SEA LEPUS 600 User manual

International registered trademark n. 804888

67410014 REV. 08 - 02/2023

SEA S.p.A.

Zona Industriale Sant’Atto - 64100 - Teramo - ITALY

Telephone: + 39 0 861 588341 - Fax: + 39 0 861 588344

www.seateam.com

LEPUS

MOTORIDUTTORE PER CANCELLI SCORREVOLI

MOTOR REDUCER FOR SLIDING GATES

MOTEUR POUR PORTAILS COULISSANTS

FRANÇAIS

ENGLISH

ITALIANO

11

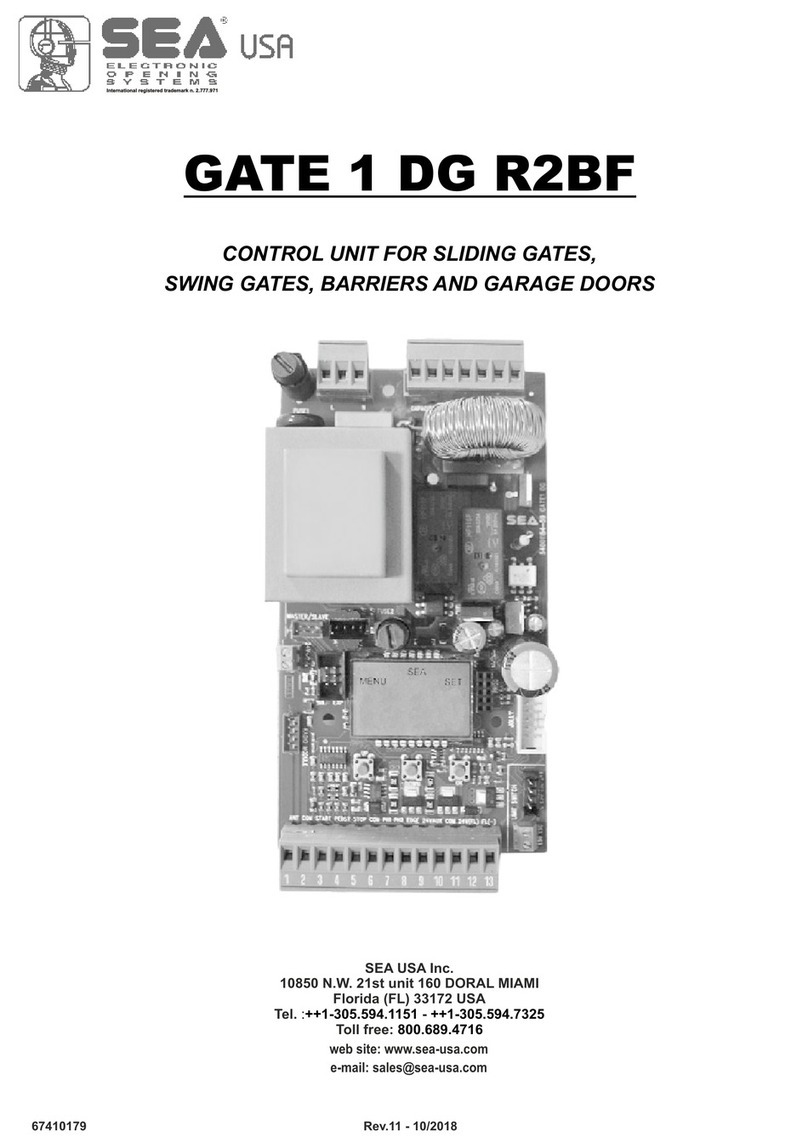

Fig. 1

1

2

3

4

5

67

8

9

347,5

325

160

LEPUS 110V

LEPUS 2000

THREE-PHASE LEPUS 2000

THREE-PHASE

2000 Kg

1600 Kg

600 Kg

800 Kg

75%

90%

60%

LEPUS

600

LEPUS

600

LEPUS 1600 LEPUS 1600

LEPUS

110V

Fig. 2

MAX. GATE WEIGHT

MAX. USAGE RATE

MOTORS

GENERAL FEATURES

COMPONENTS

APPLICATION CHART DIMENSIONS (mm)

LEPUS is an oil-bathed motor-reducer designed for the automation of sliding gates.

It is IRREVERSIBLE to allow a perfect and safe closing of the gate avoiding the installation of the electric lock.

