Tractel Blocfor Installation guide

PT

NO

SE

FI

DK

PL

EN

FR

DE

NL

ES

IT

Acessórios Tractel®para o Davitrac Tractel®

Tractel®-tilbehør for Tractel®Davitrac

Tractel®-tillbehör för Tractel®Davitrac

Tractel®Davitract -laitteen Tractel®-lisälaitteet

Tractel®-tilbehør til Tractel®Davitrac

Akcesoria Tractel®do Davitrac Tractel®

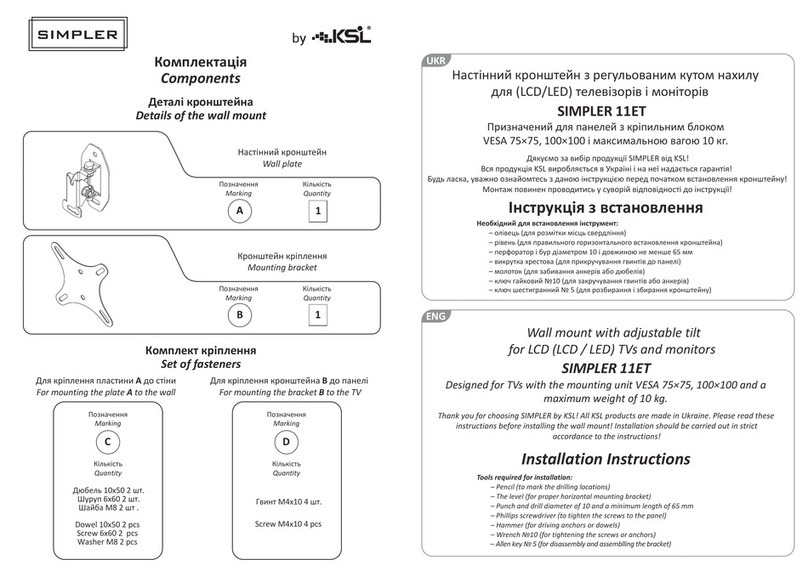

Blocfor™, Carol™ and Scafor™ brackets for Davitrac

Tractel®accessories for the Tractel®Davitrac

Accessoires Tractel®pour le Davitrac Tractel®

Tractel®-Zubehör für Tractel®Davitrac

Tractel®-accessoires voor de Tractel®-Davitrac

Accesorios Tractel®para el Davitrac Tractel®

Accessori Tractel®per Davitrac Tractel®

Installation, operating and maintenance manual English Original manual EN

Manuel d'installation d'emploi et d'entretien Français Traduction de la notice originale FR

Installations-, Gebrauchs- und

Wartungsanleitung Deutsch Übersetzung der Originalanleitung DE

Handleiding voor installatie, gebruik en

onderhoud Nederlands Vertaling van de oorspronkelijke handleiding NL

Manual de instalación, de utilización y de

mantenimiento Español Traducción del manual original ES

Manuale dʼinstallazione, dʼimpiego e di

manutenzione Italiano Traduzione del manuale originale IT

Manual de instalação, de uso e de manutenção Português Tradução do manual original PT

Installasjons-, bruks- og vedlikeholdshåndbok Norsk Oversettelse av originalanvisning NO

Installations-, bruks- och underhållsanvisning

Svenska Översättning av originalbruksanvisningen SE

Asennus-, käyttö- ja huoltokäsikirja Suomi Alkuperäisen ohjeen käännös FI

Manual for installation, brug og vedligeholdelse Dansk Oversættelse af den originale manuall DK

Instrukcja instalacji, użytkowania i konserwacji Polski Tłumaczenie oryginalnej instrukcji obsługi PL

