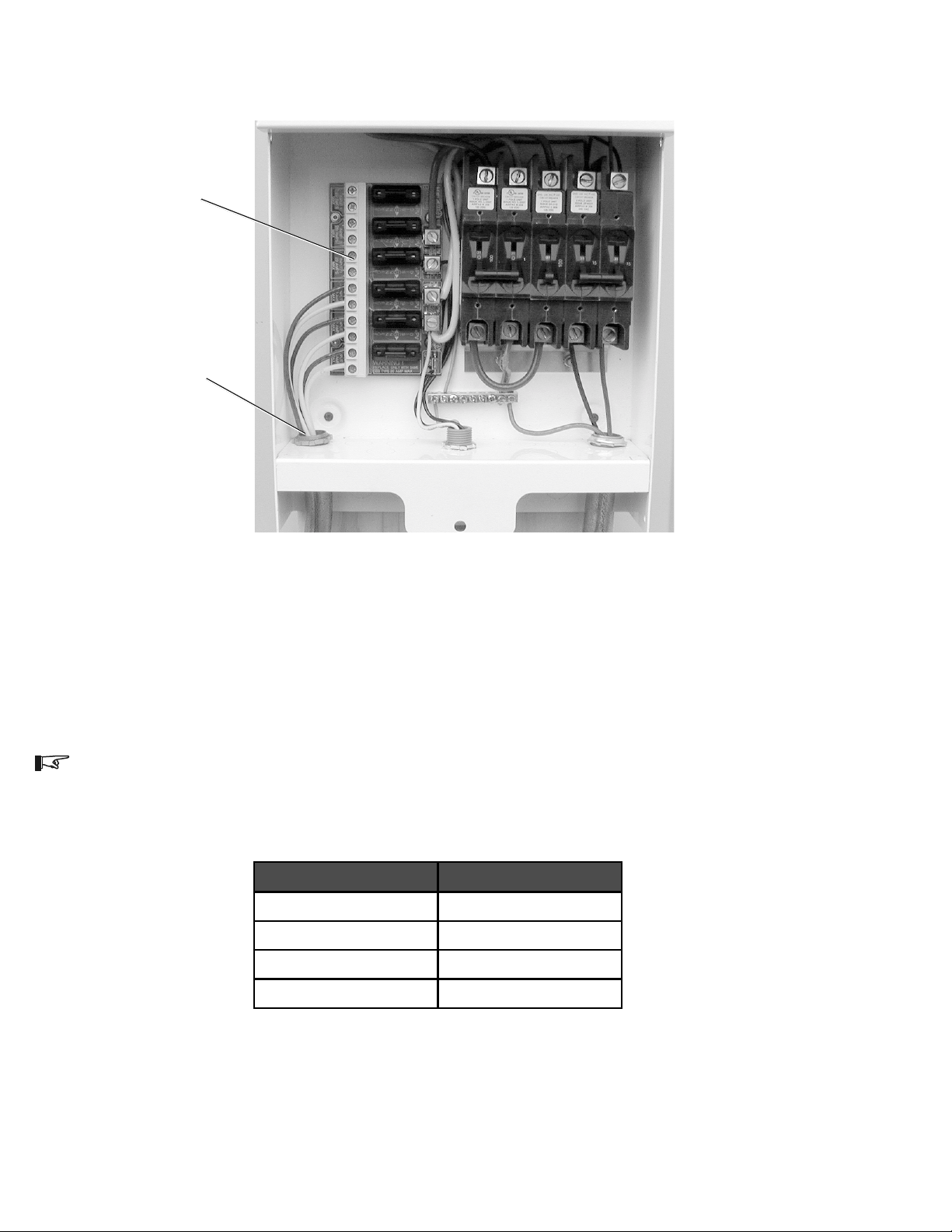

Figure 9

PV Array DC Connection Points (ST1500 and ST 500)

Wiring: (continued)

Wire Size Torque (in-lb)

14 -10 AWG 35

8 AWG 40

4 - 6 AWG 45

2 - 1/0 AWG 50

975-000-003

6. Repeat this procedure for each PV array circuit, connecting the #2 PV Negative wire to the

terminal labeled PV INP T 2 NEGATIVE, etc.