It is equipped with a RELEASE SYSTEM - placed on the front part of the external box - allows the manual

opening and closing in the event of a power failure.

It is also equipped with an ADJUSTABLE MECHANICAL CLUTCH which guarantees the control of the gate thrust.

Moreover, the electronic inversion system through ENCODER, makes the LEPUS a safe and reliable

operator and allows to comply with the Laws in force in the Countries where the product is installed

1 ADJUSTABLE FOUNDATION PLATE

2 ANCHOR BOLTS

3 SIDE COVER

4 PINION

5 RELEASE LEVER

6 ADJUSTING SCREW FOR MECHANICAL CLUTCH

7 ELECTRONIC CONTROL UNIT

8 OIL FILLER CAP

9 MAGNETIC ENCODER

International registered trademark n. 804888

ENGLISH

12

230V (±5%) 50/60 Hz

115V (±5%) 50/60 Hz

330 W 450 W 650 W 330 W

25 µF 35 µF -80 µF

75% 60%

1400 rpm 1550 rpm

1÷30

-20°C +55°C

130°C

15 Kg 15,5 Kg

1,75 L

50 Nm 70 Nm 90 Nm 60 Nm

600 Kg 1600 Kg 2000 Kg 800 Kg

11 m

MECHANICAL IN OIL-BATH OR ELECTRONIC

MECHANICAL WITH LEVER OR INDUCTIVE

15 Kg

0,13 m/s

IP 55

0,175 m/s

0,2 m/s

!

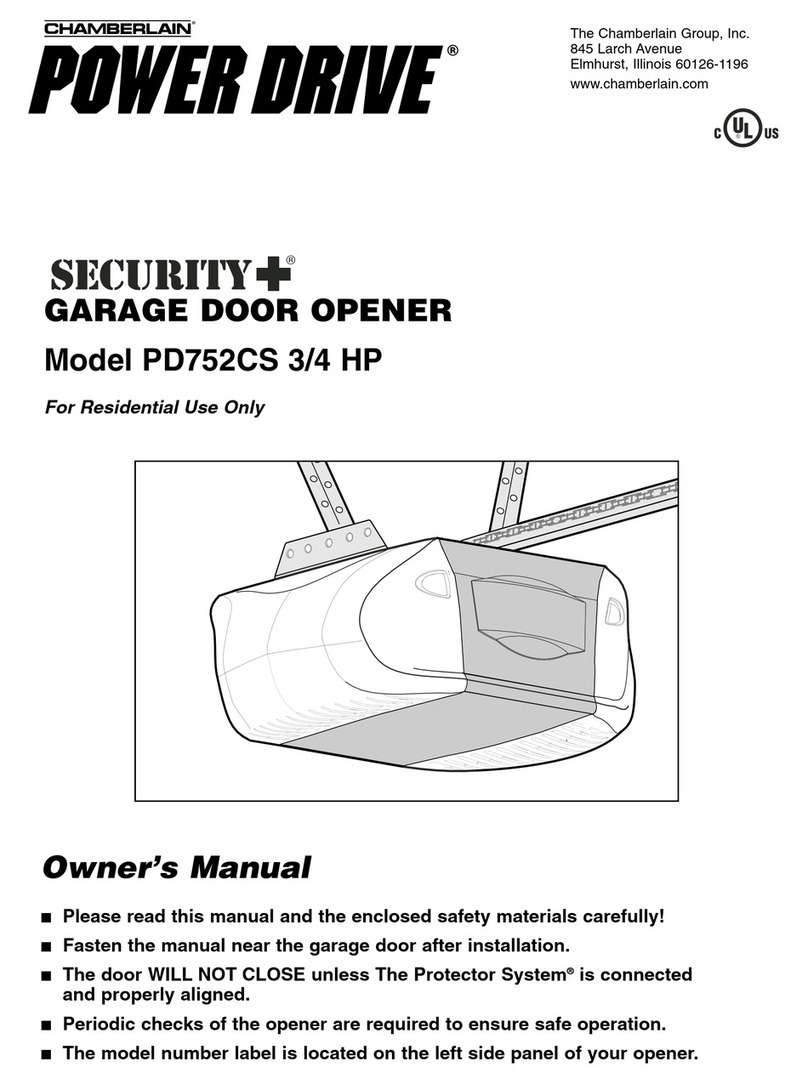

WARNING

Moving Gate Can Cause

Serious Injury Or Death

- KEEP CLEAR ! Gate may move at any

time without prior Warning.

