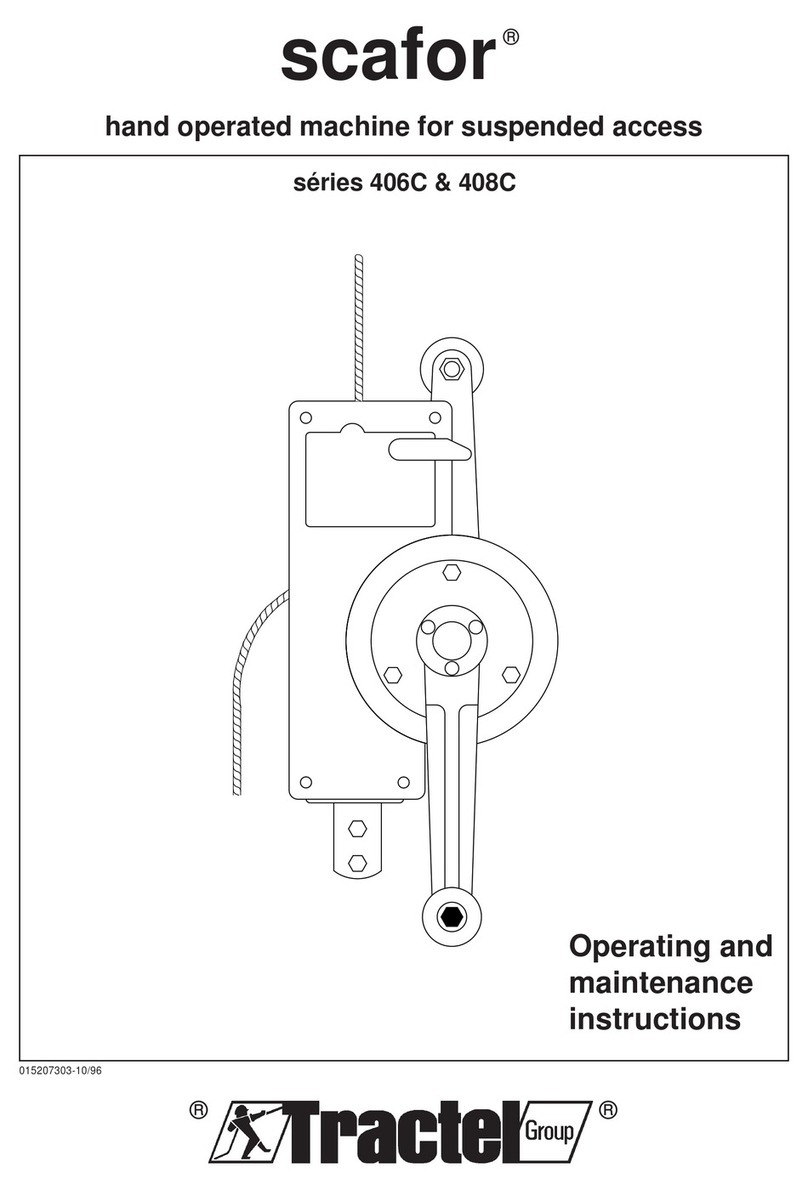

Tractel Group jockey Manual

jockey®&J5

Lifting and pulling machines

models

JOCKEY

J5

equipment

in accordance

with CE directives

operating

and

maintenance

instructions

109325-03 - ind 04 - 09/02

Anglia Handling Services Ltd

2

CONTENTS Page

General warning 3

Technical data 3

1. Description of equipment 4

2. Rigging arrangements 4

3. Installing the wire rope 5

4. Releasing and closing the jaws 6

5. Anchoring 6

6. Operation 6

7. Taking out of service and storage 7

8. Safety devices 7

9. Wire rope 8

10. Mantenance instructions 8

11. Warnings against hazardous operations 9

12. Troubleshooting 9

13. Health and safety at work 9

Always concered to improve the quality of its

products, theTRACTEL Group reserves the right

to modify the specifications of the equipment

described in this manual.

The companies of the TRACTEL Group and their

agents or distributors will supply on request

descriptive documentation on the full range of

TRACTEL products : lifting and pulling machines,

permanent and temporary access equipment,

safety devices, electronic load indicators,

accessories such as pulley blocks, hooks, slings,

ground anchors, etc.

1. Anchor hook

2. Forward operating lever

3. Reverse operating lever

4. Rope release catch

5. Side buttons

6. Rope guide

7. Wire rope

8. Operating handle

9. Anchor sling

8

6

7

9

1 4 2

A B

3

8

6

7

9

1 4

23

5

ORIGINAL MANUAL

The TRACTEL network is able to

supply an after-sales and regular

maintenance service.

Anglia Handling Services Ltd

3

1- Before using the machine, it is essential for safe and correct operation of the equipment that

this manual be read and fully understood and that all the instructions be followed. This manual

should be made available to every operator. Extra copies of this manual will be supplied on

request.

2- The JOCKEY machine allows the operator to carry out work with complete safety. Ensure that

the machine is only handed over for use or rigging to an operator who is trained to operate it in

a responsible manner

3- Never use a machine which is not in good working condition. Replace any worn or damaged wire

rope. A continous monitoring of the condition of the machine, its wire rope and anchor sling is an

important safety consideration.

4- The manufacturer declines any responsibility for the consequences of dismantling or altering the

machine by any unauthorised person. Specially excluded is the replacement of original parts by

parts of another manufacturer.

5- The models covered by this manual must not be used under any circumstances for lifting people.

6- Moreover, these models are designed for manual operation and must not be motorised.

TRACTEL has designed special motorised models (TU-16H and TU-32H).

7- Never apply or attempt to apply to the machine a load or effort greater than the working load limit.

8- JOCKEY machines are not designed for use in explosive atmospheres.

9- IMPORTANT : If the equipment described in this manual is supplied to an employed person,

check and ensure that you meet your obligations with respect to the safety at work regulations,

particularly relating to inspection and tests before operation (See section 13 on page 9).

