Train-Tech SC300 User manual

See our website, your local model shop or contact us for a free colour brochure

DCP Microdevelopments, Bryon Court, Bow Street, Great Ellingham, NR17 1JB, UK

Telephone 01953 457800 • email sales@dcpmicro.com • www.dcpexpress.com

www.Train-Tech.com

SC300 Dapol Semaphore Controller

•DCC Control 2 Dapol N/OO Semaphore Signals

•Automatic signals with Train-Tech Track Sensors

•Also control from optional Mimic Switches

•Regulated power supply for signals built -in

•Power and use with either 12-16V DC or DCC

Train Tech overview - ask for free catalogue

Signal kits - OO/HO low cost easy to make signals for DC

Sensor Signals - easy automatic block signalling - DCC or DC

Smart Lights - small effects built in - DC/DCC - just 2 wires:

Arc welding • Emergency vehicle • TV • Fire effect •!Party disco

Automatic Coach Lights - motion - no pickups or wiring:

Older Warm White • Modern Cool White • Tail Light • Spark Arc

Automatic Tail Lights - motion - easy, no wires - lantern LED:

Flickering flame oil lamp • Modern Flashing • Constant light

Track Tester - quickly tests DC polarity or DCC - N-TT-HO-OO

SFX+ Sound capsules - no wires! - real trains - DC or DCC

Steam •!Diesel • DMU • Passenger coach • Shunted stock

Buffer Light - clip in lights for buffer stops - N or OO - DC/DCC

LFX Lighting effects - DC/DCC - screw terminals - with LEDs:

Home & Shop lighting • Welding •!Flashing Effects •!Fire

Traffic Lights - fully assembled - just connect to DC or DCC

Level Crossings - assembled - N & OO versions - DC / DCC

DCC fitted signals - slide in the track - easy one touch setup:

2 aspect • 3 aspect • 4 aspect • Dual head • Feathers • Theatre

DCC Point Controllers

DCC Signal Controllers

LEDs

Tools etc

COMPREHENSIVE CATALOGUE FREE ON REQUEST

www.train-tech.com

SC300 Signal Controller

Dapol OO or N signals

connect direct to this

module for

easy DCC power

and control

SC300 Signal Controller

1"

Please read these instructions fully before connecting and powering up!!

Document Ref D779618/1 DP171117

Introduction

The SC300 is a Signal controller designed to power and control one or two standard Dapol OO

or N gauge semaphore signals. It offers the following functions:

" " • DCC Control of Dapol Semaphore Signals

" " • Automatic control of Semaphore signals using Track sensors

" " • Control of Semaphore signals using Mimic Switches

" " • Built in stable and regulated power supply for the Dapol signals

Contents

This instruction booklet explains how to connect, setup and use the SC300 on your layout and

we strongly recommend you read it before starting installation.

" " Locating the SC300 and wiring" " " Page 2

" " Controlling signals by DCC " " " Page 3

" " Automatic Control using one Track Sensor"Page 4

" " Automatic Control using two Track Sensors"Page 5

" " Controlling signals with Mimic switches" " Page 6

" " Additional information & Troubleshooting"Page 7

Making it easy….

The SC300 can be powered either by DC or DCC - on DCC the SC300 can connect directly to

the nearest DCC track to minimise wires - it takes both its commands and power from the rails.

Just wire in standard Dapol Semaphore signals and they can be instantly controlled using DCC

- add a Track Sensor and connect with just one wire and your signals change automatically!

DCC is a system which transmits both power and digital commands down 2 wires or rails to

control and power locomotives and accessories.

At Train-Tech we believe that DCC technology should make life easier to build, control and use

model railways, so all of our range of DCC Signals, Controllers and accessories connect using

just 2 wires and are all setup using just a single button press which we call ‘One-Touch DCC’.

A note about DCC accessory control

If this is the first accessory you have controlled by DCC you need to be aware that accessories

are controlled by a slightly different command than the locomotives.

Accessory commands are completely separate to Loco commands and most DCC hand and

computer linked controllers offer this facility, usually by pressing a specific button to enter into

accessory command mode (eg ACC) or by using a specified range of addresses for accessories

(eg on the Hornby Select addresses over 60 are for accessories only). There are only a few

controllers which do not offer control of DCC accessories including the basic Bachmann EZ

command (as supplied in sets) and Prodigy Express (not the Prodigy Advance which does).

