Bernal Sensor-Line S 401 User manual

Instruction manual

Sensor-Line S 401

Please keep this manual in a safe place.

S 401 GB - 1 - 03-06

G

B

B 190.028-GB

S 401 GB - 2 - 03-06

Index

1.0 Technical Data .................................................................................................... 3

2.0 General Instructions........................................................................................... 4

2.1 General safety instructions................................................................................ 4

2.2 Designated use................................................................................................. 4

2.3 Indication for operating...................................................................................... 4

3.0 Drive assembly ................................................................................................... 6

3.1 Scope of supply................................................................................................. 6

3.2 Required tools ..................................................................................................... 6

3.3 Installation requirements....................................................................................... 6

3.4 Assembly ............................................................................................................ 7

3.5 Installation......................................................................................................... 9

3.6 Initial operation................................................................................................ 13

3.6.1 Insert red/green light module.................................................................... 13

3.6.2 Functions and connections....................................................................... 14

3.6.3 Set-Up...................................................................................................... 15

3.6.3.1 Adjustment of force and travel ........................................................................15

3.6.3.2 Individual adjustments.....................................................................................15

3.6.4 Perform safety check................................................................................ 18

3.6.5 Warning notices........................................................................................ 18

3.6.6 Radio........................................................................................................ 18

3.6.6.1 Installation of the radio....................................................................................18

3.6.6.2 Set-Up of the radio.........................................................................................18

3.6.6.3 Testing the radio .............................................................................................18

4.0 Maintenance...................................................................................................... 19

5.0 Demounting and disposal................................................................................ 19

6.0 Failure analysis................................................................................................. 20

7.0 Operating Instructions radio system PICO, 868,5 MHz................................. 21

8.0 TÜV-Certificate.................................................................................................. 22

9.0 TÜV-Doors......................................................................................................... 22

10.0 EC-Manufacturer's Declaration ..................................................................... 23

11.0 EC- Manufacturer’s Declaration according to EC Directive........................ 24

12.0 Handing over................................................................................................... 24

S 401 GB - 3 - 03-06

1.0 Technical Data

Description S 401-60 S 401-80 S 401-100 S 401-120

standard circuit

board B 300.01

head

variations

optional red /

green light mod-

ule (red / green

light red/ green,

230VAC, 50Hz,

1A)

B 300.04

electric supply 230 V / 50 Hz

temporary peak load max. 600 N max. 800 N max. 1000 N max. 1200 N

motor voltage

circuit board voltage 0 – 24 VDC

motor power max. 110 W max. 120 W max. 150 W max. 180 W

tractive- /pressure power max. 600 N max. 800 N max. 1000 N max. 1200 N

switch-on-time 30%

speed (without load) max. 14cm/sec

lighting 40W/230V (E14)

duration of lighting 30-180 sec

Radio (standard delivery) 868,5 MHz

ambient temperature -20°C/ +40°C

idle running – power loss < 1 W

fusible cut-out F1:3,15AT/250V

F2:6,3AT/250V F1:3,15AT/250V

F2:6,3AT/250V F1:3,15AT/250V

F2:10AT/250V F1:3,15AT/250V

F2:10 AT/250V

minimum mounting height 35 mm

overall drive length 3,31 m

head height 145 mm

ca. weight (with 3,00m rail) ca. 18 kg

travel path (with 3,00m rail) 2,40 m (with extension up to 5,4 m possible)

max. area of door (smooth

running, good balanced doors) 8 m² 10 m² 12 m² 14 m²

S 401 GB - 4 - 03-06

2.0 General Instructions

This instruction manual is being released by

BERNAL without any warranty.

BERNAL reserves the right to make changes

or modifications on the equipment at any time

and on this manual without giving any prior

notes.

2.1 General safety instructions

Important Safety Instructions:

Qualified personnel should only

perform the assembly and installa-

tion of the garage door opener.

Faulty installation may lead to serious inju-

ries! Disconnect power plug before any

work on the device is done. (except on test

and learning procedures) !

On installation the relevant regula-

tions for the operational safety act

/ employers mutual insurance as-

sociation have to be followed, e.g. UVV, DIN

EN 60335-1 and VBG4.

The electro installation has to be

performed by a qualified electri-

cian, and has to conform to the

relevant industrial safety regulations, ac-

cording to DIN VDE 0100 and DIN VDE 0113.

The power point must be easily accessible

and at a max. distance of 50cm from the

opener head.

Do not operate the garage door

opener at all, until it is confirmed,

that the garage door is in accor-

dance with the safety norm 98/37/EG and a

valid EC-Declaration of Conformity certifi-

cate is issued.

.

An improper installation or any change to the

opener without the manufacturers previous

approval, any warranty or product liability is

null and void. The installation has to be per-

formed in accordance with this instruction. The

installation of foreign elements endangers the

safe operation of the opener and is not permit-

ted.

You have to pay attention that the relevant na-

tional VDE-regulations for operating electrical

appliances are strictly adhered to.

We do not take any responsibility for the im-

proper operating or maintenance of the door,

accessories and the opener.

2.2 Designated use

The garage door opener is designed only for

the operation with well-balanced swing- and

sectional doors in the non-commercial sector.

The recommended max. door measurements

are listed under 1. Technical Data. The door

has to be in accordance with the valid specifi-

cations (e.g. DIN EN 12604 and DIN EN

12605). Before mounting the opener, check

that the door can to be easily moved by hand.

FOR THE SAFETY AND LIFE OF PER-

SONS IT IS ABSOLUTELY NECESSAR

Y

TO FOLLOW ALL INSTRUCTIONS.

KEEP THESE INSTRUCTIONS

The opener is designed for the operation in dry

rooms.

The garage ceiling has to be constructed, so

that a safe attachment of the opener is as-

sured.

2.3 Indication for operating

For garages without a second entrance, a

emergency release is necessary. A function

test of the emergency release has to be car-

ried out monthly!

Do not hang on the cord of the emergency re-

lease with your weight!

Make sure, that the emergency release of the

opener does not collide with the roof rack or

any protrusions of the vehicle or the door.

Instruct all persons, who are using the ga-

rage door and opener, about a safe and

proper handling. Demonstrate and test the

reversion (with a 50 mm high obstacle at

max. 150 N) as well as the mechanical

unlocking.

Operate the door only, when you can see

the whole door area unobstructed. Pay at-

tention, that there are no persons or any

objects in the door operating area.

Wait until the door stands still. Persons or

vehicles are only allowed in door operating

area, when the door is completely open and

at standstill.

S 401 GB - 5 - 03-06

oor, opener and extra installed safety ac-

ttention: an shut down faster with weak,

hen service- or adjustment work is ur-

Do not permit children to

play with the automated ga-

rage door. Transmitters are

to be kept safe and away

from children !

Fixed accessories (like key switch or simi-

lar) have to be attached in sight of the door.

The accessory distance to the moving parts

of the door, and at a minimum mounting

height of 1,80m. Accessories have to be in-

stalled beyond the reach of children! Alert

stickers against pen in have to be put close

to the fixed key switch.

D

cessories have to be checked regularly.

See chapter 4 maintenance.

A

The door c

broken or damaged springs or a defective

counterweight. Under this circumstances

using the emergency release may lead to

uncontrolled movements of the door.

W

gently required, do not use the opener . A

badly balanced door, or a faulty garage

door drive may cause damage and injuries.

