AFDH-SVN01A-EN 7

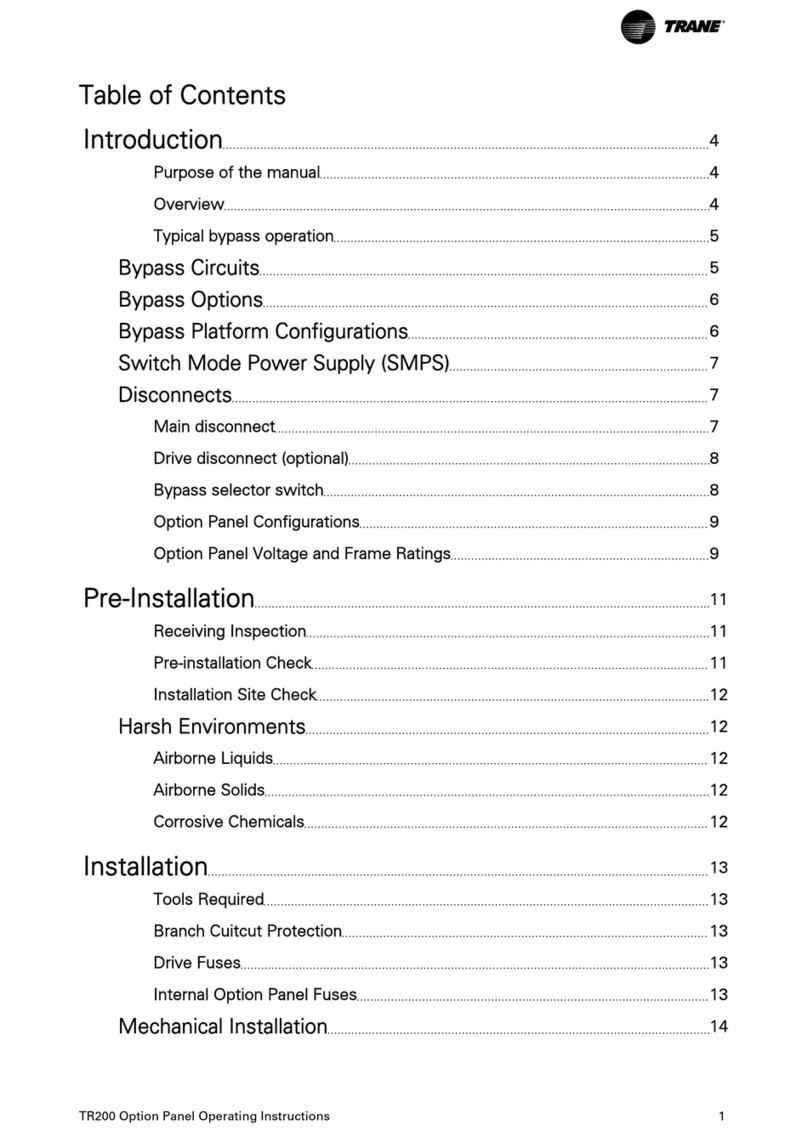

Table 4. AFDH D-Frame unit weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Table 5. AFDH E-Frame unit weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

D-Frame and E-Frame Drive unit components . . . . . . . . . . . . . . . . . . . . . . . . 26

Drive unit component parts housed within the custom enclosure . . . . . 26

Figure 12. Mounting location of D and E-Frame custom enclosure parts . . . . . 26

Table 6. Custom enclosure parts; D-Frame 302 amp model drives . . . . . . . . 28

Table 7. Custom enclosure parts; D-Frame 361 amp model drives . . . . . . . . 28

Table 8. Custom enclosure parts; D-Frame 443 amp model drives . . . . . . . . 29

Table 9. Custom enclosure parts; E-Frame 540 amp model drives. . . . . . . . . 30

Table 10. Custom enclosure parts; E-Frame 590 amp model drives. . . . . . . . . 30

Table 11. Custom enclosure parts; E-Frame 678 amp model drives. . . . . . . . . 31

Table 12. Custom enclosure parts; E-Frame 730 amp model drives. . . . . . . . . 31

Control box components for UCP2 version AFDH . . . . . . . . . . . . . . . . . . 32

Figure 13. D and E-Frame AFDH UCP2 control box components . . . . . . . . . . . 32

Table 13. UCP2 control box component part numbers . . . . . . . . . . . . . . . . . . 32

Additional hardware shipped with all UCP2 AFDH packages . . . . . . . . . 33

Table 14. UCP2 miscellaneous hardware package contents . . . . . . . . . . . . . . 33

Figure 14. Buss bar specifications; UCP2 miscellaneous hardware packages . . 33

Control box components for CH531/AdaptiView version AFDH . . . . . . . 34

Figure 15. D and E-Frame AFDH CH531/AdaptiView control box components . 34

Table 15. CH531/AdaptiView control box component part numbers . . . . . . . . 34

Additional hardware shipped with CH531/AdaptiView AFDH packages 35

Table 16. CH531/AdaptiView miscellaneous hardware package contents . . . . 35

Figure 16. Buss bars specifications; CH531/AdaptiView hardware packages . . . 35

Other AFDH drive package accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 17. Floor stand kit parts for stand-mounted D-Frame AFDH. . . . . . . . . . 36

