Traffic-Manager SY3800110 User manual

24 X 48 & 30 X 60 boards

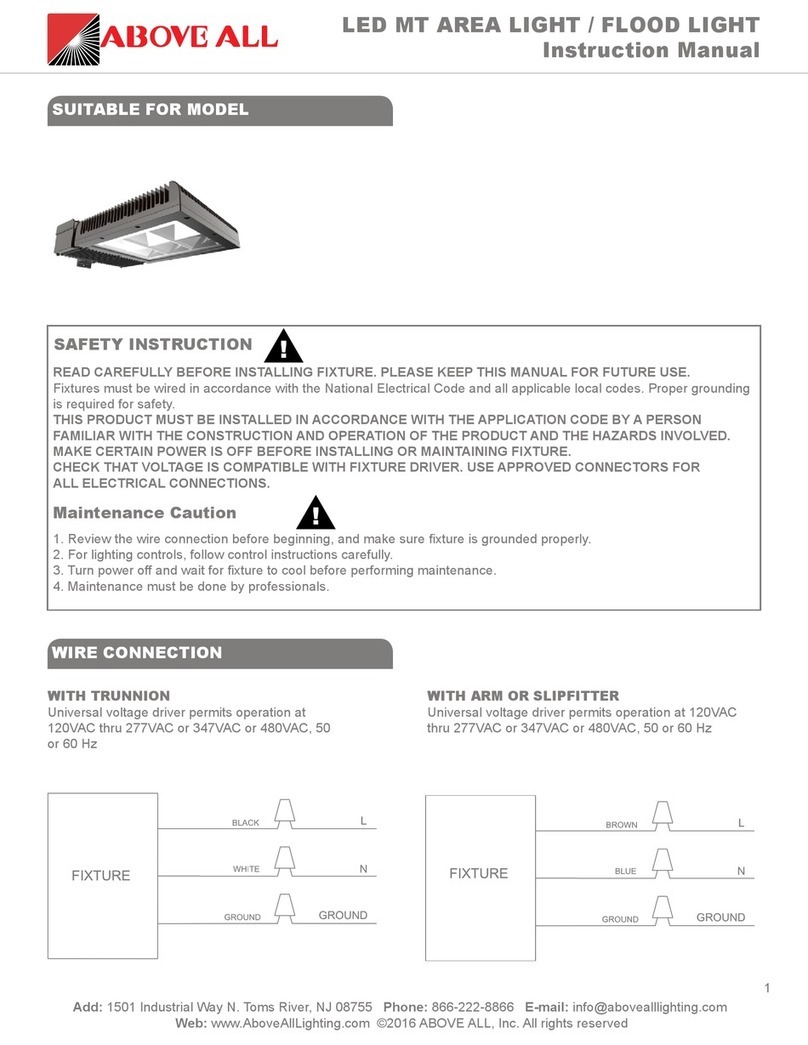

180° over Cab MoUNT KIT

1. Unpack all items and check that you have received a complete kit prior to beginning installation.

2. Determine the proper hole conguration needed to obtain the correct width for your particular sign by examining Fig 2 and Chart 1.

3. Before the sign is mounted, you must install the actuator power cable and the travel position switch cable into the sign. To do this, rst remove the

access panel on the back of the sign. Next you need to insert the quick disconnect spade end of both cables into the hole on the side or bottom of

the sign. Once the wires have been routed through the sign to the driver, press each disconnect onto the proper corresponding spade terminal as

indicated by the label on the driver and in the arrow board manual. Be sure to wire tie the wires to the main loom to help relieve strain. Replace

the back access panel and the sign is ready to mount.

4. Mount the sign brackets (items 3 and 4) to your arrow board using items 18, 21 and 24.

5. Install the left sign bracket (item 4) into the left frame assembly (item 2) and loosely secure using items 19 and 22 as depicted in Fig 2 making sure

to support the far side of the board. Then slide the other end of the frame over and repeat the installation for the right side of the frame assembly.

6. Using items 15, 19 and 22, bolt the base together making sure that the holes obtained from the gure in step 2 are properly aligned.