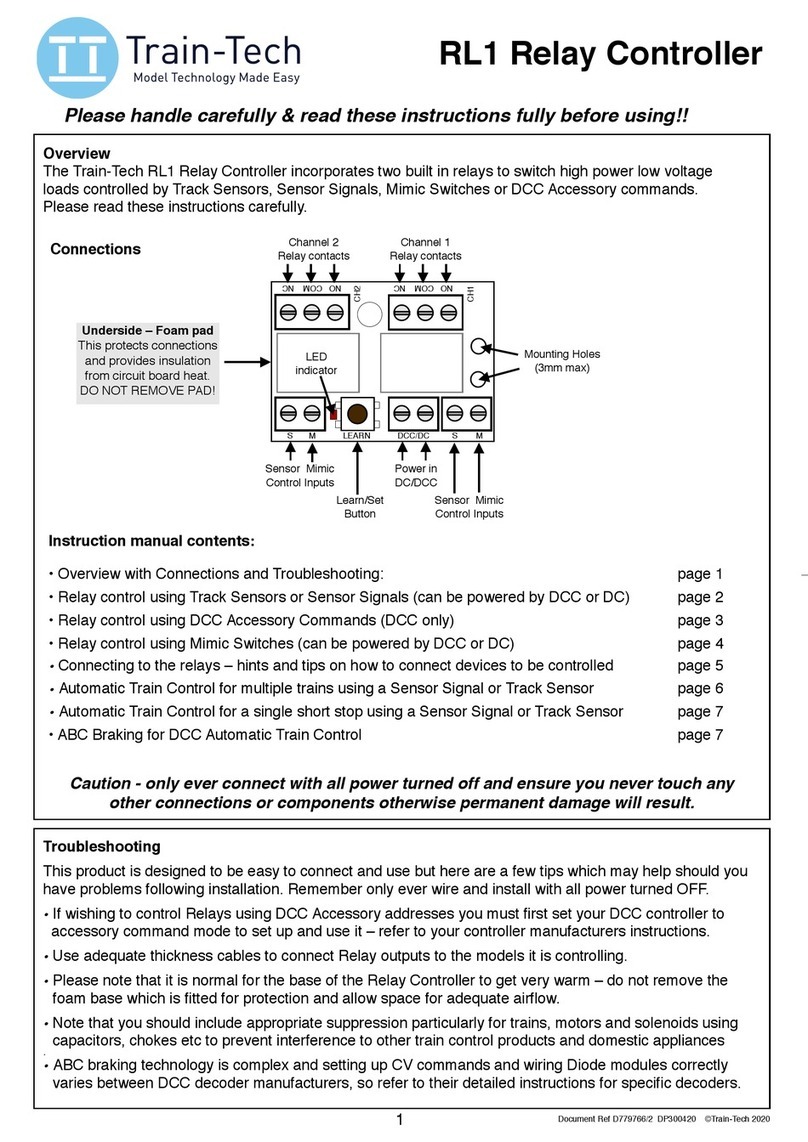

•Locating the SC300 and wiring

Firstly, before installing or connecting any wiring SWITCH OFF ALL POWER!

Locating the SC300

As most of the wiring to the SC300 is for the signals we suggest that it is mounted under the

baseboard close to where at least one of the signals are. It can be held in place using small screws

with a max diameter of 3mm through the 2 holes the top corners - make sure it is not mounted on

any conductive or metallic surfaces as there are many exposed connections underneath.

Connecting Signals

Dapol OO and N gauge Semaphore signals have 4 prefitted wires; a red and black wire for power

and two yellow wires which control the signal. Have a look on the top edge of the SC300 and you

will see there are 6 signal terminals; two pairs of terminals for the yellow wires and two for the red

and black wires. If using 2 signals with the SC300 connect both black wires together into the

terminal marked black and both red wires into the terminal labelled red.

If you need to extend signal wires use suitable wire such as 7/0.2mm, but do not connect any more

than two signals to an SC300 as this will overload the power regulator and may damage the signal

or cause it to malfunction.

Connecting Power

The SC300 can be powered direct from DCC, or if DCC control is not required, 12-16 volts smooth

DC. It also contains a regulator circuit designed to power two Dapol Semaphore signals at an

appropriate stable level.

When used on DCC, power can be taken from the nearest DCC rails, DCC bus or direct from the

controller output using standard model railway wire of 7/0.2mm or thicker.

For use on DC, where control of the signals is to only be from Track Sensors and/or Mimic

Switches, the power input can be connected to a suitable 12-16 volts smooth DC supply.

Please note that the supply must be smooth, which means true DC as opposed to part rectified

unsmoothed DC. If you do not have a suitable power supply the Gaugemaster WM4 is a suitable

and reasonably priced regulated and smooth 12 volts DC power supply.

2

Fixing hole

Signal2 Blk Red Signal1

Yellows Yellows

POWER

DCC or

12V DC

Track Sensor

& Mimic

switch inputs

Fixing hole

3

• Controlling the Signals by DCC

The SC300 enables you to control one or two signals using DCC Accessory commands (which

are different from the Loco commands used to control the trains as explained on page 1).

The following assumes you have connected up your SC300 to 1 or 2 signals and DCC power and

that you have familiarised yourself with controlling DCC accessories using your controller.

Once in accessory mode most controllers use a direction button to send a left or right command to

the accessory, although on some controllers it is buttons 1 and 2. In these instructions we assume

it is a direction control and show it as tor u, but you should check the manufacturers

instructions for details on how to control accessories on your particular control system.

Assigning the DCC address for each signal

Each signal output has an accessory ‘address’ assigned to it and with One Touch™ DCC this is

very quick and easy to set up. The SC300 has 2 signal outputs and you can set each to any

address you choose. If you are using a distant and a home signal on the same line you can also

give them both the same DCC address so that they change at the same time like the real thing.

Initial setting up

•Switch on your DCC controller - the LED on the SC300 should light.

•Set up your controller to control DCC accessories (see above).

Setting the DCC address for each signal

•To set Signal 1 address, set your chosen address for signal 2 on your controller and press the

‘Learn’ button’ on the SC300 once - the LED will flash. Then send either a tor ucommand

from your controller - the LED will stop flashing and your SC300 output for Signal 1 is now set to

the to the address you set.

•To set Signal 2 address, set your chosen address for signal 2 on your controller and press the

‘Learn’ button’ on the SC300 twice - the LED will double flash. Then send either a tor u

command from your controller - the LED will stop flashing and your SC300 output for Signal 2 is

now set to the to the address you set.

To control the signals

•To control your signals simply set your controller to the relevant DCC accessory address and

send a tor ucommand to activate them

Synchronising the signal position to a specific tor ucommand

The Dapol signals were designed to simply operate using a push button switch to ‘toggle’ between

up and down with each press of the button without specific up and down control wires, so the

SC300 can only emulate the pushbutton and make the signal change to one position for tand

the other position for u.

However the SC300 does remember the position of the signal once it is set up and so if, for

example, you want to have the signal go up when you press the ucommand and it is doing the

opposite at the moment, you should only need to change it once to get it into ‘sync’ with the

control.

You can swap the position of the signal by shorting the two yellow wires of the signal together

briefly whilst it is powered. You can also do this by carefully using a short link of insulated wire and

touching the link into the two yellow signal terminals on the SC300. Make sure the link wire is

short and does not touch any other wire or terminal or permanent damage may result!

The signal should now operate using the opposite tcommand on your controller - you can also

do this to swap the position for the other Track Sensor and Mimic Switch methods of control.

`

4

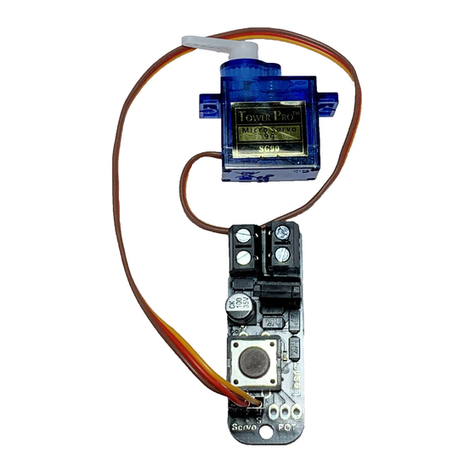

• Automatic control using Track Sensors

As well as controlling Signals manually by DCC or Mimic Switch you can also control them by

Track Sensors, so that when a Train approaches the signal automatically changes!