NOTE: The solar arrays do not have to connect in the order marked on the board (this is just for

reference). All solar array negatives on the combiner board are electrically tied together.

7. Torque wires according to the following table.

Table 4

Wire Torque alues

PV array iring

(note polarity)

DC conduit iring

(from solar arrays)

13

2.0 INSTALLATI N

©2000 Xantrex/Trace Engineering

Wiring: (continued)

ST1000 and ST 000 DC Wiring (Refer to Figure 10)

PV Array Conduit/Wire Run

1. Install the DC conduit from the PV arrays to the bottom of the ST unit, via one of the knockout

holes.

. Route the wires from the PV array through conduit and into the lower section of the ST

enclosure.

3. Connect the positive (+) wire from the array to the 100 amp DC CIRC IT BREAKERs lower

terminal. Check that the wire is in the proper location and tighten the screw (Figure 10).

4. Connect the negative () wire from the PV array to the DC NEGATIVE TERMINALs lower

connection. Check that the wire is in the proper location and tighten the screw (Figure 10).

5. Torque all wires according to Table 4 (previous page).

Figure 10

PV Array DC Connection Points (ST1000 and ST 000)

PV Array DC Negative

(-) Wire

PV Array DC Positive

(+) Wire

Use knockouts in lo er

section of ST for installing

conduit and routing ires

14

2.0 INSTALLATI N

©2000 Xantrex/Trace Engineering

Wiring: (continued)

AC Wiring

AC HOT wiring is connected to the ST units L1 and L2 breakers, the ground wire connects to

the GRO ND bar. All AC wiring is located in the lower section of the ST unit.

WARNING: AC UTILITY WIRING TO THE ST UNIT IS PERFORMED DIRECTLY AT THE MAIN

BREAKER PANEL. THIS SHOULD BE DONE ONLY BY A QUALIFIED UTILITY INSTALLER OR

ELECTRICIAN WITH PRIOR UTILITY COMPANY APPROVAL.

NOTE: The ST unit can be connected to a single bidirectional meter, or to dual meters, where one

meter indicates power used the second meter indicates power sold (power supplied back to the

utility). The installer and utility must determine the proper components to install.

WARNING: BEFORE WIRING THE ST UNIT, ENSURE THE MAIN 1 0/ 40 VOLT BREAKER IN

THE MAIN UTILITY BREAKER BOX IS SWITCHED OFF. SWITCH THIS BREAKER TO ON ONLY

AFTER ALL WIRING IS COMPLETED AS INSTRUCTED IN THE PROCEDURES.

1. Run conduit from the main utility breaker panel to the lower section of the ST unit. Run the

two HOT wires (L1 and L2) and ground through the conduit and into the ST units lower

section.

. Install a dual 15 amp, ganged circuit breaker in the main utility breaker panel.

3. Connect the L1 HOT wire (black) from the 15 amp, double-pole breaker installed in the main

breaker panel, to the breaker labeled L1 in the ST unit. Refer to Figure 11A for ST1500 and

ST2500, or Figure 11B for ST1000 and ST2000 models.

4. Connect the L2 HOT wire (red) from the remaining 15 amp, double-pole breaker installed in

the main breaker panel, to the breaker labeled L2 in the ST unit.

5. Connect the ground wire (green or bare copper) from the GRO ND bar in the main breaker

panel, to the GRO ND bar in the lower section of the ST unit.

6. Ensure all connections are correctly wired and properly torqued.

7. Torque wires according to the following table.

Table 5

Wire Torque alues

Wire Size Torque (in-lb)

14 -10 AWG 35

8 AWG 40

6 AWG 45

975-0003-D-003

This manual suits for next models

3

Table of contents

Popular Inverter manuals by other brands

Onan

Onan 3.0 kW AJ GEN SET Operator's manual

Fimer

Fimer UNO-DM-COM KIT Quick installation guide

Analytic Systems

Analytic Systems IPSi1200 Series Installation & operation manual

Goodwe

Goodwe EH Series Quick installation guide

Kostal

Kostal PIKO MP plus installation guide

Huawei

Huawei SUN2000 M0 Series user manual