LIFTING PEOPLE AND SPECIAL APPLICATIONS

For further information on equipment for lifting people, and for any special application, please refer to

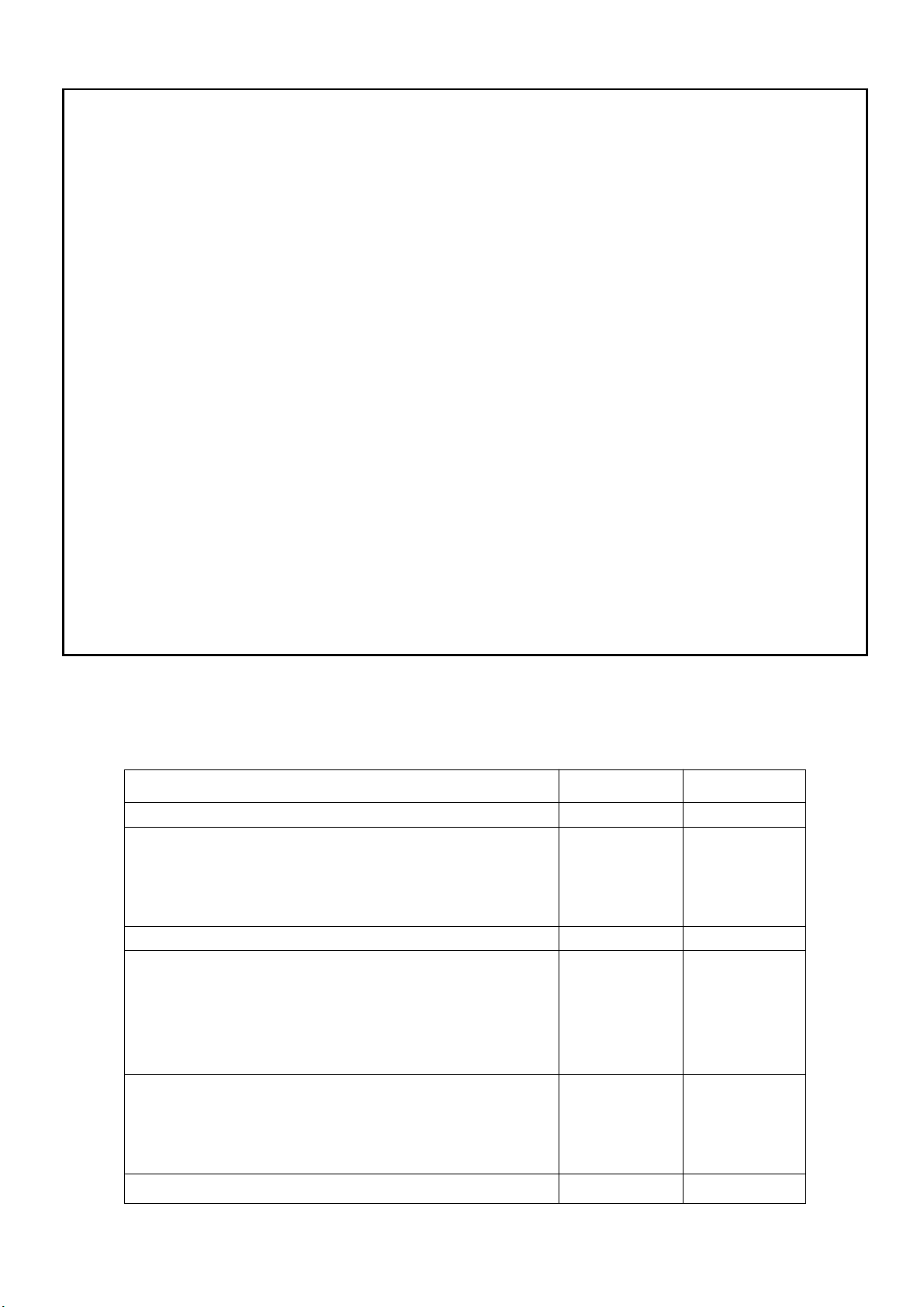

TRACTEL TECHNICAL DATA

MODELS jockey jockey J5

Working load limit kg 300 500

Weight

machine kg 1.750 3.750

operating handle kg 0.270 0.350

standard length of wire rope 10m/20m kg 1.0 / - 1.9 / 3.7

Total weight of standard equipment kg 3.0 / - 6.0 / 7.8

Machine dimensions

length mm 320 370

height mm 200 215

width mm 40 55

operating handle mm 400 500

JOCKEY wire rope

diameter mm 4.72 6.5

guaranteed breaking strain* kg 1800 3100

weight per meter kg 0.09 0.185

Rope travel (foward/reverse)** mm 28 / 32 24 / 34

*Including end fittings of the wire rope.

** One complete cycle of the operating lever with working load limit.

Anglia Handling Services Ltd

4

1. DESCRIPTION OF EQUIPMENT

The JOCKEY machine is a hand-operated lifting

and pulling machine. It is versatile, portable and

multipurpose, not only for pulling and lifting but

also for lowering, tensioning and guying.

The originality of the JOCKEY machine is the

principle of operating directly on the wire rope

which passes through the mechanism rather than

being reeled onto a drum of a hoist or conventional

winch. The pull is applied by means of two pairs of

self-energised jaws which exert a grip on the wire

rope in proportion to the load being lifted or pulled.

An operating handle fitted to either the forward or

the reverse lever transmits the effort to the jaw

mechanism to give forward or reverse movement

of the wire rope.

The machine is fitted with an anchor hook so that

it can be secured quickly to any suitable anchor

point.