S 401 GB - 6 - 03-06

3.0 Drive assembly

3.1 Scope of supply

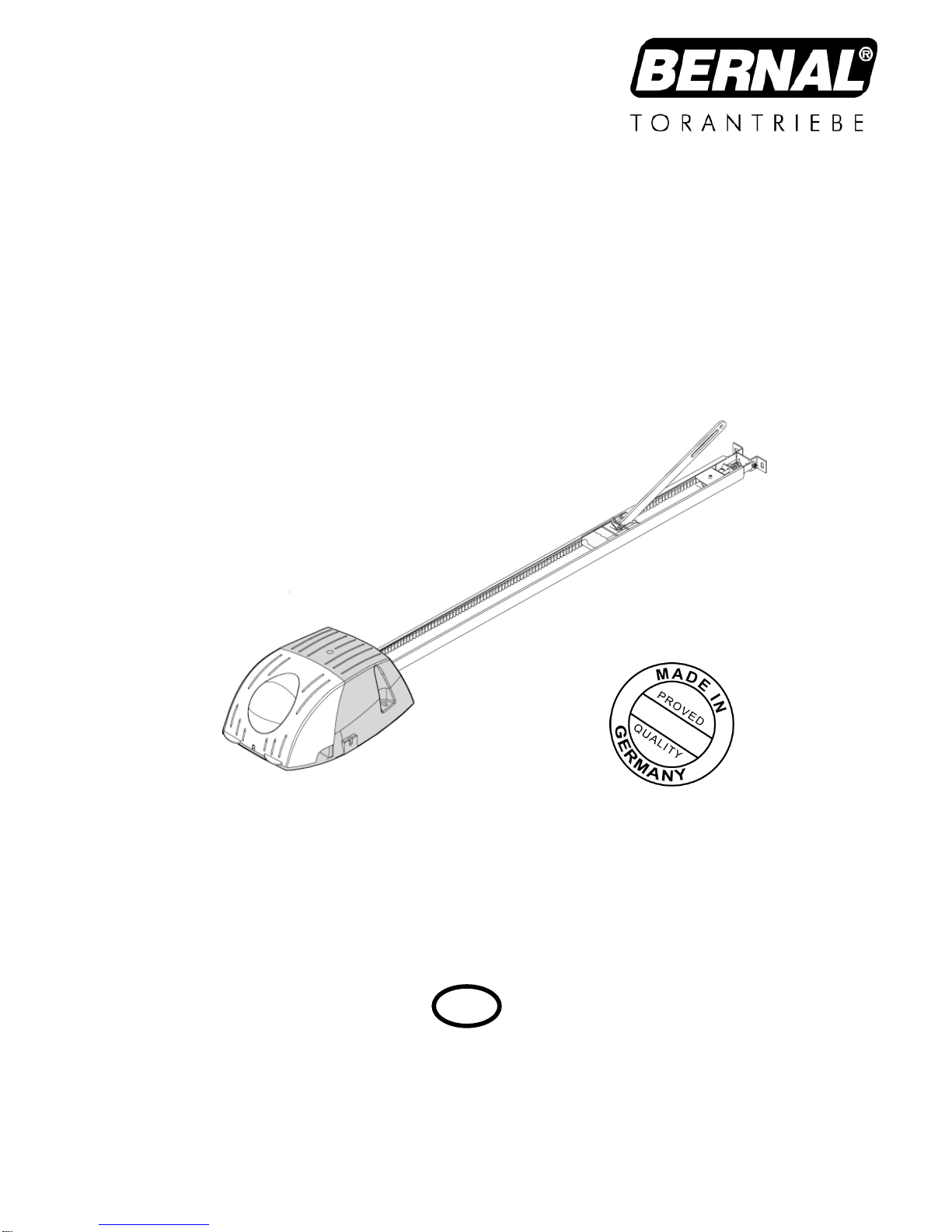

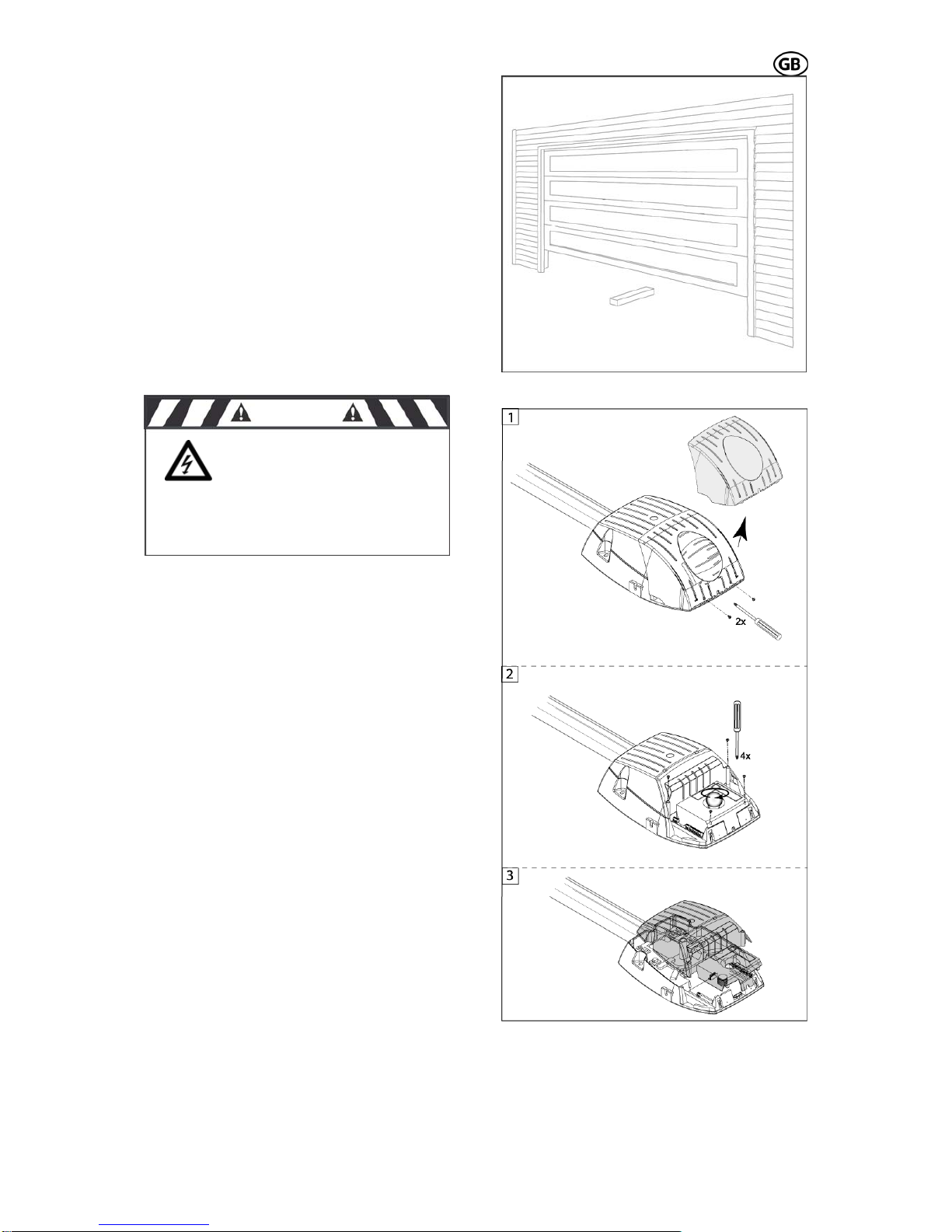

The scope of supply, as shown on the Fig. 1

and 2, may vary according to the drive ver-

sion.

3.2 Required tools

For the assembly und mounting of the drive

the tools shown in Fig. 3 are required (not in

the scope of supply).

