TrafSys Walker Wireless THM3020 User manual

W

Wi

ir

re

el

le

es

ss

s

O

Ov

ve

er

rh

he

ea

ad

d

T

Th

he

er

rm

ma

al

l

S

Se

en

ns

so

or

r

M

Mo

od

de

el

l:

:

T

TH

HM

M3

30

02

20

0

Traf-sys/Walker Wireless, Inc | 190 Industry Drive –Pittsburgh, PA 15275 Page 1 of 18

Ph: 888-815-6568 | Fax: 928-222-7279 | www.trafsys.com

Introduction

The Traf-sys/Walker Wireless Wireless Overhead

Thermal Sensors are a discreet and highly

accurate solution to track foot traffic through a

given area or entrance. The counter consists of

two parts, a base and the sensor, and determines

traffic using heat signatures from customers’

heads; upon a heat signature crossing configured

IN/OUT lines, a count of the appropriate direction

is transmitted to the wireless transmitter.

Table of Contents

Introduction.....................................................................................................................1

Table of Contents............................................................................................................1

Required Equipment........................................................................................................1

Mounting and Orientation................................................................................................2

Single Sensor Entrance...............................................................................................2

Calibrating the Sensors...................................................................................................4

Required Equipment for Calibration.............................................................................4

Attaching the Setup Module.........................................................................................4

Single Sensor Entrance Calibration.............................................................................6

Multiple Sensor Entrance Calibration.........................................................................14

Troubleshooting ............................................................................................................16

Thermal Issues..........................................................................................................16

Mounting Issues........................................................................................................16

Software Issues.........................................................................................................16

Safety and Occupancy Issues...................................................................................16

LED Codes................................................................................................................17

Appendix A: Sensor Base Wiring...................................................................................18

Required Equipment

Traf-sys/Walker Wireless Thermal Sensor Configuration Software

Windows XP or later laptop PC with an available 9 pin RS-232 Serial Port.

THM3020S Setup Module (do not attempt to use any other setup module).

Straight and Philips head screwdrivers (not included)

Mounting bolts/screws (not included)

Wall mount bracket or ceiling mounting plate (optional; not included)

Wireless Transmitter and Power Supply (included in kit)

RJ-45 patch cables (included in kit)

Category 5 Ethernet cable for multiple sensor connection (not included)

Female to female RJ-45 Category 5 Ethernet jacks (two per sensor)

Cable/jack tester

W

Wi

ir

re

el

le

es

ss

s

O

Ov

ve

er

rh

he

ea

ad

d

T

Th

he

er

rm

ma

al

l

S

Se

en

ns

so

or

r

M

Mo

od

de

el

l:

:

T

TH

HM

M3

30

02

20

0

Traf-sys/Walker Wireless, Inc | 190 Industry Drive –Pittsburgh, PA 15275 Page 2 of 18

Ph: 888-815-6568 | Fax: 928-222-7279 | www.trafsys.com

Mounting and Orientation

The accuracy and reliable operation of the Wireless Overhead Thermal Sensor is

largely dependent on proper mounting and orientation of the sensor(s). Per Figure 1,

always be sure that the sensor’s LEDs are closest to the inside of the store.

Figure 1

Always follow these guidelines when installing sensors:

60° (low mount) sensors accommodate heights between 7’3” and 15’9”.

40° (high mount) sensors accommodate heights between 11’5” and 24’7”.

Sensors are always mounted at an entrance inside of a store/facility; never

outside or in a vestibule.

Keep field of vision of the sensor(s) free from obstruction (e.g. hanging

signage or walls).

Cable connections are not data cables; they are simply made from the same

cable type. Do not alter or rewire the cabling connections.

Ensure that the sensor base is mounted parallel to the ceiling and securely

and flat against its mounting surface (ceiling, plate or bracket).

Single Sensor Entrance

A single sensor can be used when the mounting height allows the sensor’s field

of view to equal or exceed the width of the entrance. Figure 2 below illustrates a

single sensor installation.

Figure 2

W

Wi

ir

re

el

le

es

ss

s

O

Ov

ve

er

rh

he

ea

ad

d

T

Th

he

er

rm

ma

al

l

S

Se

en

ns

so

or

r

M

Mo

od

de

el

l:

:

T

TH

HM

M3

30

02

20

0

Traf-sys/Walker Wireless, Inc | 190 Industry Drive –Pittsburgh, PA 15275 Page 3 of 18

Ph: 888-815-6568 | Fax: 928-222-7279 | www.trafsys.com

Follow these checkpoints when installing the sensor:

1. Find an appropriate mounting point for your sensor. Ensure the field of

view is free from obstruction and that the mounting height allows the

sensor’s field of view to adequately cover the entrance.

2. Mount the sensor at the mount point and ensure the sensor’s LEDs are

closest to the inside of the store.

3. Connect the power supply to the wireless transmitter and the wireless

transmitter to the sensor. The sensor receives its power through the

wireless transmitter and also passes data to the wireless transmitter.

