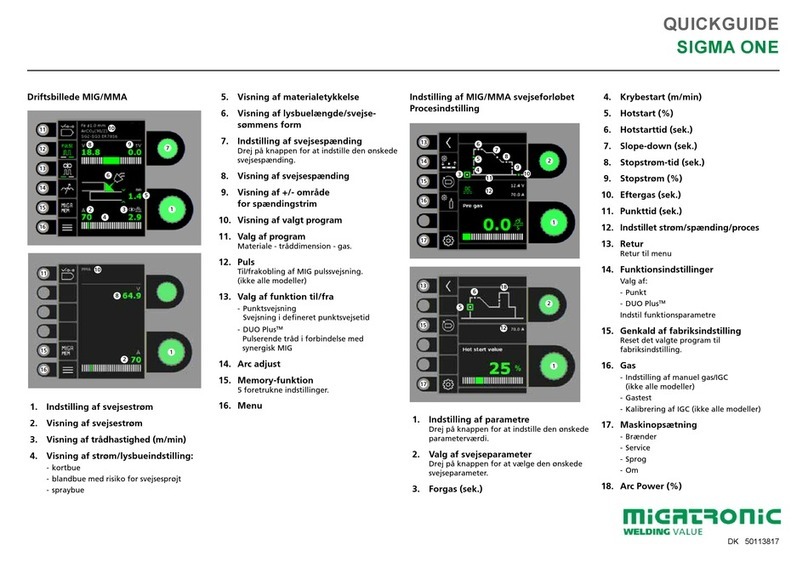

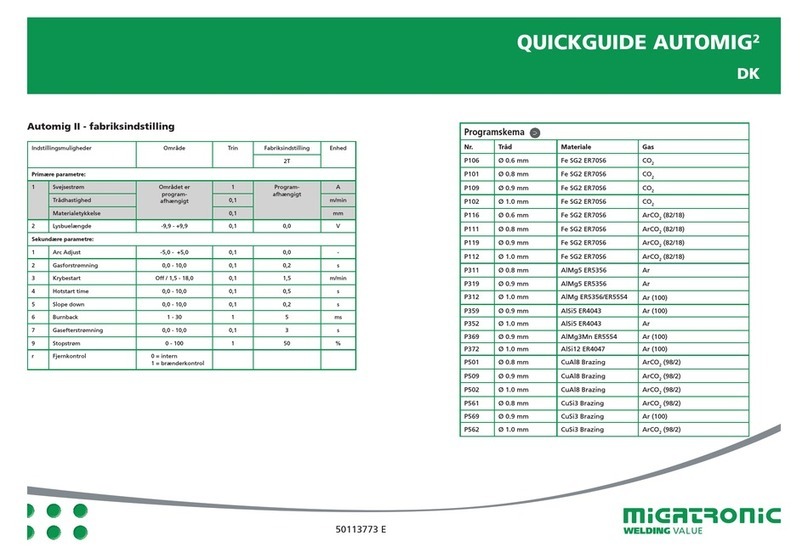

Migatronic AUTOMIG 2 User manual

Other Migatronic Welding System manuals

Migatronic

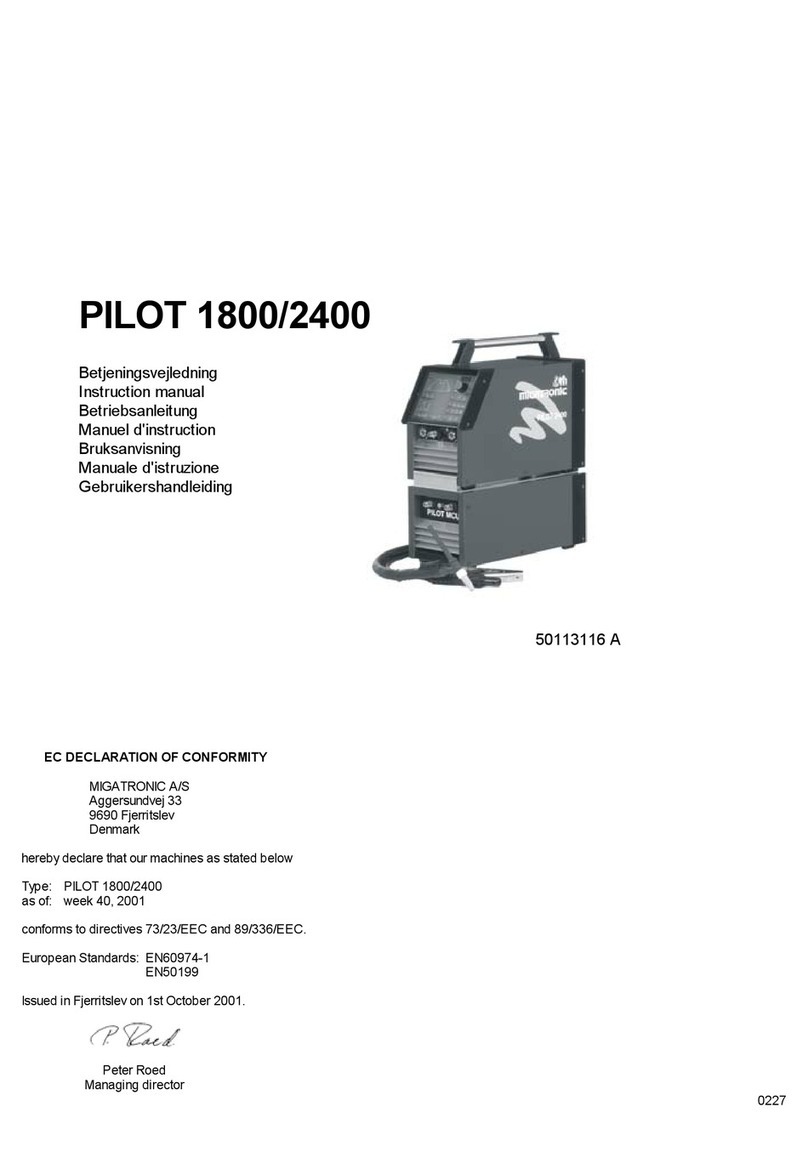

Migatronic PILOT 1800 User manual

Migatronic

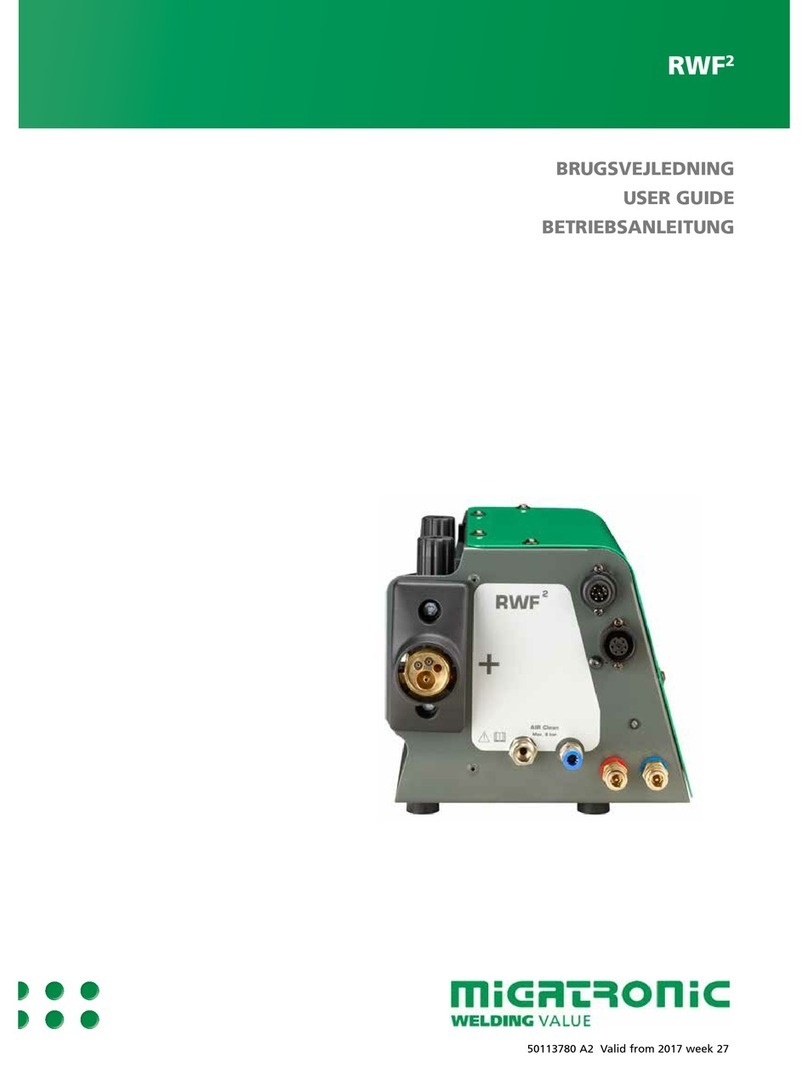

Migatronic RWF2 User manual

Migatronic

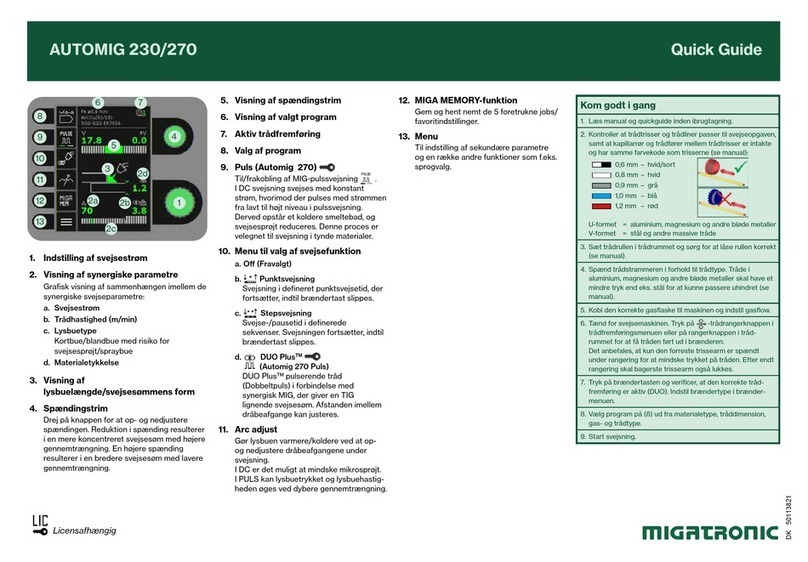

Migatronic Automig 230 User manual

Migatronic

Migatronic AUTOMIG2 223i/273i User manual

Migatronic

Migatronic SIGMA2 300 STBOFF SHORE User manual

Migatronic

