Trademaster TM26005 User manual

Operator’s Manual for

10" Sliding Compound Mitre Saw

Model No. TM26005 UPC 7-72142-26005-4

Trademaster Parts & Service

205 Frobisher Drive

Waterloo, ON

N2V 2G4

tel: 866-332-3307

fax: 866-332-3308

GENERAL SAFETY INSTRUCTIONS

WARNING! Read and understand all instructions. Failure to follow all instructions listed below may result in

electrical shock, fire and/or serious personal injury.

SAVE THESE INSTRUCTIONS

Work Area

• Keep your work area clear, clean and well lit.

Cluttered work surfaces and dark areas invite

accidents.

• Keep people not involved in the work, especially

children away from the work area while operating

a power tool. Distractions can cause you to lose

control of the tool.

• Do not operate power tools in an unsafe

environment such as in an explosive atmosphere,

near flammable liquids, gases and dust. A spark

created by a power tool may ignite the fumes or dust.

• DON’T USE IN DANGEROUS ENVIRONMENT. Don’t

use power tools in damp or wet locations, or expose

them to rain. Keep work area well lighted.

Electrical Safety

• Double insulated tools are equipped with a

polarized plug (one blade is wider than the other.)

This plug will fit into a polarized outlet only one

way. If it does not fit fully in the outlet, reverse the

plug and try again. If it still does not fit fully, contact

a qualified electrician to install a polarized plug. Do

not modify the plug in any way. Double insulation

eliminates the need for the three wire grounded power

cord and grounded electrical system.

• Avoid body contact with grounded surfaces such

as radiators, pipes, ranges and refrigerators. There

is an increased risk of electrical shock if your body is

grounded.

• Do not operate power tools in the rain or wet

conditions. Water entering a power tool increases the

risk of electrical shock.

• Do not stress the power cord. Never carry the

power tool by the cord or disconnect the plug from

the receptacle by yanking on the cord. Keep cord

away from sharp edges, heat, solvents and oil.

Replace damaged cords immediately. Damaged cords

increase the risk of electrical shock.

• Use outdoor extension cords when operating the

power tool outside. Outdoor power cords are

marked "W-A" or "W" and are rated for outdoor use.

These cords reduce the risk of electrical shock.

Personal Safety

• Dress appropriately. Do not wear loose clothing

or jewelry. Keep long hair in place and contained.

Keep clothing, hair and gloves away from moving

parts. Loose clothing, jewelry and hair can be

snagged in moving parts.

•Use common sense, stay alert and watch what

you are doing while operating a power tool. Do

not use tools while under the influence of alcohol,

medication, or drugs. Keep focusing on the work at

hand while using a power tool to prevent personal

injury.

• Make sure the power switch is in the "OFF" position

before plugging it into the receptacle. This will

prevent accidental starting. Carrying tools with your

finger on the switch or plugging in the tools with the

switch in the "ON" position invites accidents.

• Remove adjusting tools such as wrenches or keys

before turning the tool on. A wrench or key left

attached to a rotating part will fly off and may cause

personal injury.

• Do not overreach while operating a power tool.

Keep proper footing and balance at all times. Good

balance and solid footing enables better control in

unexpected situations.

• Always wear appropriate safety equipment. Always

wear eye protection while operating a power tool.

Use appropriate dust respirators, hearing protection,

hard-hat, face shield or safety shoes as dictated by the

work and tool.

• NEVER STAND ON TOOL. Serious injury could

occur if the tool is tipped or if the cutting tool is

unintentionally contacted.

• NEVER LEAVE TOOL RUNNING UNATTENDED. TURN

POWER OFF. Don’t leave tool until it comes to a

complete stop.

WARNING

b) Keep hands out of path of saw blade.

c) Do not operate saw without guards in place.

d) Do not perform any operation freehand.

e) Never reach around saw blade.

Tool Use and Care

• Secure the work piece with clamps or other

practical methods to provide a secure work

platform. Holding the work by hand or against your

body is not secure and may lead to loss of control.

• Use the correct tool for the work. The proper tool

will do the work faster and safer.

• Do not use the tool if the "ON/OFF" switch is not

working. Operating a tool that cannot be controlled

by you is dangerous and must be repaired before use.

• Always disconnect the power cord from the

electrical outlet before storing the tool, making

adjustments or adding/replacing accessories. This

simple prevention will reduce the risk of accidental

starting of the tool.

• Store the tool in a secure place out of reach of

children. A secure storage location will prevent the

unauthorized use by untrained users.

• Properly maintain tools. Keep all cutting tools sharp

and clean. Remove contaminants from the tool and

keep clean. Check for broken parts or binding of

moving parts before use. If damaged, have the tool

serviced before use. Prevent accidents caused by

poorly maintained tools.

• Use only accessories recommended for your

model. Accessories suitable for one tool may become

hazardous when used on another tool.

• MAKE WORKSHOP KID PROOF with padlocks, master

switches, or by removing starter keys.

• DON’T FORCE TOOL. It will do the job better and

safer at the rate for which it was

designed.

• USE RIGHT TOOL. Don’t force tool or attachment to

do a job for which it was not designed.

Service

• Tool service, mechanical and/or electrical is to

be performed only by qualified repair personnel.

Service performed by unqualified personnel may

result in a risk of injury.

• When servicing a tool, use only identical

replacement parts. Use of unauthorized parts or

failure to follow maintenance instructions may create

a risk of electrical shock or injury.

Additional Safety Instructions for Mitre

Saws

• Wear safety goggles.

• Always wear appropriate safety equipment when

operating the tool.

• Do not use this tool in the presence of flammable

liquids or gases.

• The saw blade must be properly sharpened to ensure

maximum cutting capacity. Replace any deformed

or broken saw blades to avoid accidents before you

operate this tool.

• Use only the special flanges provided for this tool.

• Be careful not to damage the output spindle, flanges

(especially the fitting surfaces) and the bolt. Check

whether the saw blade is in good condition.

• Make sure the rotary table is secured firmly so that it

cannot move while it is operating.

• Clear chips and small blocks on the base to ensure a

smooth, clean surface.

• Before cutting any work pieces, make sure that the

nails and screws around the cutting position have

been cleared.

• Make sure that the armature shaft lock is in the off

position by the shaft locking arm before you turn it on.

• Make sure that the saw blade will not touch the rotary

table when the saw blade is in its lowest position.

• Never operate this tool with a single hand. Secure the

work piece with the vice. Holding the work by hand is

not secure and may lead to loss of control.

• Hold the handle of the saw firmly.

• Keep your hand away from the cutting line and do not

touch the saw blade during operation.

• Do not approach the saw blade during operation.

• Before switching on the motor, the saw blade must not

contact the work piece.

• Before carrying out any work, allow the motor to

idle for a while. Make sure there is no oscillation

caused by improper installing of the saw blade or the

unbalance of a warped saw blade.

• Start your work after the motor has reached its

maximum speed.

• If anything goes wrong during operation, switch the

tool off and stop working immediately.

• Do not try to fix the saw when the switch is in the

“ON” position.

• Before carrying out any maintenance and adjustment

of the saw, make sure to disconnect the power cord

from the electrical outlet and the saw blade has

stopped rotating.

• Stay alert and watch what you are doing while

operating the saw, especially in repeat and

monotonous operation. Do not create an illusive safe

feel, because the saw blade is dangerous.

• Be sure to use the accessories specified in this

manual.

• Do not damage the cord. Never carry the tool by the

cord or disconnect the plug from the receptacle by

yanking on the cord. Keep the cord away from heat,

oil and sharp edges.

• KEEP GUARDS IN PLACE and in working order.

• ALWAYS USE SAFETY GLASSES. Also use face or dust

mask if cutting operation is dusty. Everyday eyeglasses

only have impact resistant lenses, they are NOT safety

glasses.

• DIRECTION OF FEED. Feed work into a blade or

cutter against the direction of rotation of the blade or

cutter only.

Total Extension Cord Length (in feet)

Table A

25 50 100 150 200

AMP Rating Wire Gauge

0–10 18 14 12 10 8

10–12 16 14 10 8 8

12–14 14 12 10 8 6

14–16 14 12 10 8 6

16–18 12 12 8 8 6

Extension Cords:

Make sure your extension cord is not damaged. When

using an extension cord, be sure to use one heavy

enough to carry the current your product draws.

For lengths more than100 ft, No. 10 AWG extension

cords should be used. An undersized cord results in a

drop in line voltage and loss of power and overheating.

(NOTE: Table A below shows the correct size to use

depending on cord length and nameplate ampere

rating. When in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier the cord.)

Using the Laser collimator system

WARNING: Do not stare directly at the laser beam.

Never aim the beam at any person or an object other

than the work piece.

Do not deliberately aim the beam at personnel and

ensure that it is not directed towards the eye of a person

for longer than 0.25s.

Always ensure the laser beam is aimed at a sturdy work

piece without reflective surfaces, i.e. wood or rough

coated surfaces are acceptable. Bright shiny reflective

sheet steel or the like is not suitable for laser use as

the reflective surface could direct the beam back at the

operator.

Only turn the laser beam on when the tool is on the work

piece.

1. Mark the line of the cut on the work piece.

2. Adjust the depth of the cut and bevel angle as

required.

3. Rest the front edge of the base on the work piece.

4. Switch on the laser beam using the laser light on/off

button.

5. Align the beam with the line on the work piece.

6. Start the motor by squeezing the trigger switch.

7. Always let the blade reach full speed (approximately

2 seconds) before you begin to cut into the work

piece.

8. Slowly push the saw forward using both hands,

keeping the red laser light beam on the line of cut.

9. After completing your cut, release the trigger switch

and allow the blade to come to a complete stop. Do

not remove the saw from the work piece while the

blade is moving.

10. Switch off the laser beam on completion of the cut.

Safety rules for laser lights

The laser guide used in the tool is Class II with a

maximum output of 1 mW and a wavelength of 650 nm,

Complies with 21 CFR, Subchapter J, Parts 1010 and

1040, Class II laser product. The laser guide does not

normally present an optical hazard, although staring at

the beam may cause flash blindness.

User Information

CAUTION – The use of optical instruments with this laser

product will increase eye hazard.

CAUTION – The use of controls or adjustments or

performance of procedures other than those specified

herein may result in hazardous radiation exposure.

• Do not stare into the laser beam.

• The laser shall be used and maintained in accordance

with the manufacturer’s instructions.

• Never aim the beam at any person or an object other

than the work piece.

• Do not disassemble the laser.

• Operate the laser only when cutting. Turn the laser off

after use.

Always ensure the laser beam is aimed at a sturdy work

piece without a reflective surface, i.e. wood or rough

coated surfaces are acceptable. Bright shiny reflective

sheet or the like is not suitable for laser use as the

reflective surface could direct the beam back at the

operator.

This label is located on the top of the motor enclosure

(part # 63).

This label is located on the top

of the rocker arm (#87) beside

the laser battery box (#145) and

switch of laser (#139).

This label is located

on the lower back

edge of the safety

guard (#105)

Technical Specifications

OPERATING INSTRUCTIONS

SAVE THESE INSTRUCTIONS

ITEM DESCRIPTION

Motor No-Load Speed:4600RPM

Power Supply 120V/60Hz/Single Phase/15 Amps

Arbor Diameter 0.625” (5/8")

Blade Diameter 10”

Cutting Capacity Cross cut 90°: 11.81” x 2.95” (300mm x 75mm)

Bevel cut 45° x 90°: 8.26” x 2.95” (210mm x 75mm)

Compound cut 45° x 45°: 8.26” x 1.57” (210mm x 40mm)

Mitre cut 45°: 11.81” x 1.57” (300 x 40mm)