4. Ensure that both the sensor and wireless transmitter are receiving power.

The wireless transmitter’s screen should display numbers and the sensor

should show activity on its LEDs.

Multiple Sensor Entrance

When an entrance’s width spans an area much larger than what a single sensor

can cover, multiple sensors are required. One sensor will be configured to be the

master unit while the others will be configured as nodes; the nodes will receive

their power and transmit data to the master in a daisy chain fashion. It is also

advised that the master sensor is mounted furthest on the right when looking at

the entrance from the inside of the store. See Figure 3 below for an illustration.

Figure 3

Follow these checkpoints when installing multiple sensors:

1. Find an appropriate mounting point for your sensors. Ensure the field of

view is free from obstruction and that the mounting height allows the

sensors’ field of view to adequately cover the entrance.

2. Mount the sensors at the mount point and ensure the sensors’ LEDs are

closest to the inside of the store. Ensure that the master sensor is on the

right side when looking at the entrance from the inside of the store.

3. Connect the master and node sensors together using the gray cables

attached to their bases.

4. Connect the power supply to the wireless transmitter and the wireless

transmitter to the master sensor via the black cable. The sensor receives

W

Wi

ir

re

el

le

es

ss

s

O

Ov

ve

er

rh

he

ea

ad

d

T

Th

he

er

rm

ma

al

l

S

Se

en

ns

so

or

r

M

Mo

od

de

el

l:

:

T

TH

HM

M3

30

02

20

0

Traf-sys/Walker Wireless, Inc | 190 Industry Drive –Pittsburgh, PA 15275 Page 4 of 18

Ph: 888-815-6568 | Fax: 928-222-7279 | www.trafsys.com

its power through the wireless transmitter and also passes data to the

wireless transmitter; it will also pass to the node sensors in the same

fashion.

5. Ensure that all the sensors and the wireless transmitter are receiving

power. The wireless transmitter’s screen should display numbers and the

sensor should show activity on its LEDs.

Defining Base Characteristics

Type of Base

Base with One Black Cable

Single Sensor Base

Base with One Black Cable and One Gray Cable

Master Base (Multi-Sensor)

Base with Two Gray Cables

Intermediate Node (Multi-Sensor)

Base with One Gray Cable

Final Node (Multi-Sensor)

Table 1

Calibrating the Sensors

Once the sensors are physically installed, they must be calibrated correctly to ensure

high accuracy and proper operation. Single sensor and multiple sensor entrance

configurations are very similar, but there are a few extra things to be mindful of when

configuring a multiple sensor entrance.

Required Equipment for Calibration

Windows XP or later laptop PC with an available 9 pin RS-232 Serial Port.

Traf-sys/Walker Wireless Thermal Sensor Configuration Software installed.

(available at http://sw.trafsys.com/IRC3000/)

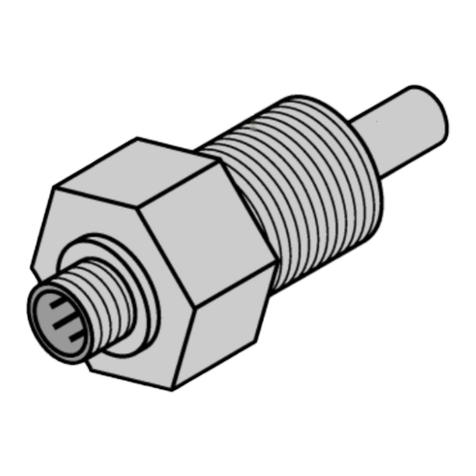

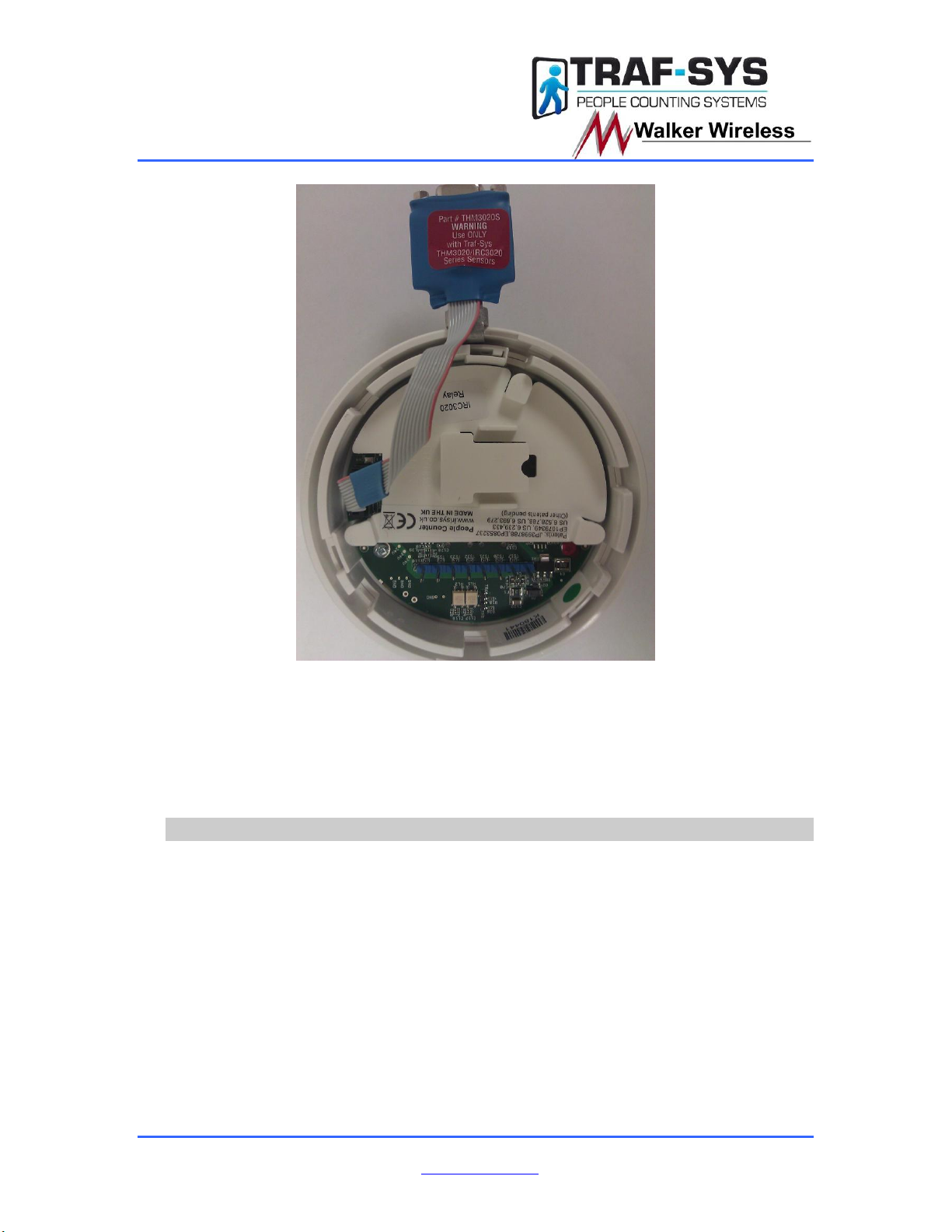

THM3020S Setup Module; see Figure 4 below (do not attempt to use any other

setup module).

A length of serial cable long enough to reach the setup module and the RS-232

port on your PC.

Attaching the Setup Module

1. Remove the sensor from its base. This can be done by twisting the

sensor counter-clockwise to unlock the sensor from the base. After the

sensor is unlocked, pull to remove it from the base.

2. Connect the setup module at the 10 pin female connector inside the

sensor; the 10 pin connector and port are black colored plastic. See

Figure 5 below; also see Figures 6 & 7 for further illustration.

W

Wi

ir

re

el

le

es

ss

s

O

Ov

ve

er

rh

he

ea

ad

d

T

Th

he

er

rm

ma

al

l

S

Se

en

ns

so

or

r

M

Mo

od

de

el

l:

:

T

TH

HM

M3

30

02

20

0

Traf-sys/Walker Wireless, Inc | 190 Industry Drive –Pittsburgh, PA 15275 Page 5 of 18

Ph: 888-815-6568 | Fax: 928-222-7279 | www.trafsys.com

Figure 5

3. Hook the metal part of the setup module just inside the case of the

sensor. This will allow the setup module to slide through a slot on the

base and allow it to be available externally while the sensor is mounted.

See Figure 6 & 7 below.

Figure 6

W

Wi

ir

re

el

le

es

ss

s

O

Ov

ve

er

rh

he

ea

ad

d

T

Th

he

er

rm

ma

al

l

S

Se

en

ns

so

or

r

M

Mo

od

de

el

l:

:

T

TH

HM

M3

30

02

20

0

Traf-sys/Walker Wireless, Inc | 190 Industry Drive –Pittsburgh, PA 15275 Page 6 of 18

Ph: 888-815-6568 | Fax: 928-222-7279 | www.trafsys.com

Figure 7

4. With the setup module in place, attach the sensor to its base again. Line

the sensor back up with its pins on the base and push it into the base.

Twist the sensor clockwise until it locks in to place. It is normal for the fit

to tighter due to the setup module.

5. After the sensor is locked in to place, attached the serial cable to both the

setup module and your laptop PC.

Single Sensor Entrance Calibration

Now that you are connected serially to the sensor with your laptop, please follow

these steps to calibrate the sensor:

1. Launch the Thermal Sensor Configuration Software.

2. Select the appropriate COM port that your serial cable is connected to

and click OK.

3. After the software connects to the sensor, the setup wizard will run and

should tell you that the IDs need to be configured. Press Next and you

will be asked to enter a Comms ID for the sensor with flashing lights. In a

single sensor setup, using “1” will be safe. See Figure 8 below for

illustration.