Powering the Track Sensor

A Track sensor must be powered by the same power supply as the SC300 which can either be

Digital DCC or Analogue 9-16 Volts DC and one wire links from the middle socket of the Track

Sensor to a TS input on the SC300. If used with DCC a Track Sensor can be clipped straight into

some types of track in the power clip slots (eg Hornby or Bachmann), but if not the slide-in fingers

can be cut off and the two pads wired to DCC or 9-16 Volts DC - see below.

Power by sliding sensor into track - for DCC

If using DCC you

can power the

sensor from the

track by sliding

these two ‘fingers’

under the rails into

the slots in some

types of track, like

a power clip.

ensure good

connections!

Track Sensor (or

a Sensor Signal)

To power using

DC or DCC solder

2 wires into the

pads shown

Power by wiring to sensor - for DC or DCC

Track Sensor (or a

Sensor Signal)

Cut off the two fingers

with sharp cutters

where marked - - -

• Automatic control using one Track Sensor and timing

There are two methods of using Track Sensors to control the SC300.

This method only needs a single Track sensor and the signal will change as the train goes over

the sensor and remain changed for around 10 seconds after the last part of the train has passed

the sensor before changing back. To look realistic a semaphore signal needs to show clear well in

advance of the train reaching it, which depends on the distance the Track sensor is away from the

signal. This will be down to personal preference, the typical speed of your trains and the available

space, but ideally should be at least 12”/0.3m away at OO scale.

Alternatively you can also fit the Track Sensor immediately after the signal to make it change to

stop as the train passes it to prevent another train following into that section until it is well clear.

Power the SC300 and Track Sensors from the same power source (either DCC or 12V DC) and

use single core wire (as supplied with Track Sensors) between the centre socket of the Track

Sensor to the TS1 or TS2 terminal of the SC300 as shown below:

Track sensor

Direction

of Trains

POWER

You must power both the track sensor and SC300

from the same power supply, either DCC from the

rails/bus or wire both to 9-16V smooth DC supply.

Distance between sensor and signal = time before signal changes back

Link wire to SC300 TS terminal

5

• Automatic control using two Track Sensors

This is an alternative method of automatic control, where instead of the signal changing back a

fixed time after the train has passed a Track Sensor (as on the previous page) this operates using

two Track Sensors; one to change the signal on the approach to the signal and another Track

sensor to change back again after it has passed the signal, so you can decide where the signal

changes because it depends on where you locate the two sensors. Note that you can set signal to

clear on approach and back to stop when it is past the signal or vice versa for block signalling type

operation, just by the location of the sensors and changing the direction of signals (see below).

Decide where on your train line you want the signal to change and locate the two Track sensors at

these points. Note that the post signal sensor has a built in delay to only change once the moving

train has passed it. The Track Sensors must be powered by the same power supply as the SC300

(see previous page) and the approach Sensor needs a single link wire from its centre socket to a

SC300 TS terminal and another single link wire between the two Sensors as shown below:

Pairing two semaphore signals to change together

There are times when it can be useful to ‘pair’ two Semaphore signals so that they change

together, such as adjacent distant and home signals which usually go up and down together.

If controlled by DCC this is easily achieved by giving both signals the same DCC address, but

when using Track Sensors or a Mimic Switch to control signals another solution is needed.

We have built in a ‘pairing’ option so that you can lock the two signals connected to that SC300

together and they will always do what the other one does, regardless of whether they are

controlled by Track Sensor, DCC or Mimic Switch.

•!To put the SC300 into paired mode switch power on and press and hold the Learn button for 5

seconds - the LED will now flash 5 times to show that the two outputs are synchronised.

•To take the SC300 out of paired mode press the Learn button for 5 seconds again - the LED will

flash 3 times to indicate it is back into standard independant mode.

Changing the direction/position of signal arms

If the signal moves the opposite way to what you want (eg changes to stop instead of clear) just

touch the 2 yellow wires of that signal together briefly - this will swap directions (see page 4).

You can do this to one or both signals connected to the SC300 to swap their position.