2

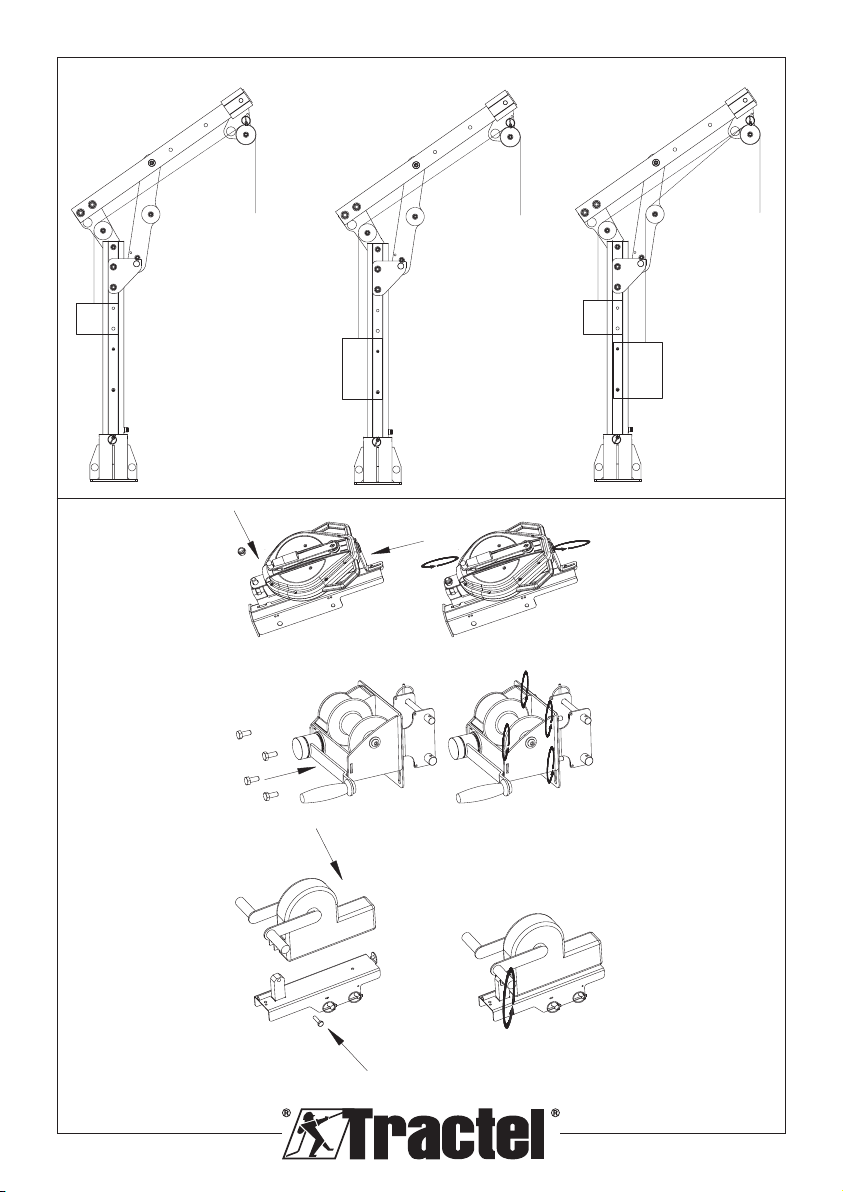

Fig. 1

Fig. 2

3

Fig. 3a Fig. 3cFig. 3b

FIG 4.a

FIG 4.b

FIG 4.c

4

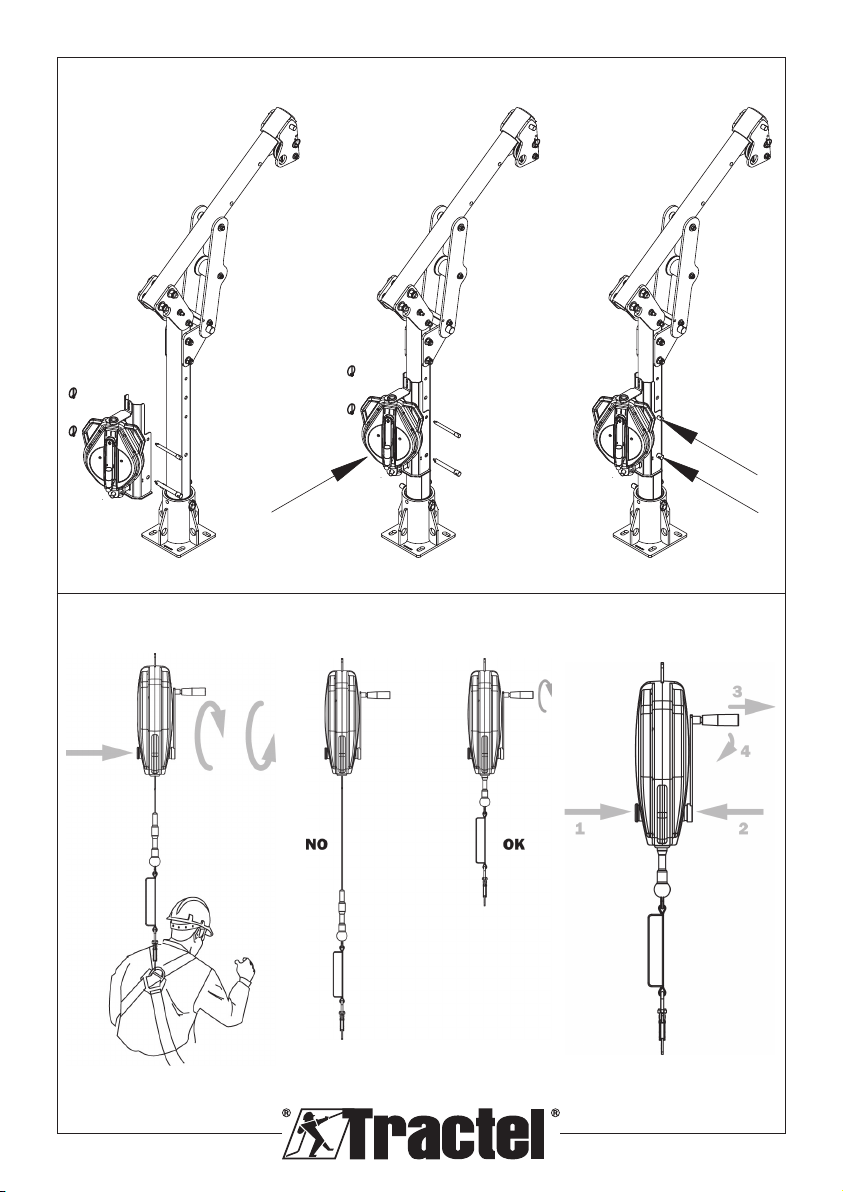

FIG 5

Fig. 6a Fig. 6cFig. 6b

5

EN

Table of contents

1. Important instructions ..............................................6

2. Denitions and pictograms ......................................6

2.1. Denitions.......................................................6

2.2. Pictograms......................................................7

3. Operating conditions................................................7

3.1. Checks before use..........................................7

3.1.1. Blocfor™ 20R and 30R..........................8

4. Functions and descriptions......................................8

4.1. Blocfor™ 20R and 30R...................................8

4.2. Carol™............................................................8

4.2.1. Carol™ R...............................................8

4.2.2. Carol™ TS.............................................9

4.2.3. Carol™ MO............................................9

4.3. Scafor™ R ......................................................9

5. Installation ...............................................................9

5.1. Blocfor™ 20R and 30R...................................9

5.1.1. Installation of the Blocfor™ 20R and

30R on the Blocfor™ Davitrac bracket ..9

5.1.2. Installation of the Blocfor™ Davitrac

bracket on the mast of the Davitrac.....10

5.1.3. Dismantling of the Blocfor™ bracket

from the Davitrac mast ........................10

5.2. Carol™..........................................................10

5.2.1. Installation of Carol™ winches on

the Carol™ Davitrac bracket ...............10

5.2.2. Installation of the Carol™ Davitrac

bracket on the mast of the Davitrac.....10

5.2.3. Dismantling of the Carol™ Davitrac

bracket.................................................10

5.3. Scafor™ R ....................................................10

5.3.1. Installation of the Scafor™ R winch

on the Scafor™ Davitrac bracket.........10

5.3.2. Installation of the Scafor™ Davitrac

bracket on the mast of the Davitrac.....10

5.3.3. Dismantling of the Scafor™ R

Davitrac bracket................................... 11

6. Use ....................................................................... 11

6.1. Blocfor™ 20R and 30R................................. 11

6.1.1. Rescue operation with Blocfor™ R...... 11

6.1.1.1. Activating the recovery

function.................................. 11

6.1.1.2. Return to the fall arrest

function.................................. 11

6.2. Carol™..........................................................12

6.2.1. Carol™ R.............................................12

6.2.1.1. Rescue operation with the

Carol™ R winch ....................12

6.2.1.2. Load lifting operation .............. 12

6.2.2. Carol™ TS...........................................12

6.2.3. Carol™ MO..........................................12

6.3. Scafor™ R ....................................................12

7. Prohibited use........................................................12

8. Associated equipment ........................................... 12

8.1. PPE...............................................................12

8.2. Lifting ...........................................................13

9. Transport and storage .......................................... 13

10. Equipment compliance ........................................13

11. Marking................................................................13

12. Periodic inspection and repair .............................13

12.1. Checking the cable .....................................14

12.1.1. Composition of the cable .....................14

12.1.2. Checking the general condition of

the cable ..............................................14

12.2. Checking the Blocfor™ R ...........................14

12.2.1. Checking the marking..........................14

12.2.2. Checking the compulsory

components are present......................14

12.2.3. Checking the general condition of

the fall arrest .......................................15

12.2.4. Checking the general condition of

the cable .............................................15

12.2.5. Checking the general condition of

the tear-o energy absorber ...............15

12.2.6. Checking the fall arrest function .......... 15

12.2.7. Checking the rescue lifting system ......15

12.3. Checking the Carol™ R, Carol™ TS

and Carol™ MO winches............................ 15

12.3.1. Checking the marking..........................15

12.3.2. Checking the compulsory

components are present......................16

12.3.3. Checking the general condition of

the Carol™ winch ...............................16

12.3.4. For the Carol™ MO ............................. 16

12.3.5. Checking the general condition of

the cable ..............................................16

12.3.6. Checking the proper functioning of

the Carol™ winch ................................16

12.3.6.1. Additional check for the

Carol MO...............................16

12.4. Checking the Scafor™ R ............................16

12.5. Checking the Blocfor™, Carol™ and

Scafor™ brackets .......................................16

12.5.1. Checking the marking..........................17

12.5.2. Checking the compulsory components

are present ..........................................17

6

EN

12.5.3. Checking the general condition of

the bracket...........................................17

13. Service life........................................................... 17

14. Disposal...............................................................17

10. The operator must be physically and mentally t

when using this product. If in doubt, check with

your doctor or your occupational doctor. Pregnant

women may not use this product.

11. This product should not be used beyond its limits or

in any situation other than for its intended use. (See

chapter 4, Functions and descriptions.)

12. Before each use of a fall-arrest system, check that

there is enough fall clearance and that there are no

obstacles in the path of the fall.

13. A full body harness in accordance with EN 361 is

the only equipment around the body that may be

used in a fall-arrest system; secure it to the point

marked A on the harness.

14. It is essential for operator safety that the device or

anchor point is correctly positioned and that work

is carried out so as to minimise the risk of falls and

the height.

15. For the operator’s safety, if the product is re-

sold outside the initial destination country, the

distributor must supply: an instruction manual and

maintenance instructions for periodic inspections

and repairs, all written in the language of the

product’s country of use.

16. In addition to fall protection equipment, it is essential

for the safety of the operator and supervisor that

they use personal protective equipment such as

helmets, safety glasses, gloves and safety shoes

when handling and using this product.

17. The product may only be used with the associated

equipment described in this manual. (See chapter

8, Associated equipment.)

18. This product may only be used in the presence of at

least two operators.

19. Do not use more than two associated pieces of

equipment on the product at the same time.

20. Danger While using several pieces of equipment

where the safety function of one may aect or

interfere with the safety function of another.

21. Before use, the supervisor and operator must read

and understand the information in the EN 1496 and

EN 360 device manuals, the permanent bases for

Davitrac and davimast manual and Davitrac manual.

NOTE:

For any special application, contact Tractel®.

2. Denitions and pictograms

2.1. Denitions

“System”: This refers in this manual to the fall arresters

or winches which is attached to their Davitrac bracket.

1. Important instructions

1. Before using the product, it is essential that the

supervisor and operator review and understand

the information in the manual provided by Tractel

SAS, in order to ensure safe and eective use of the

equipment. This manual must be made available at

all times to all operators. Additional copies can be

obtained on request from Tractel®.

2. Before using this safety equipment, it is essential

that users are trained in its use. Check the condition

of the product and associated equipment and

ensure there is enough fall clearance.

3. The product may only be used by trained and skilled

operators or by operators under the oversight of a

supervisor.

4. The product must not be used and must be checked

by Tractel SAS or by an authorised and qualied

technician who must authorise in writing the re-

commissioning of the product if:

• It is not in a visibly good condition;

• There are concerns about how safe it is;

• It has been used to arrest a fall; or

• It has not undergone a periodic inspection over

the past 12 months; user safety depends on

keeping the equipment eective and strong.

5. A visual inspection is recommended before each

use; the operator must make sure that each

component is in good working order, in particular by

inspecting the condition and presence of the mast

rotation ring on the mast. When it is put in place,

the safety functions must not be deteriorated in any

way.

6. No modications or additions may be made without

the prior written consent of Tractel SAS. The

equipment must be transported and stored in its

original packaging.

7. If the weight of the operator plus that of their

equipment is between 100 kg and 150 kg, it is

essential to make sure that the total weight does not

exceed the safe working load of each component of

the fall-arrest system.

8. This product may be used in temperatures ranging

from -35°C to +60°C.

9. Comply with locally applicable occupational

regulations.

7

EN

“Supervisor”: The individual or department responsible

for the management and safe use of the product

described in the manual.

“Technician”: A qualied person responsible for the

maintenance operations described in the manual, who

is qualied and familiar with the product.

“Operator”: The person using the product as

intended.

“PPE”: Personal protective equipment against falls from

height.

“Connector”: The element connecting the components

of a fall-arrest system. It is EN 362-compliant.