3.3 Installation requirements

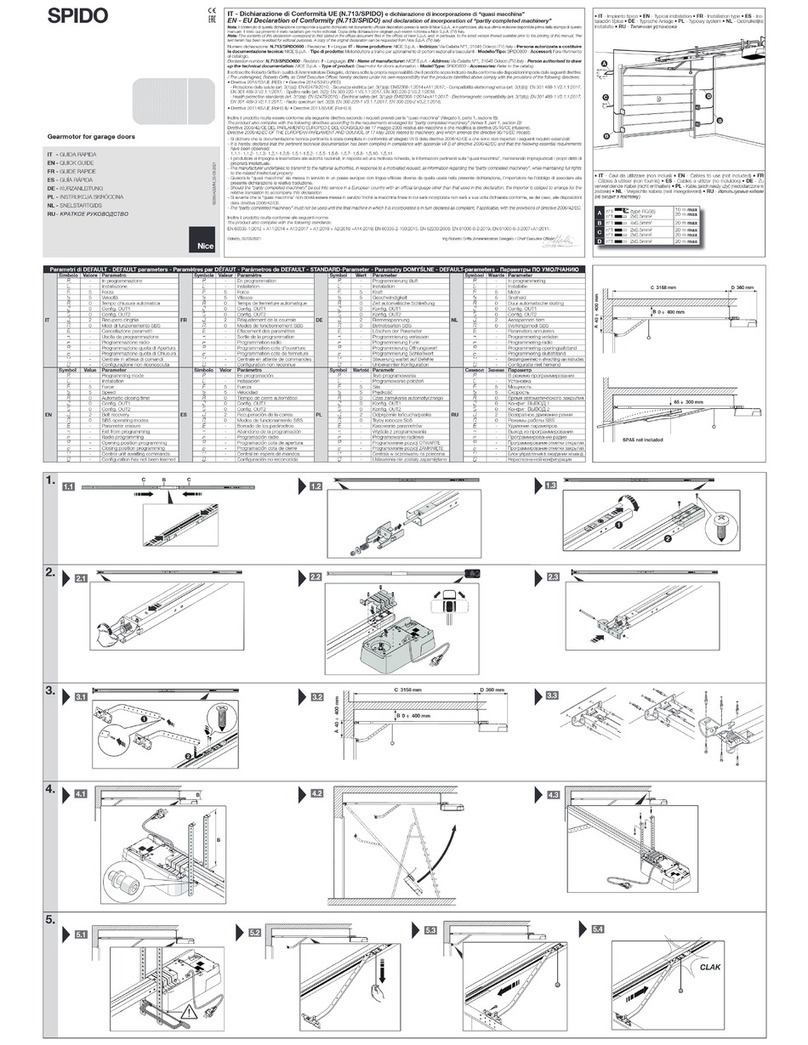

The garage door opener is suitable for the

automation of spring balanced swing doors

(Fig. 4a) and sectional door (Fig. 4c).

(max. sizes see 1.0 technical data).

For an optimal attachment of the push rod to

the sectional door, a sectional door attachment

is available as an accessory.

For doors, that are non-protruding up-and-

over, a curved arm is available as accessory.

(Fig. 4b)

For the mounting a minimum lintel height of 35

mm is necessary (Fig. 4).

Fig.1

CAUTION

IMPORTANT INSTRUCTIONS FOR A

SAFE MOUNTING

ATTENTION – INCORRECT MOUNTING

MAY LEAD TO SERIOUS INJURY – ALL

MOUNTING INSTRUCTIONS HAVE TO

BE FOLLOWED

Fig. 2

Fig. 3

Fig. 4

3.4 Assembly

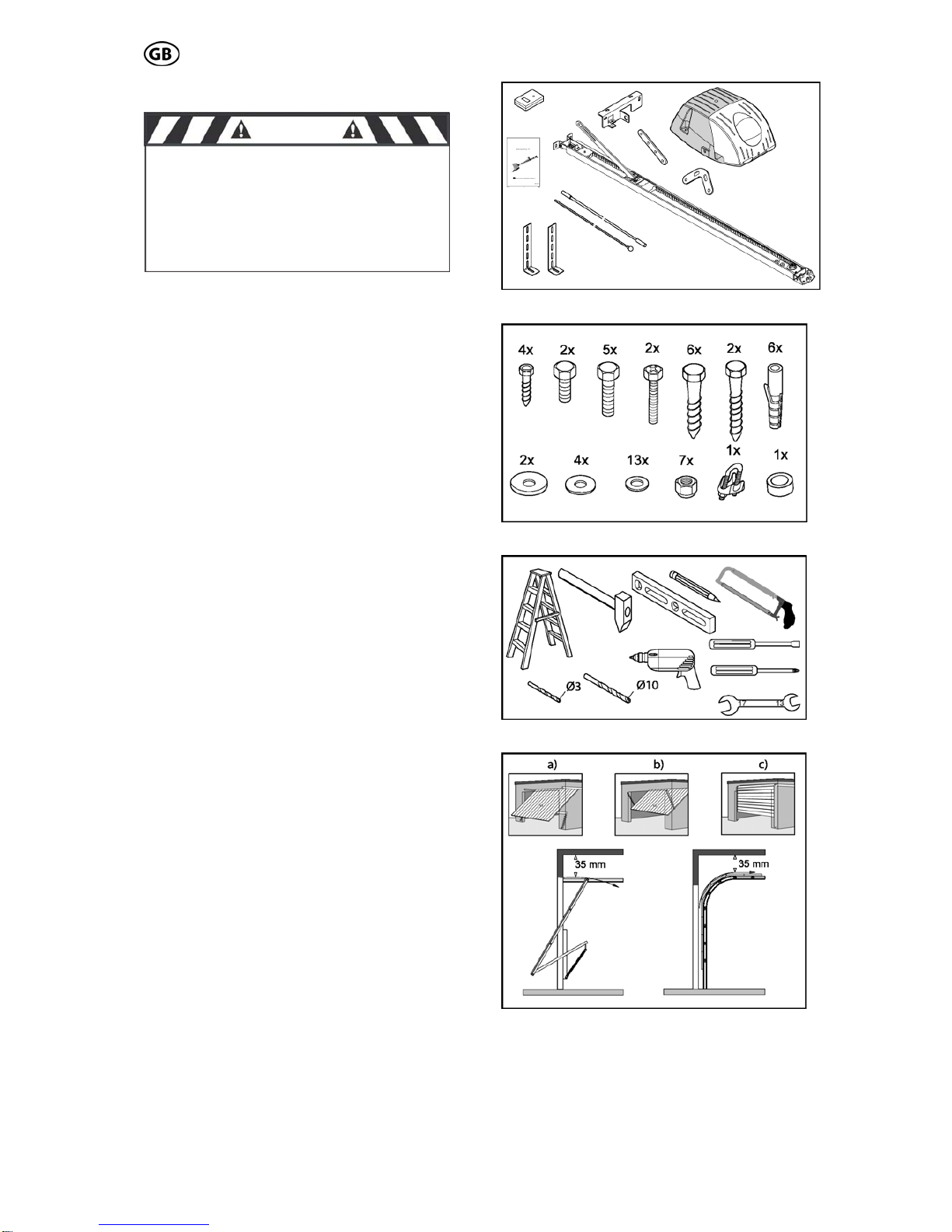

Pre-assembly of rail

According to the version, the rails have to be

pre-mounted as requirements.

Put the rails together via the connection rail.

(Fig. 5) Slide the rails together to the stop posi-

tion.

Pull the rear bracket (Fig. 6.1) together with the

belt (Fig. 6.2) out of the rail. Remove the

transportation covering (Fig. 6.3) and press the

pinion (Fig. 6.4) into the bearing. Take care of

the belt not being squeezed. Then attach the

transportation covering again and push the

complete rear bracket back into the rail.

S 401 GB - 7 - 03-06

Adjust the tension of the chain or belt by pull-

ing the idler wheel towards the chain end.

Make sure, that the chain lock (Fig. 7a) is on

the left side of the rail. (Fig. 7)

Then push the tensioning bracket towards the

end of the chain and guide the coach bolt

through the hole of the tensioning bracket. Pay

attention that the coach bolt fits into the ten-

sioning bracket.