- Do not let children operate the gate or

play in the gate area.

- This entrance is for vehicle only.

Pedestrians must use separate entrance

1

2

3

4

5

6

6

7

8

9

10

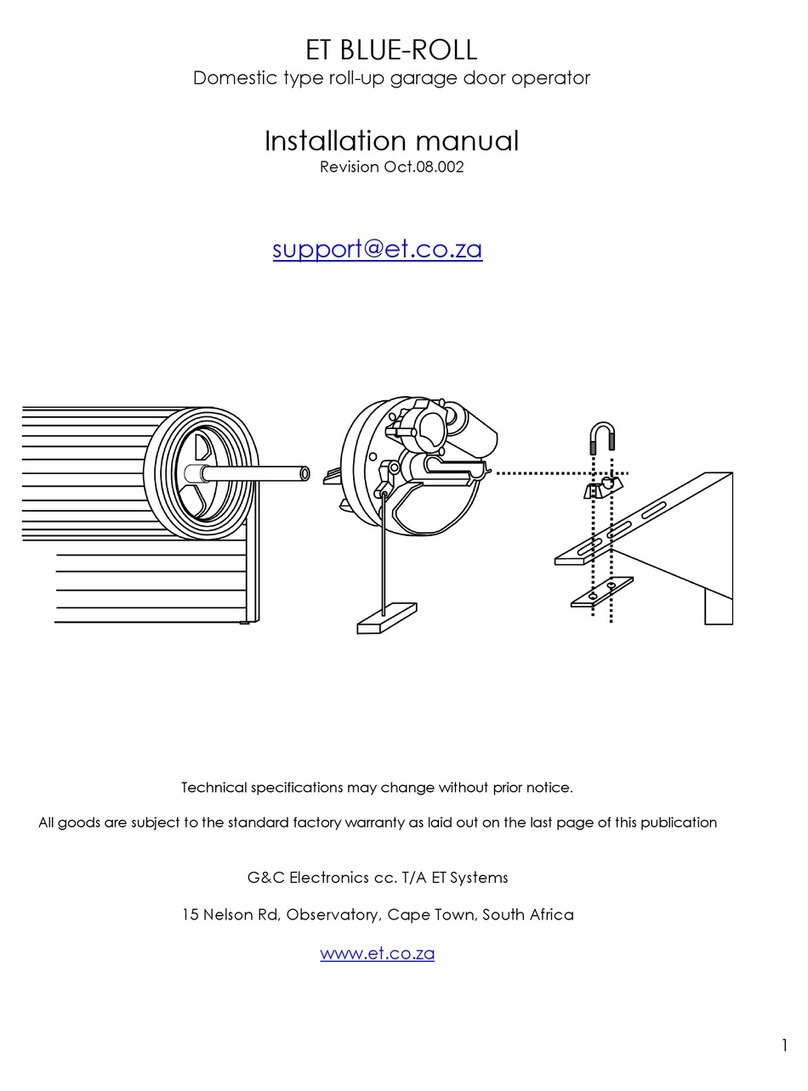

Fig. 3

The indicated usage rate is valid only for the first operating hour and at a 20°C temperature

LEPUS 600 LEPUS 1600 LEPUS 2000

TRIFASE LEPUS 110V

TECHNICAL DATA

POWER SUPPLY

MOTOR POWER

STARTING CAPACITOR

USAGE RATE

MOTOR ROTATION SPEED

REDUCTION RATIO

OPERATING TEMPERATURE

THERMAL PROTECTION

OPERATOR WEIGHT (WITH OIL)