Migatronic RALLY MIG 161i User manual

Migatronic

Migatronic RALLY MIG 161i User manual

Migatronic

Migatronic MWF 11x User manual

Migatronic

Migatronic OMEGA2 CoWelder 300 User manual

Migatronic

Migatronic SIGMA2 300 Compact User manual

Migatronic

Migatronic PI 200 DC User manual

Migatronic

Migatronic RALLY MIG 161i User manual

Migatronic

Migatronic FOCUS STICK 161 E PFC User manual

Migatronic

Migatronic AUTOMIG 223i/273i User manual

Migatronic

Migatronic PI 200 DC HP User manual

Migatronic

Migatronic RALLY MIG 161i User manual

Migatronic

Migatronic FOCUS MIG 300 User manual

Migatronic

Migatronic PI PLASMA User manual

Migatronic

Migatronic DELTA 160 HP User manual

Migatronic

Migatronic PI 350 AC/DC User manual

Popular Welding System manuals by other brands

TAFA

TAFA 30*8B35 owner's manual

Lincoln Electric

Lincoln Electric INVERTEC V350-PRO CE Technical specifications

ESAB

ESAB Buddy Arc 145 instruction manual

CIGWELD

CIGWELD 636804 use instructions

Red-D-Arc

Red-D-Arc DC-400 Operator's manual

Hobart Welding Products

Hobart Welding Products Spool Gun DP 3035-10 owner's manual