The JOCKEY machines, intended for lifting and

pulling materials, are available in two models :

• Jockey, capacity 300 Kg

• Jockey J5, capacity 500 Kg

Jockey : the standard kit comprises a machine

with its operating handle, a 10 m length of special

Jockey wire rope fitted with a hook with safety

catch and two wire rope slings, one 1m in length

and the other 2 m in length. The equipment is

contained in a sturdy carton for carrying and

storing the kit. Other lengths of wire rope are

available on special order.

Jockey J5 : the J5 is available in two standard kits

comprising a machine with its operating handle

and with :

• either a 10m length of special wire rope fitted

with a hook with safety catch and two anchor

slings of 2m in length :

• or a 10m length of special wire rope fitted with a

hook with safety catch, two anchor slings of 2m in

length and pulley block allowing the capacity of the

machine to be doubled.

This manual together with a guarantee card are

supplied with each machine, as well as the CE

declaration of conformity.

IMPORTANT : JOCKEY wire rope has been

specially designed to meet the particular

requirments of the JOCKEY machines.

TRACTEL does not guarantee the safe

operation of JOCKEY machines used with wire

rope other than JOCKEY wire rope.

2. RIGGING ARRANGEMENTS

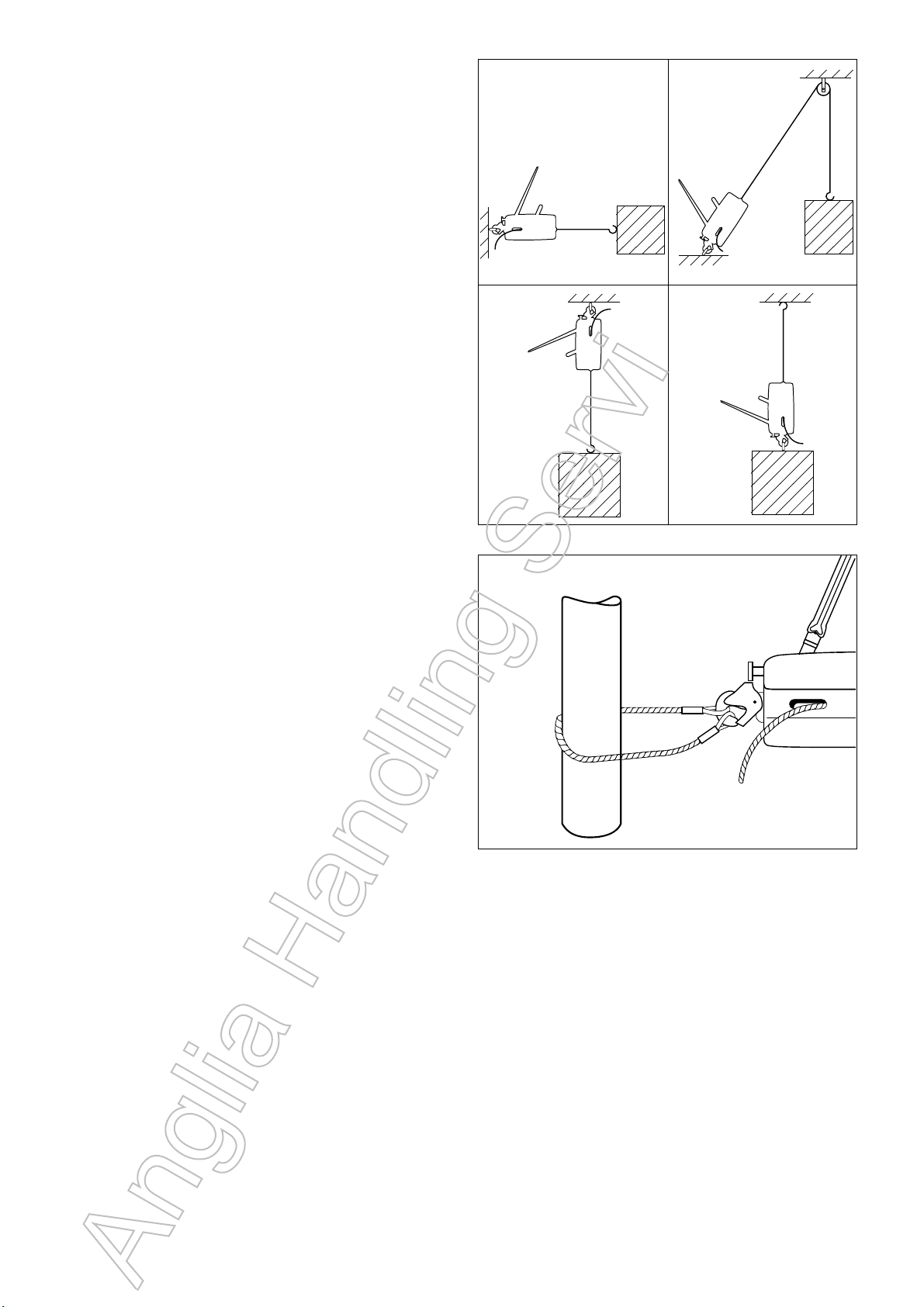

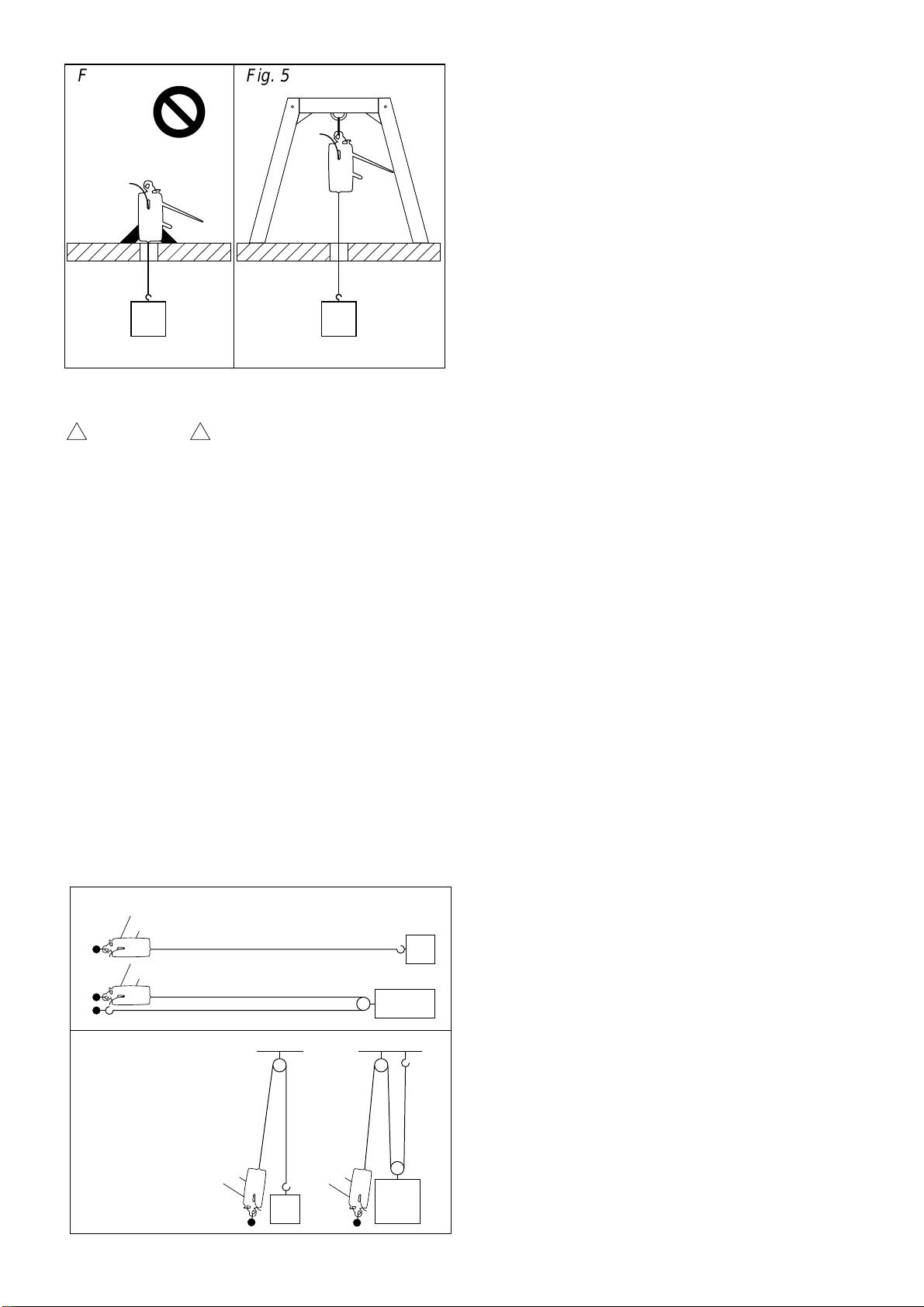

Various ways of rigging are shown in Figs. 2.1,

2.2, 2.3 and 2.4. Figs. 4 and 5 show particular

arrangements (one forbidden and the other

recommended).

The machine may be anchored to a fixed point

with the wire rope travelling towards the machine

(Figs. 2.1, 2.2, 2.3, or travel along the wire rope,

with the load, the wire rope itself anchored to a

fixed point (Fig. 2.4).

In example 2.2, the capacity of the pulley and the

anchor point should be greater than twice the load.

N.B. : Whatever the rigging arrangement, and if

the machine is anchored directly to a fixed point,

ensure that there are no obstructions around the

machine which could prevent the wire rope, the

machine and anchor from operating in a straight

line. It is therefore recommended to use a sling of

an appropriate capacity between the anchor point

Fig. 2.1 Fig. 2.2

Fig. 2.3

Fig. 3

Fig. 2.4

,

,

,

,

,

,

Anglia Handling Services Ltd

5

and the machine (Fig. 3).

WARNING : Any rigging arrangement

which requires the calculation of the forces applied

should be checked by a competent engineer, with

special attention to the appropriate strength of the

fixed points used.

For work such as guiding the trunk in tree felling,

the operator should ensure that he is outside the

danger area by passing the wire rope around one

or more return pulleys.

The capacity of the machine may be inceased

considerably for the same effort by the operator by

using a pulley block. (See the examples set out in

Figs. 6.1 and 6.2). The increase in the capacity

shown is reduced depending on the efficiency of

the pulleys.

The diameter of the pulleys used should be equal

to at least 18 times the diameter of the wire rope.

(Refer to the applicable regulations).

For any rigging arrangement other than those

described in this manual, please consult

TRACTEL or a competent specialist engineer

before operating the machine.

3. INSTALLING THE WIRE ROPE

N.B. : When handling the wire rope it is

recommended to protect the hands by using work

gloves.

If the wire rope is to be anchored to a high anchor

point, the wire rope should be anchored before

fitting the wire rope in the machine.

3.1. Jockey (green plastic casing).

1. Uncoil the wire rope in a straight line to prevent

loops or kinks.

2. Release the internal mechanism (See section 4 :

‘Releasing and closing the jaws’).

3. Insert the tapered end of the wire rope through

the rope guide E and push it through the

mechanism until it emerges at S (Fig. 7.2).

4. Pull the slack wire rope through the machine to

the point required.

5. Engage the jaws by operating the rope release

catch (See section 4 : ‘Releasing and closing

the jaws’).

6. Couple the two eyes of the sling which is around

the anchor point to the hook of the machine.

(See section 5 : ‘Anchoring’).

7. Fit the operating handle on the forward

operating lever and by moving it back and forth

the wire rope will be pulled through the

machine. The reverse operating lever allows the

user to slacken off tension or to lower the load.

After this procedure the machine is ready for

operation, providing the load is correctly anchored

to the machine or the wire rope (See section 5 :

‘Anchoring’ and section 2 : ‘Rigging arrangement’).

3.2. Jockey J5 (aluminium casing)

1. Uncoil the wire rope in a straight line to prevent

loops or kinks.

2. Release the internal mechanism (See section 4

: ‘Releasing and closing the jaws’).

3. Insert the tapered end of the wire rope through

the rope guide E and push it through the

mechanism until it emerges at S (Fig. 8.2).

4. Couple the two eyes of the sling which is around

the anchor point to the hook of the machine.

(See section 5 : ‘Anchoring’).

5. Pull the slack wire rope through the machine to

the point required.

6. Engage the jaws by operating the rope release

catch (See section 4 : ‘Releasing and closing

the jaws’).

!

!

Fig. 5Fig. 4

INTERDIT BON

1

1

2

2

Fig 6.1 - Traction

Fig 6.2 - Levage

1

1 1 1 1 1

1

1

1

1

12

2 2

2

1

Anglia Handling Services Ltd

6

7. Fit the operating handle on the forward

operating lever and by moving it back and forth

the wire rope will be pulled through the

machine. The reverse operating lever allows the

user to slacken off tension or to lower the load.

After this procedure the machine is ready for

operation, providing the load is correctly anchored to

the machine or the wire rope (See section 5 :

‘Anchoring’ and section 2 : ‘Rigging arrangements’).

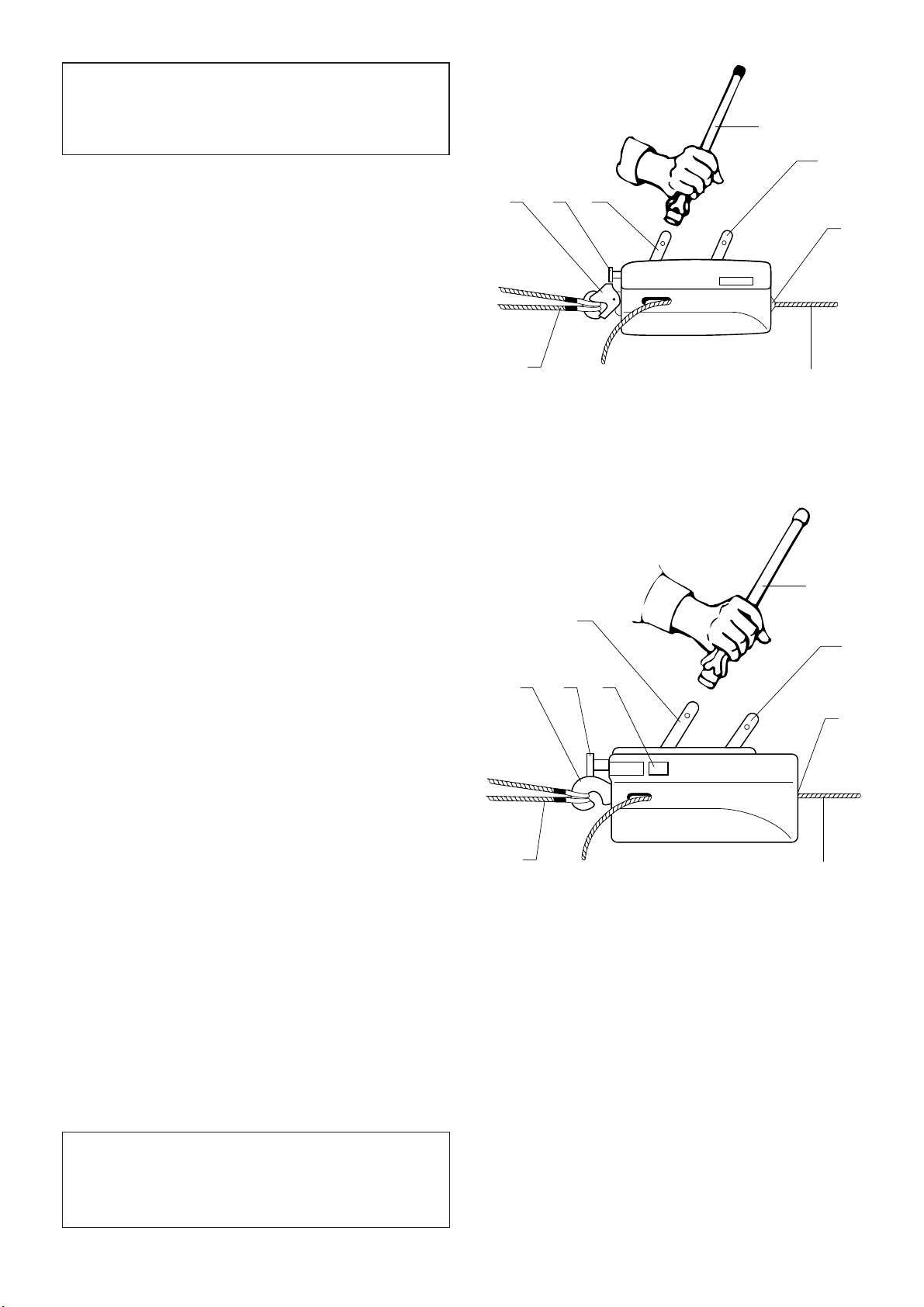

4. RELEASING AND CLOSING THE JAWS

Each machine is fitted with a rope release catch

(item 4 in Fig. 1 on page 2) for releasing the jaw

mechanism and which should only be operated

when the machine is not under load.

4.1. Jockey

Releasing : Release the rope release catch by

pushing it against the machine lightly and

upwards. Then pull the catch outwards. (Fig. 7.1).

Closing : Push the rope release catch towards the

machine and then downwards, until it locks in

position. (Fig. 7.2).

4.2. Jockey J5

Releasing : Release the rope release catch by

pushing it against the machine and then pressing in

the two catches on either side of the machine.

Then pull the rope release catch outwards. (Fig. 8.1).

Closing : Push the rope release catch towards the

machine until it locks in position. (Fig. 8.2).