OIL TANK CAPACITY

PROTECTION CLASS

Z13 PINION SPEED

Z16 PINION SPEED

Z20 PINION SPEED

MAXIMUM TORQUE

GATE MAX. WEIGHT

GATE MAX. LENGTH

ANTI-CRUSHING CLUTCH

LIMIT SWITCH

1) OPERATOR

2) PHOTOCELLS

3) FLASHING LAMP

4) SAFETY EDGE

5) KEY BUTTON

6) MECHANICAL STOPS

7) RECEIVER

8) JUNCTION BOX

9) DIFFERENTIAL SWITCH 16A/30mA

10) WARNING NOTICE

STANDARD INSTALLATION

International registered trademark n. 804888

ENGLISH

13

Z16

Z20

98 mm

108 mm

50-55

55-60

Max 5 mm

Fig. 5

Fig. 6

Q

150

65

350

200

Fig. 4

A

1 - GATE ARRANGEMENT

3 - PINION MOUNTING

Before the installation, check that all gate parts (fixed and mobile) have a strong and non-deformable

structure; also make the following checks:

a) The gate must be rigid and compact;

b) The lower gate slideway must be perfectly straight, horizontal and without any obstacles which could

obstruct the gate sliding;

c) The lower sliding wheels must be equipped with greasable or watertightened bearings;

d) The upper slideway must be perfectly straight and placed so that the gate could be in vertical position;

e) The mechanical stops of the gate must always be installed in order to avoid any possible derailment

To install the foundation plate it is necessary to:

2.1. Prepare a concrete basement according to the dimensions shown in Fig. 4; The foundation plate and

the anchor bolts must be concreted inside the basement

IF ALLOWED BY THE GATE STRUCTURE, IT IS RECOMMENDED TO LIFT THE FOUNDATION PLATE OF ABOUT 50mm

FROM THE GROUND, IN ORDER TO AVOID EVENTUAL WATER STAGNATION.

2.2. Before cementing the plate insert a flexible plastic pipe of at least 30 mm in diameter into the special

hole of the plate

2.3. Before concreting the plate, make sure that it is perfectly levelled and that the distance of 50 - 55 mm as

shown in Fig. 5 is respected

2 - INSTALLATION OF THE FOUNDATION PLATE

3.1. Insert the «A» pin into the gearmotor

shaft as shown in Fig. 3a

3.2. Mount the pinion and the two seegers

on the shaft of the gearmotor as shown in

Fig. 6

MIN. Q DIMENSION

PLINTH

ELECTRIC

CABLES

PIPE

DIMENSIONS IN mm

International registered trademark n. 804888

ENGLISH

14

ABC

Fig. 9 Fig. 10 Fig. 11

1,5 mm

Fig. 13

Fig. 12

4.1. Fix the gearmotor to the foundation plate by the use of the supplied screws - Fig. 7, then adjust its lateral

position and height - Fig. 8 - to comply with the dimensions mentioned in Fig. 5

4.2. Insert the two interlocking side covers - Fig. 7

Fig. 7 Fig. 8

4 - INSTALLATION OF THE OPERATOR

5 - GEAR RACK MOUNTING

ATTENTION! R

, - C 9

5.4. Make sure that all the gear rack elements are perfectly aligned and correctly placed (the teeth must be

in phase). It is suggested to oppose an element to two aligned elements as shown in Fig. 12;

5.5. Repeat the above described operation for all the remaining gear rack elements to be installed;

5.6. To avoid that the gate weights down the pinion - Fig.13 - lift up the whole rack about 1,5 mm.

Caution! - Keep a gap of about 0,5 mm between pinion tooth and gear rack tooth;

5.7. Make sure that the gear rack works at the midpoint of the pinion along all the rack elements, if

necessary, adjust the length of the spacers

5.1. Release the operator and open the gatecompletely;

5.2. Fix on each gear rack element the support pawls with the appropriate lock screws, making sure to put

them in the upper part of the hole - Fig. 9;

5.3. Lean the gear rack element on the toothed pinion of the operator in parallel to the ground slideway of the

gate, as shown in Fig. 10 and weld the central pawl B to the gate structure - Fig. 11.

Manually move the gate until pawl C is placed in front of the pinion and fix it through electric welding. Repeat

the same procedure for pawl A after having placed it in front of the pinion;

International registered trademark n. 804888

ENGLISH

15

50 mm

X

Fig. 14 Fig. 15 Fig. 16

Fig. 17

Fig. 18 Fig. 19

6 - LIMIT SWITCH INSTALLATION ON THE GEAR RACK

6.1.

- Fully open the gate

- : place the plate - Fig. 14 - on the rack according to the desired gate stop position; fix the

plate on the rack using the screws.

- : place the plate - F. 15 - on the rack according to the desired gate stop position;

fix the plate on the rack using the screws. Bring the inductive limit switch opening plate (indicated by an

arrow on the limit switch) in correspondence with point «X» of the plate on the rack (50 mm from the folded

side of the plate - Fig. 16).