“Fall-arrest harness”: The device worn around the

body for fall protection. It consists of straps and buckles.

It features fall protection attachment points marked with

an A if they may be used alone, or marked with A/2 if

they are to be used in combination with another A/2

point. It is EN 361-compliant.

“Self-retracting fall protection”: The fall-arrest

device with an automatic locking function and a

self-tensioning and retraction system for the self-

retractable lanyard.

“Self-retracting lanyard”: The connecting element of a

self-retracting fall protection system. It may be made of

a metal cable, strapping or synthetic bre depending on

the type of device.

“Maximum operator weight”: The maximum weight of

the clothed operator, wearing PPE and workwear and

carrying the tools and parts required for a job.

“Working load limit”: The limit working load of an

equipment lifting device.

“Fall-arrest system”: Set of the following items:

• An anchor device;

• A linking component;

• Fall protection in accordance with the standard

EN 363; and

• A fall-arrest harness.

“ Elevation rescue device EN 1496 class B”: A

component or subassembly of rescue equipment

allowing an operator to be winched with the help of a

rescuer from a low point to a high point and equipped

with an additional manually operated lowering function

to lower the operator over a distance of up to 2 m.

“ Rescue equipment”: The personal fall protection

system by which a person can save himself or others,

so that any fall is prevented.

2.2. Pictograms

DANGER: When placed at the beginning of a

paragraph, indicates instructions for avoiding injuries

to operators, particularly fatal, serious or minor injuries,

and damage to the environment.

IMPORTANT: Placed at the beginning of a

paragraph, indicates instructions intended to avoid

a fault in or damage to equipment, but not directly

endangering the life or health of the operator or that

of others, and/or unlikely to cause damage to the

environment.

NOTE: When placed at the beginning of a

paragraph, indicates instructions for ensuring the

eectiveness or convenience of installation, use or

maintenance operations.

3. Operating conditions

3.1. Checks before use

DANGER: Before any installation work, the

installer must have these instructions available.

Before installing a system on the Davitrac bracket

• The product marking must be present and legible.

• Before each use, make sure that the product is in

a visibly good condition, free from marks, impacts

or deformation. If not, do not use it and inform the

supervisor.

• For PPE systems, check that the system (Blocfor™

20R and 30R) is correctly attached to its Blocfor™

Davitrac bracket.

• For lifting rescue devices, check that the system

(Carol™ R 250 20 m and 30 m, Scafor™ R 500,

Blocfor™ 20R and 30R) is correctly attached to its

dedicated Davitrac bracket.

• For lifting systems, check that the system (Carol™ TS

or MO) is correctly attached to the Carol™ Davitrac

bracket.

• Before performing the work, the installer must

arrange the site so that installation work is carried

out under the required safety conditions, specically

in accordance with occupational regulations. He

must use the collective and/or personal protective

equipment required for that purpose.

After installing a system on the Davitrac bracket

• Check that the Davitrac bracket with its system is

correctly attached to the Davitrac mast with the pins

and locking pins that are xed in place on the bracket

with a cablet.

• Check that the system cables are routed correctly

above the guide pulleys without crossing each other.

8

EN

• Check that the PPE system cables are routed above

the pulley identied as PPE (g. 2) and that cables

for lifting or moving the operator are routed above the

pulley identied as lifting (g. 2). These pulleys are

positioned on the anchor head of the Davitrac.

• For information on how to use the systems, see the

operating instructions supplied with the system.

• Always check before use that:

• The cable shows no signs of abrasion, fraying,

burns or cuts; and

• The cable shows no signs of bending, abrasion,

corrosion or cut wires.

3.1.1. Blocfor™ 20R and 30R

• Check the condition of the entire length of the lanyard;

the metal cable must not show any signs of bending,

abrasion, corrosion or cut wires.

• Check that the lanyard locks when its end is pulled

quickly and that it rolls up and unwinds normally over

its entire length.

• Check the condition of the housing (no distortion,

screws present, etc.).

• Check the condition and function of the connectors:

no visible distortion, can be opened, closed and

locked.

• Check the condition of the associated components

harness and connectors. Refer to the specic

instructions for each product.

• Check the whole fall-arrest system.

• Check that the bracket is locked properly on the

Davitrac mast.

• Check that the equipment is in automatic fall arrest

function: the recovery function should not be engaged

before use.

• Check that the recovery function engages and

disengages properly.

• Check that the lanyard locks when its end is pulled

quickly and that it rolls up and unwinds normally over

its entire length.

4. Functions and descriptions

IMPORTANT: The Davitrac brackets are

intended for a specic system for exclusive use on

the Tractel® Davitrac.

• The Blocfor™ Davitrac bracket may only be used

as an anchor point with the Blocfor™ 20R or 30R

in line with the standard EN 360.

• The Blocfor™, Carol™ and Scafor™ Davitrac

brackets may only be used as anchor points

respectively with the lifting rescue devices

Blocfor™ 20R and 30R, Carol™ R and Scafor™ R

in accordance with the standard EN 1496.

• The Carol™ and Scafor™ Davitrac brackets may

only be used as anchor points respectively with

the working devices for rope access Carol™ R,

Carol™ MO and Scafor™ R in accordance with

the requirements of Directive 2001/45/EC.

• The Carol™ and Scafor™ Davitrac brackets may

only be used as anchor points respectively with

the load lifting systems Carol™ TS 500 Carol™

MO and Scafor™ R in accordance with the

requirements of Directive 2006/42/EC. In this

case, the maximum WLL is 500 kg for Carol™

TS 500 and Carol™ MO and 400 kg for Scafor™

for load lifting.

NOTE:

When the Davitrac is used to lift a load, it is strictly

forbidden to use it simultaneously as a PPE

anchor point. In this conguration, an independent

fall-arrester anchor point must secure the operator.

4.1. Blocfor™ 20R and 30R

The Blocfor™ 20R and 30R fall arrester is a self-

retracting fall arrester in accordance with EN 360; see

section 4 of the enclosed Blocfor™ ESD - EN 360

manual.

• The Blocfor™ 20R and 30R with a cable made of

galvanised steel is tested to ensure it can hold the

weight of an operator equipped with his tools and

equipment up to 150 kg.

• The Blocfor™ Davitrac bracket is tested to ensure it

can hold the weight of an operator equipped with his

tools and equipment up to 150 kg.

It is equipped with a rescue device by lifting up or

down (EN 1496 class B): recovery function allowing

the rescuer to lift and/or lower the operator after a

fall. It is used vertically when installed on the Davitrac

bracket.

This device is disengaged when the Blocfor™ is in fall

arrest use.

The downward rescue function is limited to a maximum

descent of 2 m. Above this height, use a descender

according to EN 341.

4.2. Carol™

The Carol™ Davitrac bracket can be used to attach:

• A winch for a lifting rescue device, Carol™ R;

• A winch for lifting loads, Carol™ TS; and

• A winch for lifting loads or rope access, according

to Directive 2001/45/EC, Carol™ MO.

4.2.1. Carol™ R

Usage in rescue lifting

The Carol™ R winch is a winch which is an EN 1496

lifting rescue device. In this conguration, its maximum

capacity is 150 kg. Its recovery function allows the

rescuer to raise and/or lower the operator after a fall.

9

EN

Use in load lifting

The Carol™ R winch is a load lifting winch in accordance

with Directive 2006/42/EC with a max. WLL of 250 kg.

Its lifting function allows the operator to raise and/or

lower a max. load of 250 kg.

4.2.2. Carol™ TS

The Carol™ TS winch is a load lifting winch in

accordance with Directive 2006/42/EC with a max. WLL

of 500 kg. Its lifting function allows the operator to raise

and/or lower a max. load of 500 kg.

4.2.3. Carol™ MO

The Carol™ MO winch is a motorised load lifting winch

in accordance with Directive 2006/42/EC with a max.

WLL of 500 kg. Its lifting function allows the operator to

raise and/or lower a max. load of 500 kg.

When using for rope access, only one operator can be

connected to the Carol™ MO winch. It must always be

connected to a fall arrester with a recovery function.

See the Carol™ MO manual.

4.3. Scafor™ R

The Scafor™ Davitrac bracket can be used to attach a

Scafor™ winch.

Usage in rescue lifting

The Scafor™ R winch is a winch which is an EN 1496

lifting rescue device. In this conguration, its maximum

capacity is 150 kg. Its recovery function allows the

rescuer to raise and/or lower the operator after a fall.

Use in load lifting

The Scafor™ R winch is a load lifting winch in

accordance with Directive 2006/42/EC with a max. WLL

of 500 kg. Its lifting function allows the operator to raise

and/or lower a max. load of 400 kg.

5. Installation

For information on how to use the systems attached

to the brackets, see the manuals supplied with each

system.

Before positioning the Davitrac bracket on the mast of

the Davitrac, the operator must ensure that the mast

is placed correctly on its base and that the base is

securely attached to the structure in accordance with

the Davitrac base instructions.

The Davitrac anchor bracket may only be tted on the

mast of the Davitrac.

They are equipped with keying devices designed to

position the bracket at the top or bottom of the Davitrac

mast.