Using Track Sensors with N Gauge The Track sensor is designed primarily for OO gauge

track, however we have found that they can be successfully used with N gauge if the slide-in

fingers are removed (see previous page) and the sensor is placed close to (but not touching) the

rail by removing some parts of sleepers on N gauge tracks

Approach Signal

Track sensor

Direction

of Trains

POWER

You must power both the track

sensors and SC300 from the

same power supply, either DCC

from the rails/bus or wire both

to 9-16V smooth DC supply.

Link wire between the Track sensor sockets as shown

Past Signal

Track sensor

Link wire to SC300 TS

6

• Controlling Signals with Mimic switches

In addition to controlling a signal by DCC or Track Sensors they can also be controlled by Train-

Tech Mimic Switch. A Mimic switch not only controls the Signal but also has a red/green LED light

to show the signal state and if Track sensors are used for automatic operation a white LED will

light when the train passes the sensor for occupancy indication.

There are two types of Mimic Switch available; toggle (MS1) and push button (MS2) and they only

need 2 wires to connect to the same power supply as the SC300 and 1 wire to the terminal

marked MS. If you have several Mimic switches on a panel all the power terminals can be

connected together and just a single wire to each SC300 making wiring neat and simple.

Once connected the signals can be controlled by the Mimic Switch as well as DCC and / or Track

sensors if fitted. Track Sensors will change the signal automatically but this can be overridden

manually using a Mimic Switch or DCC. If a signal is overridden LED A will flash slowly to indicate

that it is under manual control.

Mimic Switch

Signal 2

Power input

12-16V DC or DCC

Mimic Switch

Signal 1

P

M

P

P

M

P

Top LED A indicates Signal

status (red or green)

(turn LED around if

displaying wrong colour)

Lower LED B indicates

Train passing/occupancy

(if Track Sensors are used)

Signal connections

To Track

Sensors

(if used)

Top LED A indicates Signal

status (red or green)

(turn LED around if

displaying wrong colour)

Lower LED B indicates

Train passing/occupancy

(if Track Sensors are used)

7

• Additional information

Using multiple SC300 and accessories on a layout

DCC is designed to allow lots of locos and accessories to all be connected and controlled at the

same time, but of course there is a practical limit of how many things can be powered which

depends on your DCC controller and associated power unit. Low cost starter controllers tend to

have power capabilities of 1 amp or so, whereas larger systems can supply 4 amps or more.

As a guide, an SC300 with 2 signals consumes around 0.1A when stationary and 0.2A peak (if 2

signals move together). If you have a lot of DCC items like locos and lights which all get switched

on at once when you power up your layout, potentially this could overload your DCC controller.

Ultimately may need to invest in a bigger power supply or controller, but you may be able to

reduce this ‘switch on surge’ by ensuring that Locos with sound (which can take more than 0.5amp

each!) are all shut down properly before you switch off.

Power ‘bus-bar’

If you intend to fit lots of different DCC accessories and lights etc around your layout you may find

it is better to install a ‘bus-bar’ system instead of using the track to carry the load for everything.

A bus-bar can made of 2 thick wires which you distribute around the underside of your baseboard -

eg thick solid copper wires stripped from some surplus heavy duty house wiring mains cable.

Pairing two semaphore signals to change together

There are times when it can be useful to ‘pair’ two Semaphore signals so that they change

together, such as an adjacent distant and home signal which usually go up and down together. If

controlled by DCC this is quite easily achieved by giving both signals the same DCC address, but

when using Track Sensors or a Mimic Switch to control signals another solution is needed.

We have built in a ‘pairing’ option so that you can lock the two signals connected to the same

SC300 together, where Signal 2 will always do what Signal 1 does, regardless of whether the

control input for Signal 1 is a Track Sensor, DCC command or Mimic Switch. (note that when in

paired mode any DCC, switch or sensor input for Signal 2 is ignored)

•!To put the SC300 into paired mode switch power on and press and hold the Learn button for 5

seconds - the LED will now flash 5 times to show that the two outputs are synchronised.

•To take the SC300 out of paired mode press the Learn button for 5 seconds again - the LED will

flash 3 times to indicate it is back into standard independant mode.

Important Do not connect more than two signals to an SC300 and only connect one per output - if

you connect more than two signals you are liable to overload the regulated power output and

damage the controller and/or the signal and they are unlikely to work reliably.

• Troubleshooting...