Accessories 10” x 40T Carbide Tipped Blade

Material Hold Down Clamp

Material Support Brackets

Stop Plate For Repeated Cuts Of Same Dimension

Lug Style Arbor Wrench

Dust Bag

Spare Carbon Brushes

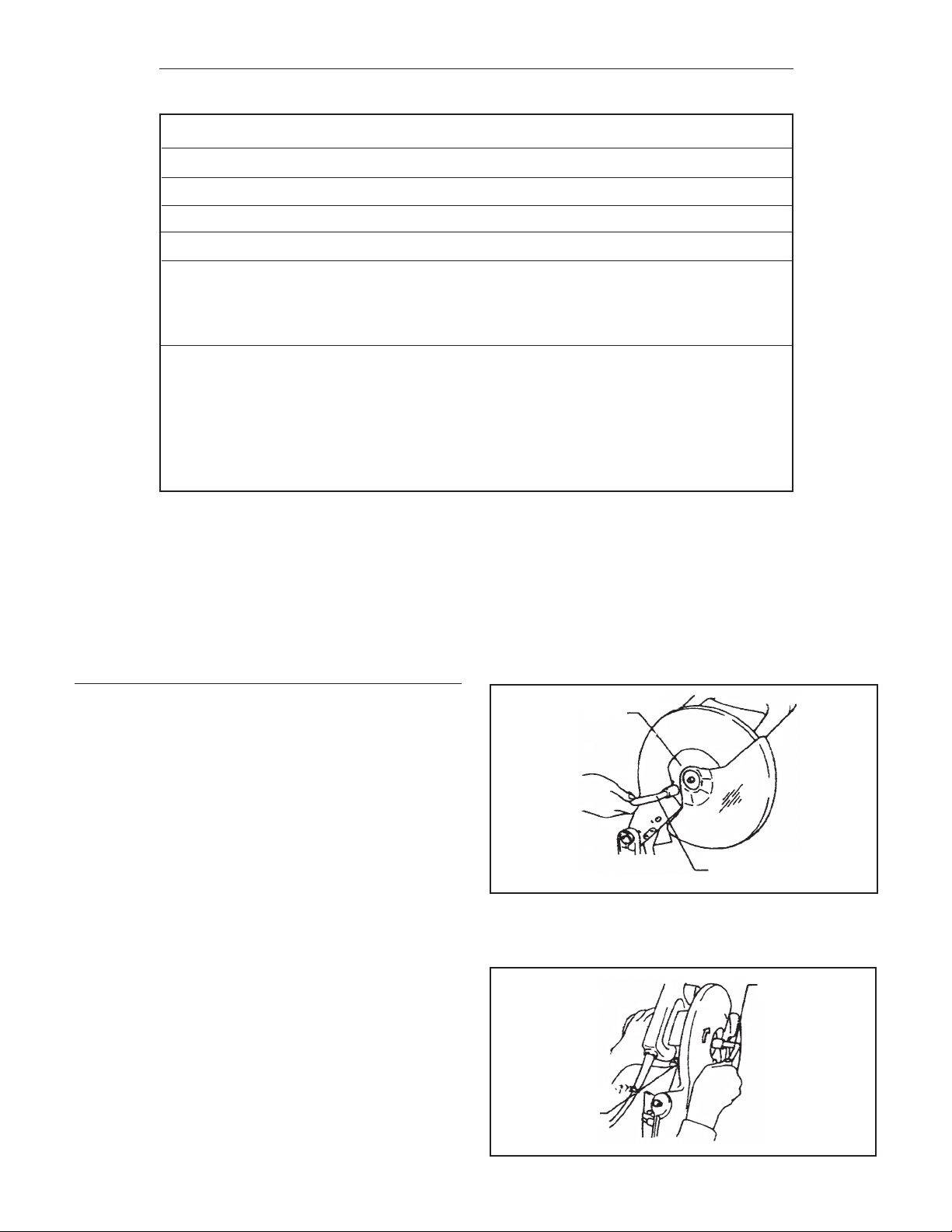

Changing the Saw Blade

To remove the saw blade loosen the bolt that fixes the

central cover by turning it counter clockwise using the

socket wrench provided. Then, raise the central cover

and move it down from the original position.

Central Cover

Socket Wrench

Shaft Locking

Arm

Socket Wrench

When removing the saw blade, first raise the lowest

position handle and press down the shaft locking arm to

lock the saw blade. Then loosen the hex bolt by turning

it clockwise using the socket wrench and remove the hex

bolt, the outer flange and the saw blade.

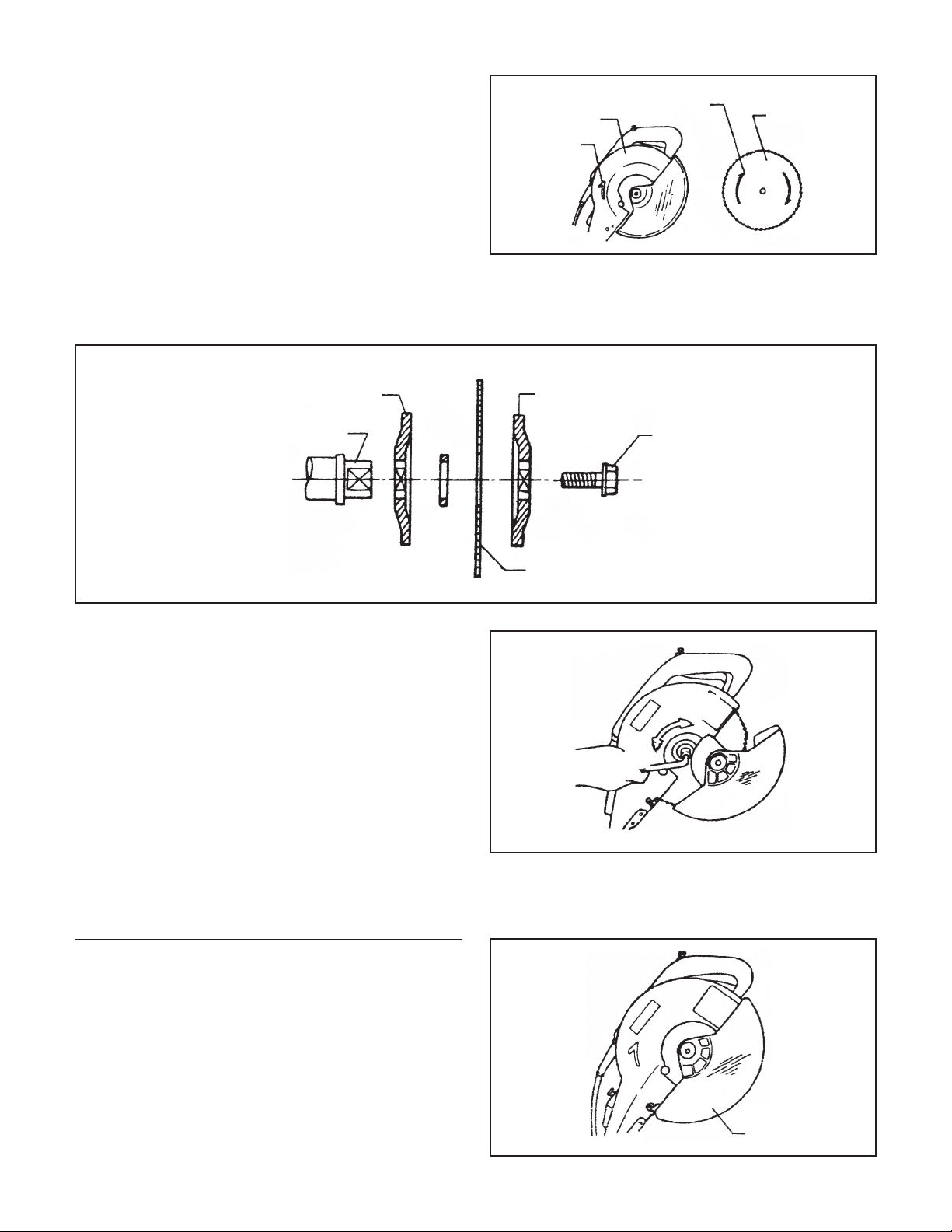

Install the outer flange and the hex bolt. Then, press

down on the shaft locking arm, and tighten the hex bolt

firmly by turning it counter clockwise using the socket

wrench. Adjust the hex bolt in a clockwise direction to fix

the central cover.