6.2.

- Fully close the gate

- : place the plate - F. 14 - on the rack according to the desired gate stop position; fix the

plate on the rack using the screws.

- : place the plate - F. 15 - on the rack according to the desired gate stop position;

fix the plate on the rack using the screws. Bring the inductive limit switch closing plate (indicated by an arrow

on the limit switch) in correspondence with point «X» of the plate on the rack (50 mm from the folded side of

the plate - Fig. 16).

GATE

GATE GATE

F ,

International registered trademark n. 804888

ENGLISH

16

7 - INSTALLATION OF THE CHAIN SYSTEM

Fig. 20 Fig. 21 Fig. 22

45 mm

Fig. 23 Fig. 24

Fig. 25 Fig. 26

UNLOCK THE OPERATOR

BEFORE ADJUSTING THE

CHAIN TENSION!

GATE

GATE

BRACKET

CHAIN TENSIONER

OBLIGATORY PATH OF

THE CHAIN INSIDE THE

PINION UNIT

7.1. Secure two sturdy brackets at the two extremities of the gate for attaching the chain - Fig. 20

7.2. Install a chain tensioners on each bracket to adjust the chain tension - Fig. 20

7.3. UNLOCK THE OPERATOR USING THE SPECIAL RELEASE KEY - SEE CHAPTER 12

7.4. Install the chain on the chain tensioner at the end of the gate, pass it through the pinion unit, as shown in

Fig. 21 and hook it to the chain tensioner on the opposite side. Fig. 23 and Fig. 24 show the correct

installation, respectively, with open and closed gate. The chain must always be in line and equidistant from

the gate - Fig. 22; if not perfectly aligned - Fig. 25 and Fig. 26, derailments from the pinion unit may occur or

the operator could be damaged by excessive overheating due to effort

M . 45 mm - Fig. 22

International registered trademark n. 804888

ENGLISH

17

10 - CLUTCH ADJUSTMENT (OPTIONAL)

Fig. 32

A

Fig. 27

9 - BREATHER CAP REPLACEMENT (OR BREATHER SCREW REPLACEMENT *)

9.1. Before starting the operator, remove the red transport cap (or the transport screw) and replace it with the

black cap (or screw) supplied and equipped with the airhole

*

Fig. 28 Fig. 29

Fig. 30 Fig. 31

10.1. Switch off the electric power supply

10.2. To adjust the clutch, act on the grub

screw «A» - Fig. 32 - as follows:

- C = less clutch

sensitivity - more thrust force

- C- =

more clutch sensitivity - less thrust force

+ POWER

- SENSITIVITY

- POWER

+ SENSITIVITY

8 - GROUNDING

8.1. Before connecting the

operator to the power supply,

provide for its earthing, by the use

of the special earthing screw as

shown in Fig. 27

TRANSPORT

SCREW

*LEPUS

WITH ELECTRIC BRAKE BREATHER

SCREW

*LEPUS

WITH ELECTRIC BRAKE

BLACK

CAP

RED

CAP

THE VERSION WITH ELECTRIC BRAKE IS EQUIPPED WITH A BREATHER SCREW

International registered trademark n. 804888

ENGLISH

18

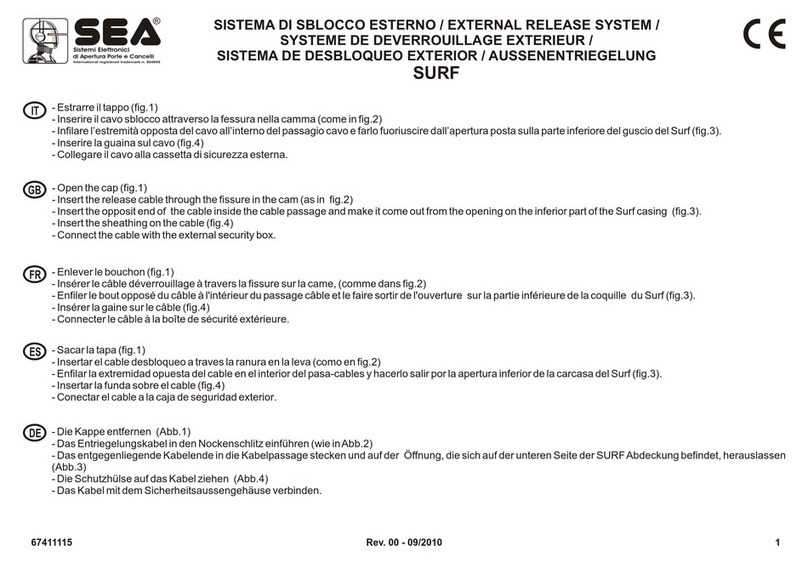

11 - EXTERNAL RELEASE SYSTEM - OPTIONAL

Fig. 33

11.1. An external release system

wired to a safety box can be

connected to the LEPUS operator,

as shown in Fig. 33

C

Fig. 34 Fig. 35

O

SAFETY

BOX

PART FOR BOTH INSTALLER AND END-USER

ALL THE UNLOCKING AND LOCKING OPERATIONS AND ALL PERIODIC MAINTENANCE OPERATIONS

MUST BE CARRIED OUT IN ABSENCE OF POWER SUPPLY!

12 - RELEASE SYSTEM

12.1. TO RELEASE THE OPERATOR

- Open the lock cover, insert the key and rotate 90° clockwise - Fig. 34

- Pull the release lever until it stops, about 90° - Fig. 35

when pulling the release lever, the control unit receives a safety stop impulse thanks to a micro-switch inside

the operator (anyway, it is higly recommended to switch OFF the power supply before)

12.2. TO LOCK THE OPERATOR

- Push the release lever to the complete closing

- Rotate the key counter-clockwise and extract it

- Close the protective lock cover

Once the lock has been restored the electronic control unit reactivates - if the power supply was ON!

CHECK THE OIL LEVEL (TRANSPARENT CAP ON THE SIDE OF THE BELL-SHAPED REDUCER)

CHANGE THE OIL

CHECK THE CORRECT OPERATION OF THE RELEASE SYSTEM

CHECK THE CORRECT OPERATION OF THE CLUTCH

CHECK THE DISTANCE BETWEEN PINION AND GEAR RACK (1.5 mm)

CHECK THE CONDITION OF THE PINION AND THE GEAR RACK (IF OVERUSED OR DAMAGED)

CHECK THE FIXING SCREWS

CHECK THE CONDITION OF THE ELECTRIC CABLES

CHECK THE OPERATION OF THE LIMIT SWITCHES AND THE CONDITION OF THE STOP PLATES

13 - PERIODIC MAINTENANCE - FOR INSTALLERS ONLY!

ALL OPERATIONS MUST BE CARRIED OUT EXCLUSIVELY BY AN AUTHORIZED INSTALLER

ALL OPERATIONS MUST BE CARRIED OUT IN ABSENCE OF POWER SUPPLY

ANNUAL

4 YEARS

ANNUAL

ANNUAL

ANNUAL

ANNUAL

ANNUAL

ANNUAL

ANNUAL

International registered trademark n. 804888

ENGLISH

19

International registered trademark n. 804888

GENERAL NOTICE

RISK EXAMINATION: The points pointed by arrows are potentially dangerous. The

installer must take a thorough risk examination to prevent crushing, conveying,

cutting, grappling, trapping so as to guarantee a safe installation for people, things

and animals (Re. Laws in force in the Country where installation has been made). As

for misunderstandings that may arise refer to your area distributor or call our help

desk. These instructions are part of the device and must be kept in a well known

place. The installer shall follow the provided instructions thoroughly. SEA products

must only be used to automate doors, gates and wings. Any initiative taken without

SEA explicit authorization will preserve the manufacturer from whatsoever

responsibility. The installer shall provide warning notices on not assessable further

risks. SEA in its relentless aim to improve the products, is allowed to make

whatsoever adjustment without giving notice. This doesn’t oblige SEA to upgrade the past production. SEA can not be

deemed responsible for any damage or accident caused by product breaking, being damages or accidents due to a failure to

comply with the instructions herein. The guarantee will be void and the manufacturer responsibility will be nullified if SEA

original spare parts are not being used. The electrical installation shall be carried out by a professional technician who will

release documentation as requested by the laws in force. Packaging materials such as plastic bags, foam polystyrene, nails

etc must be kept out of children’s reach as dangers may arise.

