Delta DAC-633 User manual

Other Delta Controllers manuals

Delta

Delta 2SP2 User manual

Delta

Delta VFD-ED Series User manual

Delta

Delta VFD-M-D series User manual

Delta

Delta DVP-EH2 Series User manual

Delta

Delta NC200 User manual

Delta

Delta DVP-20PM User manual

Delta

Delta ASDA-A2 Series User manual

Delta

Delta NC EM Series User manual

Delta

Delta AS Series User manual

Delta

Delta AX Series User manual

Delta

Delta AH500 series User manual

Delta

Delta DVP-PM Series Instructions for use

Delta

Delta DVP-EH3 User manual

Delta

Delta DVP-SX2 User manual

Delta

Delta DVP-PLC Instructions for use

Delta

Delta DVP-SS2 User manual

Delta

Delta DVP-ES2 User manual

Delta

Delta DC-132 Series User manual

Delta

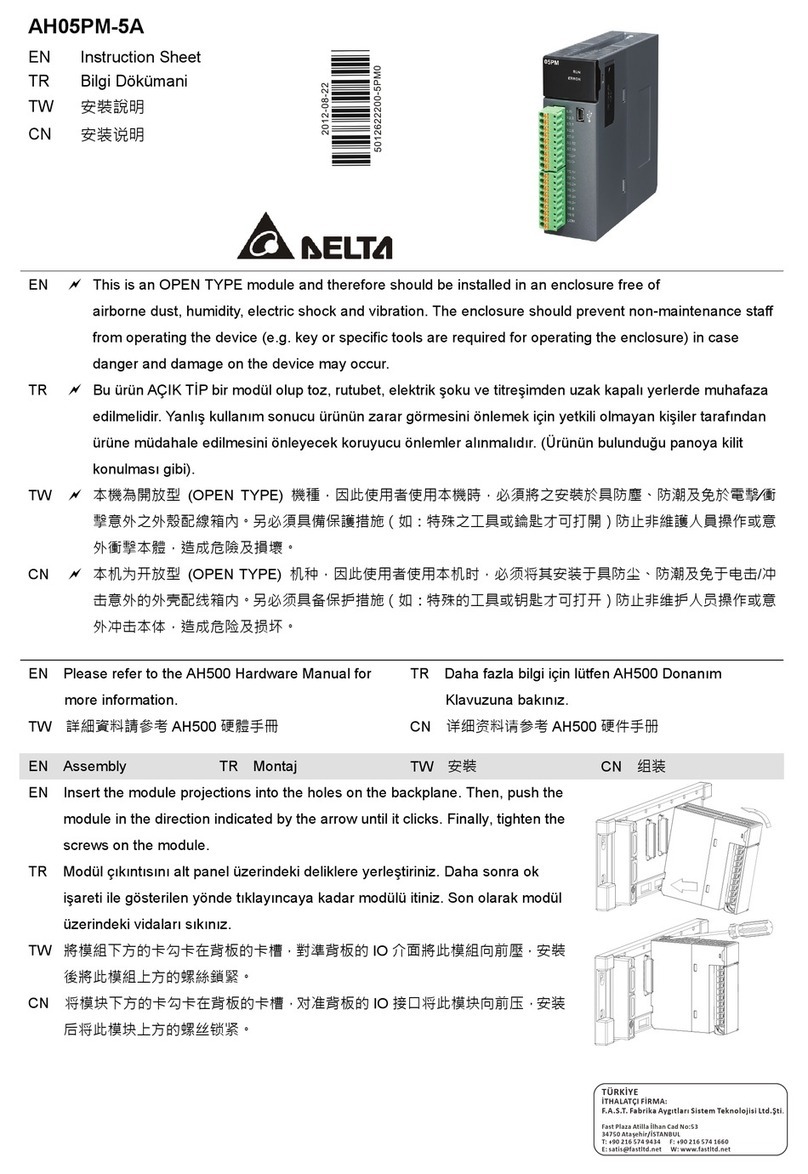

Delta AH05PM-5A User manual

Delta

Delta 29FWC-100E User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions