Tracker Safe M12 Series User manual

Safe

Owner Use

and

Care Manual

M Series:

T592320M-DLG

T592320M-ELG

T593024M-DLG

T593024M-ELG

T593625M-DLG

T593625M-ELG

T724227M-DLG

T724227M-ELG

Safe Identication...................................................................Page 3

Opening your Safe for the First Time..................................Page 4

Lock Opertaion...................................................................... Page 4-6

Removing Shipping Feet....................................................... Page 7

Bolting your Safe to the Floor................................................Page 8

Shelf Installation......................................................................Page 9

Use, Care, & Maintenance.....................................................Page 10

Warranty...................................................................................Page 11

Table of Contents

2

Serial Number:

Original Receipt: (Attach Here)

Combination:

ATTENTION:

DO NOT STORE THIS MANUAL

IN YOUR SAFE

3

Opening your safe for the rst time

If the safe is in the unlocked position the door will open by turning the

handle clockwise until it stops. en pull door open.

If safe is in the locked position then please follow the directions below:

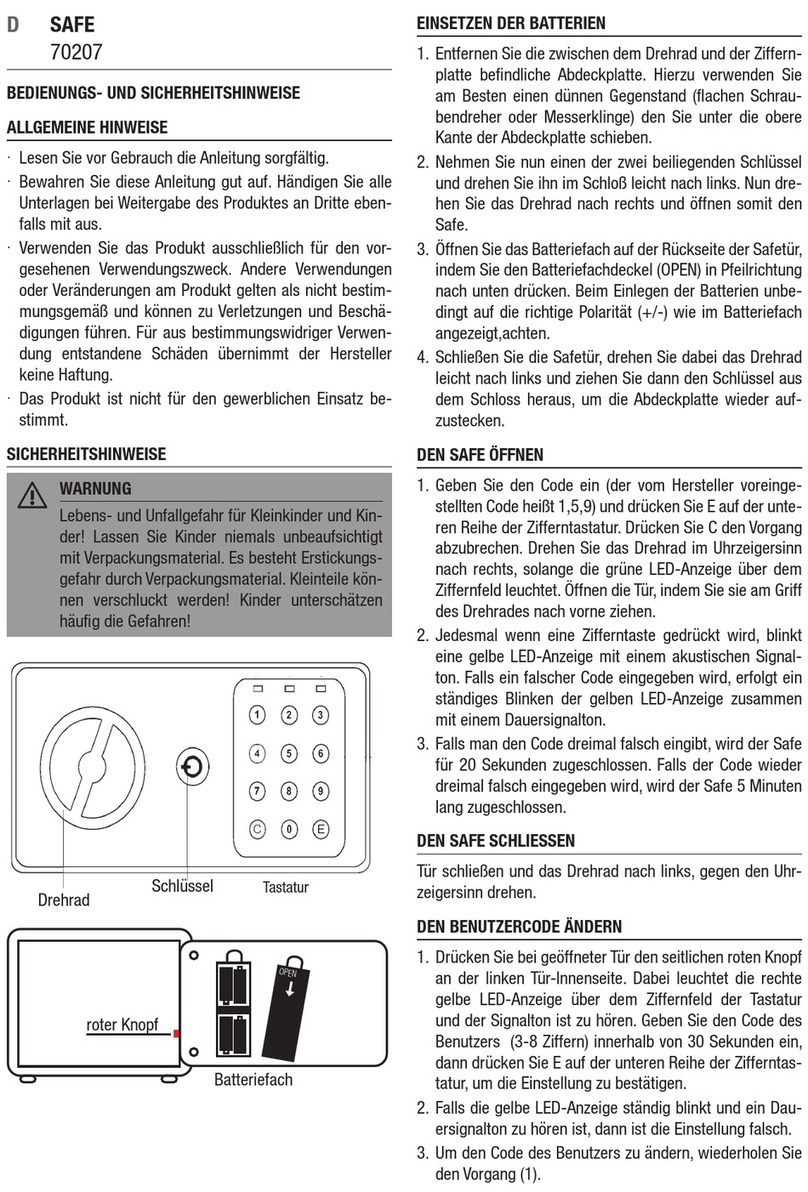

Use the Opening Index located at the twelve o’clock position.

1) Turn the dial LEFT(counterclockwise), passing the rst number in

your combination three times. en stop exactly on the number the

FOURTH time around.

2) Turn the dial RIGHT(clockwise), passing your second number in the

combination two times. en stop exactly on the number the THIRD

time around.

3) Turn the dial LEFT(counterclockwise), passing the last number in the

combination one time. en stop exactly on the number the SECOND

time around.

4) Turn the dial RIGHT(clockwise) until the dial stops completely. en

turn the safe handle clockwise to open the door.

To lock the safe: Close the door. Turn the handle counterclockwise until

it stops. Spin the dial FOUR complete turns either direction. Turn the safe

handle to be sure the safe is locked.

LaGard™ Mechanical Dial Lock:

Operating your Mechanical Dial Lock:

Important Notes:

•Turn the dial slowly and evenly.

•Do not over rotate past a number. If an

error is made, start from the beginning.

•Always view the dial straight on, not at an

angle.

4

Opening your safe for the rst time

5

WARNING:

Always perform code change with the door OPEN and the bolts

extended in the locked position.

1) With the door in the open position, enter “zero”(0) six(6) times.

2) Within four (4) seconds, enter the existing six (6) digit code ONE (1)

time.

3) Within four (4) seconds, enter the NEW six (6) digit code TWO(2)

times.

4) Test your new code several times before closing and locking the door.

Valid Code Entry: Two (2) Beeps at the same time as two (2) LED

ashes aer valid six(6) digit code is entered.

Invalid Code Entry: ree (3) Beeps at the same time as three (3) LED

ashes and the old code is still valid.

If a mistake is made while programming the new code, wait thirty (30)

seconds and repeat steps 1-3.

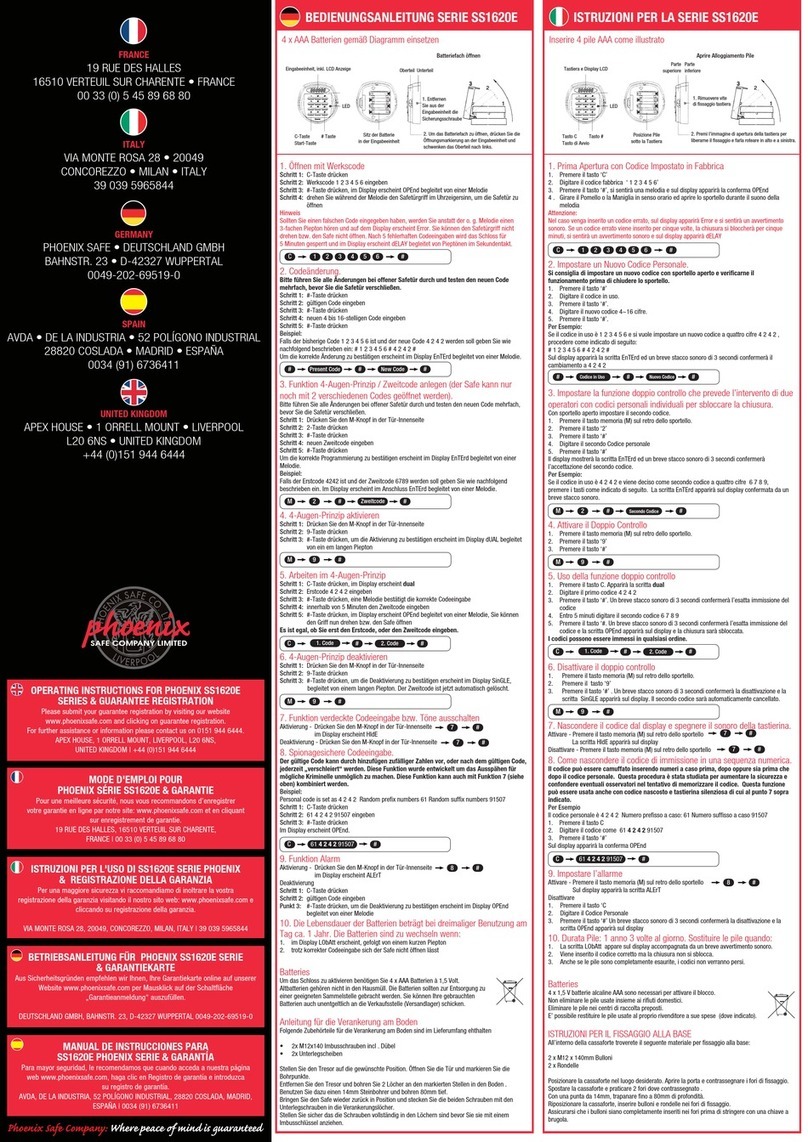

LaGard™ Electronic Lock:

Programing your LaGard™ Electronic Lock:

1) Turn the handle counter-clockwise until it stops.

2) Enter the factory code 1-2-3-4-5-6.

3) e lock will conrm a vaild combination with two (2) beeps at the

same time as two (2) LED ashes.

4) Within four (4) seconds, turn the handle clockwise until the handle

stops.

5) Pull the door open.

Invalid Combination Entry will be conrmed by three (3) beeps at the

same time as three (3) LED ashes.

Replacing the Battery:

1) Slide the keypad housing up and carefully pull away from

mounting surface to expose the battery compartment.

2) Remove the old 9-Volt alkaline battery by unsnapping it from the

two terminals on top of the battery.

CAUTION: DO NOT PULL BATTERY LEADS OUT OF THE

HOUSING!

3) Connect a new 9-volt alkaline battery.

(Recommended brands: Duracell™, Energizer™, Eveready™)

4) Carefully position the keypad over the mounting screws and

slide the keypad housing down. Ensure there are no wires or

cables trapped between the keypad housing and the safe door.

Pinched cables can result in a short circuit.

Low Battery Warning:

Repeated LED ashing and beeping during an opening indicates

that the battery is low and needs immediate replacement.

Wrong Try Lock Out Period:

Four (4) consecutive invalid combinations starts a ve (5) minute

lock out period. e LED light will ashes red at ten (10) second

intervals. At the end of the lock out period, two (2) more invalid

combinations will restart the ve (5) minute lock out period.

