AFDH-SVN004C-EN 5

Model Number Descriptions

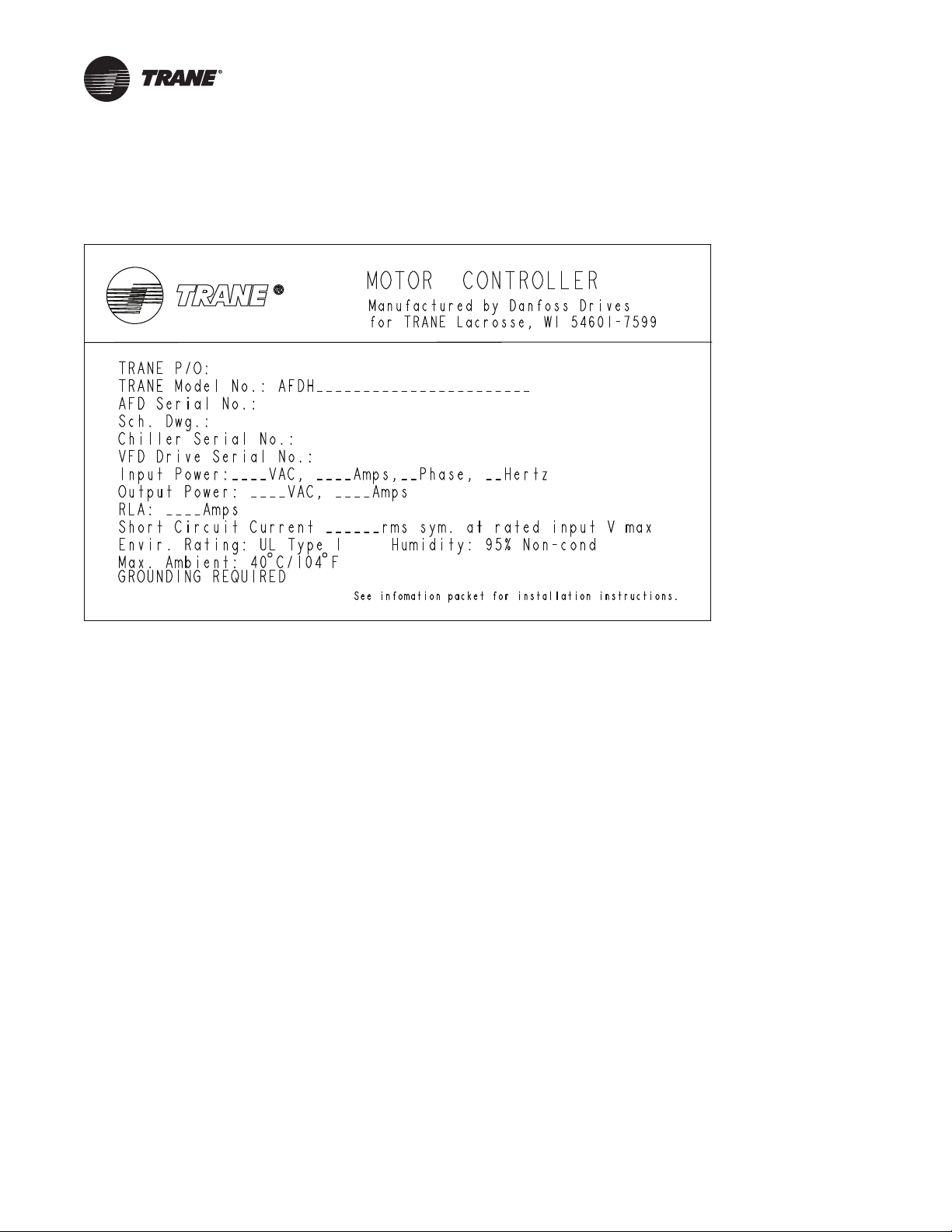

Unit Model Number

For service purposes, Trane®Model

AFDH Air-Cooled drive upgrade

packages are assigned a multiple

character alphanumeric model

number that precisely identifies each

unit.

An explanation of the identification

code that appears on the unit

nameplate is shown below. Use of

the service model number will

enable the owner/operator, installing

contractors, and service technicians

to define the operation, components,

and options for any specific unit.

Refer to the model number printed

on the nameplate when ordering

replacement parts or requesting

service.

Digits 1, 2, 3 — Air Cooled

Adaptive Frequency Drive

AFD =Air Cooled Adaptive Frequency

Drive

Digit 4 — Development

Sequence

H

Digits 5, 6, 7, 8 — Starter Size

(Performance RLA rating)

Performance RLA = Performance RLA

Digit 9 — Chiller Voltage

D = 380V 60 Hz 3 Phase

E = 440V 60 Hz 3 Phase

F = 460V 60 Hz 3 Phase

G = 480V 60 Hz 3 Phase

H = 575V 60 Hz 3 Phase

J = 600V 60 Hz 3 Phase

R = 380V 50 Hz 3 Phase

T = 400V 50 Hz 3 Phase

U = 415V 50 Hz 3 Phase

Digits 10, 11— Design Sequence

** = Factory assigned

Digit 12 — New Short Circuit

Rating

C = 35K Short Circuit

A = 65K Short Circuit

B = 100K Short Circuit

Digits 13, 14 — Maximum RLA

1B = 190 Maximum RLA - 60 Hz

(460/480)