Blade Guard

When sawing, the blade guard will be lifted up by the

work piece. After you finish cutting, the blade guard will

automatically reset to its original position with the handle

raised. Never abandon or remove the blade guard.

Inner Flange

Install Shaft

Outer Flange

Hex Bolt

Saw Blade

Loosen

Tighten

Blade Guard

Protective

Cover

Arrow

Arrow Saw Blade

When installing the new saw blade check that the teeth

point in the direction of the arrow (See the protective

cover).

Sawdust Collector

You can operate this machine more conveniently with the

sawdust collector. Connect the adapter of the collector

to the nozzle of the protective cover, then, fix the collector

inlet to the adapter of the collector. When the sawdust

collector is half full, take the collector off of the protective

cover and open the collector door at the bottom. Clean

the sawdust out of the collector completely.

Operating the Switch

To prevent accidental starting, the tool is equipped with a

protective switch. To start the tool, you should first press

the protective switch and then press down the trigger

switch. The tool shuts off when you release the trigger

switch.

Sawdust Nozzle

Sawdust Collector

Collector Door

Protective Button

Trigger Switch

Replacing the Carbon Brushes

Check and remove the carbon brushes regularly. Replace

them when they wear down to the limit mark. Keep the

carbon brushes clean and free to slip in the holders.

Both carbon brushes should be replaced at the same

time.

Use a screwdriver to remove the brush holder caps. Take

out the worn carbon brushes and insert the new ones

and secure the brush holder caps.

Limit Mark

Screwdriver

Brush Holder Cap

Operation

Press Cut (cutting a small work piece)

The work piece size within the scope of 70mm(H) x

210mm(W) can be cut in the following way:

Push the carriage to the end towards the cross bar,

tighten the knob to fix the carriage. Then use the vice to

secure the work piece. Switch the machine on and wait

for the saw blade to reach its maximum speed before

slowly pressing the handle downwards. After you have

finished cutting, turn the switch off and wait until the

saw blade stops rotating before you completely raise the

handle.

Slip Cut (cutting a wide work piece)

The work piece size within the scope of 80mm(H) x

300mm(W) can be cut in the following way:

Release the knob to slip the carriage freely. Completely

pull the carriage towards the operator. Switch the

machine on and wait for the saw blade to reach its

maximum speed. Then press down on the handle and

push it to the cross bar to cut the work piece. After you

have finished cutting, turn the switch off and wait until

the saw blade stops rotating before you completely raise

the handle.

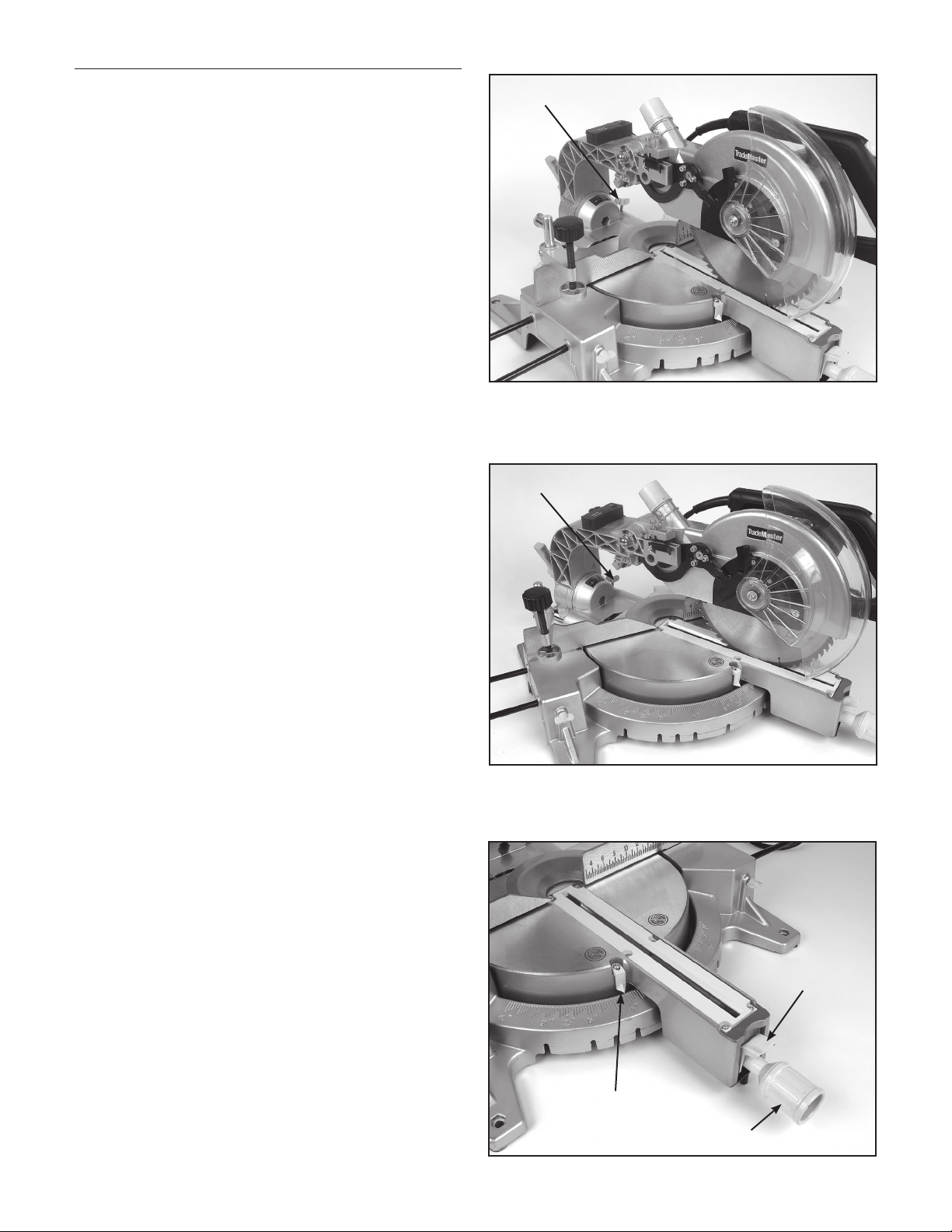

Setting a Bevelled Joint Angle

Loosen the hand shank by turning it counter clockwise.

Press down on the spring pin so that the rotary table is

free to turn. When the desired angle on the scale on the

base matches up with the arrow marked on the rotary

table, turn the hand shank clockwise to tighten it.