6

Operating the electronic Lock

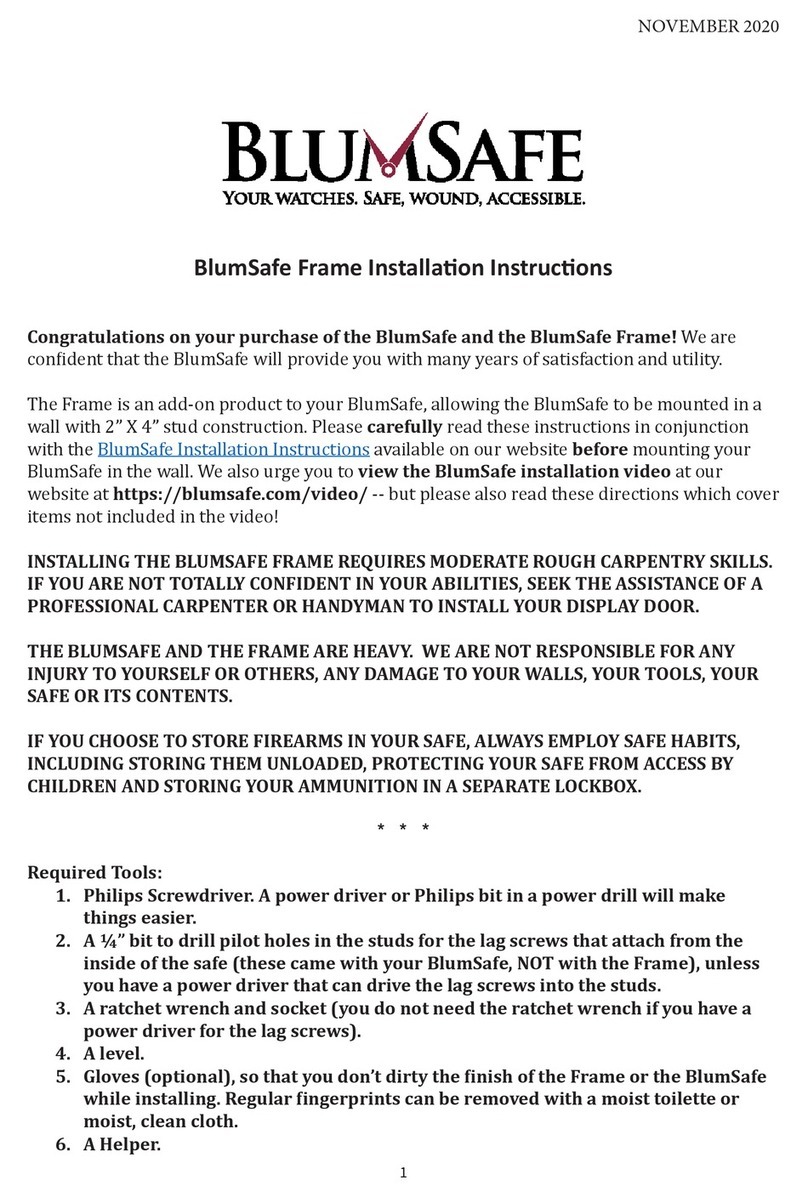

Removing Shipping Feet

7

1) For safety, put wood blocks under

the four corners of the safe.

(For example 2x4 or 4x4 pieces of wood)

2) Next, on either side of the safe, push

the top of the safe so that two of the

four feet are lied o the ground and

hold it steady.

3) While the safe is held o the ground,

have the second person unbolt the two

feet using a 11/16 inch or 17mm socket

wrentch. Move the feet and wood

blocks out from under the safe.

4) Gently lower the safe back down to

the ground.

5) Remove the other side by repeating

steps 1 through 3.

WARNING:

is process requires a minimum of two (2) people.

Attention:

If the shipping feet won’t unscrew completely then use a metal

hack saw to cut the feet o.

Bolting your Safe to the Floor

WARNING:

Safe must be bolted to the oor. e safe presents a safety hazard

unless bolted down.

WARNING:

is process requires at least 2 people.

Your safe is equipped with fou (4) predrilled holes from the factory for

securing the safe to a concrete oor. For wood oors, purchase anchors

suited for your oor type and follow the anchor manufacturers directions

for installation.

Step 1: Shipping feet must be removed.

(see Removing Shipping Feet on page 8)

Step 2: Remove the four (4) black bolt down hole caps located inside the

safe on the oor.

Step 3: Place the safe in the exact location where you want it bolted

down. Mark the oor through the holes in the bottom of the safe.

Step 4: Move the safe and drill four (4) three (3) inch deep holes in the

concrete oor using a 1/2 inch masonry bit.

(Masonry bit not included)

Step 5: Vacuum out debris caused by newly drilled holes in the concrete.

Step 6: Insert the outer sleeve into the hole.

Step 7: Place the safe carefully on top of the holes.

(Note: Level the safe using shims. Shims not included.)

Step 8: From inside the safe, insert the bolts

and tighten using a 11/16 inch or 17mm socket wrench.

Do not over tighten.

Step 9: For best re protection, ll the area around the bolt with a re re

sistant sealant/caulk. (Fire resistant sealant not included)