The Davitrac brackets are equipped with locking pins

with a safety pin, connected by a steel cablet.

When only one system is installed, it must be installed

at the rear of the mast:

• A Scafor™ R or Carol™ winch is placed in the

high position (g. 3.a); and

• The Blocfor™ R fall-arrest device is in the low

position (g. 3.b).

When several systems are installed, they must be

installed as follows:

• A Scafor™ R or Carol™ winch is placed in the

high position at the rear of the mast (g. 3.c); and

• The Blocfor™ R fall-arrest device is in the low

position at the front of the mast (g. 3.c).

No other conguration is permitted.

Depending on the positioning of your system, route

the cable over the transfer pulleys (g. 3). For front-

mounted equipment, the cable should pass over the

front pulley. For rear-mounted equipment, the cable

should pass over the rear pulley.

The position of the anchor head can be set to three

positions as required. Always lock it into position with

its safety pin.

NOTE: No other assembly than those set out

above is permitted without the written approval of

Tractel®.

NOTE: The stated loads are the maximum

values applicable, which must not in any event be

multiplied by the number or anchor points located on

the head or mast of Davitrac.

5.1. Blocfor™ 20R and 30R

Before using Blocfor™ 20R or 30R for the rst time,

it needs to be installed on its bracket provided for this

purpose.

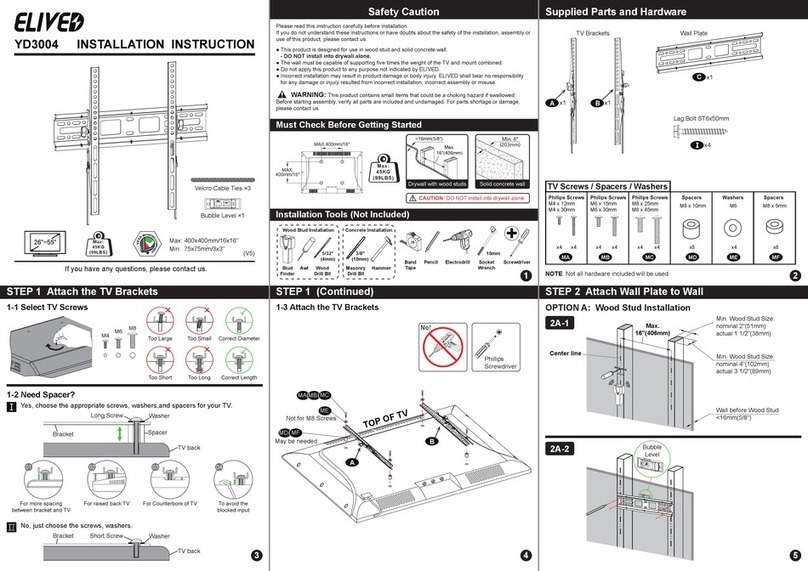

5.1.1. Installation of the Blocfor™ 20R and 30R on

the Blocfor™ Davitrac bracket

1. Position the Blocfor™ anchor point on the bracket

anchor point (g. 4.a), and position the washer and

locknut without tightening them.

2. Place the at-angle bracket on the cable tray of the

Blocfor™ bracket and adjust it. Then put in place its

mounting screw.

3. Tighten the locknut rmly (g. 4.a) and tighten the

screw of the at-angle bracket (g. 4.a).

10

EN

5.2.2. Installation of the Carol™ Davitrac bracket

on the mast of the Davitrac

1. The Carol™ Davitrac bracket is always placed in

the high position at the rear of the mast (g. 5).

2. Position the holes in the bracket inline with the two

holes at the top of the mast (g. 5).

3. Insert the pins attached to the bracket into the holes

(g. 5).

4. Lock the pins with the safety pins (g. 5).

5. Take the cable out of the Carol™ to pass it over the

corresponding guide pulley (g. 5).

6. Remove the anti-jump cable pin and position the

cable above the lifting pulley on the anchor head

(g. 5) (for rescue and load lifting operations or rope

access).

7. Insert the anti-jump cable pin and lock the safety

pin (g. 5).

5.2.3. Dismantling of the Carol™ Davitrac bracket

1. Unlock the anti-jump cable safety pin and remove

it (g. 5).

2. Remove the cable from the pulleys (g. 5).

3. Remove the safety pins attached to the pins on the

Carol™ bracket (g. 5).

4. Remove the pins from the bracket (g. 5), and hold

the bracket and Carol™ to avoid any damage to the

equipment.

5. Replace the pins and safety pins on the bracket.

5.3. Scafor™ R

Before using Scafor™ R for the rst time, it needs to be

installed on its bracket provided for this purpose.

5.3.1. Installation of the Scafor™ R winch on the

Scafor™ Davitrac bracket

1. Position the Scafor™ R winch on the upper

positioning pin of the Scafor™ Davitrac bracket (g.

4.C).

2. Position the anchor clip of the Scafor™ R winch

opposite the hole in the anchor point of the Scafor™

bracket (g. 4.C).

3. Insert the screw supplied with the bracket into the

hole in the anchor point of the Scafor™ R winch

(g. 4.C).

4. Position the washer on the screw then tighten the

locknut rmly (g. 4.C).

5.3.2. Installation of the Scafor™ Davitrac bracket

on the mast of the Davitrac

1. The Scafor™ Davitrac bracket is placed outside

the mast on the two anchor holes at the top of the

Davitrac mast (g. 5).

5.1.2. Installation of the Blocfor™ Davitrac

bracket on the mast of the Davitrac

1. The Blocfor™ Davitrac bracket is always placed in

the down position on the mast (g. 5):

• At the front if other compliant equipment is used;

and

• At the rear if the Blocfor™ bracket is the only

equipment.

2. Position the holes in the bracket inline with the two

holes at the bottom of the mast (g. 5).

3. Insert the pins attached to the bracket into the holes

(g. 5).

4. Lock the pins with the safety pins (g. 5).

5. Take the cable out of the Blocfor™ to pass it over

the corresponding guide pulley (g. 5).

6. Remove the anti-jump cable pin and position the

cable above the PPE pulley on the anchor head

(g. 5).

7. Insert the anti-jump cable pin and lock the safety

pin (g. 5).

5.1.3. Dismantling of the Blocfor™ bracket from

the Davitrac mast

1. Unlock the anti-jump cable safety pin and remove

it (g. 5).

DANGER: The cable is automatically brought

back by the Blocfor™ bracket; be careful of it making

any sudden movements.

2. Remove the cable from the pulleys (g. 5).

3. Remove the safety pins attached to the pins on the

Blocfor™ bracket (g. 5).

4. Remove the pins from the bracket (g. 5), and hold

the bracket and Blocfor™ bracket to avoid any

damage to the equipment.

5. Replace the pins and safety pins on the bracket.

5.2. Carol™

Before using Carol™ for the rst time, it needs to be

installed on its bracket provided for this purpose.

5.2.1. Installation of Carol™ winches on the

Carol™ Davitrac bracket

1. Position the Carol™ winch on the plate of the

Carol™ Davitrac bracket (g. 4.b).

2. Position the Carol™ winch facing the corresponding

holes on the plate of Carol™ bracket (g. 4.b).

3. Insert the four screws supplied with the bracket into

the holes (g. 4.b).

4. Position the washers on the screws then tighten the

four locknuts rmly (g. 4.b)

11

EN

2. Position the holes in the bracket inline with the mast

holes (g. 5).

3. Insert the pins attached to the bracket into the holes

(g. 5).

4. Lock the pins with the safety pins (g. 5).

5. Take the cable out of the winch to pass it over the

external mast guide pulley (g. 5).

6. Remove the anti-jump cable pin and position the

cable.

a. Above the lifting pulley (g. 5) for a rescue

operation

b. Above the lifting pulley (g. 5) for a load lifting

operation

c. Above the lifting pulley (g. 5) for rope access.

7. Insert the anti-jump cable pin and lock the pin with

the safety pins (g. 5).

5.3.3. Dismantling of the Scafor™ R Davitrac

bracket

1. Remove the anti-jump cable pin (g. 5).

2. Remove the cable from the pulleys (g. 5).

3. Remove the safety pins attached to the pins (g. 5).

4. Remove the pins attached to the bracket in the

holes (g. 5) and remove the Scafor™ Davitrac

bracket with the Scafor™ R winch and store it in its

original packaging.

For information on how to use the Scafor™ R winch and

its Davitrac bracket, see the manul “Scafor™ R winch

- Equipped with a bracket for the Davitrac Tractel®”

supplied with it.

6. Use

DANGER: The presence of a second

operator nearby is essential to carry out a

possible evacuation.

The rescue operations to be planned must have been

studied beforehand in order to dene the human

resources and equipment to be used to rescue the

injured person within a period of less than 15 minutes.

After that time, the operator is in danger.

Throughout the rescue phase, there must be

direct or indirect visual contact or other means of

communication between the rescuer and other

persons involved in the rescue.

For rescue operations, the use of a comfortable

harness EN 813 (type Promast™, Transport,

Emergency) or a harness equipped with an EN 1497

emergency shoulder strap is recommended.