Knob

Knob

Indicator

Hand Shank

Spring Pin

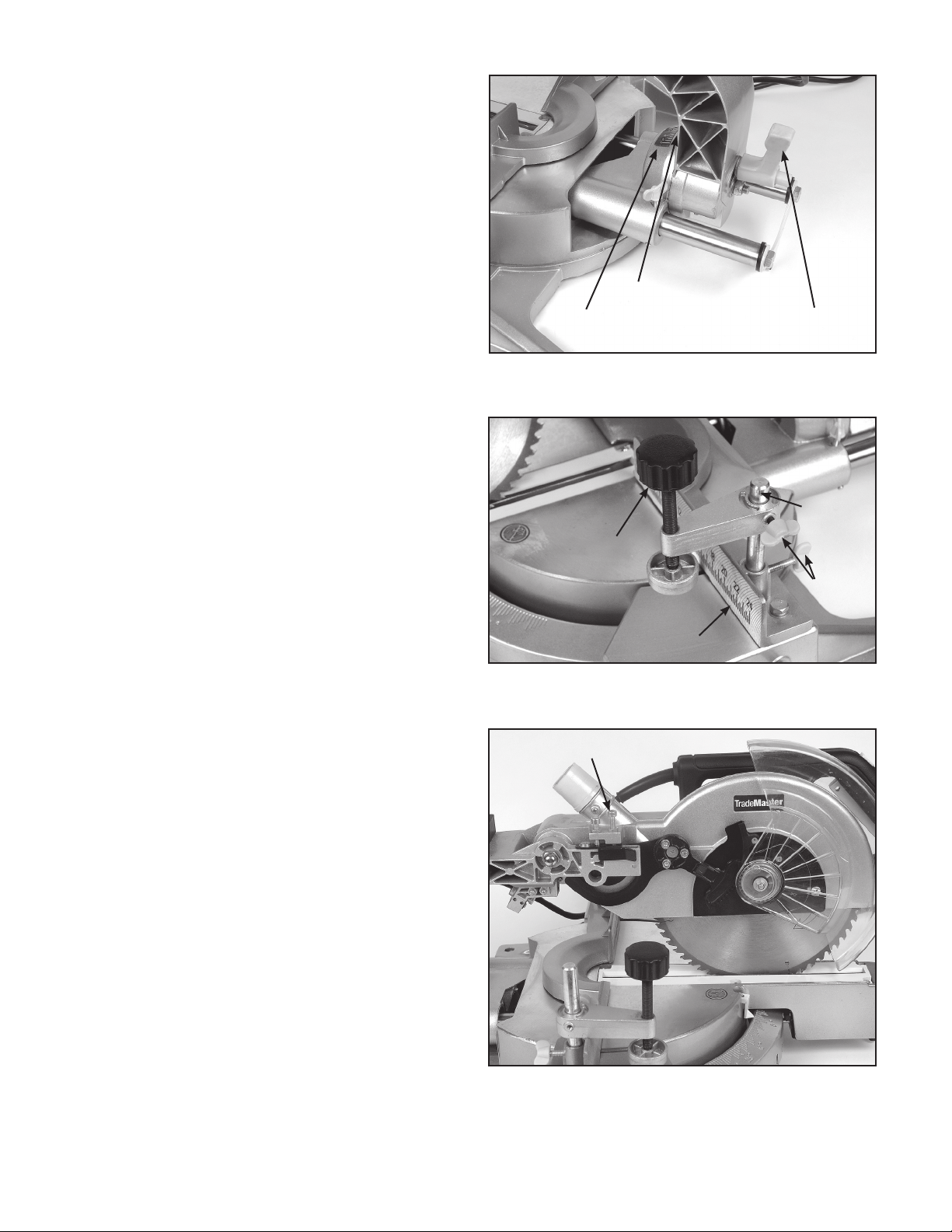

Setting a Bevelling Angle

Only when the auxiliary stopper is fixed on the left side,

as shown on the drawing, can the saw blade be bevelled

to a 45° angle. To adjust the bevelling angle, loosen the

fixed handle, then incline the saw blade to the left until

the indicator reaches the desired angle on the mitre

square. Then tighten the fixed handle firmly.

Indicator

Mitre Square Fixed Handle

Keep the Maximum Cutting Capacity

Before making any adjustments, remove the plug from

the socket. This machine has been adjusted by the

manufacturer to keep the maximum cutting capacity

using a ø210mm(8”) saw blade. When the diameter of

the sawblade becomes smaller, because of grinding,

adjust the machine by following the illustration: Push the

carriage to the cross bar direction and put the handle

to the lowest position. Turn the adjustable bolt using the

socket wrench to make the place where the saw blade

edge on the top of the rotary table surface and the front

surface of the cross bar intersect below the top surface

of the rotary table. Be sure the plug has been removed,

and then turn the saw blade with you hand. Press the

handle to its lowest position to check that the saw blade

does not contact the table. If necessary, you can adjust it

a bit.

Note: Before installing the new saw blade, make sure the

saw blade does not contact the table.

Secure the Work piece

The vertical vise can be installed in the hole of the guide

bar or the work piece supporter component (selective

purchasing). Install the vise rod in the hole of the guide

bar or work piece supporter component and then tighten

the bolt. You should adjust the position of the vise arm

according to the shape and thickness of the work piece

and tighten the vise arm with the bolt. Lean the work

piece against the guide bar and the rotary table and

place the work piece in the desired cutting position. Then

tighten the clamp bolt to secure the work piece.