Step 10: Reinstall the four (4) black bolt down caps to cover the holes

8

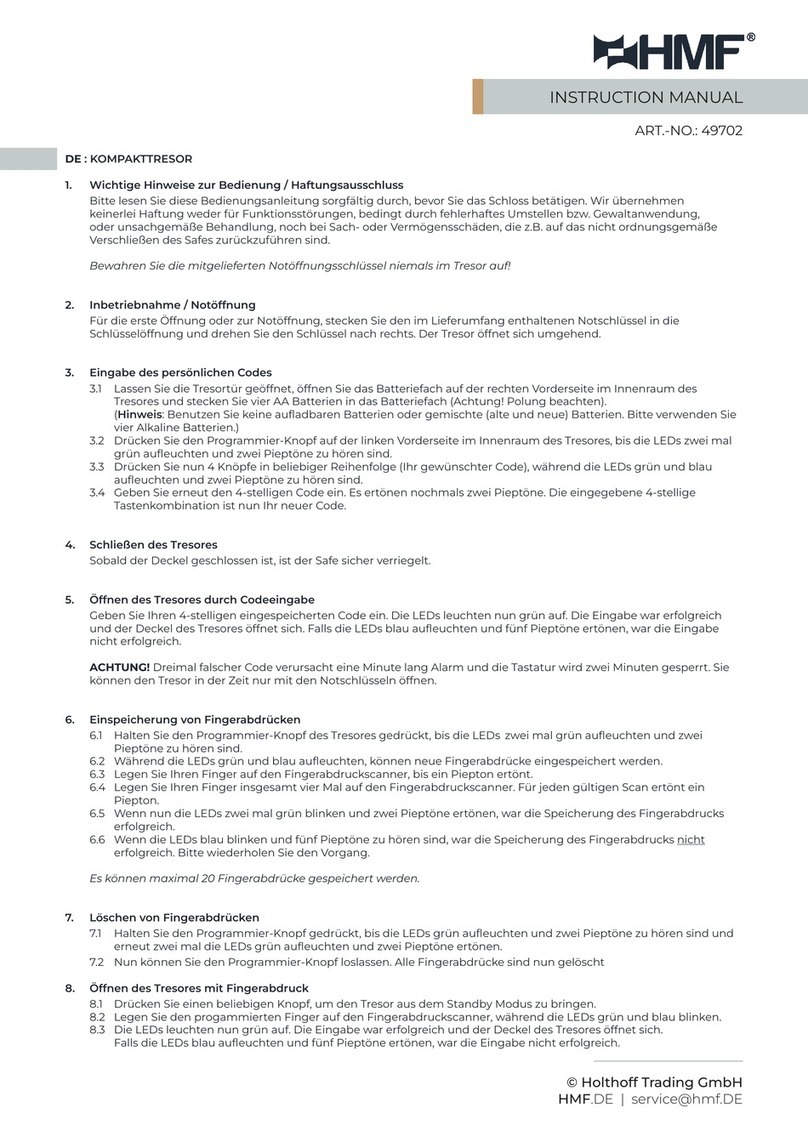

Shelf Installation

Step 1: Determine the desired height of the shelf.

Step 2: Insert the top of the clip into the desired notch then push

the bottom into the notch below the top notch.

9

Step 3: Repeat Step 2 for all 4 clips required for each shelf. Make

sure they are all aligned with one another.

Attention: Remove clips by pulling up on the bottom part of the clip.

Step 4: Move the shelf into the

safe angled diagonally (le side

lower then the right side) and

move it above the clips before

leveling the shelf. Bring the shelf

down onto the clips slowly.

Caution: Do not exceed 25

pounds on a single shelf.

Overloading shelves can cause

shelves or clips to break.

Use, Care, & Maintenance

PLACEMENT OF YOUR SAFE:

Before moving the safe into the desired location, be sure to plan

your route from the beginning to the end location. Make sure

you measure each doorway, stair, corner, or other obstacle before

moving the safe to be sure that it will t. Also, protect the various

types of ooring or stair materials that the safe will be traveling

across. e weight of the safe may damage some ooring.

It is recommended that you place a barrier between the safe and

the oor once the safe is in its nal position. A rubber mat, treated

wood, and carpet are good examples of barriers.

Make sure that you level your safe using shims. is will help the

safe door open smoothly. Shims are not included with your safe but

may be purchased from your local hardware store.

MOVING YOUR SAFE:

Caution: Never move a safe with any contents inside. is can

cause severe damage to the contents being stored and can possibly

cause the safe to be locked in the closed position due to shiing of

contents.

In the event that you have to move the safe, it is best to have a

certied safe technician maintain the safe before moving.

EXTERIOR CLEANING:

Use a so cloth like a microber cloth with a mild cleaner (i.e.,

window cleaner) to clean the exterior of the safe. Make sure to wipe

dry and never use harsh cleaners. Wipe around logos and graphics

gently.

CHROME LOCKING BOLTS:

We recommend lubricating the chrome locking bolts once a year

with a little Vaseline or other petroleum based lubricant.

10

MANUAL DIAL LOCKS:

Once per year, have a certied lock technician service your lock.

ELECTRONIC LOCKS:

At least once a year, replace the battery with a 9-volt alkaline

battery that has a “use date” of at least 5 years on it. When replacing

the battery make sure to inspect the wires for signs of abuse

like exposed wires or pinched wires. Also, make sure to keep

the battery contacts clean of debris. (Recommend: Duracell™,

Energizer™, Eveready™)

INTERNAL LOCKING MECHANISM:

e internal locking mechanism does not require maintenance.

However, if there is a sudden change in feel or operation of the

safe or lock, please contact a certied lock or safe technician for

immediate service.

HINGES:

Once per year, lubricate the ball bearing hinges with a silicone

spray.

MOISTURE/HUMIDITY:

We recommend that you use some form of a dehumidier to

control the level of moisture inside the safe.

Use, Care, & Maintenance Continued

Learn more about other gun storage by Tracker Safe on our website.

This manual suits for next models

8

Table of contents

Other Tracker Safe Safe manuals