6.1. Blocfor™ 20R and 30R

After a fall, the mechanism of the Blocfor™ is locked.

To evacuate the operator up or down, engage the

recovery mechanism by pushing the lock button and

then operate the crank.

The self-retracting fall-arrest system Blocfor™ 20R and

30R 150 kg is equipped with two handles to facilitate

its handling and use in rescue by lifting by holding the

equipment handle with one hand and the crank handle

with the other.

For information on how to use the Blocfor™ 20R and

30R device in fall arrest mode, see the Blocfor™ EN

360 instructions.

6.1.1. Rescue operation with Blocfor™ R

6.1.1.1. Activating the recovery function

See gure 6.1.

• (1) Press the red lock button to engage the recovery

function.

• (2) Pull and turn the crank to recover the operator:

• Clockwise to go up; or

• Anti-clockwise to go down.

6.1.1.2. Return to the fall arrest function

6.1.1.2.1. Rewinding the cable in the device

See gure 6.2.

When the recovery is complete, rewind the entire cable

into the unit by turning the crank clockwise.

DANGER: Do not disengage the recovery

function from the unit if the cable is not fully wound

in the housing, otherwise the cable may rewind itself

at high speed.

6.1.1.2.2. Disengaging the recovery function

See gure 6.3

• To disengage the winch mechanism, press the red

button (1) and the crank shaft (2) simultaneously.

• Make sure that the crank handle is positioned

vertically, with the handle at the top so that this

operation can be carried out.

• Pull the handle (3) before folding it back (4).

DANGER:

Any lifting operation with Blocfor™ R is prohibited.

The winch system is intended for rescue operations

only.

12

EN

6.2. Carol™

6.2.1. Carol™ R

6.2.1.1. Rescue operation with the Carol™ R winch

IMPORTANT: During rescue operations, the winch

system may only be used for rescue operations and

may not be used for lifting loads.

To perform a rescue operation by lifting, turn the crank

handle in the direction of the arrow M to evacuate the

operator to be rescued upwards (g 4.b).

DANGER: Any load lifting operation with the

Carol™ winch is forbidden in combination with a

rescue operation by lifting a person or rope access.

During rescue operations, the winch system may only

be used for rescue operations.

6.2.1.2. Load lifting operation

For information on how to use the Carol™ R winch for

a lifting operation, see the manual “Carol™ - TS-type

hand winch with worm screw”.

6.2.2. Carol™ TS

For information on how to use the Carol™ TS winch for

a lifting operation, see the manual “Carol™ - TS-type

hand winch with worm screw”.

6.2.3. Carol™ MO

For information on how to use the Carol™ TS winch

for a lifting operation, see the manual “Carol™ MO -

Installation, use and maintenance manuals - Motorised

drum winch”.

6.3. Scafor™ R

For information on how to use the Scafor™ R winch for

a lifting operation, see the manual “Scafor™ R winch

- Equipped with a bracket for the Davitrac Tractel®”.

7. Prohibited use

It is strictly prohibited:

• To install or use a Davitrac bracket equipped with

its system without the proper authorisation and

recognition or, failing that, without the supervision of

an authorised and recognised competent person;

• To use a Davitrac bracket if any of the markings are

illegible;

• To install or use a Davitrac bracket without rst

verifying it thoroughly;

• To use a Davitrac bracket if it has not undergone a

periodic inspection within the past 12 months by a

technician who has permitted its reuse in writing;

• To connect a Davitrac bracket to the Davitrac if it has

not undergone a periodic inspection within the past 12

months by a technician who has permitted its reuse

in writing;

• To use a Davitrac bracket for any applications other

than those described in this manual;

• To attach a system to a Davitrac bracket by any

means other than as described in this manual;

• To use a Davitrac bracket in contradiction with the

information specied in the section 13, Service life;

• To use a bracket system beyond the capacities

mentioned in this manual in chapter 4, Functions and

descriptions;

• To use a Davitrac bracket if it has arrested a fall;

• To use a Davitrac bracket in a highly corrosive or

explosive atmosphere;

• To use a Davitrac bracket outside the temperature

range specied in this manual;

• To use a Davitrac bracket if you are not in good

physical shape;

• To use a fall arrest if you are pregnant;

• To use a Davitrac bracket if the safety function of

any of the associated items is aected by the safety

function of another item or may interfere with it;

• To perform any repair or maintenance operations

on a Carol™, Scafor™ or Blocfor™ R winch without

rst having been trained and qualied, in writing, by

Tractel®;

• To use a Davitrac bracket if it is not complete;

• To use a Carol™, Scafor™ or Blocfor™ winch, if it is

not complete, if it has been dismantled beforehand

or if components have been replaced by any person

unauthorised by Tractel®.

• To use the device if a rescue plan has not been put in

place beforehand in the event of a fall by the operator;

• To install a Tractel® fall-arrest anchor device on a

structure with a mechanical breaking strength below

16 kN vertically and horizontally. This load may

be applied vertically with a maximum lever arm of

700 mm; and

• To simultaneously use the PPE anchor point at the

end of the jib with an equipped bracket.

8. Associated equipment

8.1. PPE

• A Blocfor™ R (EN 360) fall-arrest system with lifting

rescue device (EN 1496);

• A Carol™ R winch, EN 1496 lifting rescue device;

• A Scafor™ R winch, EN 1496 lifting rescue device;

• A Davitrac + Davitrac EN 795:2012 base type A or B;

• A connector (EN 362);

• A full body harness (EN 361) or (EN 361/358/813);

• A full body harness (EN 360, EN 353-2 or EN 355).

All other associated equipment is forbidden.

13

EN

8.2. Lifting

Lifting winch in accordance with Machinery Directive

2006/42/EC as follows:

• Carol™ TS;

• Carol™ MO;

• Scafor™ R.

9. Transport and storage

For associated systems, see the specic manuals of

the associated products.

During storage and/or transport, the product must be:

• Stored at a temperature between -35°C and 60°C;

and

• Protected from chemical, mechanical or any other

type of attack.

10. Equipment compliance

Tractel SAS, RD 619, Saint-Hilaire-sous-Romilly,

10102 Romilly-sur-Seine, France hereby declares that

the safety equipment described in this manual:

The oor-standing, surface-mounted, oset wall-

mounted and built-in oor bases in combination with

the Davitrac and:

The bracket and Blocfor™ 20R and 30R:

• Is identical to the equipment that has been tested

for compliance with the standard EN 1496 of 2017

by APAVE SUDEUROPE SAS, CS 60193, 13322

Marseille, France;

• with a breaking strength of 15 kN;

The bracket and Carol™ R:

• Is identical to the equipment that has been tested

for compliance with the standard EN 1496 of 2017

by APAVE SUDEUROPE SAS, CS 60193, 13322

Marseille, France;

• Is subject to a declaration of conformity to:

• Directive 2001/45/EC, rope-suspended working

devices;

• Machinery Directive 2006/42/EC, load lifting;

• With a breaking strength of 15 kN;

The bracket and Carol™ TS:

• Is subject to a declaration of conformity to:

• Machinery Directive 2006/42/EC, load lifting.

• With a breaking strength of 15 kN;

The bracket and Carol™ MO:

• Is subject to a declaration of conformity to:

• Directive 2001/45/EC, rope-suspended working

devices; and

• Machinery Directive 2006/42/EC, load lifting.

• With a breaking strength of 15 kN;

The bracket and Scafor™ R:

• Is identical to the equipment that has been tested

for compliance with the standard EN 1496 of 2017

by APAVE SUDEUROPE SAS, CS 60193, 13322

Marseille, France;

• With a breaking strength of 15 kN;

• Is subject to a declaration of conformity to:

• Directive 2001/45/EC, rope-suspended working

devices; and

• Machinery Directive 2006/42/EC, load lifting.

The non-EC examination certicate of conformity

issued by APAVE and the declarations of conformity

to standards exclude applications associated with

other directives. Depending on their use, these other

products are subject to a declaration of conformity as

specied above.

11. Marking

The product marking described in this manual indicates:

a. The trade name: TRACTEL®,

b. The product description;

c. The reference standard followed by the year of

application;

d. Product reference, e.g. 286819;

e. The CE logo followed by the number 0082,

identication number of the notied body

responsible for production inspection;

f. The YY/MM batch number;

g. The serial number;

h. A Pictogram showing that the manual must be read

before use;

o. The minimum breaking strength of the anchor

device;

p. The number of individuals: One operator maximum;

w. The safe working load; and

aa. The date of the next periodic inspection.

12. Periodic inspection and repair

An annual periodic inspection is mandatory; however,

depending on the frequency of use, environmental

conditions and regulations of the company or the

country of use, periodic inspections may be more

frequent.

If this equipment is dirty, wash it with clean and cold

water with a synthetic brush. During transport and

storage, protect the equipment in moisture-resistant

packaging from any hazards (direct heat source,

chemical products and UV light, etc.).

Periodic inspections must be carried out by a qualied

technician in strict compliance with periodic inspection

procedures.

14

EN

Conrming the legibility of the product markings is an

integral part of the periodic inspection.