Push the provided spring and washer on the

end of the coach bolt and screw the nut on the

coach bolt. (Fig. 8)

Paste rubber buffers

If you have a chain drive, we recommend stick-

ing the provided rubber buffers to the inside of

the rail (Fig. 9c). Those serve to minimize the

noise caused, when the chain touches the rail.

Assure, that the rubber buffers are not in the

travel path of the trolley. The buffers have to

be put close to the end of the chain, so that the

trolley doesn’t touch them in door-closed- (Fig.

9a) or in door-open-position (Fig. 9b).

Fig. 5

Fig. 6

Fig. 7

Fig. 8

Fig. 9

S 401 GB - 8 - 03-06

S 401 GB - 8 - 03-06

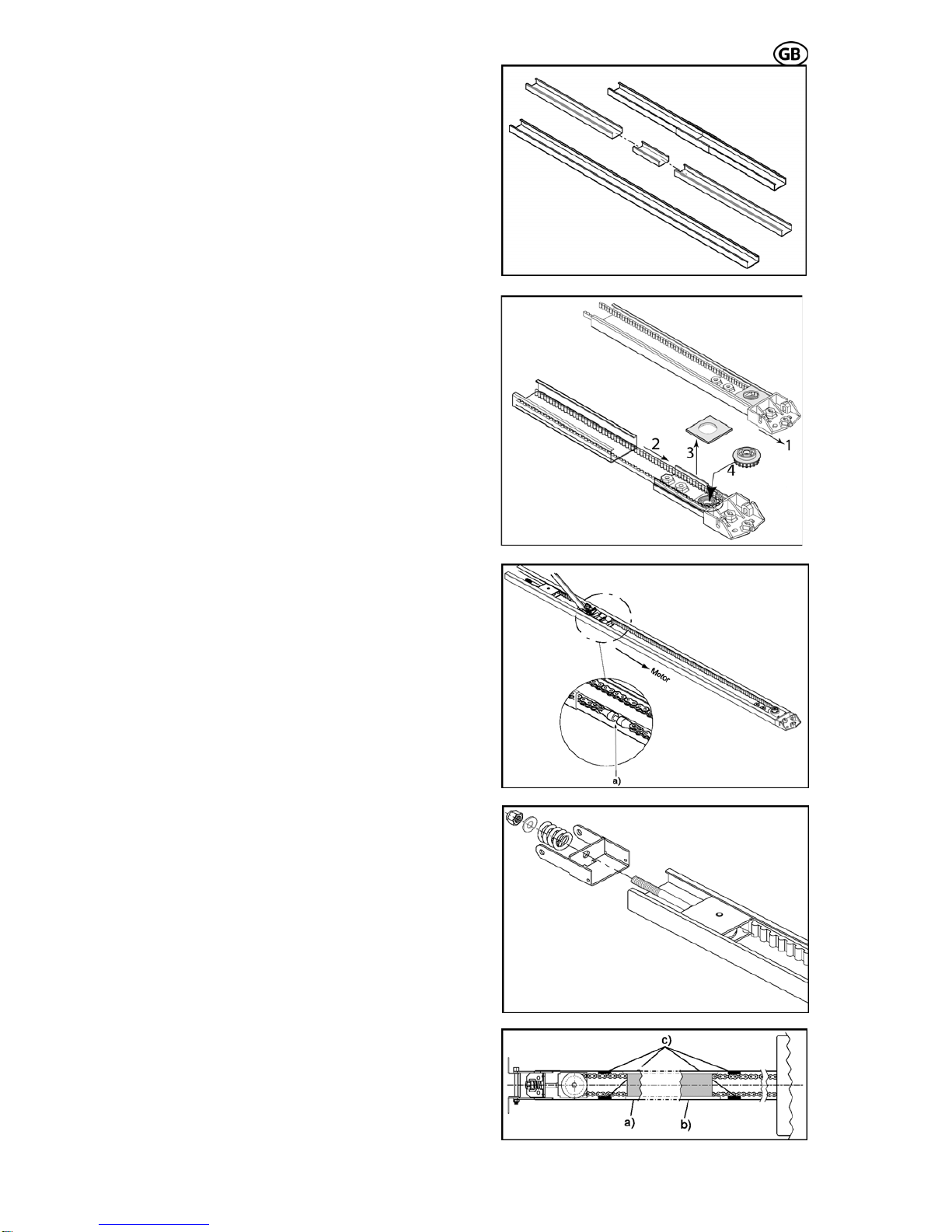

sion chain / belt

Turn the nut to tension the chain or belt

slightly. Fig. 10).

Trolley test

Check afterwards, that the trolley can easily be

moved by hand. To release the trolley, from

the chain lock, pushes the lever on the trolley

and at the same time move the trolley in the

rail (Fig. 11).

Make absolutely sure, that after this test the

trolley engages on the chain lock. To perform

this, move the trolley without holding the lever

over the chain/belt lock and the trolley en-

gages automatically.

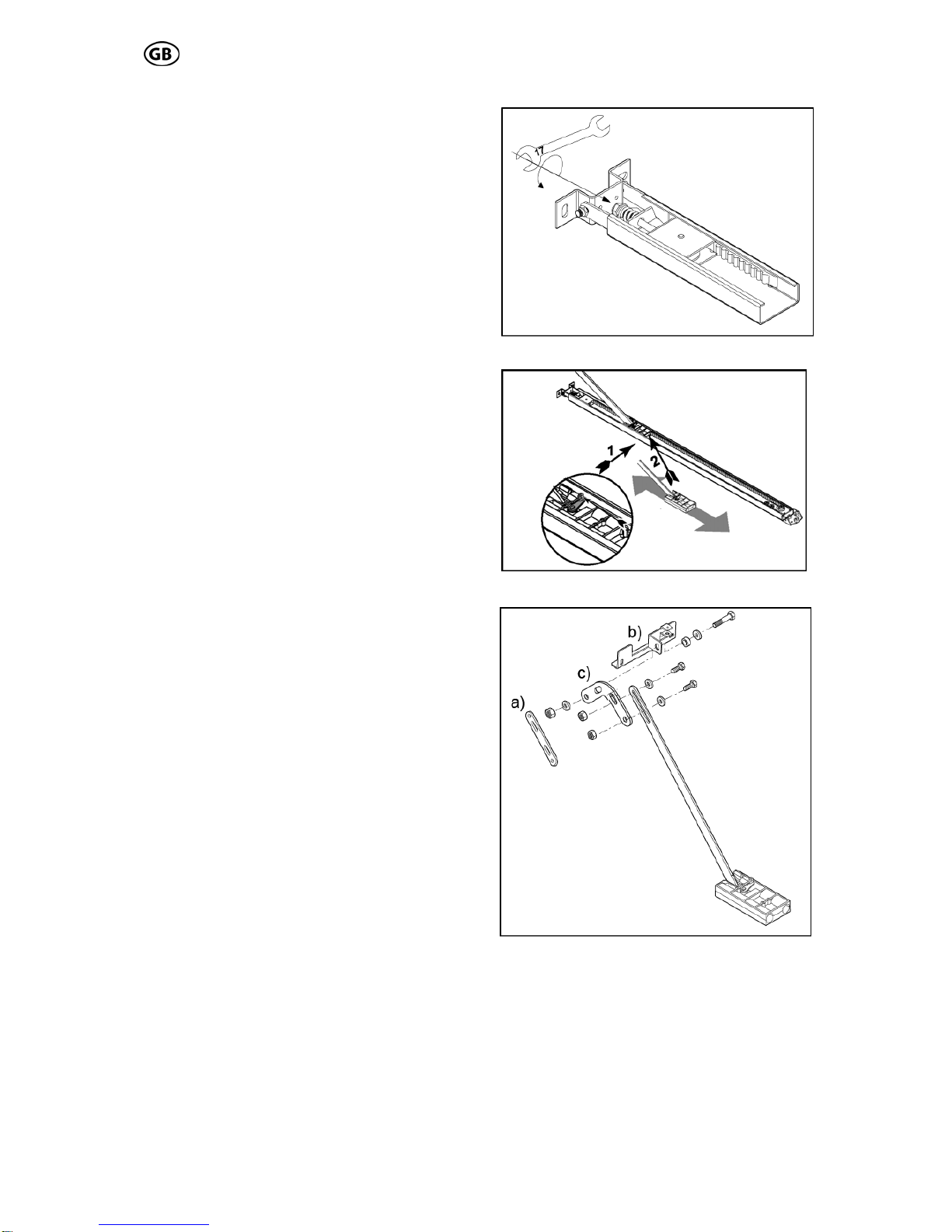

Assembly of door bracket

According to the installation situation the pro-

vided push rod components can be combined

as needed (Fig. 12).