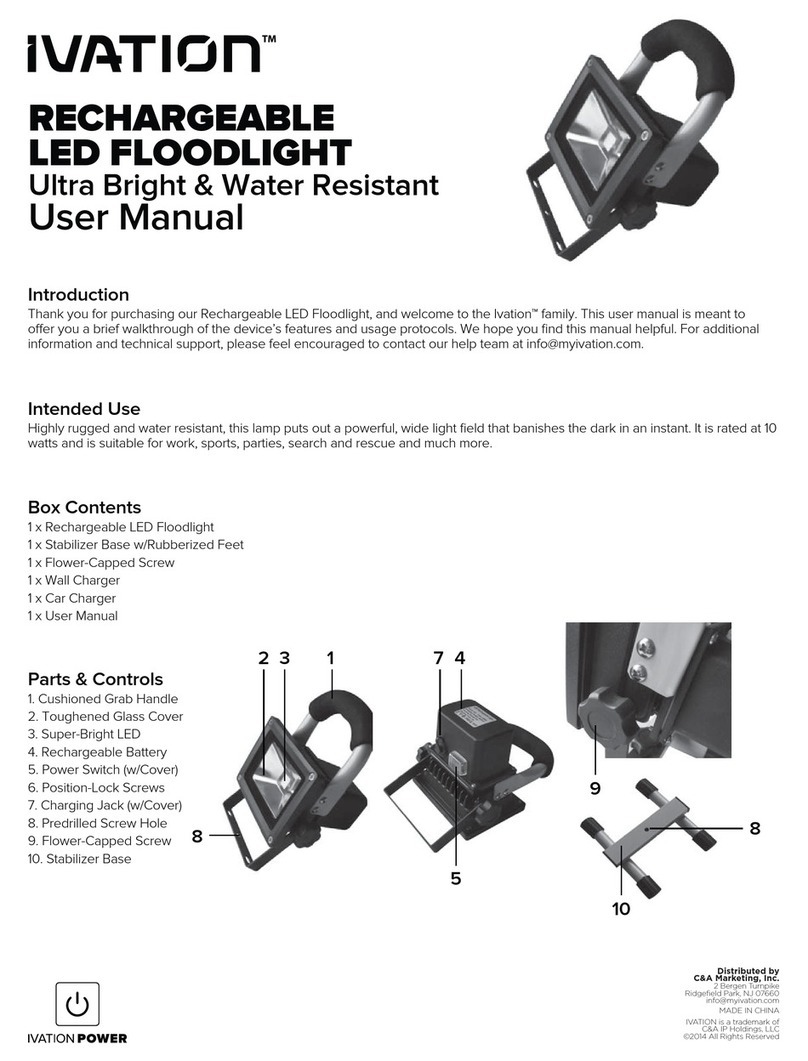

7. Install the actuator bracket (item 7) onto the actuator (item 5) using items 14, 19, and 22 as shown in Fig 1. Note the orientation of the tab on

item 7 when installing.

8.

Mount the actuator (item 5) to the frame and to the pivot links (items 8 and 9) as depicted in Fig 1 using items 14, 13, 19, and 22 making sure to

mount the links and the actuator in the proper orientation. It may be necessary to slightly extend the actuator in order to properly bolt the unit in place.

9. The unit is now ready to be placed onto vehicle.

10. After placing the assembly where you wish to mount it, carefully route the wires to the battery making sure to fuse the positive wire within 10 inches

of the battery (60A for incandescent and 20A for LED boards). When routing the wires, avoid moving or rotating truck parts and avoid getting too

close to hot items such as exhaust. When running wire through a hole in metal, be sure to use a grommet and carefully secure the wire.

11. Power the unit on and move the actuator to the bottom position, staying clear of the sign.

12. Once the sign is in the full upright position, nd a suitable place to drill the frame in order to securely mount it to the vehicle.

13. After mounting, recheck all hardware to ensure it is tightened properly.

14. Manually raise and lower the unit with the controller and check for any obstructions or binding problems.

15. Turn the unit off. The unit is now ready to have the position switch installed and adjusted for auto traveling position (optional).

assembly

safety

This product is warranted against defects in materials or workmanship for one year from the date of purchase. Should service be required, the customer

should return the product for warranty consideration. Shipping will be prepaid via ground transportation. All products requiring warranty service shall be re-

turned within one year from the date of purchase. Exclusions from this warranty are the nish and damage caused by improper installation or use.

The manufacturer assumes no liability for costs incurred to remove or reinstall the product, or for lost revenues due to equipment down time.