W

Wi

ir

re

el

le

es

ss

s

O

Ov

ve

er

rh

he

ea

ad

d

T

Th

he

er

rm

ma

al

l

S

Se

en

ns

so

or

r

M

Mo

od

de

el

l:

:

T

TH

HM

M3

30

02

20

0

Traf-sys/Walker Wireless, Inc | 190 Industry Drive –Pittsburgh, PA 15275 Page 7 of 18

Ph: 888-815-6568 | Fax: 928-222-7279 | www.trafsys.com

Figure 8

4. After setting the Comms ID, press Next and the wizard should report that

it has saved your settings successfully.

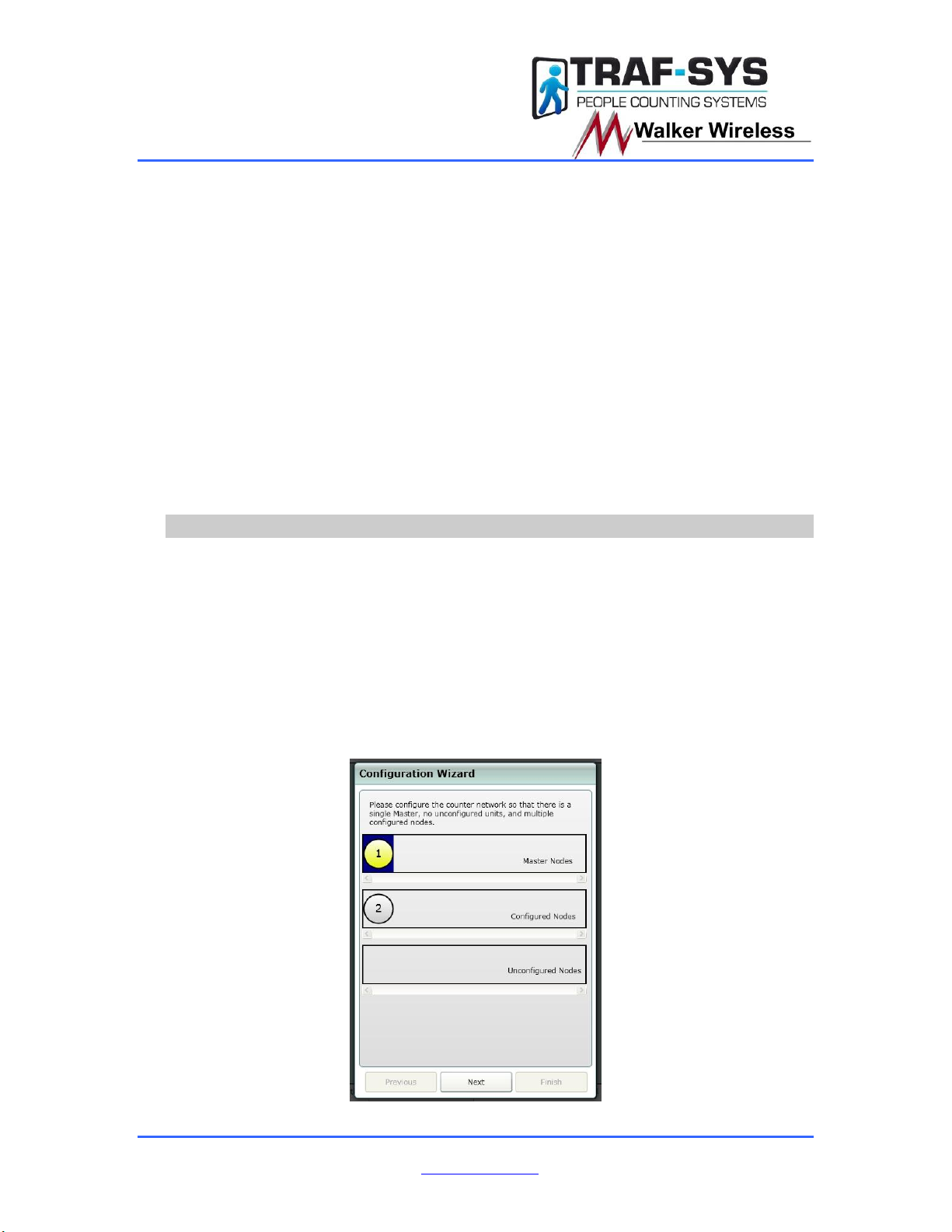

5. Press Next and you will be presented with a screen detailing Master

Nodes, Configured Nodes and Unconfigured Nodes. Click and drag the

red circle for your sensor to the Master Nodes section; the number on the

circle represents its Comms ID. See Figure 9 & 10 below for illustration.

Figure 9

Figure 10

6. Press Next and the wizard should report that it has saved your settings

successfully.

W

Wi

ir

re

el

le

es

ss

s

O

Ov

ve

er

rh

he

ea

ad

d

T

Th

he

er

rm

ma

al

l

S

Se

en

ns

so

or

r

M

Mo

od

de

el

l:

:

T

TH

HM

M3

30

02

20

0

Traf-sys/Walker Wireless, Inc | 190 Industry Drive –Pittsburgh, PA 15275 Page 8 of 18

Ph: 888-815-6568 | Fax: 928-222-7279 | www.trafsys.com

7. Press Next and you will be presented with a confirmation screen showing

the number of sensors and the desired measurement format. See Figure

11 below for an illustration.