If the length of the push rod is not sufficient, it

can be adjusted via the extension rod (Fig.

12a). In adoption with sectional doors, we rec-

ommend the use of a sectional door angle

(Fig. 12c). Then the provided door bracket

(Fig. 12b) has to be attached to the push rod.

For the assembly use the provided screws,

washers and nuts, and tighten them firmly.

Fig. 10

Pre-ten

Fig. 11

Fig. 12

S 401 GB - 9 - 03-06

3.5 Installation

Mark the middle of the door

Measure the width of the door and mark the

iddle of the door at the lintel. (Fig. 13)

alculation of the necessary height

est door point (Fig. 14.1)

he angle a(Fig. 15) may not exceed 30°; o-

se a correct transmission of the power is

ot guaranteed.

he distance between the lower edge of the

il and the upper edge of the garage door

hould be between 5 and 7 cm in closed condi-

on.

m

C

The rail has to be mounted on such a height,

that between the high

(the highest point that the door can reach dur-

ing the movement) and the lower edge of the

rail, a clearance of at least 10-20 mm is avail-

able (Fig. 14.2).

Pay attention, that the rail is always mounted

at a level position.

T

therwi

n

T

ra

s

ti

Fig. 13

Fig. 14

Fig. 15

talling the drive all mechani-Before ins

cal locks of the door have to be put out

of order!

CAUTION

S 401 GB - 10 - 03-06

bracket

xtend the door measurements on the lintel,

so that the provid 16) is

exactly in the middle of the door and above the

required highest door position.

Us

lin

Attention:

Then attach the lintel bracket (Fig. 17) to the

lintel. (depending on the installation situation

e provided fastening screws have to be re-

laced by others).

hen fasten the rail to the lintel bracket with a

oach bolt and a lock nut (Fig. 18).

Mounting the lintel

Eed head bracket (Fig.

e a pen and mark the bracket holes on the

tel and drill the required holes (Fig. 16).

When drilling, cover the drive!

th

p

Attaching the rail to the head bracket

T

c

Fig. 16

Fig. 17

Fig. 18

Fixing of the retaining angle

S 401 GB - 11 - 03-06

g

e

(Fig. 19).

fterwards mark the points where the retaining

e

r

oles and affix the retaining

ngles to the ceiling (Fig. 20.1).

ttention: When drilling, cover the drive!

ttachment of the drive head

d shaft

n the collet of the return head (Fig. 20.2).

shown in Fig. 20.3 the drive head has to be

ttached with the 2 Phillips-screws and spring

ashers to the return head.

Bring the rail in a level position, fit the retainin

angles to the return head. Make sure, that th

rail is in a level position. The excess lengths of

the angles have to be sawed off

Attachment of the rail

A

angles shall be attached to the ceiling. Mak

sure, that the rail is aligned with the earlie

marked middle of the door.

Drill the required h

a

A

A

The next step is to insert the drive hea

o

As

a

w

Fig. 19

Abb. 20.1-20.3

- 12 - 03-06

belt

l the

hain or belt can be pushed together to

in the middle of the

il.

trolley, (Fig. 22.1)

or, where the

rill the required holes at the door and attach

, firmly to the

oor (Fig. 22.3 + 22.4).

se of an emer-

ency the door can be opened from outside.

he Bowden cable has to be moved through

e eye of the „key shaft“ and the mantle.

ig. 23.1 + 23.2) Afterwards the linkage has to

e moved through the door bracket (Fig. 23.2).

t the end of the installation of the Bowden

able has to be attached at the door handle

ig. 23.3).

is absolutely necessary, to check the correct

nction of the emergency release, before us-

g the garage door opener.

Before operating the garage door

opener: unlock the trolley and

open and close the door to the full

top by hand.

he trolley has to come to a full stop, be-

re bumping the drive head or the return

uide assembly, with the door in open /

losed position.

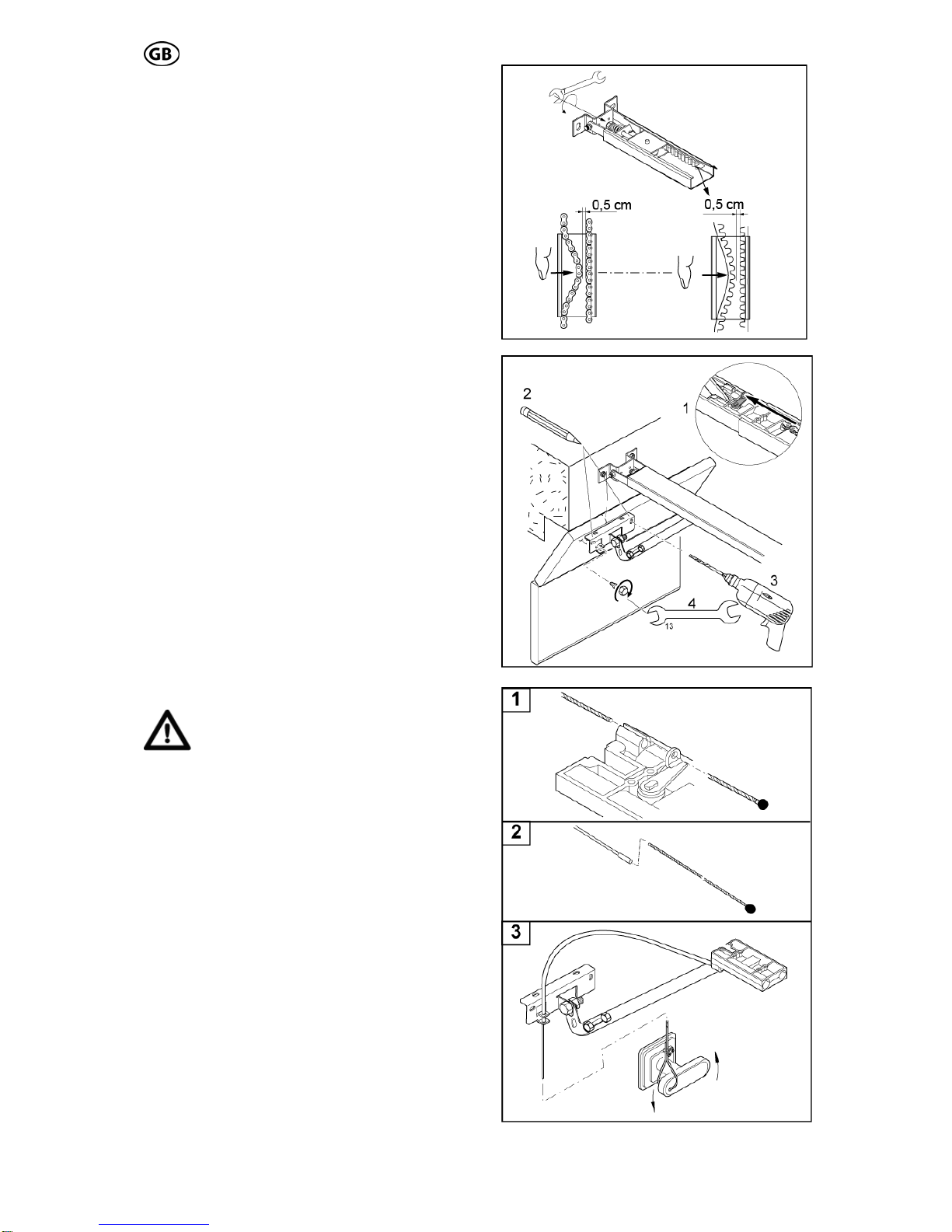

Adjust the tension of chain or

Turn the nut of the tension unit (Fig. 21), so

that the spring is completely compressed.