Figure 18. D and E-Frame floor-mounted AFDH; corner support kit parts . . . . . 37

Table 17. Part numbers for motor panel transition covers . . . . . . . . . . . . . . . 37

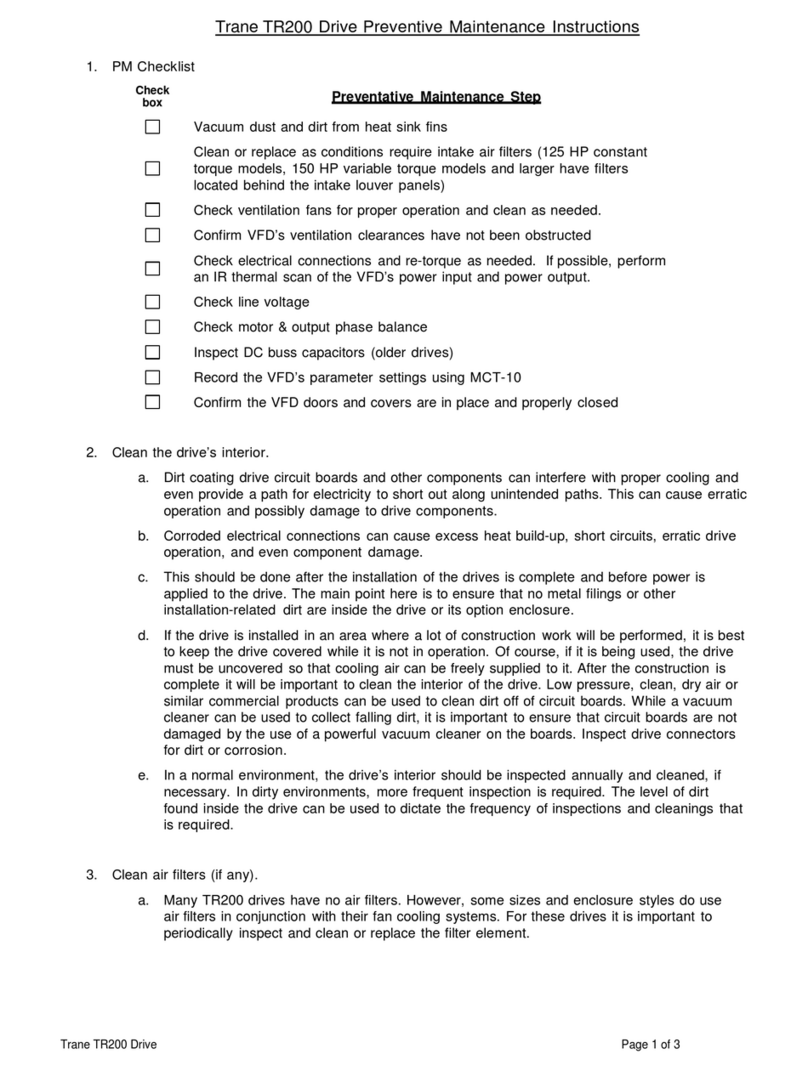

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Removal of electrical connections to the existing starter . . . . . . . . . . . . . . . 38

Mechanical removal of the existing unit-mounted starter . . . . . . . . . . . . . . 39

Mechanical removal of the existing remote-mounted starter . . . . . . . . . . . . 40

Mechanical installation of a Unit-Mounted AFDH drive . . . . . . . . . . . . . . . . . 40

Figure 19. Removal of Z-bracket weldment nuts . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 20. Position cabinet base over evaporator brackets and install clips . . . 42

Figure 21. Leveling the AFDH drive cabinet against the Z-bracket . . . . . . . . . . 42

Mechanical installation of a stand-mounted D-Frame AFDH . . . . . . . . . . . . 43

Figure 22. Assembly of floor stand kit components . . . . . . . . . . . . . . . . . . . . . 44

Figure 23. Attach assembled floor stand to drive unit. . . . . . . . . . . . . . . . . . . . 45

Mechanical installation of a remote floor-mounted AFDH . . . . . . . . . . . . . . 46

Figure 24. Assembly and installation of corner support kit components. . . . . . 47

Electrical installation (all AFDH models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Install shorting buss bars . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Figure 25. Buss bar installation on compressor motor terminal board . . . . . . . 49

Input power wire installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Figure 26. Conduit shroud and two-piece incoming wire access cover . . . . . . . 50

Figure 27. Factory installed input disconnect circuit breaker . . . . . . . . . . . . . . 51

Grounding AFDH cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Figure 28. Location of AFDH cabinet ground terminal . . . . . . . . . . . . . . . . . . . 52

Output wiring from the AFDH to the CTV motor . . . . . . . . . . . . . . . . . . . 52