®

®

®

®

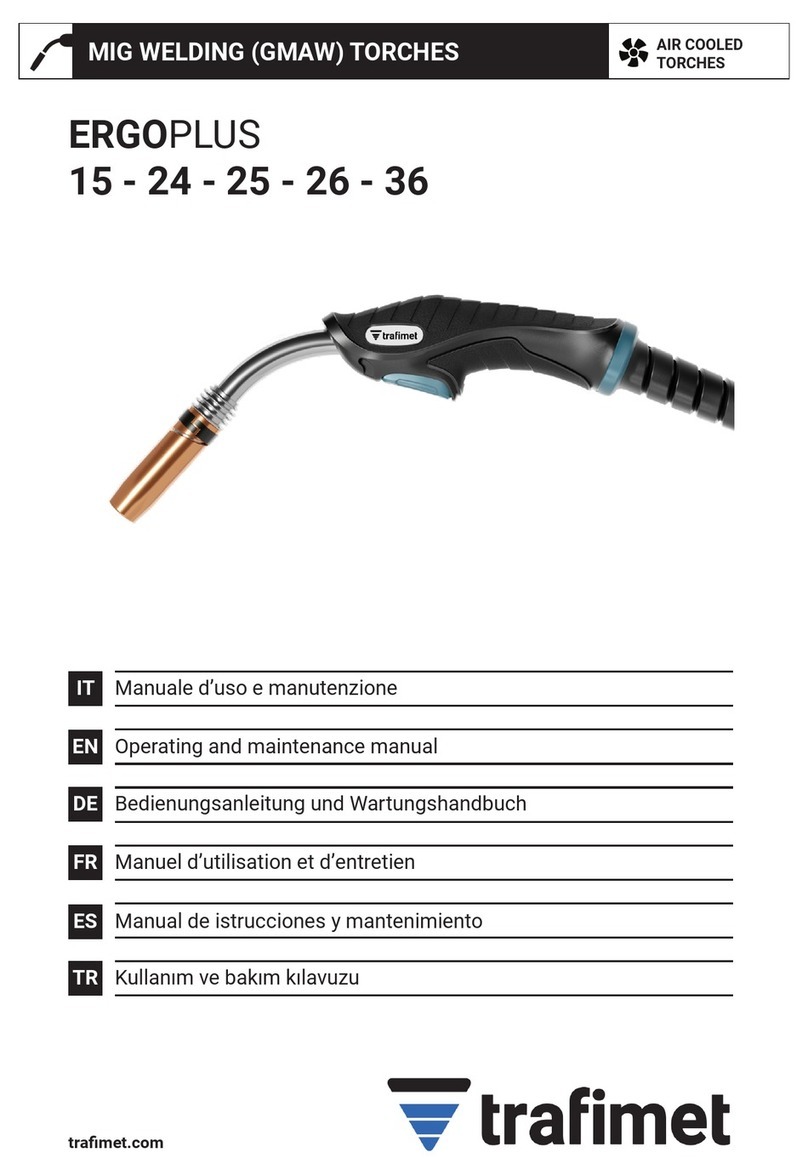

EN 50078

EN 50192

PW 180 MANUAL

PW 180 P AUTOMATIC

TRAFIMET spa claim that all items on this catalogue are manufactured in conformity

with the "low voltage" CE 73/23 directive as per EN 50078 and EN 50192 standards.

The company reserve the right to modify any products without notice.

TRAFIMET spa is the registered owner of all trademarks, patents and models.

Copyright ©July 1997 • by TRAFIMET spa (Print 05/98) EA 0446

ØA

1.2 50 - 80

1.4 70 - 100

1.6 90 - 140

1.8 110 - 160

2.0 130 - 180

MAX

MIN

PD 115-16

CV 91

Flowmeter

Flussometro

Durchflussmessrohr

Indicateue

d'écoulement

PW 180

CV 80

PACKAGING

Torch (1)

Tip (10)

Electrode (10)

Torch head (1)

Diffuser (2)

Nozzle

(2 or 4)

Warning For proper use and maintenance refer to the user's handbook attached to the torch.

Attenzione Consultare il manuale di uso e manutenzione allegato alla torcia.

Achtung Bitte unbedingt das beigefügte Bedienungshandbuch beachten.

Attention Consultez le manuel d'utilisation et de manutention joint à la torche.

Check the state of the swirl ring. Air holes must be open.

If not, the low cooling system will damage the torch head.

Controllare lo stato di efficienza del diffusore aria, che deve

sempre presentare i fori di accesso aria liberi da occlusioni.

Uberprüfen des Luftverteilers, das die Löcher nicht verstopft sind.

Contrôler le rendement du diffuseur d'air dont les trous

d'accès d'air doivent rester libres de toutes occlusions.

Operating instructions

The excessive wear of tip and electrode may cause some damage

to the torch head. Replace the electrode before its total

consumption as well as the tip when showing an irregular hole

or an increased diameter.

Modalità d'uso

L'eccessiva usura di cappa ed elettrodo può creare danni

al corpo torcia, sostituire l'elettrodo prima del totale consumo

dell'inserto e la cappa quando presenta un foro irregolare

o di diametro maggiorato.

Gebrauchsanweisung

Elektrode und Schneiddüsen sollten auf den Verschleiß hin

überprüft werden, überhöhte Beanspruchung führt zu

verschlechterten Schneidergebnissen und kann zu einer

Beschädigung des Brennerkörpers führen.

Modalite d'usage

L'usure excessive de la tuyère et de l'electrode peuvent causer

des dommages au col de cygne, remplacer l'electrode avant

l'usure totale de l'insert en HF ainsi que la tuyère si celle-ci

présente une "usure irrégulière" ou un diamètre majoré.

Choose the hole of the tip according to the following table:

Il diametro del foro della cappa va scelto secondo

la seguente tabella:

Schneiddüsen Durchmesser laut der nachstenden Tabelle:

Choisir le diamètre de la tuyère selon le tableau suivant:

Warranty will be valid only for genuine TRAFIMET

spare parts

La garanzia viene riconosciuta soltanto per ricambi

originali TRAFIMET

Garantie wird nur für Original TRAFIMET

Teile übernommen

Utiliser seulement pièces d'usure originales TRAFIMET