Than release the tension of the spring by turn-

ing the nut back about 1 to 2 turns, unti

c

approx. 0,5 cm distance

ra

Attachment of the door bracket assembly

First press the lever on the

and move the trolley towards the lintel.

Then mark the points of the do

door bracket shall be attached (Fig. 22.2).

D

S 401 GB

the door bracket, with 2 screws

d

Installing the emergency release

If the garage is without a second entrance, the

installation of a emergency release set is abso-

lutely necessary, so that in ca

g

T

th

(F

b

A

c

(F

It

fu

in

s

T

fo

g

c

Fig. 21

Fig. 22

Fig. 23

S 401 GB - 13 - 03-06

.6 Initial operation3

3.6.1 Insert red/green light module

If you want to insert the red/green light module,

you have to do the following steps:

At first, the 2 safety screws have to be re-

moved as shown in Fig. 24.1 and the light

screws of

cover has to be taken off.

Then turn out the light bulb and the 4

the cover (Fig. 24.2).

Now the cover can be taken off (Fig. 24.3) and

the red/green light module can be inserted

(correct position see Fig. 25 circuit board lay-

out).

The red/green light module has to be attached

with the provided screws on the circuit board,

and the heads of the screws have to be iso-

lated with the provided plastic covers (Fig.

24.4).

Then break out the pre-punched notch for the

red/green light module in the cover and reas-

semble the cover – screws – light bulb and

ght cover. Now plli ug the opener to the mains.

Abb. 24.1-24.4

CAUTION

Before removing the

light cover - disconnect the

power plug! 230V ~

CAUTION

The heads of the

screws must be isolated with the

ti

unde

plas c covers. The screws are

r 230 V mains voltage!

S 401 GB - 14 - 03-06

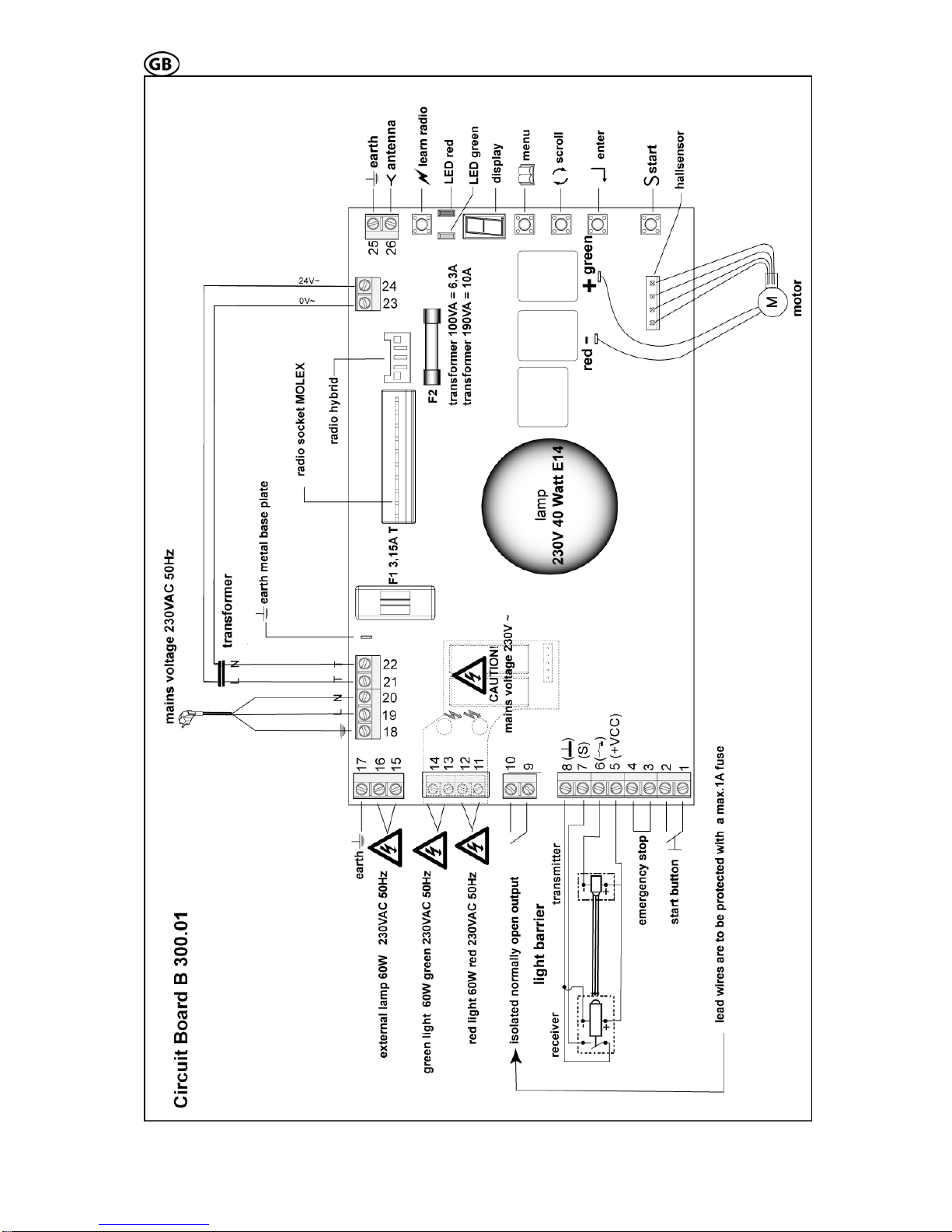

connections

e

hown in Fig. 25. For the activation and set-up

to be

nted.

The standard circuit board B 300.01 has the

follo

tion

Sta

term

The board, the start

button external and the radio receiver have the

ame function during operation (exception:

drive

oor

art button activates

the

g

mergency stop during door open move-

s to be applied. The connection ca-

le has to be laid fail safe. (e.g. with cable

type: ÖLFLEX-CLASSIC-100 2x,5mm²).

Light barrier with integra heck accord-

ing to safet

tr

te

te

re

te

terminal 7 (S): signal

rminal 8 (-): earth

sub point 4 has to be set on 1 (= active).

he receiver is always connected to the mains

ltage.

he transmitter is only active when the drive is

orking. When the drive is activated, the

ansmitter of the light barrier receives his volt-

ge.

he receiver is being activated via the

ansmitter diode and the signal of the light

arrier is switched on.

efore every start the function of the light bar-

er is being controlled.

there occurs an error on the light barrier,

ere is no start possible!

If the light barrier is activated during door clos-

ing, the drive stops and reverses (completely

or partially, according to the setting on the cir-

cuit board, menu point b1).

If there is an activation while the door opens,

there is no reaction.