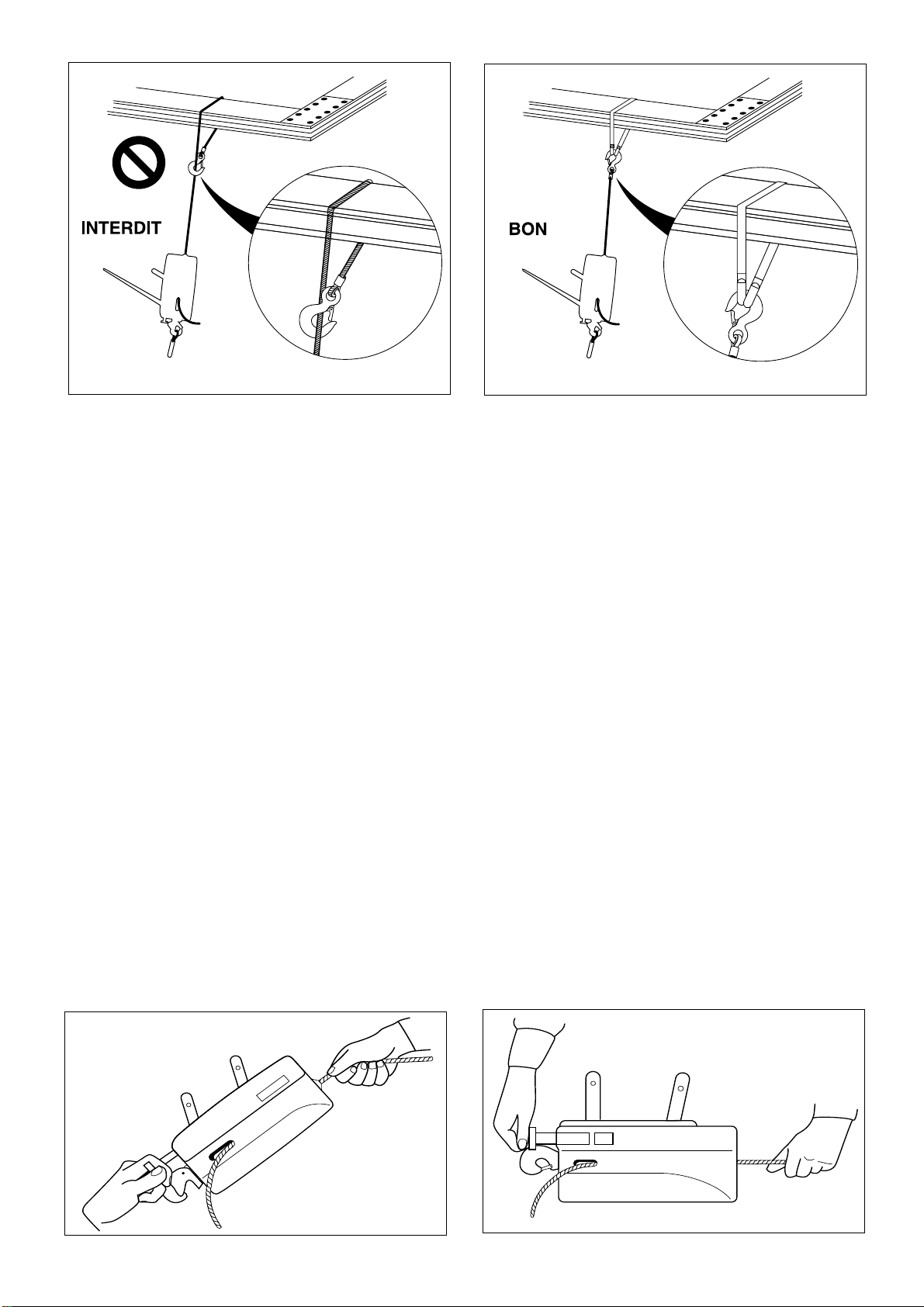

5. ANCHORING

Failure to anchor the JOCKEY machine

correctly runs the risk of a serious accident.

The user must always check, before operating

the machine, that the anchor point of the

machine and the wire rope are of sufficient

strength to take the load applied (lifting or

pulling).

It is recommended to anchor JOCKEY machines

to the fixed point or to the load using an

appropriate capacity sling. It is forbidden to use

the machine’s wire rope as a sling by passing it

around the load and hooking it back onto itself

(Fig. 9.1 : forbidden anchoring arrangement ; Fig.

9.2 correct anchoring arrangement).

Warning : It is essential for the safe

operation of the machine to ensure that, before

loading the machine, the anchor points (hooks) are

correctly secured, (with the safety catch correctly

located on the hook).

Pass one of the slings around the fixed point (tree,

beam, etc…)

Anchor the other sling to the load to be lifted or

pulled. Attach the two eyes of this sling to the wire

rope hook.

6. OPERATION

JOCKEY machines are very easy to use. Place the

operating handle on either the forward or reverse

operating lever and move the operating handle to

!

!

!

!

Fig. 7.1 Fig. 8.1

SS

Fig. 8.2

E

E

Fig. 7.2

Anglia Handling Services Ltd

and fro. The operating arc is variable for ease of

operation.

When operation stops, both jaws automatically grip

the wire rope and hold the load which is spread

equally between the jaws.

The to and fro operation of forward or reverse lever

gives continous movement of the load.

7. TAKING OUT OF SERVICE AND STORAGE

7.1. Jockey

When the work is completed take the load off the

machine before attempting to release the jaws. To

do this, operate the reverse operating lever until

there is no tension in the wire rope

Remove the sling and release the machine as

follows:

-release the mechanism by pushing the rope

release catch towards the machine and

upwards (Fig. 7.1).

-pull the wire rope out with one hand while

holding the machine by its rope release catch with

the other hand (Fig. 10).

Carefully coil the wire rope avoiding any loops or

kinks.