Figure 11

8. Confirm that the information displayed is correct and press Next. The

wizard should report that it has saved your settings successfully.

9. Press Next and you will be presented with a screen stating that

configuration is complete. Press Finish to exit the wizard. See Figure 12

below for an illustration.

Figure 12

W

Wi

ir

re

el

le

es

ss

s

O

Ov

ve

er

rh

he

ea

ad

d

T

Th

he

er

rm

ma

al

l

S

Se

en

ns

so

or

r

M

Mo

od

de

el

l:

:

T

TH

HM

M3

30

02

20

0

Traf-sys/Walker Wireless, Inc | 190 Industry Drive –Pittsburgh, PA 15275 Page 9 of 18

Ph: 888-815-6568 | Fax: 928-222-7279 | www.trafsys.com

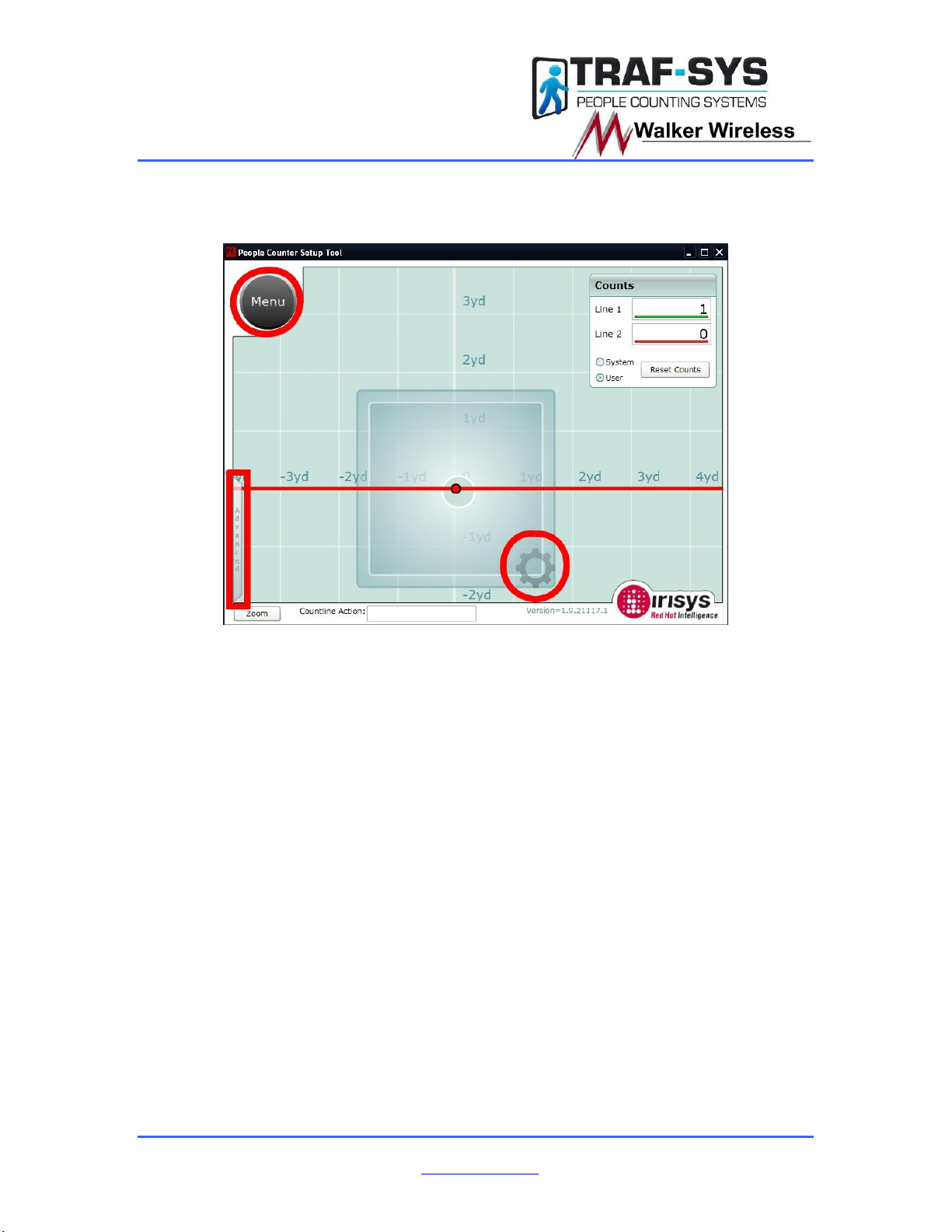

10. In the main screen of the configuration utility, there are a few important

buttons to be mindful of: Menu, Advanced and Device Settings. The

locations of these menus are highlighted in red in Figure 13 below.