CAUTION:

3.6.2 Functions and

The assembly as well as the connection- and

adjustment possibilities of the circuit board ar

s

of some connections (for example, light barrier,

safety edge, etc.) some individual adjustments

s described in paragraph 3.6.3 have

a

impleme

wing connection possibilities and func-

s:

rt button external terminal 1 (earth) and

inal 2 (signal)

start button on the circuit

s

learn function). With the start button the

can be started and stopped. During d

movement, pressing the st

the soft-stop.

Emergency stop terminal 3 and terminal 4

Wire jumper bridges terminal 3 and 4, if

emergency stop is not connected. Activatin

the e

ment, the drive is immediately stopped; when

activating while the door closes, the door stops

immediately with reversion.

If you are using a slip door, a fail safe slip door

contact ha

b

ted c

y category 2 EN 954

ansmitter:

rminal 5 (+): 80 mA / 24 V

rminal 6 (-): switched earth

ceiver:

minal 5 (+): 80 mA / 24 V

r

te

Light barrier is not connected: terminal 7 and 8

are open, Menu b sub point 4 has to be set on

0 (=inactive).When using a light barrier: menu

b

T

vo

T

w

tr

a

T

tr

b

B

ri

If

th

During the learn function, the light

barrier is not activated.

Connection safety edge 8,2 or 22 kOhm

When using a safety edge, the menu point b

sub point 5 has to be set on 1 (=active).

If there is no light barrier connected simultane-

ously (menu b sub point 4 =inactive) the safety

edge has to be just connected on terminal 7

and 8.

With an additional connected light barrier, the

safety edge has to be connected in-line with

the receiver signal of the light barrier (terminal

7) (in menu b the light barrier and the safety

edge have to be activated).

Isolated normally open output for door-

closed contact or connection warning lamp

on automatic closing terminal 9 and 10

230VAC / max 1A cos Phi = 1

30VDC/ max.1A

The external wires have to be protected with

max. 1A delay fuses.

a) Red / green light module is not installed:

When setting menu point b3 (automatic closing)

on 0 (=inactive) the clamps 9 and 10 are the

door-closed contact.

When setting b3 on 1 (=active) the terminals 9

and 10 are a isolated normally open output for a

warning lamp for automatic closing.

b) Red / green light module installed (optional)

The clamps 9 and 10 are generally door-closed

contact.

The setting of the pre-warning period automatic

closing is possible on menu point U or H (when

red / green light module is plugged).

The automatic closing period (opening period)

can be set on menu point A.

External lighting terminal 15 and terminal

16, 230 VAC/60W (max.)

t, according to the set adjust-

nu L, the internal and external

ht is on.

Connection earth terminal 17

Earth e.g. for external lighting

Connection antenna to terminal 25 and 26

To avoid interferences with the circuit board we

recommend generally: when using a pluggable

receiver (MOLEX 10-pol), connect the antenna

directly to the receiver. If this is not possible, a

rod antenna can be connected to clamps 25

and 26.

Attention: Operates only in connection with a

receiver plugged in the MOLEX-socket.

After every star

ent time at me

m

lig

S 401 GB - 15 - 03-06

iver

reaching the limit stops and breakpoints

1(PH) green : terminal 13(PH)

terminal12(N) terminal 14(N) g

returns, the pre-

Start (button on the circuit board)

1. Starting and stopping of the drive

2. Controls the drive during the learn function

(see menu).

Lighting internal 230 V / 40 W E14

Adjustment of the lighting period see menu point L.

Slot radio rece

10-pin MOLEX plug socket

Soft travel

Before

the soft travel is activated. An optimal, soft

starting and stopping of the door is achieved.

After any change in the soft travel set-up a

new power- and travel learning is necessary.

Optional module: red / green light module

terminal 11 to 14

2 relays (red, green) are provided for the red /

green light module.

red : terminal1

The pre-warning time for opening and closin

is adjustable at menu point H. At menu point b

sub point 6 red light can be switched to per-

manent lighting or blinking. After every power

failure with activated red / green light, the pre-

vious condition is being restored. At status pre-

warning, when the voltage

warning period is cancelled.

Function cycle of the red / green light control

Opening:

1. Door is closed

t blinks

ntly on (according to adjustment)

nently on

2. Start impulse

3. Pre-warning period on: red / green ligh

or is permane

4. Door opens: red light perma

5. Door is open: green light on

Closing:

1. Door is open

2. Start impulse or automatic closing

. Pre-warning period on: red / green light blinks

the menu press the

26

3

or is permanently red (according to adjustment)

4. Door closes: red light permanently on

5. Door closed: red / green light off

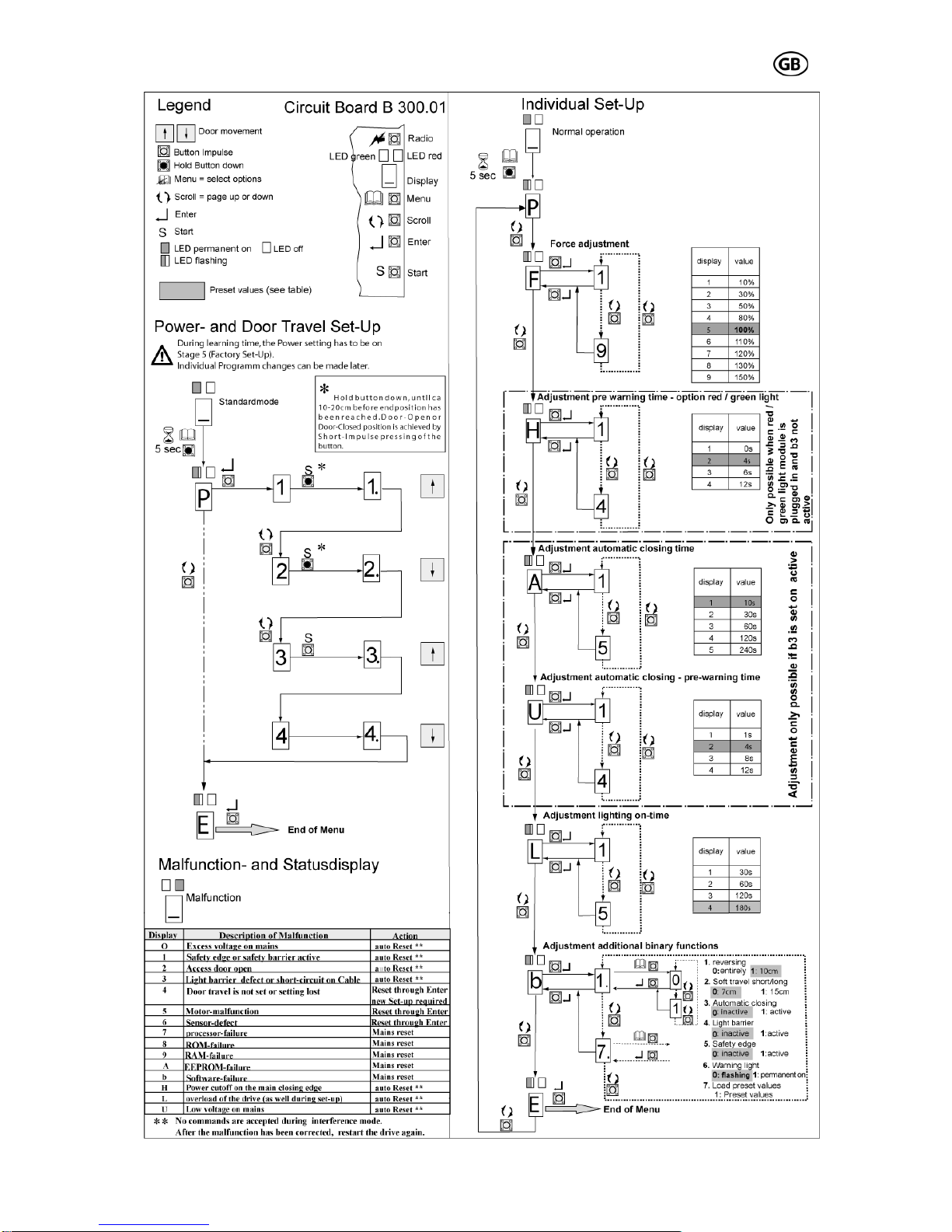

3.6.3 Set-Up

The menu structures of the different adjust-

ment possibilities are shown in Fig. 26.