Clamp Bolt

Guide Bar

Bolt

Vise Rod

Adjusting Bolt

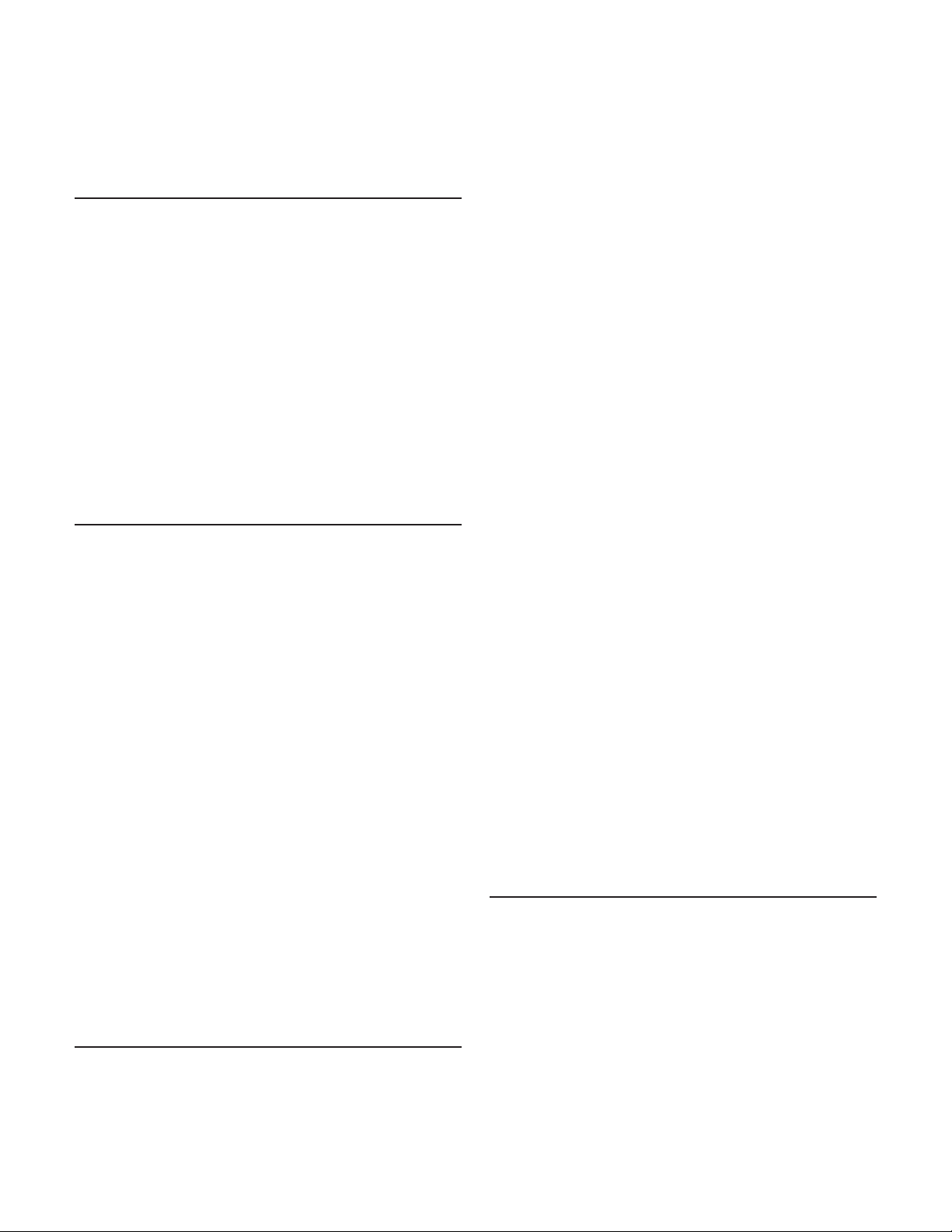

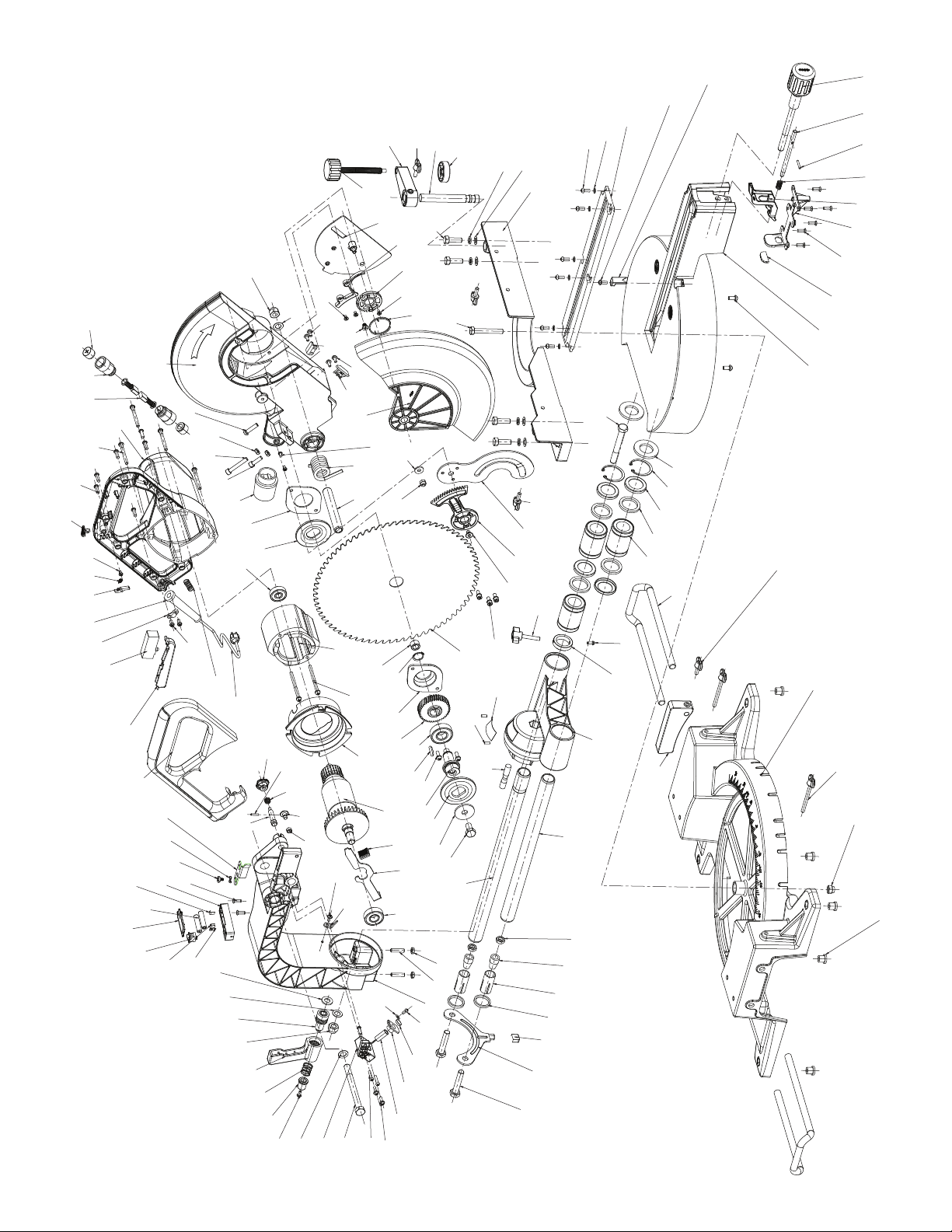

1716

15

14

13

11

10

9

8

12

7

6

5

4

3

2

1

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

62

63

64

65

66

67

68 69 70

72 73 74 75

76 77 78

79

80

71

44

45 46

47 48

49

51 52 53

54

55

61

60 59 58

57 56

42

41

40 39 38 37

43

145

144

142

143

141

113 112

111 110 108 107

106

105

109

81

82 83 84 85

104

86 87

88 89

91

90 92 93

103

102

101

100

99

98 97

96

95

124

123

122

118 117

114

115

120

121

125

116

126

127

128

129 130 131 132

133

134

135

136

137

138

139

140

119

147

146

94

50

157

158

159

160 161 162

163

164

148

149

150

151

152

153

154

155

156

TM26005

02/2009

Item Description Qty.