Only normal effort is required to operate the

Jockey. Do not force the operating handle;

otherwise the unit will be overloaded. Reduce the

load or use a pulley block to increase the capacity

of the unit.

7.2. Jockey J5

When the work is completed take the load off the

machine before attempting to release the jaws. To

do this, operate the reverse operating lever until

there is no tension in the wire rope

Remove the sling and release the machine as

follows :

-release the mechanism by pushing the rope

release catch towards the machine ;

-at the same time, press the two catches, one

on either side of the machine ;

-release the rope release catch which should

come out from the machine (pull it if necessary).

(Fig. 8.1) ;

-pull the wire rope out which one hand while

holding the machine by its rope release catch

with the other hand (Fig. 11).

Carefully coil the wire rope avoiding any loops or

kinks.

Storage : Store the machine and wire rope in a dry

place, away from the effects of the weather. The

wire rope should be completely removed from the

machine and carefully coiled. Before coiling the

wire rope, it is recommended to inspect it, clean it

and then grease it. (See section 9 : Wire rope.)

7

Fig. 9.1 - Pas d'élingage

Fig. 9.2 - Elingage correct

Fig. 10

Fig. 11

Anglia Handling Services Ltd

8

8. SAFETY DEVICES

8.1. Jockey

Only use the operating handle supplied. Its length

has been specifically set in accordance with the

capacity of the machine. The handle breaks if

the machine is overloaded.

8.2. Jockey J5

The Jockey J5 has a shear pin which breaks

should the machine be overloaded.

To replace the shear pin :

- Unscrew the 5 side case fixing screws.

-Remove the side case and then the

mechanism. Knock out the sheared pin with a

5mm punch. Position one of the two spare

shear pins located in the side case corner and

drive it in with hammer.

- Reassemble the machine.

WARNING : It is forbidden to replace

sheared pins by nonstandard pins. Use only

genuine TRACTEL shear pins of the same

model.

9. WIRE ROPE

To guarantee the safe operation of

JOCKEY machines, it is essentiel to use them

exclusively with JOCKEY wire rope which has

been specially designed to meet the

requirements of the JOCKEY machine.

One end of the wire rope has a safety hook, fitted

to a thimble fixed by a metal ferrule (see Fig. 12).

The other end of the wire rope is fused and

tapered (see Fig. 13).

A wire rope in good condition is a

guarantee of safety, to the same extent as a

machine in good condition. It is necessary to

continously monitor the state of wire rope, to clean

and oil it with a rag soaked with motor oil or

grease. Grease or oil containing graphite additives

or molybdenum disulphide must not be used.

Visual examination of the wire rope

The wire rope should be examined daily to detect

any signs of wear (damage or broken wires : see

examples in Fig. 14).

In case of any apparent wear, have the wire rope

checked by a competent person. Any wire rope

with a reduction from the nominal diameter by

more than 10 % should be replaced. (see Fig. 15

for the correct method of measuring the diameter

of a wire rope).

IMPORTANT : It is recommended, specially for

lifting applications, to ensure that the length of wire

rope is greater than actually required. Allow an

extra meter approximately beyond the machine

side case at the anchor point.

For lifting or lowering loads over long lengths of

wire rope, steps should be taken to stop the load

from rotating to prevent the wire rope from

unlaying.

Never allow a tensioned wire rope from rubbing

over sharp edges. The wire rope must only be

used with pulleys of an appropriate diameter.

Never expose the wire rope to temperatures

beyond 100 degrees C. Never use wire rope that

has be subject to damage such as fire, corrosive

chemicals or atmosphere, or exposed to electric

current. Storage : see section 7.

10. MAINTENANCE INSTRUCTIONS

The machine should be inspected, cleaned and

lubricated at regular intervals, at least annually, by

an approved repairer.

Never use grease or oils containing graphite

additives or molybdenum disulphide.

!

!

!

!

max. 1.5 dia.

Fig. 13

Fig. 12

dia.

Fig. 14 - Exemples de câble détérioré inutilisable.

position

correcte

pour mesure

Fig. 15

d

Anglia Handling Services Ltd

9

13. HEALTH AND SAFETY AT WORK

It is the responsibility of every company to ensure that its employees have been fully and properly

To clean the machine , allow the machine to soak

in a bath of some proprietary cleansing fluid but not

acetone and derivatives or ethylene trichloride and

derivatives. Then shake the machine vigorously to

loosen foreign matter and turn it upside down to

allow the dirt to come out through the openings for

the operating levers. Allow the mechanism to drain

and become dry.

After this treatment, ensure that the machine is

well lubricated by applying a quantity of oil (type

SAE 90 - 120) onto the internal mechanism

through the openings for the operating levers. To

carry out this procedure it is best for the machine

to be not under load and in the released position.

Alternatively operate the forward and reverse

operating levers to allow the lubricant to penetrate

all parts of the mechanism.

N.B. : Excess lubrication cannot cause the

machine or wire rope to slip. Any machine, the side

cases of which show signs of dents or damage, or

of which the hook is damaged, should be returned

to an approved repairer.

11.

WARNINGS AGAINST HAZARDOUS OPERATIONS

The operation of JOCKEY machines in

accordance with the instructions of this manual is

a guarantee of safety. Nevertheless, it is useful to

draw the attention of users to the following

instructions :

-JOCKEY machines described in this manual

must not be used for lifting people.

-Never attempt to motorise the models of

JOCKEY machines described in this manual.

-JOCKEY machines must not be used beyond

their nominal capacity.

-JOCKEY machines must not be used for

applications other than those for which they are

intended.

-Never attempt to operate the rope release catch

whilst the machine is under load.

-Always ensure that the operating levers and the

rope release catch are not obstructed.

-Never operate the forward and reverse operating

levers at the same time.

-Use only the operating handle supplied to

operate the JOCKEY machine.

-It is forbidden to replace sheared pins by

nonstandard pins. Use only genuine TRACTEL

shear pins of the same model (Jockey J5).