Attention: After plugging the unit to the mains

wait until the green LED is permanent on, then

start set-up.

After pressing the menu button (about 5 sec.)

you get to the menu functions. With the scroll

button you can jump from one menu point or

adjustment value to the next one. When the

desired menu point or value is reached on the

display, it has to be confirmed by pressing the

nter button. For leaving

e

scroll button until it reaches the menu point E

and then confirm with the enter button.

3.6.3.1 Adjustment of force and

travel

For start-up procedure of the garage door

opener, it is absolutely necessary, to learn the

force and the travel path once (menu point P).

Follow the particular steps as shown in Fig.

(left side).

During the learning period, the end stops and

the necessary power at the different points of

door travel, are being defined by the hallsen-

sor and saved on the circuit board .

After the learning process, a test run should be

performed.

CAUTION: Make sure, that the dynamic clos-

ing power does not exceed 400N!

During the learning process, no analysis of the

light barrier and the overload is performed.

If the learning process is interrupted by emer-

gency stop, pulse length exceeding (e.g. con-

nection for pulse generator is missing) or start

button, the complete learning process has to

at can

sid

of F until the test-run is p

shu

CA

be repeated.

Manual adjustment of the power values

If you notice after the performed test run, that

the power has to be changed again, th

be adjusted at menu point F (Fig. 26, right

e). Thereby increase step by step the value

ossible without power

t off.

UTION: Make sure, that the dynamic

sing power does not exceed 40

clo 0N!

3.6

At the menu points F to b (Fig. 26, right side)

further individual adjustments can be set:

Me

at t

Me

(op ly active, if red /

e 10 sec.)

tic closure pre

menu point b3

.3.2 Individual adjustments

nu point F: Adjust the value of switch-off power

he main door closing edge (preset value 5).

nu point H: Adjust the pre-warning time,

tion) red / green light; on

green light module is installed and b3 not ac-

tive (preset value 4 sec.)

Menu point A: Adjust automatic closure pe-

riod, only possible if menu point b3 is active

(preset valu

Menu point U: Adjust automa

if

warning period , only possible

active (preset value 4 sec.)

is

Menu point L: Adjustment lighting period

(preset value 180 sec.)

Menu point b: Addititional binary functions

1. Reversion (0: full, 1: 10 cm)

2. Soft travel (0: 7 cm, 1: 15 cm)

3. Automatic closure (0: inactive,

1: active)

4. Light barrier (0: inactive 1: active)

5. Safety edge (0: inactive, 1: active)

6. Warning light (0: blinking, 1. per-

values)

manent light)

7. Load preset values (grey

S 401 GB - 16 - 03-06

Fig. 25

S 401 GB - 17 - 03-06

Fig. 26

S 401 GB - 18 - 03-06

erform safety check

For the safety of persons and ob-

jects, a safety check has to be per-

formed. Before finishing the initial op-

eration make sure that the drive stops and re-

verses according to the valid norms (EN

12453).

When reaching an obstacle (max. 150 N force

= ca. 15 kg, above an opening width of 50 mm)

the door has to stop and reverse - completely

or partial, depending on the adjustment on the

circuit board. This test and measurement of

force can only be performed by a professional.

If the door does not move the right way or

does not reverse when reaching an obstacle,

the force and travel adjustments have to be

repeated (chapter 3.6.3.1, menu point P and

Fig. 26). If the shutdown force is too low or too

high, at menu point F (chapter 3.6.3.2 and Fig.

26) the force has to be set correspondingly.

Afterwards repeat the test.

If the door, after the performed corrections

does not stop and reverse according to the

valid norms, the door may not be operated

automatically.

3.6.5 Warning notices

Warning notices against pen in have to be pla-

ced at an eye-catching place or near to the

drive (Fig. 28).

3.6.6 Radio

3.6.6.1 Installation of the radio

If your drive is not fitted with a factory equipped

radio system, the receiver has to be fitted to

the circuit board. To fit the receiver, the light

cover has to be taken off (Fig. 27.1), then plug

the receiver on the 10-pin molex socket a) as

shown in Fig. 27.2.

3.6.6.2 Set-Up of the radio

According to the radio system used, the set-up

operation of the radio can be different. For the

standard radio system PICO there is a

description in the annex of this manual.

3.6.6.3 Testing the radio

The first function test of the radio should be

performed generally inside of the garage (Fig.

29.1).

Test the radio twice inside the garage. After

successful performance, go in front of the ga-

rage and test the radio again twice (Fig. 29.2).

3

.6.4 P

Fig. 27.1-27.2

Fig. 28

Fig. 29.1-29.2

S 401 GB - 19 - 03-06

S 401 GB - 19 - 03-06

4.0 Maintenance

We recommend, that the door system be

checked once a year by a professional.

The force shutdown, possibly installed safety

equipment and the emergency release have to

be checked every 4 weeks and have any pos-

sible failures repaired immediately by an pro-

fessional.

The force shut-off can be tested, by putting a 5

cm or higher piece of wood on the floor, in the

travel path of the door (Fig. 30). Now close the

door . When reaching the obstacle, the door

has to stop and reverse (completely or par-

tially, according to the performed setting on the

circuit board).

If an exchange of single components (e.g. cir-

cuit board, motor, etc.) of the drive is neces-

sary, first remove the light cover. For that pur-

pose remove both safety screws as shown in

Fig. 31.1. After removing the light cover turn

out the bulb. Afterwards remove the 4 screws

of the cover (Fig. 31.2) and take it off (Fig.

30.3).

When exchanging the bulb, only a bulb with

max. 40 W (E14) may be used.

Batteries and bulbs are not included in war-

ranty claims.

After finishing the repairs, put back all parts in

reverse order.

5.0 Demounting and disposal

For demounting and disposal the local safety

and disposal regulations have to be followed.

Fig. 30

Fig. 31.1-31.3

CAUTION

Before taking the cover

off, disconnect the power

plug 230V ~

S 401 GB - 20 - 03-06

L g

6.0 Failure analysis

ightin :

bulb defective:

exchange with 40W/ 230V E14 bulb

• drive is without mains voltage:

• check power plug and fuses and ex-

•

change if necessary

Radio system:

• door does not run with transmitter

check the battery of the transmitter and

exchange if necessary.

receiver has not learned the code of

the transmitter, repeat learning proc-

ess.

• range is dissatisfying:

check the connection and the location

of the antenna and correct if neces-

sary.

check the output of the battery and ex-

d:

change if necessary.

use a rod aerial.

circuit boar

ly reacts with push button:

e placement of the receiver

ange if necessary.

or me-

chanic and renew if necessary (only by

• door does not move:

check, if the safety inputs are

jumpered or safety installations are in-

stalled and not connected.

• door on

check th

and exch

• door stops while travelling:

door is too tight, check the do

a professional !!)

• door reverses while moving:

check if there is an obstacle in the

travel path and remove the obstacle.

motor: motor runs, but the door does not

check the connection between push

motor gearbox defective, exchange

the circuit board):

• move:

rod and door and correct if necessary,

check if the trolley is engaged in the

chain/belt lock?

• motor jerks:

complete motor unit

• motor does not start

• check, if the hallsensor cable is con-

nected correctly (at the motor and at

Table of contents

Other Bernal Garage Door Opener manuals