1C = 240 Maximum RLA - 60 Hz

(460/480)

0C = 302 Maximum RLA - 60 Hz

(460/480)

0D = 361 Maximum RLA - 60 Hz

(460/480)

0E = 443 Maximum RLA - 60 Hz

(460/480)

1A = 535 Maximum RLA - 60 Hz

(460/480)

0H = 590 Maximum RLA - 60 Hz

(460/480)

0J = 678 Maximum RLA - 60 Hz

(460/480)

0K = 730 Maximum RLA - 60 Hz

(460/480)

01 = 780 Maximum RLA - 60 Hz

(460/480)

02 = 890 Maximum RLA - 60 Hz

(460/480)

1D = 131 Maximum RLA - 60 Hz

(575/600)

1E = 155 Maximum RLA - 60 Hz

(575/600)

1F = 192 Maximum RLA - 60 Hz

(575/600)

0L = 242 Maximum RLA - 60 Hz

(575/600)

0M = 290 Maximum RLA - 60 Hz

(575/600)

0N = 344 Maximum RLA - 60 Hz

(575/600)

0P = 400 Maximum RLA - 60 Hz

(575/600)

0R = 450 Maximum RLA - 60 Hz

(575/600)

0T = 500 Maximum RLA - 60 Hz

(575/600)

0U = 570 Maximum RLA - 60 Hz

(575/600)

0V = 630 Maximum RLA - 60 Hz

(575/600)

03 = 729 Maximum RLA - 60 Hz

(575/600)

04 = 850 Maximum RLA - 60 Hz

(575/600)

1G = 212 Maximum RLA - 50 Hz

(380/400)

1H = 260 Maximum RLA - 50 Hz

(380/400)

0W = 315 Maximum RLA - 50 Hz

(380/400)

0X = 395 Maximum RLA - 50 Hz

(380/400)

0Y = 480 Maximum RLA - 50 Hz

(380/400)

0Z = 588 Maximum RLA - 50 Hz

(380/400)

05 = 658 Maximum RLA - 50 Hz

(380/400)

06 = 745 Maximum RLA - 50 Hz

(380/400)

07 = 800 Maximum RLA - 50 Hz

(380/400)

08 = 880 Maximum RLA - 50 Hz

(380/400)

09 = 990 Maximum RLA - 50 Hz

(380/400)

Digit 15 — Chiller Control Type

3 = AdaptiView Controls Only

Digit 16 — Agency Listing

1 = UL Listing (includes Canada and

California)

0 = No Listing

Digit 17 — AFD Type

C = NEMA 1 Upgrade Enclosure

Digit 18 — Mounting Type

C = Remote Mount

A = Transition Mount

L = LiquiFlo Mount

P = Direct Mount 440E, 5000, 5800

Frame

T = Direct Mount 400 Frame

Digit 19 — AFD to Motor

Transition

0 = No Motor Transition

A = 6" Sheetmetal Transition

C = 12" Sheetmetal Transition

B = 18" Sheetmetal Transition

Digit 20 — Frame Size

D = D - Frame

E = E - Frame

Digit 21 — Evaporator Shell Size

0 = For Transition, LiquiFlo, or

Remote

5 = 050S Short Evaporator Shell

6 = 050L Long Evaporator Shell

7 = 080S Short Evaporator Shell

8 = 080L Long Evaporator Shell

A = 142E Extended Evaporator Shell

B = 142M Medium Evaporator Shell

C = 142L Long Evaporator Shell

E = 210L Long Evaporator Shell

Digit 22 — Replacement Bracket

for LF1.0/LF1.5

0 = No Bracket Needed

1 = Replacement Bracket Kit Needed

Digit 23

0

Digit 24 — Lug Sizes

0 = All Applicable Lugs

N = Two Wire 3/0 - 250 KCmil

B = Two Wire 400 - 500 KCmil

C = Four Wire 4/0 - 400 KCmil

D = Three Wire 4/0 - 400 KCmil

E = Three Wire 500 - 750 KCmil

F = Two Wire 2/0 - 250 KCmil

G = One Wire 2/0 - 500 KCmil

H = Three Wire 3/0 400 KCmil

J = Two Wire 500 - 750 KCmil

K = One Wire 200 - 500 KCmil

L = Two Wire 3/0 - 350 KCmil

M = Two Wire 2AWG - 500 KCmil

P = Three Wire 4/0 - 500 KCmil

Q = Four Wire 4/0 - 500 KCmil

R = Four Wire 3/0 - 400 KCmil

Digit 25 — Jumper Bar Kit

0 = No Jumper Bars Required

A = Bar Kit 1 (distance between holes

5.385 and dia. .812)

B = Bar Kit 2 (distance between holes

5.831 and dia. .812)

C = Bar Kit 3 (distance between holes

6.103 and dia. .812)

D = Bar Kit 4 (distance between holes

6.103 and dia. 1.187)

E = All Bars Included

Digits 26, 27 — Design Specials

00 = No Design Special