This warranty gives you specic legal rights. You may also have other rights, which vary from state to state and country to country.

ONe yeaR WaRRaNty

Electrical/Electronic Device – Potential Shock Hazard Safety is never optional, so please read and follow all instructions shipped with

the products and the warnings that follow. These instructions are for the installation of the system on a mobile vehicle. The installer is

required to have a good working knowledge of vehicle electrical systems and the ability to work on such systems, safely.

• Donotattemptthisinstallationunlessyouhavebeenproperlytrainedinthemaintenanceandtroubleshootingofvehicleelectricalsystems.

• Beforedrillingintoanyvehiclestructure,besurethateachsideofthesurfaceisfreeofanythingthatmightbedamaged.

• Failuretofollowthesesafetyprecautionsmayresultinpropertydamage,seriousinjuryordeathtoyou,topassengers,ortoothers.

Read and understand ALL instructions before operating the arrow board.

Do not use an arrow board that is not operating properly. Be sure all lights are functioning and the appropriate arrow mode has been selected.

Check with the job Safety Engineer for correct arrow mode - mode requirements may vary from state to state.

Make sure the arrow board, rotation brackets, cross bar and gutter mounts have been installed correctly:

• Secure all the bolts and nuts.

• Make sure all electrical connections are secure and clear of hot/moving vehicle parts.

• Ensure control box is mounted securely.

• Replace any cracked, broken or damaged lights and hoods.

Always visually check the arrow board to make sure the functions operate correctly. This will properly direct traffic

preventing property damage, injury or death.

All Superior Signals’ arrow boards and power lift kits are 12v d c power.

Power Lift:

1. Position the vehicle in the desired location with the arrow board facing oncoming traffic.

2. Set the main power switch to the “ON” position. The LED will indicate the power is “ON”.

3. Be sure there are no obstructions that may interfere with the rotation of the arrow board.

4 . DO NOT exceed 50m p h in the travel position and 40m p h in the operating position.

WARNING!

POWER REQUIREMENTS:

8

11

SWITCH FINGER

23

[ 584.10 ]