• I cannot get the SC300 to work at all

Check that the SC300 LED is lit - if it is not lit but locos and accessories etc run correctly, check

the power connections between your DCC Controller and the SC300.

•I cannot set up DCC addresses on the SC300

If the SC300 LED is lit but does not flash when you send a command double check that your DCC

controller is in Accessory addressing mode - note that these are completely different to

Locomotive addresses and should be explained in your controller instructions. If not check

carefully that your controller will control DCC accessories - see page 4.

•The SC300 LED flashes when I send a command but the signal does not move

On the signal check that the small light behind the signal arm is lit - if not check the red and black

power leads. If the small signal light is lit check that the signal moves without using the SC300 by

carefully removing the 2 yellow wires from the SC300 terminals and touching the wires together -

the signal should move. If it does not change it is possible that the signal is faulty.

•The Signal is moving in the opposite direction to what I want

See the bottom of page 3 for details on how to synchronise the signal to your Track Sensor or

DCC command etc

If these checks fail please contact your supplier or DCP for advice and support.

Other Train-Tech Controllers manuals

Popular Controllers manuals by other brands

Regin

Regin TTC25 Instruction

NI

NI cRIO-9012 User manual and specifications

Penn

Penn A19 Series Mounting and installation

AFRISO

AFRISO ARM ProClick instruction manual

Novatech

Novatech Pulsafeeder MicroVision Timer Installation & operation manual

Jäger

Jäger OPUS RADIO PLUS Installation and operating instructions

Mitsubishi Electric

Mitsubishi Electric MELSERVO-JET Series user manual

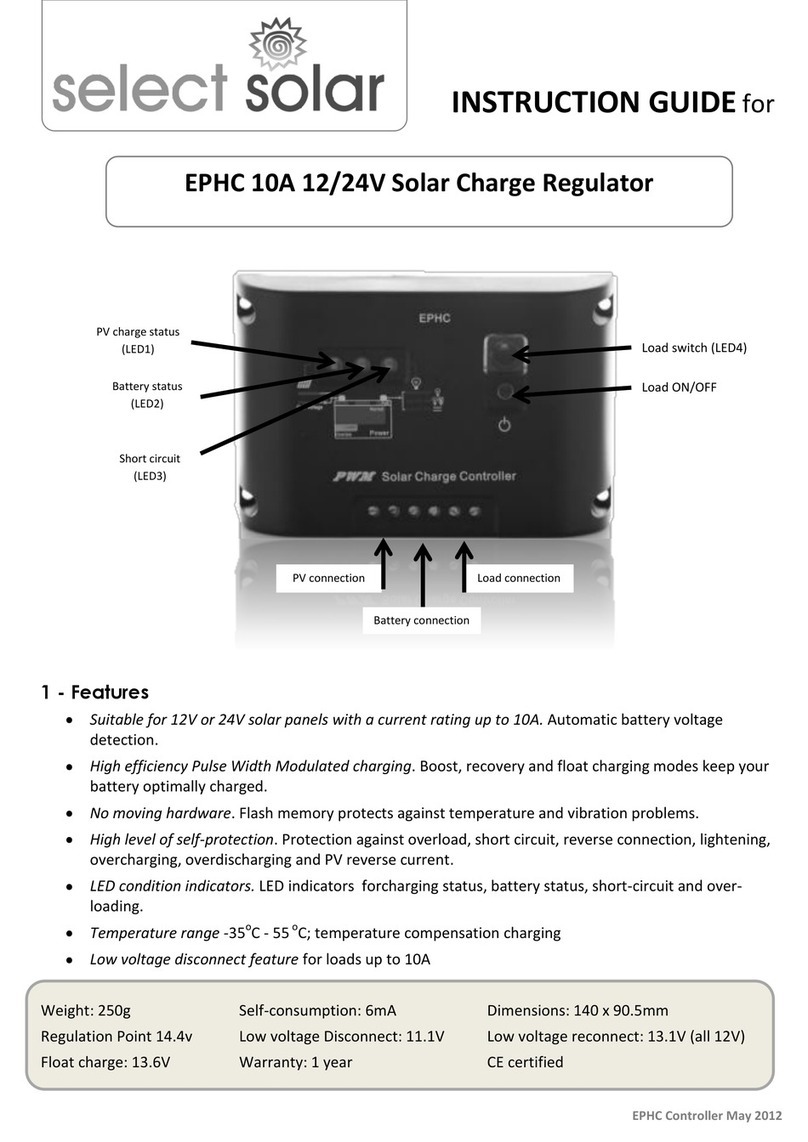

select solar

select solar EPHC 10A Instruction guide

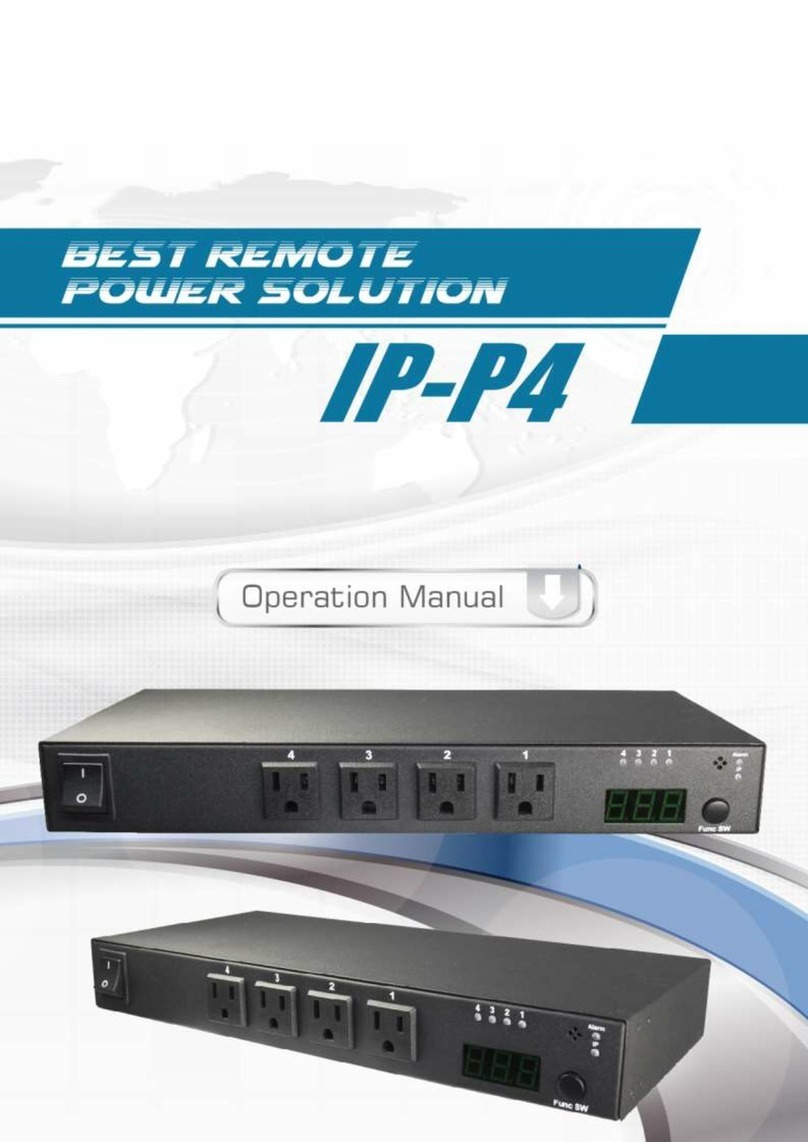

Ambery

Ambery IP-P4 Operation manual

EUCHIPS

EUCHIPS EUP40D-1HMC-0 manual

Duff-Norton

Duff-Norton SK-2389 Installation, operation & maintenance instructions

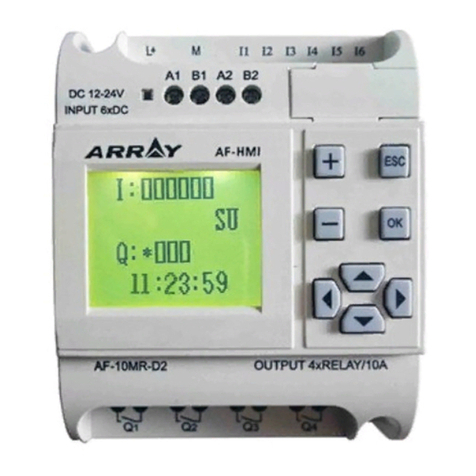

Array electronic

Array electronic FAB Series user manual