The outcome of these inspections must be recorded

in the inspection register located at the centre of these

instructions, which must be kept throughout the life of

the product until it is taken out of service.

The technician must also complete lines A to E of the

table with the following information:

A: Name of inspector;

B: Date of inspection;

C: Inspection result OK/Not OK;

D: Signature of inspector;

E: Date of next inspection.

After arresting a fall, this product must undergo a

periodic inspection as described in this section.

The Blocfor™, Scafor™ and Carol™ Davitrac brackets

are supplied with their equipped system, so it is

advisable to carry out periodic visual inspections on the

brackets and their respective system.

12.1. Checking the cable

Always wear protective gloves and goggles when

checking the cable

This chapter describes the procedure for checking a

Tractel® cable for Blocfor™, Scafor™ and Carol™.

All cables are supplied with a connector.

The fastening loop must never be a simple knot or lock

with cable clamps or a splice.

Position the cable so that it can be inspected along its

entire circumference and length.

NOTE: The cable alone is not a piece of PPE

but a sub-assembly of a system; it must be compatible

with the system it is used with.

12.1.1. Composition of the cable

The cable is made of galvanised steel or stainless steel.

To be used, the cables must have a manufactured

buckle at the end made by Tractel®.

The terminal must be:

• Buckled and sleeved with an aluminium sleeve for

galvanised cables; and

• Buckled and sleeved with a copper sleeve for

stainless steel cables.

12.1.2. Checking the general condition of the cable

• Uncoil the cable over its entire length;

• Hold the cable with your gloves on between your

thumb and forenger;

• Inspect the entire length of the steel cable and more

specically check whether:

• It is pinched;

• It has unravelled;

• It has corroded;

• Strands are cut;

• The sleeving is not in the required condition,

• The wire thimble is missing or is deformed;

• The fall indicator has been triggered on the cables

equipped with it; and

• One of the ends of the cable is non-compliant.

NOTE: If one of the above situations develops,

the equipment must be taken out of service.

If in doubt or if you do not understand this

checklist, contact Tractel®.

12.2. Checking the Blocfor™ R

The Blocfor™ R fall arrester is supplied with its Davitrac

bracket and its cable.

Position the Blocfor™ R fall arrester so that it can be

inspected on each side.

12.2.1. Checking the marking

The fall arrester must have the following markings at

least, in line with the standard EN 365:

• The manufacturer’s or supplier’s name;

• The CE label;

• This equipment reference;

• The batch or serial number;

• The CE number;

• The EN equipment standard followed by the year of

reference; and

• The logo; read the instruction manual.

NOTE: If any marking goes missing, the aected

equipment must be taken out of service.

12.2.2. Checking the compulsory components are

present

The fall arrest system must have the following at least:

• Its Davitrac bracket;

• A fall-arrest;

• A crank handle;

• Connectors; and

• The energy absorber if there is one.

15

EN

12.2.3. Checking the general condition of the fall

arrest

Inspect each side of the fall arrest and more specically

check whether:

• The housings are deformed;

• The incorrect wound or unwound of the whole cable;

• There is any corrosion;

• Any pins, screws or rivets are missing;

• The steel cable is non-compliant as per chapter 12.1;

and

• The fall indicator has been triggered or the energy

absorber has if there is one.

NOTE: If one of the above situations develops,

the equipment must be taken out of service.

12.2.4. Checking the general condition of the cable

See chapter 12.1, Checking the cable, to perform the

check.

The end of the cable must be equipped with a connector

which also needs to be checked.

12.2.5. Checking the general condition of the tear-

o energy absorber

When a tear-o energy absorber is present, inspect it

on all sides and specically check that:

• The absorber packaging is missing;

• The absorber packaging is unopened or has not

slipped;

• The absorber has not been triggered;

• The seams are not damaged;

• Fully inspect both sides of the strap and more

specically look for:

• Tears;

• Cuts;

• Surface wear due to friction; and

• Perforations due to molten metal spatters.

• Fully inspect both sides of the seams and more

specically check that they are not:

• Covered in lint;

• Damaged; or

• Cut intermittently.

NOTE: If one of these situations develops, the

equipment must be taken out of service.

12.2.6. Checking the fall arrest function

This chapter describes the procedure for checking the

Blocfor™ R fall arrest function.

In a safe environment with no risk of falling, proceed

according to the following instructions:

1. Attach the fall-arrest device to an anchor point

vertically at least 2 m from the ground;

2. Hook a 10 kg weight to the end of the cable, holding

it in position; and

3. Drop the 10 kg weight.

4. The fall must be stopped in less than one metre

(1 m) in relation to the initial position of the weight.

5. Hold the cable, unhook the weight and check the

rewinding of the cable in the Blocfor™.

NOTE: If the lock is not immediate, if it occurs

after several jolts, the product must not be used and

must be returned to Tractel® or an authorised repairer.

12.2.7. Checking the rescue lifting system

This chapter describes the procedure for checking the

Blocfor™ R lifting rescue function.

In a safe environment with no risk of falling, proceed

according to the following instructions:

1. Install the Blocfor™ fall arrest on an anchor point in

a vertical position;

2. Unwind the cable and connect a 150 kg weight to

the end of the cable;

3. Engage on the Blocfor™ winch by pushing the red

button;

4. Lift the 150 kg weight using the crank handle;

5. Release the crank handle; the locking must be done

immediately without slipping;

6. Wait three minutes; and

7. Bring the weight back down.

NOTE: If the locking is not immediate, if it occurs

after several jolts or if the weight goes down before the

three-minute delay, the product must not be used and

must be returned to Tractel® or an authorised repairer.

12.3. Checking the Carol™ R, Carol™ TS

and Carol™ MO winches

The Carol™ winch is supplied with its Davitrac bracket

and its cable.

Position the Carol™ winch so that it can be inspected

from all sides.

12.3.1. Checking the marking

The Carol™ winch must have the following marking at

least:

• The manufacturer’s or supplier’s name;

• The CE label;

• The equipment reference;

• The batch or serial number;

• The EN equipment standard followed by the year of

reference; and

16

EN

• The logo; read the instruction manual.

NOTE: If any marking goes missing, the aected

equipment must be taken out of service.

12.3.2. Checking the compulsory components are

present

The Carol™ winch must have the following at least:

• Its Davitrac bracket;

• A Carol™ cable;

• The winch with all its components;

• A crank handle arm for the Carol™ R and TS;

• A plastic handle for the Carol™ R and TS;

• A control box for the Carol™ MO; and

• Eletrical connectors for the Carol™ MO.

12.3.3. Checking the general condition of the

Carol™ winch

Inspect each side of the Carol™ winch and more

specically check whether:

• The housings are deformed;

• The crank handle and plastic handle are deformed;

• The incorrect wound or unwound of the whole cable;

• There is any corrosion;

• Any pins, screws or rivets are missing;

• The steel cable is non-compliant as per chapter 12.1;

NOTE: If one of these situations develops, the

equipment must be taken out of service.

12.3.4. For the Carol™ MO

In addition to the Carol™ checks described in chapters

12.3.1, 12.3.2 and 12.3.3, it is necessary to carry out

the following additional checks on the Carol™ MO.

• Checking the correct functioning of the control box

and all functions;

• Checking the proper condition of the electrical wire

and the absence of the following faults:

• Cut wire;

• Bare thread;

• Wire incorrectly connected; and

• Checking the correct operation of the limit switches.

NOTE: Non-compliance with the above checks

does not necessarily mean the equipment is to be

decommissioned, but the device must not be used

until it has been repaired by Tractel or an authorised

repairer.

12.3.5. Checking the general condition of the cable

See chapter 12.1, Checking the cable, to perform the

check.

The end of the cable must be equipped with a hook

which also needs to be checked.

12.3.6. Checking the proper functioning of the

Carol™ winch

In a safe environment with no risk of falling, proceed

according to the following instructions:

Install the Carol™ winch with its bracket on the mast

of a Davitrac.

To check the correct operation of the lock, use a weight

weighing:

• 275 kg attached to the end of the cable for the Carol™

R;

• 550 kg attached to the end of the cable for the Carol™

TS and Carol™ MO.

Proceed to check the stopping of the weight following:

1. Lift the weight with the Carol™ winch;

2. Release the crank handle or button on the control

box;

3. The locking of the weight must be done immediately

without slipping;

4. Wait three minutes; and

5. Bring the weight back down.

NOTE: If the lock is not immediate, if it occurs

after several jolts or if the weight goes down before the

three-minute delay, the product must not be used and

must be returned to Tractel® or an authorised repairer.

12.3.6.1. Additional check for the Carol MO

The Carol™ MO is equipped with a limit switch system

that also needs to be tested on the Davitrac. During the

lifting operation, the end of the cable must stop 50 cm

below the Davitrac head when it is in position P1 at 700

m (according to the Davitrac instructions)

NOTE: Non-compliance with the above check

does not necessarily mean the equipment is to be

decommissioned, but the device must not be used

until it has been repaired by Tractel or an authorised

repairer.

12.4. Checking the Scafor™ R

The Scafor™ R is supplied with its Davitrac bracket

without a cable.

See the instructions “Scafor™ R winch - Equipped with

a bracket for the Davitrac Tractel®” to check it.

12.5. Checking the Blocfor™, Carol™ and

Scafor™ brackets

The Davitrac brackets are supplied with their system.

For the systems check, see the corresponding

chapters.

17

EN

Position the bracket so that all sides of it can be

inspected.

12.5.1. Checking the marking

The bracket must have the following marking at least:

• The manufacturer’s or supplier’s name;

• The equipment reference;

• The batch or serial number;

• The EN equipment standard followed by the year of

reference; and

• The logo; read the instruction manual.

NOTE: If any marking goes missing, the aected

equipment must be taken out of service.

12.5.2. Checking the compulsory components are

present

The Davitrac bracket must have the following at least:

• The Davitrac bracket;

• Two pins; and

• Two safety pins connected to the bracket by means

of a cablet.

12.5.3. Checking the general condition of the

bracket

Inspect each side of the bracket and more specically

check whether:

• The bracket is deformed in any way;

• The mounting holes are deformed in any way;

• The pins and safety pins are deformed in any way;

and

• There is any corrosion.

NOTE: Non-compliance with the above check

does not necessarily mean the equipment is to be

decommissioned, but the device must not be used

until it has been repaired by Tractel or an authorised

repairer.

13. Service life

Tractel® textile PPE such as harnesses, lanyards,

ropes and energy absorbers, Tractel®mechanical PPE

such as Stopcable™ and Stopfor™ fall-arrest devices,

Blocfor™ self-retracting fall-arrest devices and Tractel®

lifelines and anchor devices may be used from their

manufacturing date providing that they:

• Are used normally in accordance with the usage

recommendations of this manual;

• Undergo a periodic inspection, which must be

performed at least once a year by an authorised and

qualied technician. On completion of this periodic

inspection, the product must be certied in writing as

t to be recommissioned; and

• Fully comply with the storage and transport conditions

set out in this manual.

As a general rule and subject to implementing the

conditions for use stated above, their service life may

exceed 10 years.

14. Disposal

When disposing of the product, the various components

must be recycled by separating and sorting metal

and synthetic components. These materials must

be recycled through specialist organisations. When

disposing of the product, a qualied person should

dismantle and separate the component parts.

Component Treat as a waste of

the type:

Bracket, pins, spacer,

screws and pulley shaft.

Steel

Carol™ R and Carol™ TS Steel

For the Carol™ MO, Scafor™ R and Blocfor™, see

their respective manual.

Manufacturer’s name and address:

Tractel SAS - RD 619 - BP 38

Saint-Hilaire-sous-Romilly

10102 Romilly-sur-Seine

18

EN

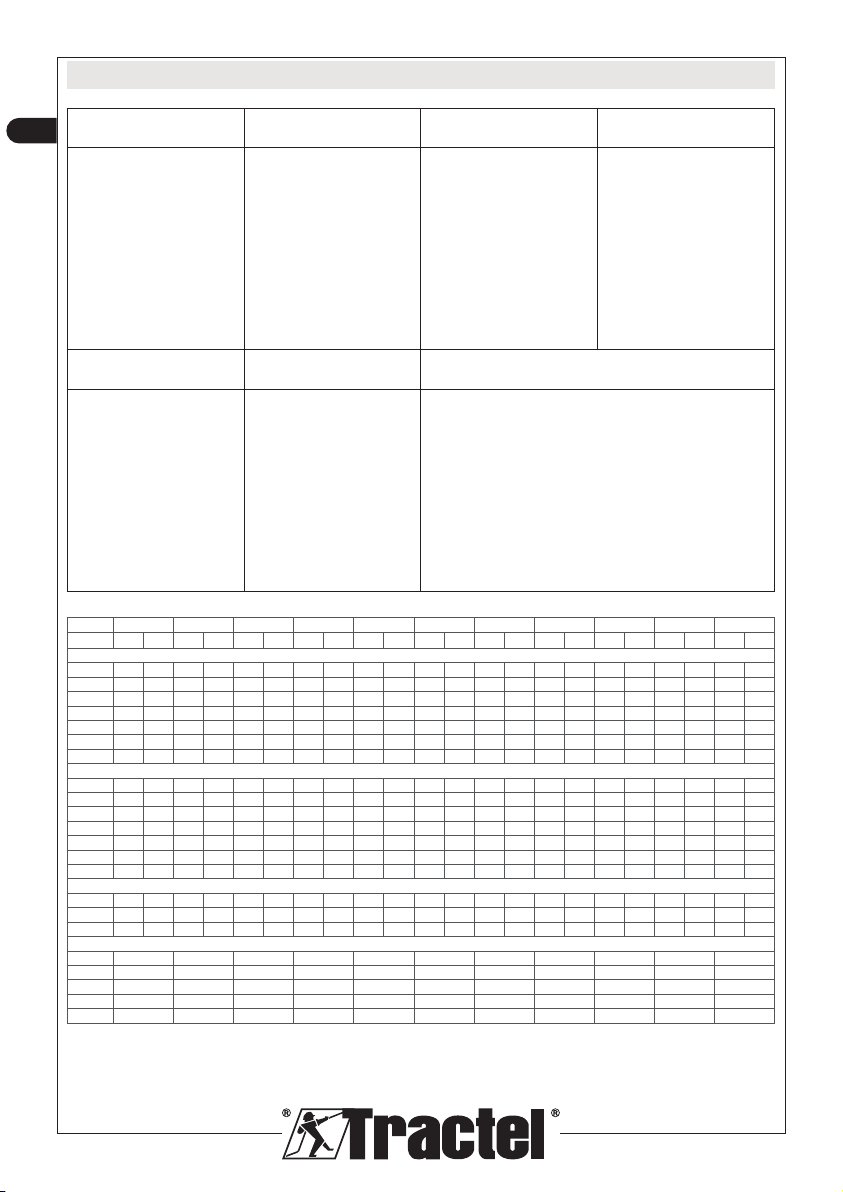

Inspection register

Type of product

Type de produit

Produktbezeichnung

Produkttype

Tipo de producto

Tipo di prodotto

Tipo de produto

Τύπος προϊόντος

Produkttype

Produkttyp

Tuotetyyppi

Produkttype

Typ produktu

Тип изделия

Product reference

Référence produit

Artikelnummer

Produktcode

Referencia producto

Riferimento prodotto

Referência do produto

Κωδικός προϊόντος

Produktreferanse

Produktreferens

Tuotteen viitenumero

Produktnummer

Oznaczenie produktu

Артикул изделия

Serial number

Numéro de série

Seriennummer

Serienummer

Numero de serie

Numero di serie

Número de série

Σειριακός αριθμός

Serienummer

Serienummer

Sarjanumero

Serienummer

Numer seryjny

Серийный номер

Name of user

Nom de l’utilisateur

Name des Benutzers

Naam van de gebruiker

Nombre del usuario

Nome dell’utilizzatore

Nome do utilizador

Όνομα του χρήστη

Brukerens navn

Användarens namn

Käyttäjän nimi

Brugerens navn

Nazwisko użytkownika

Фамилия пользователя

Date of manufacturing

Date de fabrication

Herstellungsdatum

Fabricagedatum

Fecha de fabricación

Data di produzione

Data de fabrico

Ημερομηνία κατασκευής

Fabrikasjonsdato

Tillverkningsdatum

Valmistuspäivä

Fabrikationsdato

Data produkcji

Дата производства

Date of purchase

Date d’achat

Kaufdatum

Aankoopdatum

Fecha de compra

Data di acquisto

Data de compra

Ημερομηνία αγοράς

Kjøpedato

Inköpsdatumi

Ostopäivä

Købsdato

Data zakupu

Дата покупки

X=Date of commissioning

X=Date de mise en service

X=Datum der Inbetriebnahme

X=Datum ingebruikneming

X=Fecha de puesta en servicio

X=Data di messa in servizio

X=Data de entrada em serviço

X=Ημερομηνία θέσης σε λειτουργία

X=Dato for bruk første gang

X=Första användningsdagen

X=Käyttöönottopäivä

X=Dato for ibrugtagning

X=Data przekazania do użytku

X=Дата ввода в эксплуатацию

No X X+1 X+2 X+3 X+4 X+5 X+6 X+7 X+8 X+9 X+10

12.2 Blocfor™ 20R & 30R

12.2.1

12.2.2

12.2.3

12.2.4

12.2.5

12.2.6

12.2.7

12.3 Carol™ R, Carol™ TS & Carol™ MO

12.3.1

12.3.2

12.3.3

12.3.4

12.3.5

12.3.6

12.3.6.1

12.5 brackets Blocfor™, Carol™ & Scafor™

12.5.1

12.5.2

12.5.3

A

B

C

D

E

19

FR

Sommaire

1. Consignes prioritaires..............................................6

2. Dénition et pictogrammes......................................7

2.1. Dénitions.......................................................7

2.2. Pictogrammes.................................................7

3. Conditions d’utilisation.............................................7

3.1. Vérications avant utilisation : ........................7

3.1.1. Blocfor™ 20R et 30R.............................8

4. Fonctions et descriptions.........................................8

4.1. Blocfor™ 20R et 30R......................................8

4.2. Carol™............................................................9

4.2.1. Carol™ R...............................................9

4.2.2. Carol™ TS.............................................9

4.2.3. Carol™ MO............................................9

4.3. Scafor™ R ......................................................9

5. Installation ...............................................................9

5.1. Blocfor™ 20R et 30R....................................10

5.1.1. Installation du Blocfor™ 20R et 30R

sur la console Blocfor™ Davitrac ........10

5.1.2. Installation de la console Blocfor™

Davitrac sur le mât de la potence

Davitrac ...............................................10

5.1.3. Démontage de la console Blocfor™

du mât Davitrac ...................................10

5.2. Carol™..........................................................10

5.2.1. Installation des treuils Carol™ sur

la console Carol™ Davitrac ................. 10

5.2.2. Installation de la console Carol™

Davitrac sur le mât de la potence

Davitrac ...............................................10

5.2.3. Démontage de la console Carol™

Davitrac ...............................................10

5.3. Scafor™ R .................................................... 11

5.3.1. Installation du treuil Scafor™ R sur

la console Scafor™ Davitrac ............... 11

5.3.2. Installation de la console Scafor™

Davitrac sur le mât de la potence

Davitrac ............................................... 11

5.3.3. Démontage de la console Scafor™ R

Davitrac ............................................... 11

6. Utilisation .............................................................. 11

6.1. Blocfor™ 20R et 30R.................................... 11

6.1.1. Opération de sauvetage avec

Blocfor™ R .......................................... 11

6.1.1.1. Mise en fonction de la fonction

récupérateur.......................... 11

6.1.1.2. Retour à la fonction antichute12

6.2. Carol™..........................................................12

6.2.1. Carol™ R.............................................12

6.2.1.1. Opération de sauvetage

avec le treuil Carol™ R .........12

6.2.1.2. Opération levage de charge..12

6.2.2. Carol™ TS...........................................12

6.2.3. Carol™ MO..........................................12

6.3. Scafor™ R ....................................................12

7. Contre-indications d’emploi ...................................12

8. Equipements associés...........................................13

8.1. EPI................................................................13

8.2. Levage .........................................................13

9. Transport et stockage ........................................... 13

10. Conformité de l’équipement.................................13

11. Marquage.............................................................14

12. Examen périodique et réparation ........................14

12.1. Vérication du câble ...................................14

12.1.1. Composition du câble ..........................14

12.1.2. Vérication de l’état général du câble... 14

12.2. Vérication du Blocfor™ R..........................15

12.2.1. Vérication du marquage.....................15

12.2.2. Vérication de la présence des

organes obligatoires ............................15

12.2.3. Vérication de l’état général de

l’antichute ...........................................15

12.2.4. Vérication de l’état général du câble

acier ....................................................15

12.2.5. Vérier l’état général de l’absorbeur

d’énergie à déchirement ..................... 15

12.2.6. Vérication de la fonction antichute.....15

12.2.7. Vérication du système de sauvetage

par élévation ........................................16

12.3. Vérication du treuil Carol™ R,

Carol™ TS et Carol™ MO ..........................16

12.3.1. Vérication du marquage.....................16

12.3.2. Vérication de la présence des

organes obligatoires ............................16

12.3.3. Vérication de l’état général du treuil

Carol™ ...............................................16

12.3.4. Pour le Carol™ MO ............................. 16

12.3.5. Vérication de l’état général du câble

acier.....................................................16

12.3.6. Vérication du bon fonctionnement

du treuil Carol™...................................17

12.3.6.1. Vérication supplémentaire

pour le Carol MO...................17

12.4. Vérication du Scafor™ R ..........................17

12.5. Vérication des consoles Blocfor™,

Carol™ et Scafor™.....................................17

20

FR

12.5.1. Vérication du marquage.....................17

12.5.2. Vérication de la présence des

organes obligatoires ............................17

12.5.3. Vérication de l’état général de la

console ................................................17

13. Durée de vie ........................................................17

14. Mise au rebut.......................................................18

8. Ce produit convient pour une utilisation dans une

plage de température comprise entre -35°C et

+60°C.

9. Conformez-vous à la réglementation du travail

applicable localement.

10. L’opérateur doit être en pleine forme physique et

psychologique lors de l’utilisation de ce produit. En

cas de doute, consulter son médecin ou le médecin

du travail. Interdit aux femmes enceintes.

11. Le produit ne doit pas être utilisé au-delà de ses

limites, ou dans toute autre situation que celle

pour laquelle il est prévu : cf. «4. Fonctions et

description ».

12. Avant chaque utilisation d’un système d’arrêt des

chutes, il faut vérier que le tirant d’air est susant

et qu’il n’y a aucun obstacle sur la trajectoire de la

chute.

13. Un harnais d’antichute EN361 est le seul dispositif

de préhension du corps qu’il est permis d’utiliser

dans un système d’arrêt des chutes il faut

s’accrocher sur le point marqué A du harnais.

14. Il est essentiel pour la sécurité de l’opérateur que

le dispositif ou le point d’ancrage soit correctement

positionné et que le travail soit eectué de manière

à réduire au minimum le risque de chutes ainsi que

sa hauteur.

15. Pour la sécurité de l’opérateur, si le produit est

revendu hors du premier pays de destination,

le revendeur doit fournir : un mode d’emploi, des

instructions pour l’entretien, pour les examens

périodiques et les réparations, rédigés dans la

langue du pays d’utilisation du produit.

16. En complément des équipements antichute, il

est essentiel pour la sécurité de l’opérateur et

du superviseur d’être équipé des protections

individuelles telles que : casque, lunettes de

protection, gants et chaussures de sécurité lors de

manipulations et utilisations de ce produit.

17. Le produit doit être utilisé exclusivement avec les

équipements associés décrits dans cette notice

(voir chapitre 8. Equipements associés).

18. L’utilisation de ce produit doit impérativement se

faire en présence d’au minimum deux opérateurs.

19. Ne pas utiliser plus de deux équipements associés

simultanément sur le produit.

20. Danger Lors de l’utilisation de plusieurs articles

dans lesquels la fonction de sécurité de l’un des

articles est susceptible d’aectée la fonction de

sécurité d’un article ou interfère avec celle-ci

21. Avant toutes utilisations il convient que le

superviseur et l’opérateur lisent et comprennent

les informations des notices des appareils EN1496,

EN360, la notice des embases permanentes

Davitrac et davimast et la notice de la potence.

1. Consignes prioritaires

1. Avant d’utiliser le produit, il est indispensable pour

la sécurité d’emploi du matériel et son ecacité que

le superviseur et l’opérateur lisent et comprennent

les informations dans la notice fournie par

TRACTEL SAS. Cette notice doit être conservée à

disposition de tous les opérateurs. Des exemplaires

supplémentaires peuvent être fournis sur demande

par Tractel®.

2. Avant d’utiliser ce matériel de sécurité il est

indispensable d’avoir reçu une formation à son

emploi. Vérier l’état du produit et des équipements

associés et assurez-vous que le tirant d’air est

susant.

3. Le produit ne peut être utilisé que par des opérateurs

formés et compétents ou par des opérateurs sous

la surveillance d’un superviseur.

4. Le produit ne doit pas être utilisé et doit être vérié

par TRACTEL SAS ou par un technicien habilité et

compétent qui doit autoriser par écrit la remise en

service du produit si :

• il n’est pas en bon état apparent

• Sa sécurité est mise en doute,

• il a servi à l’arrêt d’une chute

• il n’a pas fait l’objet d’un examen périodique au

cours des douze derniers mois, la sécurité de

l’utilisateur est liée au maintien de l’ecacité et à

la résistance de l’équipement.

5. Un contrôle visuel avant chaque utilisation est

recommandé, l’opérateur doit s’assurer que chacun

des composants est en bon état de fonctionnement,

en particulier vérier l’état et la présence sur le mât

de la bague de rotation du mât. Lors de sa mise

en place, il ne doit pas y avoir de dégradation des

fonctions de sécurité.

6. Toute modication ou adjonction au produit ne peut

se faire sans l’accord préalable écrit de TRACTEL

SAS. L’équipement doit être transporté et stocké

dans son emballage d’origine.

7. Si la masse de l’opérateur augmentée de la masse

de son équipement est comprise entre 100 kg et

150 kg, il est impératif de s’assurer que cette

masse totale n’excède pas la capacité maximale

d’utilisation de chacun des éléments constituant le

système d’arrêt des chutes.

Other manuals for Blocfor

1

This manual suits for next models

2

Table of contents

Languages:

Popular TV Mount manuals by other brands

PEERLESS

PEERLESS Smartmount D-FPT-220 Installation and assembly

La Siesta

La Siesta SEGURO manual

Strong

Strong VersaMount SM-VM-ART1-IW-M installation manual

Dynamic Mounting

Dynamic Mounting Down and Out Mount Assembly & Installation Directions

arkitect

arkitect ATVBCT14 instruction manual

Stell

Stell SHO 7530 manual