INITIAL TEST AND STARTING OF THE AUTOMATION: After having completed the necessary operations for a correct

installation of the product and after having evaluated all the risks which could arise in any installation, it is necessary to test

the automation to guarantee the maximum security and, in particular, to guarantee that the laws in force are fully

respected. The first Start must be executed according to the rule EN 12445 which establishes the methods of tests for

checking the gate automation respecting the limits established by the rule EN 12453

SAFETY PRECAUTIONS: All electrical work should comply with the current regulations. A 16A / 0,030 differential switch

must be used. Separate the source cables (operators, power supply) and command cables (photocells, push-buttons,

etc). Be sure the entire system is properly earth bonded. Always run cables in separate ducts to prevent interferences

INTENDED USE: The operator has been designed to be used for the automation of sliding gates only

SPARE PARTS: Send request for spare parts to: SEA S.p.A. - Teramo - ITALY - www.seateam.com

SAFETY AND ENVIRONMENTAL COMPATIBILITY: Don’t waste product packing materials and/or circuits

STORAGE: T = -30°C/+60°C ; Humidity = min. 5% / max. 90% (without condensation); Materials must be properly

packaged, handled with care and with appropriate vehicles

WARRANTY LIMITS - see the sales conditions

MAINTENANCE AND DECOMMISSION: must only be carried out by specialised and authorised personnel

THE MANUFACTURER CAN NOT BE DEEMED RESPONSIBLE FOR ANY DAMAGE OR INJURY CAUSED BY

IMPROPER USE OF THIS PRODUCT

SEA S.p.A. reserves the right to make any required modification or change to the products and/or to this manual without any

advanced notice obligation.

1. Read carefully these Instructions before beginning to install the product. Store these instructions for future reference

2. Don’t waste product packaging materials and /or circuits

3. This product was designed and built strictly for the use indicated in this documentation. Any other use, not expressly indicated here, could compromise the good

condition/operation of the product and/or be a source of danger. SEA S.p.A. declines all liability caused by improper use or different use in respect to the intended one.

4. The mechanical parts must comply with Directives: Machine Regulation 2006/42/CE and following adjustments, Low Tension (2006/95/CE), Electromagnetic

Consistency (2004/108/CE); Installation must respect Directives: EN12453 and EN12445.

5. Do not install the equipment in an explosive atmosphere.

6. SEA is not responsible for failure to observe Good Techniques in the construction of the locking elements to motorize or for any deformation that may occur during the

use

7. Before attempting any job on the system, cut out electrical power and disconnect the batteries. Be sure that the earthing system is perfectly constructed, and connect

to it the metal parts of the gate

8. Use of the indicator-light is recommended for every system, as well as a warning sign well-fixed to the frame structure.

9. SEA declines all liability concerning the automated system safety and efficiency, if components used are not produced by SEA

10. For maintenance, strictly use original parts by SEA.

11. Do not modify in any way the components of the automated system.

12. The installer shall supply all information concerning the system manual functioning in case of emergency and shall hand over to the user the warnings handbook

supplied with the product.

13. Do not allow children or adults to stay near the product while it is operating. The application cannot be used by children, by people with reduced physical, mental or

sensorial capacity or by people without experience or necessary training. Keep remote controls or other pulse generators away from children, to prevent involuntary

activation of the system.

14. Transit through the leaves is allowed only when the gate is fully open.

15. The User must not attempt to repair or to take direct action on the system and must solely contact qualified SEA personnel or SEA service centers. The User can

apply only the manual function of emergency.

16. The power cables maximum length between the central engine and motors should not be greater than 10 m. Use cables with 2,5 mm2 section. Use double

insulation cable (cable sheath) to the immediate vicinity of the terminals, in particular for the 230V cable. Keep an adequate distance (at least 2.5 mm in air), between the

conductors in low voltage (230V) and the conductors in low voltage safety (SELV) or use an appropriate sheath that provides extra insulation having a thickness of 1 mm

PART FOR BOTH INSTALLER AND END-USER

29

International registered trademark n. 804888

DECLARATION OF CONFORMITY

DICHIARAZIONE DI CONFORMITÀ

SEA S.p.A. declares under its proper responsability and, if applicable, under the responsability of its

authorised representative that, by installing the appropriate safety equipment and noise filtering,

the products:

La SEA S.p.A. dichiara sotto la propria responsabilità e, se applicabile, del suo rappresentante autorizzato che, con

l’installazione degli adeguati dispositivi di sicurezza e di filtraggio disturbi, i prodotti:

DESCRIPTION - DESCRIZIONE MODEL - MODELLO TRADEMARK - MARCA

- are built to be integrated into a machine or to be assembled with other machinery to create a

machine under the provisions of Directive 2006/42/CE;

- comply with the essential safety requirements related to the products within the field of

applicability of the Community Directives 2014/35/UE and 2014/30/UE

- sono costruiti per essere incorporati in una macchina o per essere assemblati con altri macchinari per costruire una

macchina ai sensi della Direttiva 2006/42/CE;

- sono conformi ai requisiti essenziali di sicurezza relativi ai prodotti entro il campo di applicabilità delle Direttive

Comunitarie 2014/35/UE e 2014/30/UE

THE MANUFACTURER OR THE AUTHORIZED REPRESENTATIVE

IL COSTRUTTORE O IL RAPPRESENTATE AUTORIZZATO

SEA S.P.A.

ZONA INDUSTRIALE SANT’ATTO

64100 - TERAMO - ITALY

+ 39 0 861 588341

www.seateam.com

PLACE AND DATE OF ISSUE

LUOGO E DATA DI EMISSIONE

TERAMO, 06/09/2022

SEA

LEPUS 600

(AND ALL ITS BY-PRODUCTS - E TUTTI I SUOI DERIVATI)

LEPUS 1600

(AND ALL ITS BY-PRODUCTS - E TUTTI I SUOI DERIVATI)

LEPUS 2000 THREEPHASE - TRIFASE

(AND ALL ITS BY-PRODUCTS - E TUTTI I SUOI DERIVATI)

11102025

11110500

11110300 SEA

SEA

SEA S.p.A.

Zona Industriale Sant’Atto - 64100 - Teramo - ITALY

Tel. +39 0 861 588341 r.a. Fax +39 0 861 588344

www.seateam.com

International registered trademark n. 804888

This manual suits for next models

3

Table of contents

Other SEA Garage Door Opener manuals

SEA

SEA USER 1 - 24V DG R1B User manual

SEA

SEA TAURUS RACK Series User manual

SEA

SEA SURF Series User manual

SEA

SEA SATURN 24V 1500 Quick start guide

SEA

SEA USER 1 User manual

SEA

SEA BLEU B200 User manual

SEA

SEA STAR 500 User manual

SEA

SEA SURF User manual

SEA

SEA FLIPPER Instruction manual

SEA

SEA Compact 400 Instruction manual

Popular Garage Door Opener manuals by other brands

Automatic Technology

Automatic Technology GDO-6 EasyRoller owner's manual

SOMFY

SOMFY Elixo 500 230 V installation manual

Steel-Line

Steel-Line SD800 Installation and operating instructions

Wisniowski

Wisniowski AWso2018 Assembly and operating instructions

B&D

B&D Series 2 Firmadoor installation instructions

Chamberlain

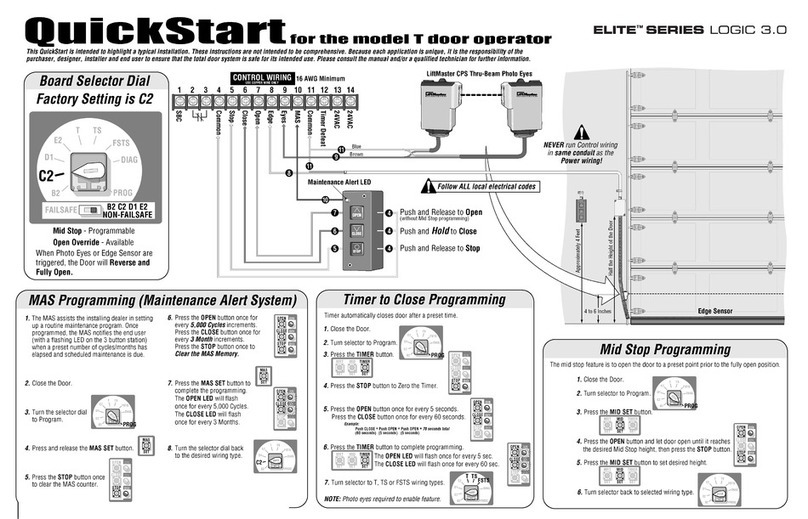

Chamberlain T quick start guide