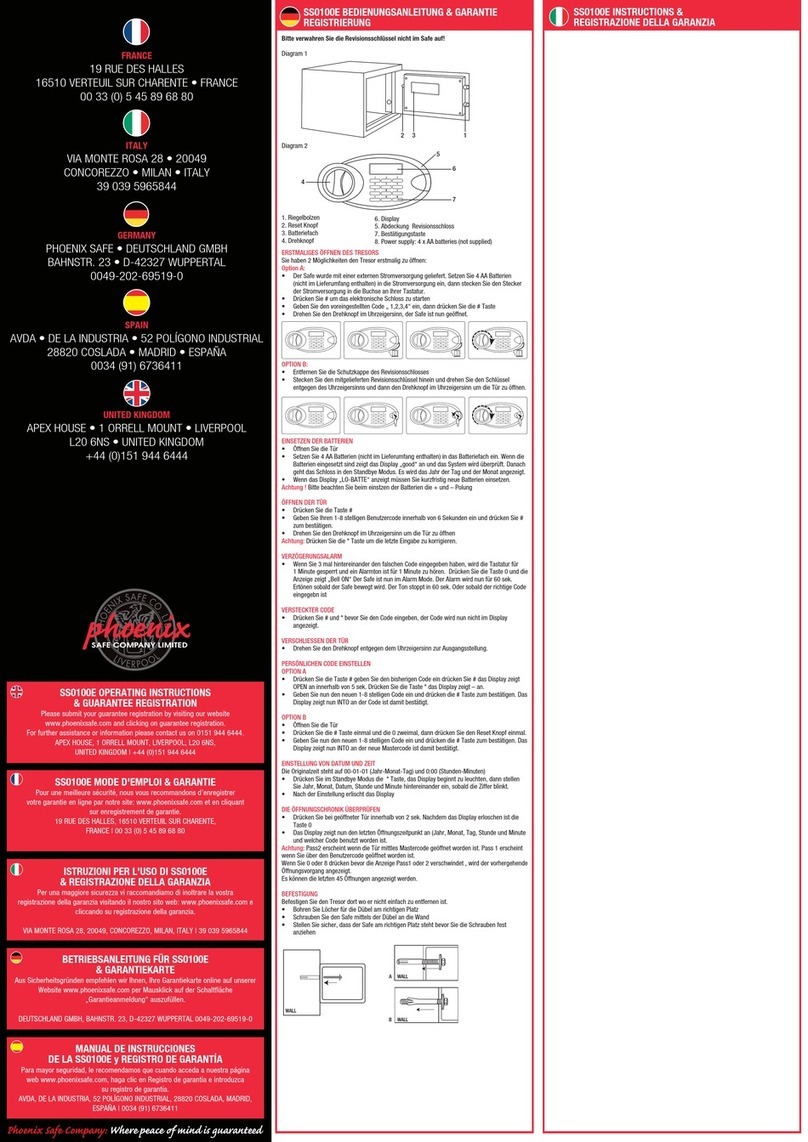

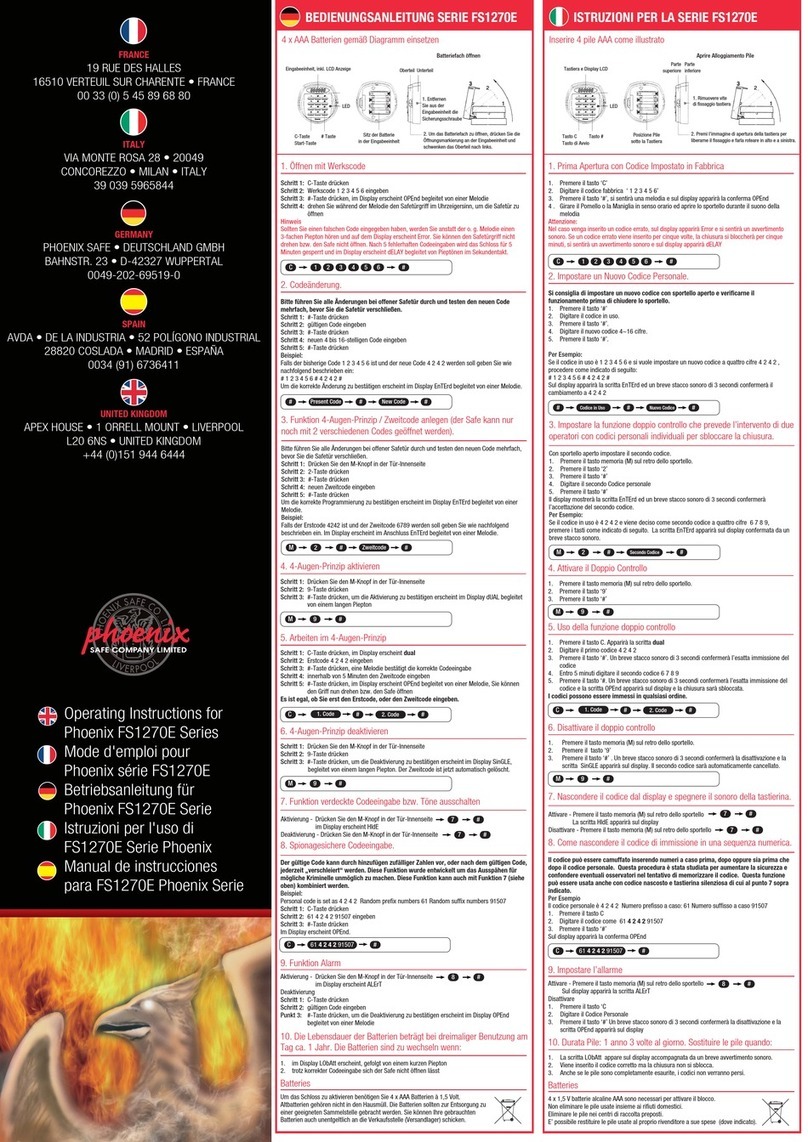

Operation - closing

Closing of a safe fitted with a key lock only:

1. Close the door by pressing it against the body (door bolts must be concealed).

2. Turn the handle anti-clockwise.

3. Turn the key by over 90°(over 1/4 of a turn) anticlockwise, resistance indicates that the safe is

locked.