Figure 13

11. These three menus expand to reveal sub-menus. In Figure 14 below you

will see the expanded Menu and Advanced while in Figure 15 below you

will see the Device Settings menu (opened by clicking the gear).

W

Wi

ir

re

el

le

es

ss

s

O

Ov

ve

er

rh

he

ea

ad

d

T

Th

he

er

rm

ma

al

l

S

Se

en

ns

so

or

r

M

Mo

od

de

el

l:

:

T

TH

HM

M3

30

02

20

0

Traf-sys/Walker Wireless, Inc | 190 Industry Drive –Pittsburgh, PA 15275 Page 10 of 18

Ph: 888-815-6568 | Fax: 928-222-7279 | www.trafsys.com

Figure 14

W

Wi

ir

re

el

le

es

ss

s

O

Ov

ve

er

rh

he

ea

ad

d

T

Th

he

er

rm

ma

al

l

S

Se

en

ns

so

or

r

M

Mo

od

de

el

l:

:

T

TH

HM

M3

30

02

20

0

Traf-sys/Walker Wireless, Inc | 190 Industry Drive –Pittsburgh, PA 15275 Page 11 of 18

Ph: 888-815-6568 | Fax: 928-222-7279 | www.trafsys.com

Figure 15

12. The sub-menu functions of Menu are as follows:

a. Global –The global settings and errors generated. Global

Settings allow you to set Site information, Date, Time, Time Zone

and Logging Interval. Errors and Warnings displays generated

errors and warnings as well as options to clear and save them.

b. Backup/Restore –You may choose to Backup, Restore or

Compare settings in this menu. Backup saves settings to a file;

Restore takes settings from a file and applies them to the current

sensor while Compare will compare the current settings to a

previously saved file.

c. Lines –This menu allows you to reset the lines to their default

positions or to invert their directions.

d. Run Wizard –Allows you to run the wizard detailed in steps 3-9

again.

e. Permanent All –This sub-menu saves all changes made to be

persistent. This sub-menu should be used frequently and after

any changes are made that should remain.

f. Relay Config –This sub-menu controls which relays the counter

communicates on. The settings in this menu are crucial to the

counter operating properly. See Figure 16 below for the correct

W

Wi

ir

re

el

le

es

ss

s

O

Ov

ve

er

rh

he

ea

ad

d

T

Th

he

er

rm

ma

al

l

S

Se

en

ns

so

or

r

M

Mo

od

de

el

l:

:

T

TH

HM

M3

30

02

20

0

Traf-sys/Walker Wireless, Inc | 190 Industry Drive –Pittsburgh, PA 15275 Page 12 of 18

Ph: 888-815-6568 | Fax: 928-222-7279 | www.trafsys.com

settings to communicate with the Traf-sys/Walker Wireless

Wireless Transmitter devices.

Figure 16

13. The options of the Advanced menu function as follows and an illustration

of correct Advanced menu settings will be show in Figure 17 below:

a. Discrimination Sensitivity –This slider can be adjusted for

accuracy fine tuning.

b. Large Target Couple Counting –When Enabled the sensor

attempts to count large targets (couples) as a single count. This is

typically disabled.

c. Count Mode –Immediate registers counts as lines are crossed.

Deferred registers counts using the last line crossed after the

customer leaves the field of view. Deferred should be used with

Count U-Turns disabled.

d. Deferred Initialization –This option adds an extra step to the

initialization process in an attempt to prevent “ghost” counts from

a floor that is subject to rapid temperature changes. Only use this

option if this specific scenario is observed.

e. Display Path Map Data/Reset Path Mapping –This is mostly for

calibration purposes; it gives a visual representation of where

customers get initialized and their path through the field of view.

W

Wi

ir

re

el

le

es

ss

s

O

Ov

ve

er

rh

he

ea

ad

d

T

Th

he

er

rm

ma

al

l

S

Se

en

ns

so

or

r

M

Mo

od

de

el

l:

:

T

TH

HM

M3

30

02

20

0

Traf-sys/Walker Wireless, Inc | 190 Industry Drive –Pittsburgh, PA 15275 Page 13 of 18

Ph: 888-815-6568 | Fax: 928-222-7279 | www.trafsys.com

Figure 17

14. In the Device Settings menu, you will be able to adjust the Mounting

Height, the X-Y and the Comms ID. The X-Y is the position relative to the

0yd, 0yd point on the graph shown in the background; X controls

horizontal positioning and Y controls vertical positioning. Unit Descriptor,

Device ID, Site Name, Site ID and Locale are optional settings used for

device identification and informational purposes. Refer to Figure 14

above.

15. The last step of sensor calibration is adjusting the line configuration. To

move the line as a whole, click on anywhere on the line that is not a dot.

Clicking on the dots on the line(s) allows you to create anchor points;

anchor points allow you to create a curved or otherwise customized count

line. See Figure 18 below for an illustration.

Figure 18

16. Click the Permanent All sub-menu under Menu to make all settings

persistent.