1

2

18 4 PL'S

21 4 PL'S

19

22

22

22

19

19

15

15

24 4 PL'S

4

A

B

C

D

Z

sy3800110 - 24 X 48 aND 30 X 60 bOaRDs - 180

°

OveR Cab mOuNt Kit

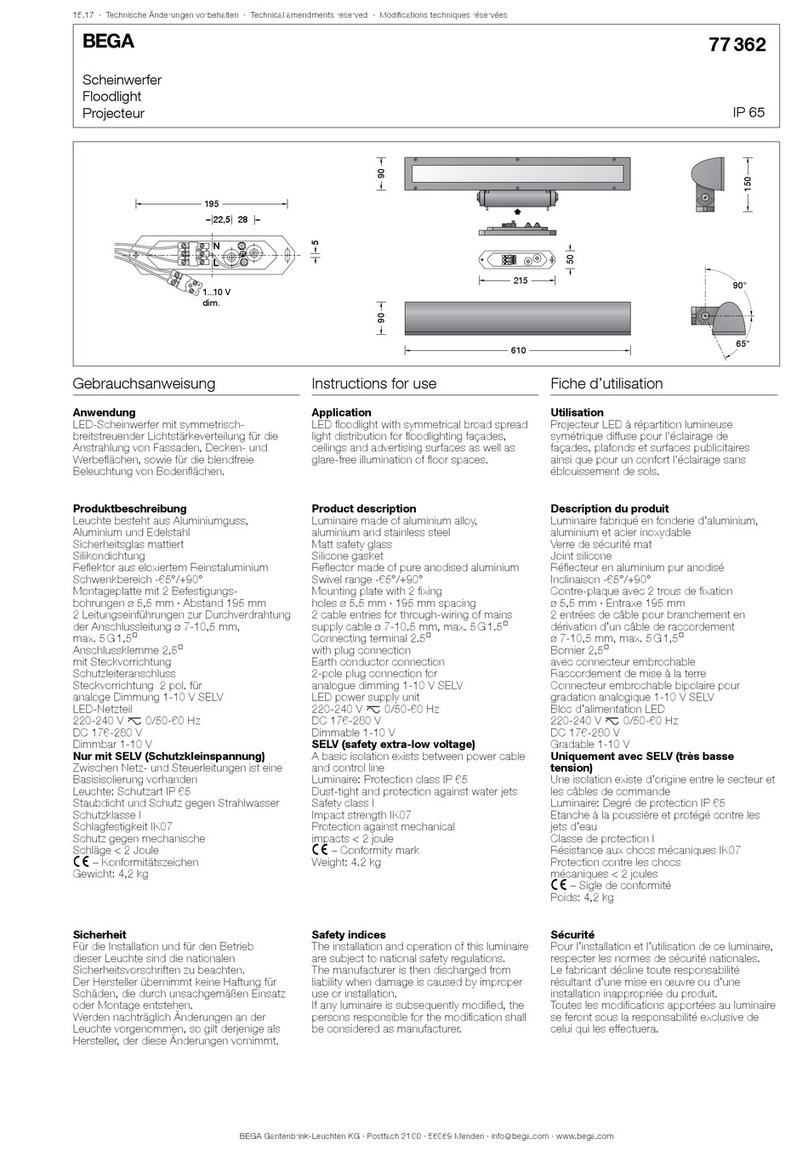

POsitiON sWitCH setuP

limit sWitCH iNstalatiON

Adjusting position switch:

1. Ensure unit is properly assembled and operational.

2. Turn the unit on. With the controller, manually position the sign where it is in the horizontal traveling position.

3. Mount the switch (item 11) to the adjuster plate (item 10) and lightly torque the screws (items 17, 21, and 24), trying not impede the movement of the

switch against the plate.

4. Attach the switch adjuster plate to the to the side of the support using items 16, 21 and 24 as shown in Fig 3, leaving the screws loose enough to adjust

the switch.

5. Move the switch in the direction parallel to the support as shown in Fig 3 until the switch is inline with the center of the switch finger and tighten the bolts.

6. Move the switch up towards the switch finger until you feel the switch click, then tighten the switch down.

7. Using the controller, manually rotate the sign to the full upright position.

8. Double tap the actuator direction button in the down position direction and watch where the sign stops. If the sign stops before the switch finger is inline with

the center of the switch, move the switch out away from the switch finger slightly. If the sign fails to stop in the traveling position, the switch needs to be

moved in towards the switch finger slightly.

9. Once the switch is adjusted properly, make sure the all the bolts are properly tightened and that the wires are routed as to not interfere with the normal

operation of the sign.