-Never anchor the machine other than by its

appropriate anchor point.

-Ensure that there are no obstructions around the

machine which could prevent the machine, the

wire rope and the anchor points from operating

in a straight line.

- Never use the JOCKEY wire rope as a sling.

-Never apply a load to the loose wire rope exiting

from the JOCKEY machine.

- Never subject the controls to sharp knocks.

-Do not operate the JOCKEY machine so that the

talurit pressing of the wire rope hook fouls the

machine side case.

-Never attempt to reverse the rope completely

through the machine whilst under load.

12. TROUBLESHOOTING

1) The forward operating lever moves freely

and does not operate the mechanism : the

machine has been overloaded and the shear pin

has sheared. See section 8.2 for replacing the

shear pin (Jockey J5).

2) Pumping : a lack of lubricant in a machine

sometimes brings about a condition known as

‘pumping’ which is not at all dangerous but which

is inconvenient. This situation occurs when the jaw

which is gripping the rope becomes locked onto it

preventing the other jaw from taking over the load.

As the operating lever is moved in one direction

the machine travels a few centimetres, but when

the operating lever travels in the other direction

the machine moves back the same distance in

sympathy with the jaw which is locked onto the

rope. The JOCKEY machine should be thoroughly

lubricated and it will recommence working

normally. If necessary, operate the machine in

reverse direction over a short distance to help

lubrication of the mechanism.

3) Jerkiness : this is also a symptom of lack of

lubrication. The JOCKEY machine should be

thoroughly lubricated. Follow the instructions for

‘pumping’ above.

4) Blockage : if the wire rope becomes blocked in

the machine, generally because a damaged section

of wire rope is stuck within the jaws, it is imperative

to stop operating the machine. The load should be

taken by another machine on a separate wire rope,

or by another means, whilst ensuring that all safety

precautions are taken. When the blocked machine

is no longer under load, it may be released and

removed. Should this not be possible, return the

machine and wire rope to an approved repairer.

!

!

Anglia Handling Services Ltd

Other manuals for jockey

2

This manual suits for next models

1

Table of contents

Other Tractel Group Lifting System manuals

Popular Lifting System manuals by other brands

MATOT

MATOT 100 installation manual

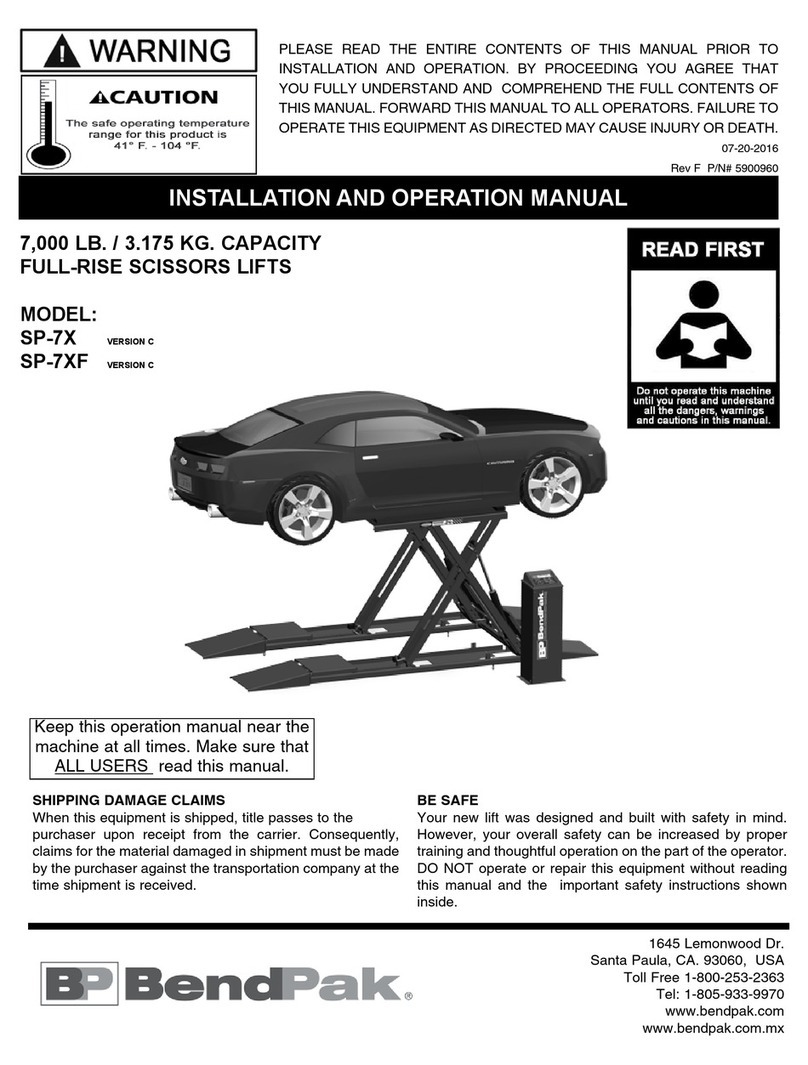

Bend-Pak

Bend-Pak HD-12LS Installation and operation manual

Bend-Pak

Bend-Pak SP-7XF Installation and operation manual

Bend-Pak

Bend-Pak HD-75BXT Installation and operation manual

BilJax

BilJax ESP 19 manual

ARJO HUNTLEIGH

ARJO HUNTLEIGH Malibu Sovereign Maintenance and Repair Manual

SmartMetals

SmartMetals 052.7250 product manual

Bend-Pak

Bend-Pak HD-9STX Installation and operation manual

Bend-Pak

Bend-Pak HDSO-14P Service manual

Bend-Pak

Bend-Pak HDSO-14AX Installation and operation manual

BraunAbility

BraunAbility Vista 2 owner's manual

FOG

FOG QUADRA 493 9021 Installation operation & maintenance