W

Wi

ir

re

el

le

es

ss

s

O

Ov

ve

er

rh

he

ea

ad

d

T

Th

he

er

rm

ma

al

l

S

Se

en

ns

so

or

r

M

Mo

od

de

el

l:

:

T

TH

HM

M3

30

02

20

0

Traf-sys/Walker Wireless, Inc | 190 Industry Drive –Pittsburgh, PA 15275 Page 14 of 18

Ph: 888-815-6568 | Fax: 928-222-7279 | www.trafsys.com

17. You will now want to test your configuration (this may require the

assistance of additional people). Be sure to test the following scenarios

in addition to “normal” counting:

a. People walking into the store and making a sharp turn. If the

sensor fails to count, you may have to customize the line shape to

better capture this type of behavior.

b. Two or more people entering at the same time, side-by-side. This

may require Large Target Couple Counting being disabled or

enabled based upon customer’s request.

c. People quickly entering and leaving the store. The sensor should

not miss counts of fast moving targets. If the sensor is missing

these counts, the lines will have to be adjusted further inside of

the store to allow more initialization time.

18. Is the sensor counting accurately? If not, adjust the appropriate settings

and repeat step 17. If the sensor is counting accurately, repeat step 16 to

make the settings permanent and you are finished calibrating.

Multiple Sensor Entrance Calibration

Single sensor configuration is remarkably similar to multiple sensor configuration,

just take note of a few key points from below:

1. You will be configuring multiple Comms IDs in step 3. The master sensor

will be Comms ID 1 and the closest sensor on its left (looking out of the

store) will be Comms ID 2. Continue in this fashion incrementing the

Comms ID for each additional sensor. You will be asked to set the

Comms ID for the sensor that is blinking its LED lights one at a time. See

Figure 3 for illustration.

2. You will have 1 Master Node and at least 1 Configured Node in step 5.

You will have to drag and drop the sensors into their necessary roles.

See Figure 19 below.

Figure 19

W

Wi

ir

re

el

le

es

ss

s

O

Ov

ve

er

rh

he

ea

ad

d

T

Th

he

er

rm

ma

al

l

S

Se

en

ns

so

or

r

M

Mo

od

de

el

l:

:

T

TH

HM

M3

30

02

20

0

Traf-sys/Walker Wireless, Inc | 190 Industry Drive –Pittsburgh, PA 15275 Page 15 of 18

Ph: 888-815-6568 | Fax: 928-222-7279 | www.trafsys.com

3. You will be required to configure the Height and X-Y of the sensors during

the wizard process. Measure the appropriate Height value and use the

Traf-sys Sensor Wide Opening Setup Calculator to determine the

necessary X-Y offsets. See Figures 20 & 21 below.

Figure 20

Figure 21

4. There will be one square for each sensor’s field of view and one gear icon

on each field of view to open the Device Settings menu specific to that

device. See Figure 22 below.

Figure 22

5. In step 15, ensure that the configured count lines span across all of the

sensors’ fields of view. As also shown in Figure 22 above.

W

Wi

ir

re

el

le

es

ss

s

O

Ov

ve

er

rh

he

ea

ad

d

T

Th

he

er

rm

ma

al

l

S

Se

en

ns

so

or

r

M

Mo

od

de

el

l:

:

T

TH

HM

M3

30

02

20

0

Traf-sys/Walker Wireless, Inc | 190 Industry Drive –Pittsburgh, PA 15275 Page 16 of 18

Ph: 888-815-6568 | Fax: 928-222-7279 | www.trafsys.com

Troubleshooting

Below are solutions to common problems you may experience with the Wireless

Overhead Thermal Sensor.

Thermal Issues

The Wireless Overhead Thermal Sensors perform at their best in a stable

thermal environment. Situations to avoid:

Locations where machinery or high powered lighting can cause hot spots

of false heat signatures that could be read by the sensor.

Where flooring materials could acquire and store heat via sunlight or high

powered lighting.

Locations where temperatures changes rapidly.

Mounting Issues

Ensure that the field of view is not obstructed by any type of hanging

signage, decorations, fans or lighting.

When mounting sensors to a wall, use the supplied bracket(s) and ensure

that the sensor(s) look directly downward on the detection area.

Do not mount sensors adjacent to vibrating equipment, HVAC vents or

pipes that could cause temperature changes.

Software Issues

The sensor view freeze for a moment or two during use.

oSome serial port drivers buffer data rather than passing it

immediately to the program connected to the COM port. This can

cause a pause during streaming data. This is not a fault of the

sensor, but a feature of the communication port/device. Certain

USB to serial converters may exhibit this problem.

“Device did not reply to ping”

oThis error is most common when using the incorrect COM port or

the sensor(s) are not powered on. Check your COM port and

sensor power and try again.

The COM port I would like to use is not listed.

oCheck other running applications. Certain applications may

require the use of a COM port (virtual or physical) and may lock a

COM port down while the application is running. Exit any

application you feel might be locking up a COM port.

oIf you feel you do not have an application running that would be

locking the COM port, check to make sure that you are using the

correct COM port and that the drivers for the device are correctly

installed.

Safety and Occupancy Issues

The use of Wireless Overhead Thermal Sensors for Occupancy or Safety related

applications is not recommended. No automated people counting solution is

100% accurate, and applications of Occupancy and Safety would almost require

W

Wi

ir

re

el

le

es

ss

s

O

Ov

ve

er

rh

he

ea

ad

d

T

Th

he

er

rm

ma

al

l

S

Se

en

ns

so

or

r

M

Mo

od

de

el

l:

:

T

TH

HM

M3

30

02

20

0

Traf-sys/Walker Wireless, Inc | 190 Industry Drive –Pittsburgh, PA 15275 Page 17 of 18

Ph: 888-815-6568 | Fax: 928-222-7279 | www.trafsys.com

that level of accuracy. If you decide to use the Wireless Overhead Thermal

Sensors for an Occupancy or Safety related application, do so at your own risk

and keep in mind that there is likely to be an error margin involved.

LED Codes

The LED Codes below are for Normal Operation. You should not be concerned

when these occur.

Both LEDs ON: Unit Start

oAs soon as power is applied to the counter it will start a boot up stage, this lasts

approximately 10 seconds and is indicated by both the red and green LEDs on

solidly. Close examination of the LEDs will reveal two small (<100ms) off periods

as different code sections are booted. Once the counter finishes its boot up

stage, it will begin its array stabilization stage.

LEDs Alternate Flashing: Array Stabilization

oAs each counter is a thermal sensing device it must stabilize to its installed

environment. This stabilization stage lasts between 45 seconds and 2 minutes,

dependant on ambient temperature, supply voltage/current etc. During this time,

the two LEDs will alternately flash starting with red ON and green OFF, then

changing to red OFF and green ON, repeating, and changing every second. If

connected via the setup software then an animation will also be displayed.

Occasional LED ‘Blip’: Functioning

oFollowing a successful warm-up period, counters will begin tracking targets and

counting normally. If the counter is not yet configured then it will flash an error

sequence as below. If the counter is configured, then, at this point, counters will

blip both of their LEDs, together, every 5 seconds to indicate correct operation (a

‘Heart beat’). Each LED will also blip independently when a person crosses the

corresponding count line; green LED for Line 1, red LED for Line 2.

Both LEDs Flashing Together Very Quickly: Unit Identification

oAll counters must be configured before they will count correctly –details such as

the height and ground plane position must be entered along with giving each

counter a unique CAN address. Because every counter will have the same

default address when installed, an LED flash sequence is instigated by the

counter setup software to indicate which counter you are currently configuring.

The sequence is both the red and green LEDs flashing together very quickly.

This is essential when configured a network of more than one counter as it is

extremely important to verify the correct counter is being configured by

recognizing this identification sequence.

The LED codes below are for Error Conditions. You should be concerned when

these occur. Error Conditions are noted by the red LED staying on permanently with

a flash sequence coming from the green LED.

Red LED ON, Green LED OFF.

oThis indicates an internal fault which is not resolvable by the user. The only

course of action available is to power down the unit, wait 10 seconds and power

on again. This will rectify the problem in the majority of cases. If this does not

correct the fault then the unit should be returned to your supplier for repair.

Red LED ON, Green LED Flashing Once per Second Repeating

oThis indicates that the counter is has not been configured and is at factory default

address of 127. This is perfectly normal for a new unit and merely indicates that

W

Wi

ir

re

el

le

es

ss

s

O

Ov

ve

er

rh

he

ea

ad

d

T

Th

he

er

rm

ma

al

l

S

Se

en

ns

so

or

r

M

Mo

od

de

el

l:

:

T

TH

HM

M3

30

02

20

0

Traf-sys/Walker Wireless, Inc | 190 Industry Drive –Pittsburgh, PA 15275 Page 18 of 18

Ph: 888-815-6568 | Fax: 928-222-7279 | www.trafsys.com

it requires configuring. All units should be configured as part of the installation

process to ensure accurate count data, and a Comms ID of between 1 and 120

should be entered for each counter. Remember that correct count line positioning

and counter configuration is the key to accurate counting.

Red LED ON, Green LED Flashing Twice per Second Repeating

oThis error can only occur on a master counter; it indicates that the master is not

receiving responses from nodes that were previously connected. This will occur if

a node is removed or disconnected; or if a node has been powered off; or there

is a wiring break between the master and the node(s). This error should not be

confused with the Green LED flashing three times error (below) which can only

occur on a node, although these errors may be seen together in certain

circumstances.

Red LED ON, Green LED Flashing Three Times per Second Repeating

oThis error can only occur on a node unit; it indicates that the node is not been

polled by the master unit. This will occur if the master is removed or

disconnected; or if the master is powered off; or if there is a wiring break between

the master and the node(s). This error should not be confused with the Green

LED flashing twice error (above) which can only occur on a master, although

these errors may be seen together in certain circumstances.

Appendix A: Sensor Base Wiring

Table of contents