10. The switch is now adjusted and the sign is ready for use.

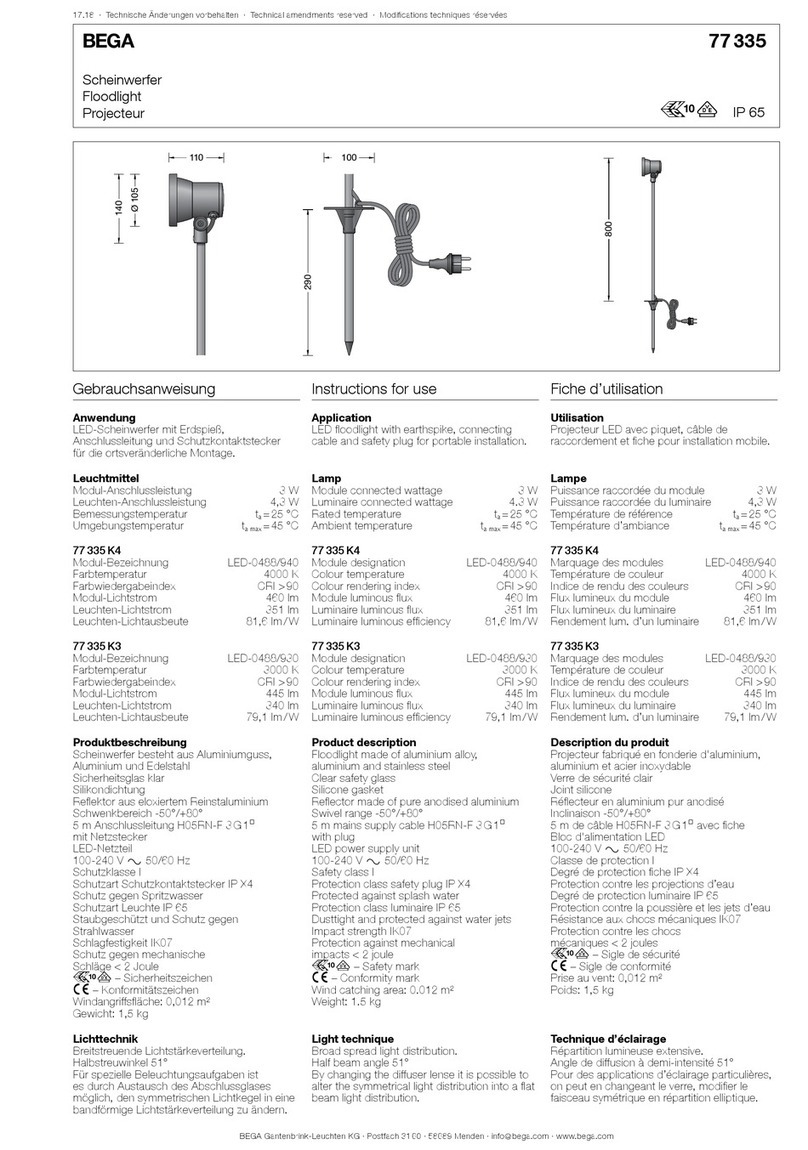

After routing the limit switch wires through the arrow board as described

in the lift kit manual, connect the wires as shown in the figure below.

Note that the photocell wire connected to the black lead on the driver

must be disconnected from the driver and re-connected to the limit

switch harness as shown.

PART

ITEM QTY DESCRIPTION NUMBER

1 1 FRAME, RIGHT, 180°

2 1 FRAME, LEFT, 180°

3 1 PLATE, PIVOT, 30 X 60 AND 24 X 48

4 1 BRACKET, SIGN, 30 X 60 AND 24 x 48

5 1 ACTUATOR, 6” STROKE SY3800090-A

6* 1 CABLE, ACTUATOR SY3800090-B

7 1 BRACKET, ACTUATOR

8 1 LINK, SWITCH FINGER

9 1 LINK, #1

10 1 MOUNT, SWITCH

11 1 SWITCH, LIMIT SY3800100-S

12 1 BOLT, HEX, 1/2-13 X 2 EL185-8100

PART

ITEM QTY DESCRIPTION NUMBER

13 2 BOLT, HEX, 1/2-13 X 2 1/4 SY3900100-F

14 1 BOLT, HEX, 1/2-13 X 2 1/2 SY3900100-N

15 5 BOLT, HEX, 1/2-13 X 3 1/4 SY3800120-V

16 2 SCREW, SLOT, #10-32 X 1 3/4 EL185-3043

17 2 SCREW, SLOT, #10-32 X 7/8 EL185-3041

18 4 BOLT, HEX, 5/16-18 X 3 SY3900100-J

19 14 WASHER, FLAT, 1/2 SY3900100-M

20 6 WASHER, FLAT, #10 EL185-4060

21 4 WASHER, FLAT, 5/16 EL185-6000

22 11 NUT, HEX, LOCKING, 1/2-13 SY3900100-L

23 4 NUT, HEX, LOCKING, #10-32 HY2308208

24 4 NUT, HEX, LOCKING, 5/16-18 SY3900100-K

*Not shown

EL510-3880

Figure 1 Figure 2

Figure 3

3

7

5

8

10

11

17 16

20 6 PL'S

23 4 PL'S

14

13

12

13

22 10 PL'S

19 12 PL'S

9

15

16355 SOUTH LONE ELM ROAD • OLATHE, KANSAS

66062 • USA • TOLL FREE: 800-447-3693 • PHONE:

913-780-1440 • FAX: 913-780-1427 • EMAIL: info@

superiorsignals.com • www.superiorsignals.com

16355 SOUTH LONE ELM ROAD • OLATHE, KANSAS

66062 • USA • TOLL FREE: 800-447-3693 • PHONE:

913-780-1440 • FAX: 913-780-1427 • EMAIL: info@

superiorsignals.com • www.superiorsignals.com

16355 south Lone eLm Road • oLathe, Kansas 66062 • usa • toLL fRee: 800-447-3693 • Phone: 913-780-1440 • faX: 913-780-1427 • emaiL: [email protected] • www.superiorsignals.com