110 Screw 1

111 Sliding Bar Ring 1

112 Screw M4X10 1

113 Needle 1

114 Cap Nut M10 1

115 Flat Washer D10 1

116 Cross Screw M4X6 2

117 Cross Screw M4X10 2

118 Positioning Plate 1

119 Cross Screw M6 1

120 Cross Screw ST3.5X9C 2

121 Safety Fence 1

122 Movable Safety Guard 1

123 Washer D6 1

124 Cross Screw ST3.5X9C 2

125 Spring 1

126 Column Pipe 1

127 Nylon Nut M6 1

128 Hex Bolt M8X55 1

129 Spring 1

130 Cross Screw M4X6 1

131 Gear 1

132 Cover of Gear 1

133 Fixed Plate of Movable

Safety Guard 1

134 Positioning Handle 1

135 Vise Jaw 1

136 Short Handle M6×20 1

137 Lever of Vise 1

138 Press Plate 1

139 Outer Hex Bolt M8×30 4

140 Elastic Washer D8 4

141 Flat Washer D8 4

142 Fence 1

143 Cross Screw M5X12 6

144 Flat Washer D5 6

145 Kerf Board 1

146 Cross Screw M5X12 1

147 Needle 1

148 Rivet 2

149 Cross Screw M4X10 2

150 Battery Box 1

151 Spring 1

152 No.7 Battery 2

153 Cover of battery box 1

154 Switch of Laser 1

155 Spring 1

156 Spring 1

157 Holder of Laser 1

158 Cross Screw M4X20 3

159 Cross Screw M4X16 3

160 Laser 1

161 Bushing of Laser head 1

162 Cover of laser head 1

163 Flat Washer D4 1

164 Cross Screw M4X10 1

Item Description Qty.Item Description Qty.

1 Rubber Bracket 4

2 Nylon Nut M8 1

3 Long Handle M6×70 2

4 Base 1

5 Plastic Fence 1

6 Short Handle M6×20 1

7 Extension 2

8 Cross Screw M6×12 2

9 Worktable 1

10 Rubber Washer 1

11 Sunk Head Screw

M5×12 6

12 Indexing Cover Plate 1

13 Indexing Spanner 1

14 Indexing Spring 1

15 D3×20 Pin 1

16 Indexing Pin 1

17 Indexing Handle 1

18 Outer Hex Bolt M10×85 1

19 Big Rubber Ring 2

20 Ring D40 2

21 Dustproof Cover 4

22 Felt Ring 4

23 Linear Bearing 3

24 Cross Screw M4×10 1

25 Braking Ring 1

26 Short Handle M6×10 1

27 Bracket 1

28 Screw M8×35 1

29 Short Sliding Bar 1

30 Hex Nut M10 2

31 Holder 2

32 Ring 2

33 Small Rubber Ring 2

34 Bracket of Sliding

Bar Support 1

35 Sliding Bar Support 1

36 Outer Hex Bolt M10×50 2

37 Short Handle M6×20 2

38 Sliding Slot of Gear 1

39 Big Gear 1

40 Screw M6 1

41 Inner Hex Bolt M5X12 3

42 Saw-Blade 1

43 Scale 1

44 Shaft Bolt 1

45 Shaft Washer 1

46 Outer Flange 1

47 Shaft 1

48 Cross Screw M5×16 2

49 Key 1

50 Ball Bearing 6203-2RZ 1

51 Helical Gear 1

52 Gear Holder 1

53 Spring D17 1

54 Oily Bearing 1

55 Stator Assembly 1

56 Cross Screw M5×70 2

57 Wind Resist Ring 1

58 Rotor 1

59 Handle 1

60 Blade Lock 1

61 Long Sliding Bar 1

62 Ball Bearing 6201-2RZ 1

63 Hex Nut M6 2

64 Inner Hex Screw M6×25 2

65 Rocker Arm 1

66 Outer Hex Bolt

M10×100 1

67 Flat Washer D10 1

68 Cross Screw M4×10 1

69 Push handle 1

70 Spring 1

71 Lock Bolt Assembly 1

72 Nylon Ring Nut M10 1

73 Lock Nut Assembly 1

74 Flat Washer D10 1

75 Washer D10 1

76 Cross Screw M4 1

77 Wave Type Washer 1

78 Stopper Plate 1

79 Handle Cover 1

80 Switch Actuator 1

81 Screw ST3.5×13C 2

82 Switch 1

83 Cord Plate 1

84 Cord Guard 1

85 Stop bolt Spanner 1

86 Spring 1

87 Screw ST3.5×9C 1

88 Stop bolt 1

89 Screw ST3.5×16F 7

90 Cross Screw M5×45 4

91 Motor Enclosure 1

92 Carbon Brush 2

93 Brush Holder 2

94 Cover of Brush Holder 2

95 Safety Guard 1

96 Cross Screw M6X25 1

97 Hex Nut M6 2

98 Inner Hex Bolt M6X40 1

99 Inner Hex Bolt M6X20 1

100 Dust Bag Port 1

101 Cover of Bearing 1

102 Inner Flange 1

103 Ball Bearing 6200-2RZ 1

104 Spring 1

105 Power Supply Cord 1

106 Lock Pin Handle 1

107 Pin D2.5×14 1

108 Spring 1

109 Lock Pin 1

Parts List

LIMITED WARRANTY

TradeMaster Parts & Service (TMPS) warrants to the original

purchaser only that its TradeMaster brand power tools will be

free from defects in material or workmanship for a period of

three years from the date of purchase.

In the event this power tool fails, return the complete tool,

transportation prepaid, to your nearest Authorized Service

Centre. We will repair at our option, any part of the product

covered under this warranty which, after examination, proves

to be defective in workmanship or material during the

warranty period.

Original Bill of Sale is required.

This warranty does not apply to any repairs required if the

tool is put to use other than intended, it has been misused,

abused, carelessly or accidentally mishandled, normal wear

and tear, repairs attempted or made by other than TMPS

or Authorized Service Center. This limited warranty does

not apply to accessory items such as circular saw blades,

drill bits, router bits, jigsaw blades, sanding belts, paper or

discs, grinding wheels and other related items. In no event

shall TMPS be held liable for any incidental or consequential

injury, death or damage arising from the sale and subsequent

use of this product. This is TMPS TradeMaster sole warranty

and explains a customer’s exclusive remedy with respect to

defective product. Under no circumstances will TMPS’s liability

under this warranty exceed the purchase price of the product.

Blade change for TM26005

Loosen this screw to release the guard fixed plate

Push the entire plastic guard assembly forward.

You will see the slot in the front of the fixed plate

that the front screw pivots on.

When pushing the guard forward, notice the gear

for the guard guide system separates, note this

as you will have to align this when putting the

guard back into place.

Pull the guard up and over the metal safety guard

It should sit out of the way and you now have

access to the blade and blade bolt.