4. Remove the key.

Closing of safes fitted with a combination or electronic lock only:

1. Close the door by pressing it against the body (door bolts must be concealed).

2. Turn the handle anti-clockwise.

3. Close the combination/ electronic lock following the steps described in the enclosed lock’s operation

manual, the safe is closed.

Closing of safes fitted with key and combination lock or electronic lock:

1. Close the door by pressing it against the body (door bolts must be concealed).

2. Turn the handle anti-clockwise.

3. Turn the key by over 90 (over 1/4 of a turn) anticlockwise, resistance indicates that the safe is

locked.

4. Close the combination/ electronic lock following the steps described in the enclosed lock’s operation

manual, the safe is closed.

Closing of safes fitted with two key locks:

1. Close the door by pressing it against the body (door bolts must be concealed).

2. Turn the handle anti-clockwise.

3. Turn the key by over 90°(over 1/4 of a turn) anticlockwise, resistance indicates that the safe is

locked.

4. Close the second lock proceeding as above

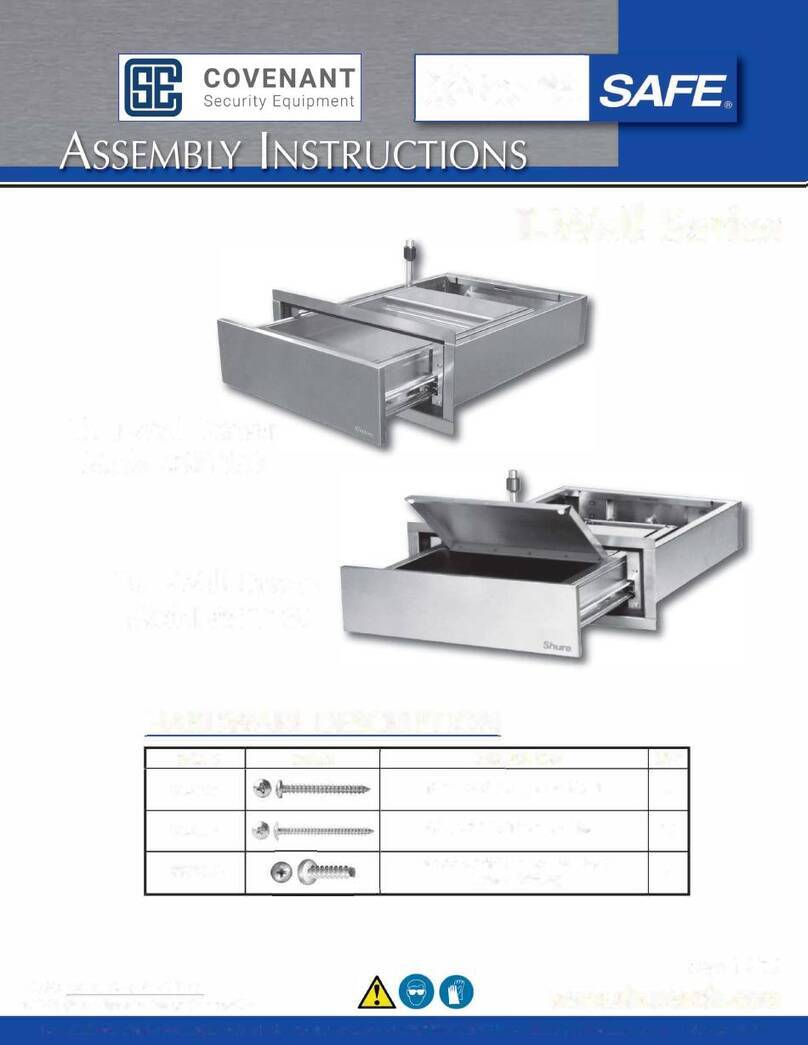

Operation –separately lockable internal box

Box opening:

1. Insert the key to the lock and turn it to the right by more than 90° (above 1/4 of a rotation).

2. Box is opened after pulling the door outwards.

Box closing:

1. Push the door against the box body.

2. Rotate the key of any lock to the left by more than 90° (above 1/4 of a rotation). Resistance is proof of

the lock blocking, remove the key, the device is locked.

Use

Products should be used in rooms protected against weather conditions, away from substances that may

cause metal corrosion. Relative humidity in the room should not exceed 75%. The device may work in

rooms where temperature ranges from +5°C to +40°C.

When closing or opening the safe, attention should be paid to movable elements: drawers, doors. When

used inappropriately, these elements may cause injuries, e.g. finger injuries when fingers are left between

the drawer and the body or between the door and the body of the safe.

Attention should be paid to the location of the bolts during door closure. Bolts must be concealed to avoid

damaging the mechanisms.

No tinkering with the locks or mechanisms is allowed, under consequence of voiding the warranty.

Only authorized service personnel or a user with a written approval of the service is allowed to install locks

and mechanisms within the warranty period.

If keys need to be changed, replacing the entire lock is recommended.

Attention should be paid to the appropriate location of the safe, as to ensure uninterrupted opening of the

safe’s door.

Bolting mechanisms and locks should work smoothly and without jamming. In the case of any reservations

regarding the operation of these items, problems should be reported to KONSMETAL service.