From here follow the directions on the manual from the point of locking the shaft.

Please note that the blade bolt is Left Hand thread so you will be turning right to loosen it.

Table of contents

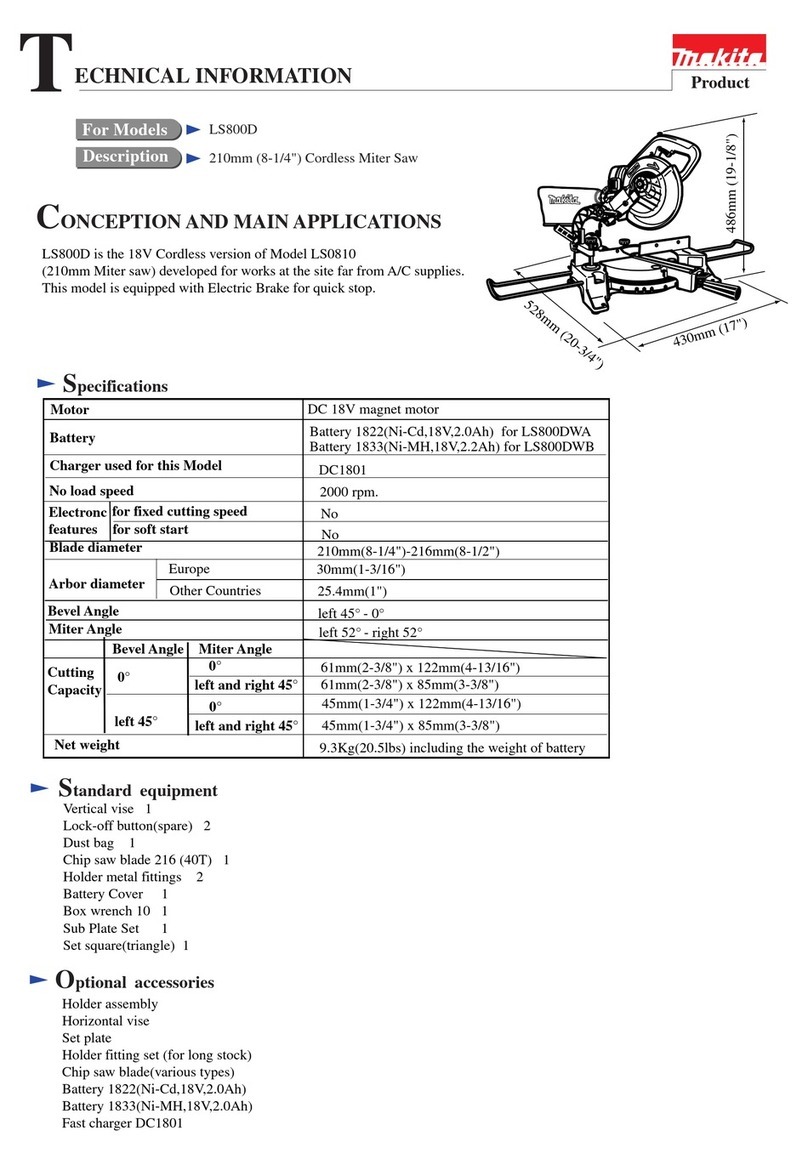

Other Trademaster Saw manuals

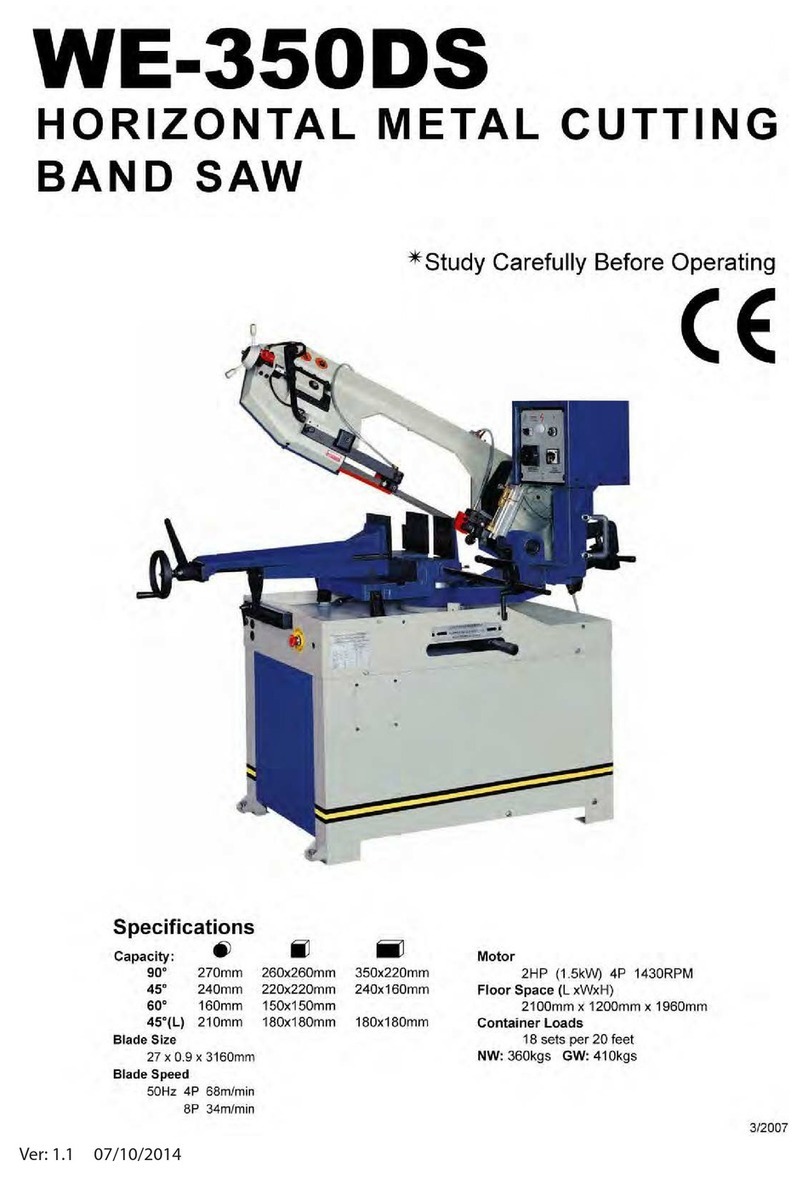

Popular Saw manuals by other brands

Zipper Mowers

Zipper Mowers ZI-WP700H Operation manual

Master Cut

Master Cut 60089 owner's manual

Rotorazer Saw

Rotorazer Saw 3000 Series user manual

Rockwell

Rockwell 10" Contractors' Saw instruction manual

MEP

MEP PH 100 Instruction manual and spare parts list

skilsaw

skilsaw SPT77WML Operating/safety instructions